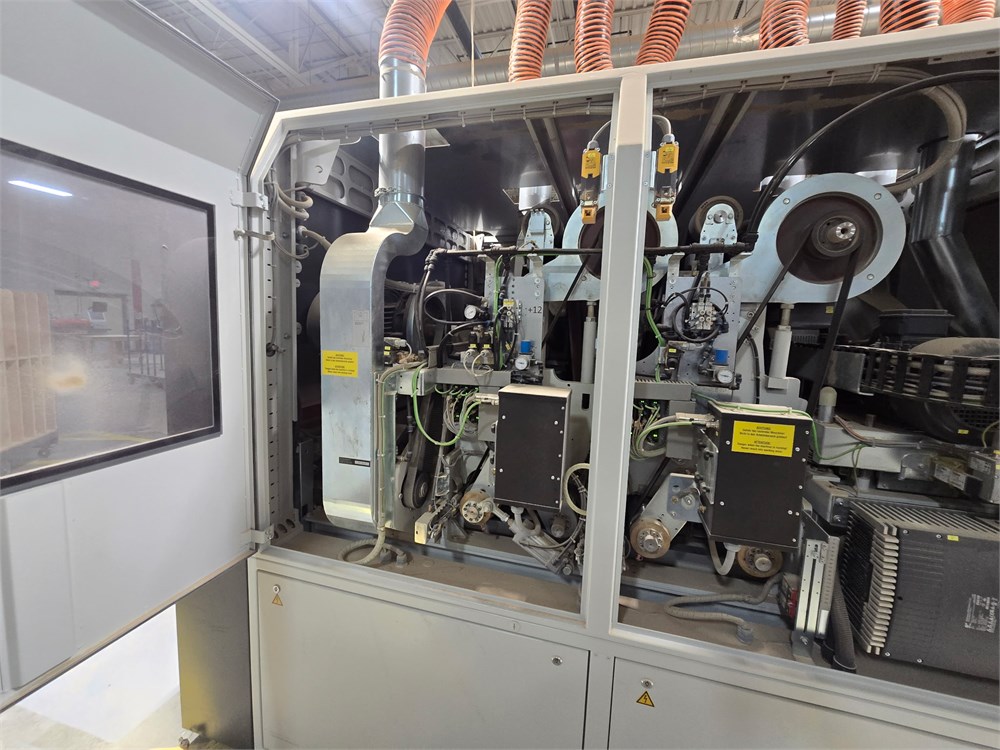

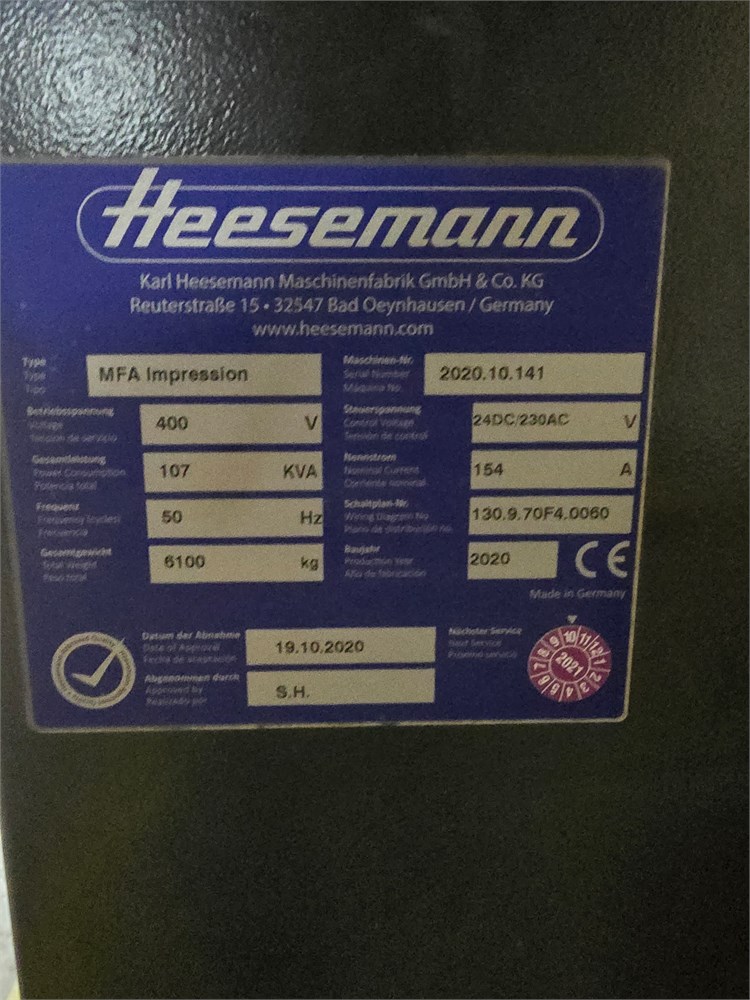

Heesemann "MFA Impression" Widebelt Sander (2020)  Active

Active

-

Make

Heesemann

-

Model

MFA Impression

-

Serial Number

2020.10.141

-

Year

2020

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Estimated Dimensions

See photos and description

-

Estimated Weight

13,200 Lbs

-

Seller Comment

Seller will disconnect and load onto buyer's flatbed truck/trailer for non-negotiable loading fee. Palletizing, crating or other services may be available at an additional cost.

-

Load Fee

1000.00

-

Lot Notes

Machine is stored in rigger's secure warehouse and ready for loading

-

Onsite Contact

Dale Kochnaik, [email protected], (262) 894-4420

-

Pick Up Location

3645 W. Elm St. Milwaukee, WI 53209

-

Load Out Period

Within (2) weeks after purchase date

-

page views

37

Heesemann "MFA Impression" Widebelt Sander (2020)

Since 1933, Heesemann has been building superior quality sanders built to withstand the highest production needs. Heesemann sanding machines are proudly designed and built to the highest standards in Bad Oeyenhausen, Germany. It is not only the superior quality, but the continuous innovation and forward thinking which has set Heesemann apart as the worldwide leader in sanding technology. Heesemann has continued to make technology breakthroughs in the sanding industry which have defined sanding as we know it, including the likes of the first profile sander, the pressure segment belt (chevron belt), the cross-belt sanding unit, and the magnetic segmented pad system CSD®. With over 120 patents registered and counting, you can be assured that you are getting the best.

Working width, 1350 mm/53"

Panel thickness, 0.12" - 6.3"

Wide abrasive belt size, 55" x 103"

Cross abrasive belt size, 6" x 189"

Working height, 36"

Feed speed, 10 FPM - 50 FPM

Heavy Duty Conveyor Drive with Dual Side Tracking

- Frequency controlled variable speed drive system for variable conveyor speed

- Heavy duty gearbox drives for withstanding heavy sanding applications

- Robust conveyor bed, robotically welded with internal webbing for highest performance

- Large diameter, precision machined and balanced drive rollers for optimal tracking

- Dual side belt tracking for handling heavy loads, high speeds or continuous operation

Single Piece Profiled Transport Belt

- Profiled rubber belt for optimal workpiece grip

High Performance Vacuum Hold Down

Equipped with a high-performance vacuum hold down system for safe movement of workpieces shorter than 500 mm (19.7") in feed direction. Heesemann’ s unique frame design integrates rigid vacuum plenums for maximum vacuum hold down force over the entire surface of the conveyor bed. The plenum design eliminates hoses that are traditionally found on vacuum hold down systems.

Vacuum table design is fabricated to evacuate dust and prevent clogging in order to maximize vacuum suction – producing the strongest vacuum hold down in the industry. Heesemann vacuum beds also include integrated clean out ports for easy access and cleaning if required after years of heavy usage.

Variable Vacuum Control

Variable vacuum control utilizes a frequency drive to adjust vacuum suction via machine control based upon workpiece parameters or sanding requirements

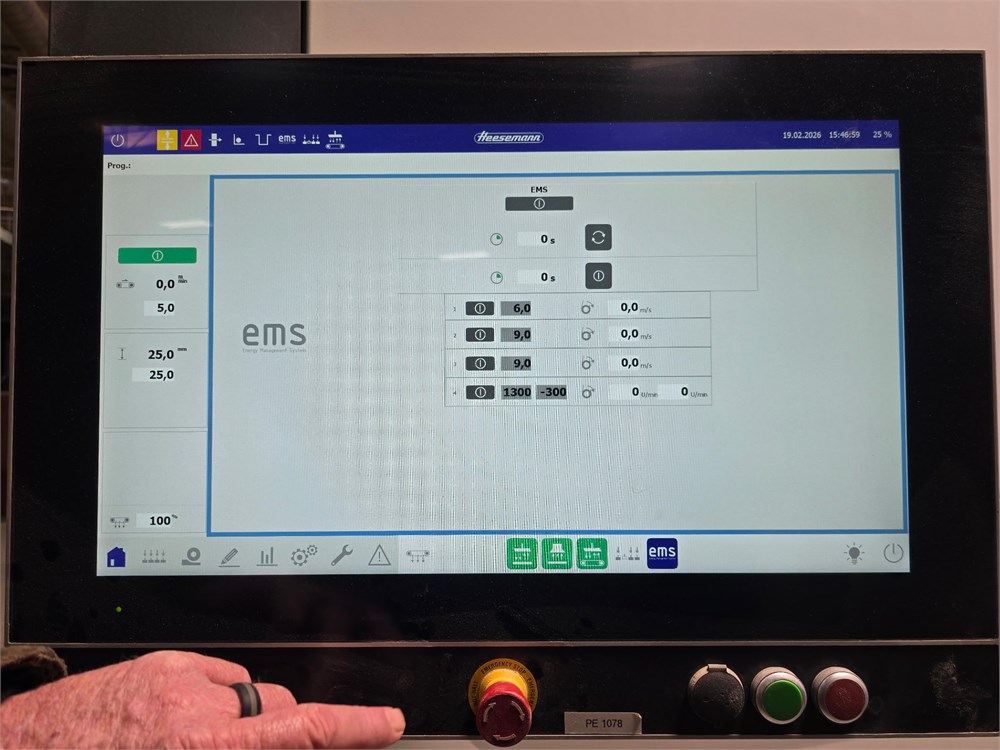

Industrial PC with Touchscreen Control

- 21.5" high resolution touch screen display

- CF cards for memory and control backup

- Windows embedded operating system

- Pendent mounted with adjustable viewing position

- Ethernet connection for remote access

- Automatic on-screen diagnostics

- Metric or imperial input

- 1000 program memory with alpha/numeric names, password protected

- Digital keypad input to control

- Workpiece thickness, and all other height adjustable components

- Conveyor belt feed speed

- Sanding pressures (surface and edge pressures)

- One button start / stop with sequential starting for all drives

Potential Free Contact

- For blast gate or extraction control

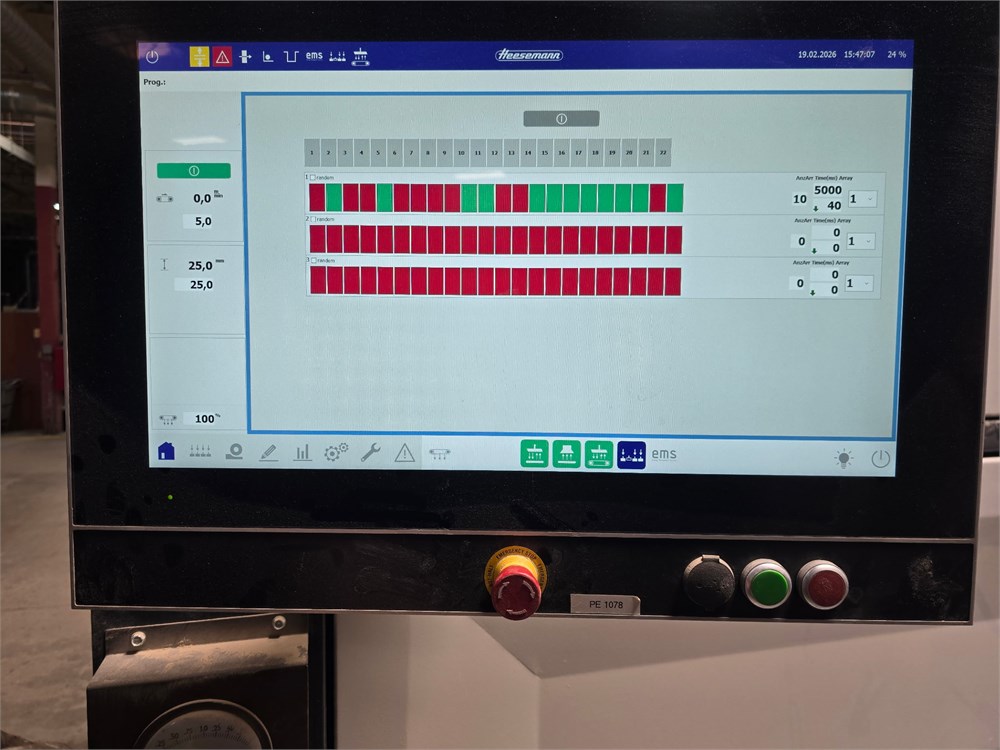

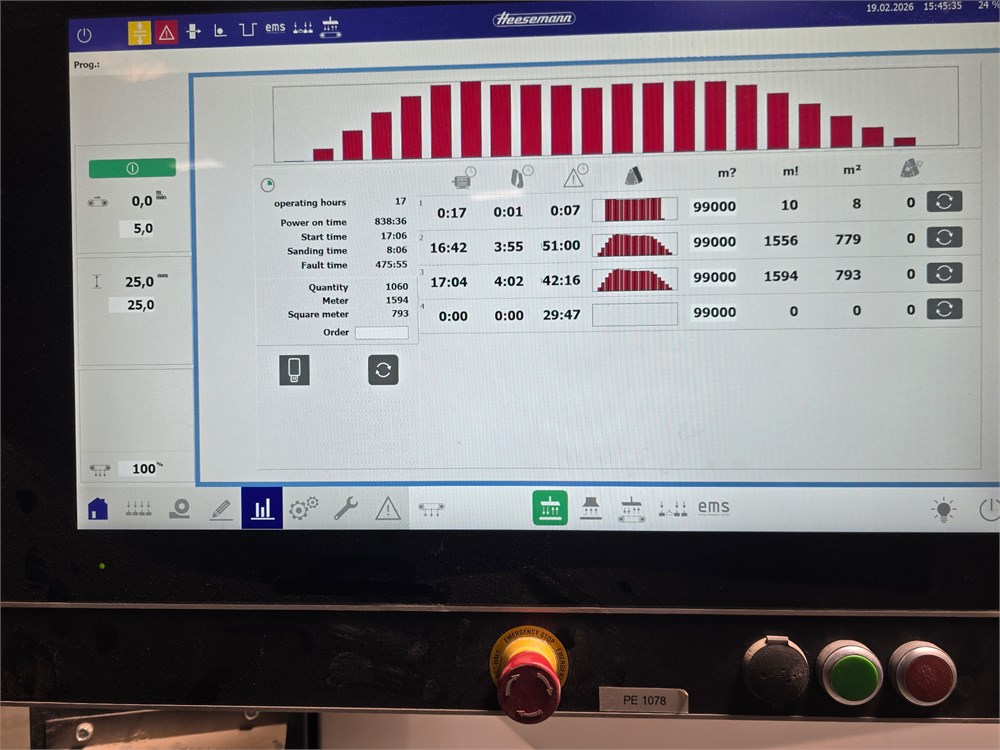

Belt Manager Software

Software tracks belt usage (left to right) according to how parts are fed into machine and also tracks sq. meters sanded per head. Each head can have a value entered to notify the operator when the value (in sq. meters) has been met, indicating when to change abrasives. Values can be freely set according to grit, application, or operation and can be used to quantitatively determine when to change abrasive belts. This feature helps maximize belt life and sanding consistency.

Infeed Hold Down Roller

- Hold down roller at infeed to hold down thin and warped workpieces

- Spring loaded and adjustable

- Includes workpiece over-thickness control

Segmented Workpiece Recognition System

- Workpiece sensing rollers for workpiece recognition at infeed

- Non-mechanical, magnetic switches for maintenance free operation

- Three (3) rollers per segment for ultimate segmented pad control

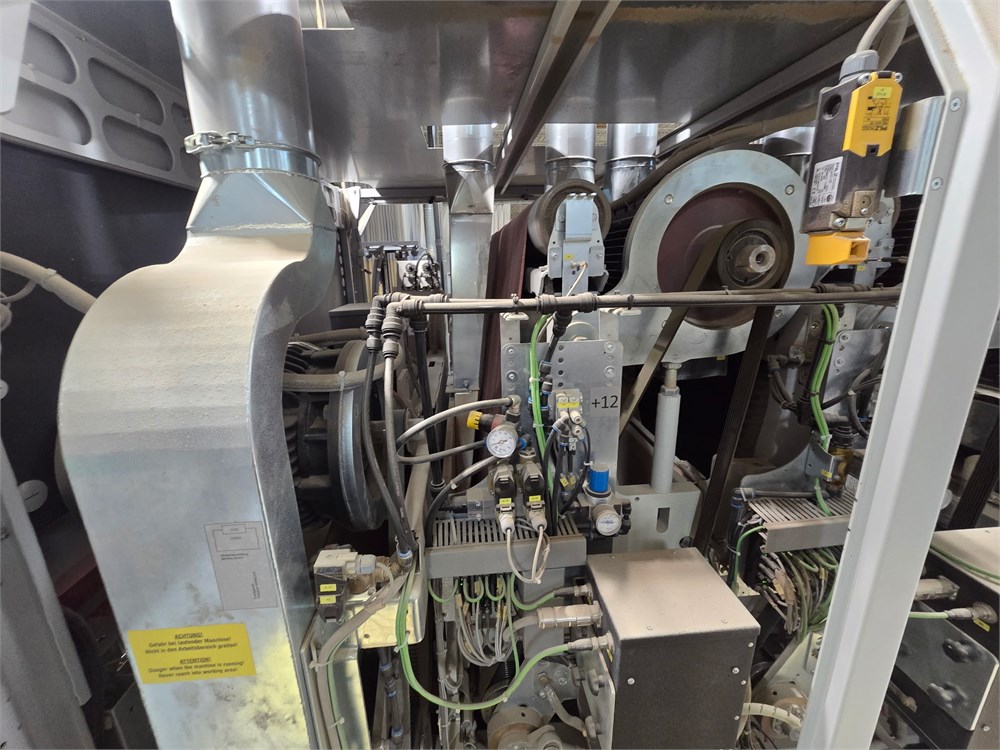

Head 1: C Head – Cross Belt Sanding Unit with Inner Chevron Belt

Heesemann's cross belt sanding unit with inner chevron belt is designed for finish sanding or effect sanding and features:

- Precision balanced drive and tensioning rollers (Q1 fine balanced according to VDI 2060)

- Servo controlled roller trimming for easy belt tracking control from outside machine

- Maintenance free, sealed bearings for long life and ultimate performance

- Poly-V belt drive for maximum power transmission, minimal vibration and easy maintenance

- System control from operating terminal for application flexibility

- Internal drive with adjustable belt tensioning, located inside machine housing for cool, dust free operation with easy access

- Maintenance free, DC motor braking, provides non-wearing braking and reduces safety concerns associated with mechanical braking

- Automatic compensation for differences in belt lengths with belt tensioning system

- Easily adjustable belt tension with pneumatic adjustment gauges for both abrasive and chevron belt

- Non-contact overtravel control via high quality infra-red photo eyes

CSD® 21 Magnetic Pad System

Abrasive Belt Cleaning Device

- For consistent sanding result and long abrasive belt life

- Intermittent pneumatic abrasive belt blasting device

- Operates only when a workpiece is sanded to conserve utilities

- Cleans directly behind the sanding area at the place where the abrasive pores are opened

- Dust extraction integrated into head dust plenum for maximum extraction and maximum belt cleaning, while conserve dust extraction and preventing additional dust collection volume or ports

Rubber Covered Hold Down Rollers

- For workpiece control and hold down

- Spring loaded and adjustable

Drive System: Frequency Controlled Variable Cutting Speed

|

Sanding belt speed: |

2 - 20 mps |

(6-65 fps) |

|

Drive size: |

15 kW |

(20 Hp) |

Abrasive Belt Size

|

Sanding belt size: |

150 mm x 4800 mm |

(6" x 189") |

Head 2: L Head – Longitudinal Combination Unit

Heesemann's longitudinal combination unit is designed for calibration, finish sanding or special applications and features:

- Contact roller with integrated pulley

- Finest precision contact roller balancing (Q1 fine balanced according to VDI 2060)

- Precision balanced drive and tensioning rollers (Q1 fine balanced according to VDI 2060)

- Maintenance free, sealed bearings for long life and ultimate performance

- Poly-V belt drive for maximum power transmission, minimal vibration and easy maintenance

- System control from operating terminal for application flexibility

- Activation of function (contact roller, platen or both) from control

- Automatic contact roller positioning via eccentric bearing with dead shaft design, for highest sanding accuracy and precision

- Internal drive with adjustable belt tensioning, located inside machine housing for cool, dust free operation with easy access

- Maintenance free, DC motor braking, provides non-wearing braking and reduces safety concerns associated with mechanical braking

- Automatic compensation for differences in belt lengths with belt tensioning system

- Adjustable belt tracing for accommodating inconsistent abrasive belts

- Easily adjustable belt tension with pneumatic adjustment gauges

- Non-contact belt tracking and overtravel control via high quality infra-red photo eyes

Helically Grooved Steel Contact Roller

|

Roller Diameter |

130mm |

(5”) |

|

Material / Durometer |

Steel |

100° |

CSD® 21 Magnetic Pad System

Cutting Direction: Bi-Directional

- For cutting with or against feed direction

Head Positioning and Grit Compensation

- Pneumatic head positioning from controller

- Grit compensation via machine control

Abrasive Belt Cleaning Device

- For consistent sanding result and long abrasive belt life

- Intermittent pneumatic abrasive belt blasting device with adjustable pressure

- Operates only when a workpiece is sanded to conserve utilities

- Cleans directly behind the sanding area at the place where the abrasive pores are opened

- Dust extraction integrated into head dust plenum for maximum extraction and maximum belt cleaning, while conserve dust extraction and preventing additional dust collection volume or ports

Rubber Covered Hold Down Rollers

- For workpiece control and hold down

- Spring loaded and adjustable

Drive System: Frequency Controlled Variable Cutting Speed

|

Sanding belt speed: |

1.8 - 18 mps |

(6-59 fps) |

|

Drive size: |

15 kW |

(20 Hp) |

Abrasive Belt Size

|

Sanding belt size: |

1400 mm x 2620 mm |

(55" x 103") |

Head 3: Lef Head – Longitudinal Sanding Unit with Inner Chevron Belt

Heesemann's longitudinal sanding unit with inner chevron belt is designed for highest quality finish sanding and features:

- Precision balanced drive and tensioning rollers (Q1 fine balanced according to VDI 2060)

- Eccentrically adjustable drive rollers for easy adjustment of chevron belt wear or for operation without chevron belt

- Maintenance free, sealed bearings for long life and ultimate performance

- Poly-V belt drive for maximum power transmission, minimal vibration and easy maintenance

- System control from operating terminal for application flexibility

- Internal drive with adjustable belt tensioning, located inside machine housing for cool, dust free operation with easy access

- Maintenance free, DC motor braking, provides non-wearing braking and reduces safety concerns associated with mechanical braking

- Automatic compensation for differences in belt lengths with belt tensioning system

- Adjustable belt tracing for accommodating inconsistent abrasive belts

- Easily adjustable belt tension with pneumatic adjustment gauges for both abrasive and chevron belt

- Non-contact belt tracking and overtravel control via high quality infra-red photo eyes

CSD® 21 Magnetic Pad System

Cutting Direction: Against Feed direction

Abrasive Belt Cleaning Device

- For consistent sanding result and long abrasive belt life

- Intermittent pneumatic abrasive belt blasting device with adjustable pressure

- Operates only when a workpiece is sanded to conserve utilities

- Cleans directly behind the sanding area at the place where the abrasive pores are opened

- Dust extraction integrated into head dust plenum for maximum extraction and maximum belt cleaning, while conserve dust extraction and preventing additional dust collection volume or ports

Rubber Covered Hold Down Rollers

- For workpiece control and hold down

- Spring loaded and adjustable

Drive System: Frequency Controlled Variable Cutting Speed

|

Sanding belt speed: |

1.8 - 9 mps |

(6-30 fps) |

|

Without chevron: |

1.8 - 18 mps |

(6-59 fps) |

|

Drive size: |

15 kW |

(20 Hp) |

Abrasive Belt Size

|

Sanding belt size: |

1400 mm x 2620 mm |

(55" x 103") |

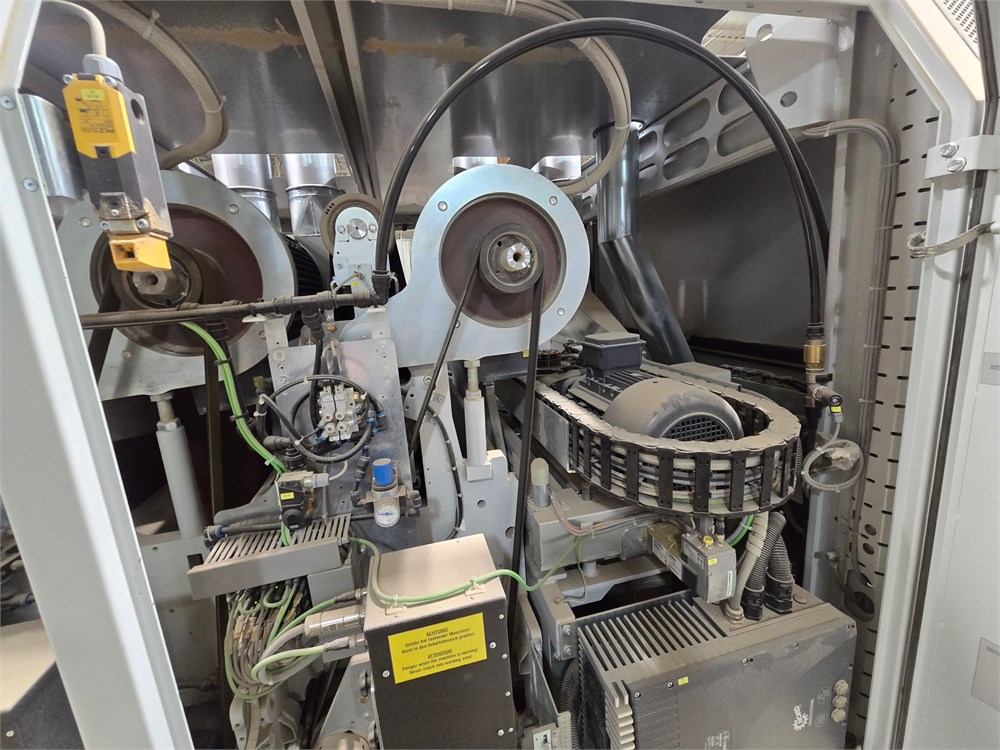

DB-S Head - Rotating Planetary Sanding Unit

Heesemann's rotating planetary sanding unit incorporates sanding disks for the purpose of smoothing the work surface, breaking edges, seal sanding, orbit sanding, polishing and texturing and includes:

- Driven brush disks rotating in same direction for cutting consistency

- Driven gearboxes, each with 2 disks rotating in same direction for cutting consistency

- Overlapping double rotation for orbital sanding pattern and full width coverage

- Clockwise or counterclockwise rotation for sanding / scratch pattern control

- Independent speed and direction control for disks and gearboxes

- Driven by gearboxes with toothed belts with belt tensioning devices

- Maintenance free, sealed bearings for long life and ultimate performance

- Central height adjustment with cardan shaft drives and gearboxes

- Slide out head for quick tooling changes and complete head access

Tool Information

|

Diameter |

150 mm |

(6”) |

|

Tool Quantity (Full Set) |

|

10 Pieces |

Set of Brush Disks

- Set of 10 discs

- Flextrim hubs with quick change adapter

- Grit, mineral, height and cut to be determined based on application

NC Controlled Head Positioning

- NC controlled head positioning and activation from controller

- Height adjustment for tool height and projection from controller

Rubber Covered Hold Down Rollers

- For workpiece control and hold down

- Spring loaded and adjustable

Drive System: Frequency Controlled Variable Tool Speed

|

Disk drive size: |

7.5 kW |

(10 Hp) |

|

Gearbox drive size: |

1.5 kW |

(2 Hp) |

CSD® - Segmented Pad System

Heesemann’s patented CSD® electro-magnetic segmented pad system delivers the most sensitive sanding system available on the market. With an interlocking design for consistent sanding of irregular shaped work-pieces, and dynamic control, you can precisely control how the workpiece is sanded, from edges, to cutouts, to frames, you can always maintain crisp edges and prevent burning through sensitive materials such as veneer or sealer. Heesemann's CSD segmented pad system also includes:

- 100% dynamic control via stepless magnetic segments – pressure is applied smoothly based on surface area being sanded and independent of compressed air source

- Maintenance-free magnetic coils for consistent, maintenance free sanding

- A sealed enclosure keeps dust and other particles out of pressure beam

- Precise surface pressure control allows for a consistent finish

- Precise edge pressure control so the work-piece is sanded consistently and evenly

- Edge pressure controls are independent from work-piece surface pressure

- Pressures that are stored and controlled in IPC for completely customizable and repeatable sanding results

- Multi-track control of edge pressures

- Three (3) rollers per segment

- Non-mechanical, magnetic switches activate the segmented pads eliminating moving parts

- Thickness compensation; 2 mm within and 2 mm between work-pieces (+/- 1mm) without any pressure variation

- Adjustable sanding start/stop that can be administered from the controller

- Interlocking phenolic segments for absolute consistent sanding results

Segmented Rotary Air Jet Cleaning

Rotating compressed air nozzles for blasting workpiece surface. Nozzles are a non-contact cleaning system which cleans both flat and profiled surfaces without touching the workpiece.

- Operate only if a workpiece is present to conserve utilities

- Each rotor is separately controlled according to part size to conserve utilities

- Integrated dust extraction ports for dust evacuation

Conveyor Belt Cleaning Program

Conveyor belt cleaning program can be activated to clean the conveyor belt.

- The machine closes to 10mm thickness and the conveyor belt completes one rotation.

- When finished, the machine returns to previous position.

- This feature is manually activated by the operator.

Lighted sound enclosure

Dust manifold

Manuals

Marketplace items are sold ‘as-is’ and ‘where-is’ without refunds or guarantees. Payment is due 48 hours after offer acceptance; buyer arranges freight within 7 days after offer acceptance.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view purchase history

LoginPlease log in to post a question

Login

There are no questions for this listing.