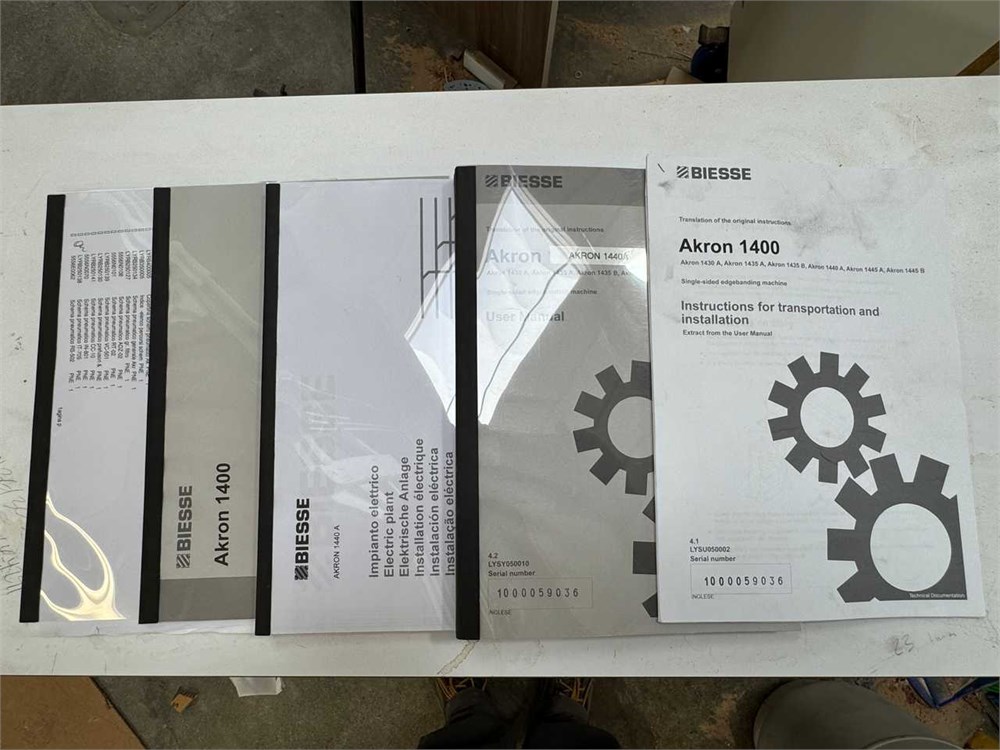

Biesse "Akron 1440 A" Edgebander (2022)  Preview

Preview

Complete Woodworking Facility Auction - Los Alamitos, CA

Los Alamitos, CA

Starts In remaining

Complete Woodworking Facility Auction - Los Alamitos, CA ( Preview #78372276 )

Commercial casework company in Southern California has ceased operations and is auctioning all assets. Most machines are 2022 and newer including Biesse CNC, edgebander, CNC bore/dowel machine, case clamp; Viet widebelt sander; (2) Nederman dust collectors; SawStop; TigerStop; RazorGage; forkift; racking; tooling and much more!

-

Pick Up Location

3882 Florista St. Los Alamitos, CA 90720

-

Make

Biesse

-

Model

Akron 1440 A

-

Serial Number

1000059036

-

Year

2022

-

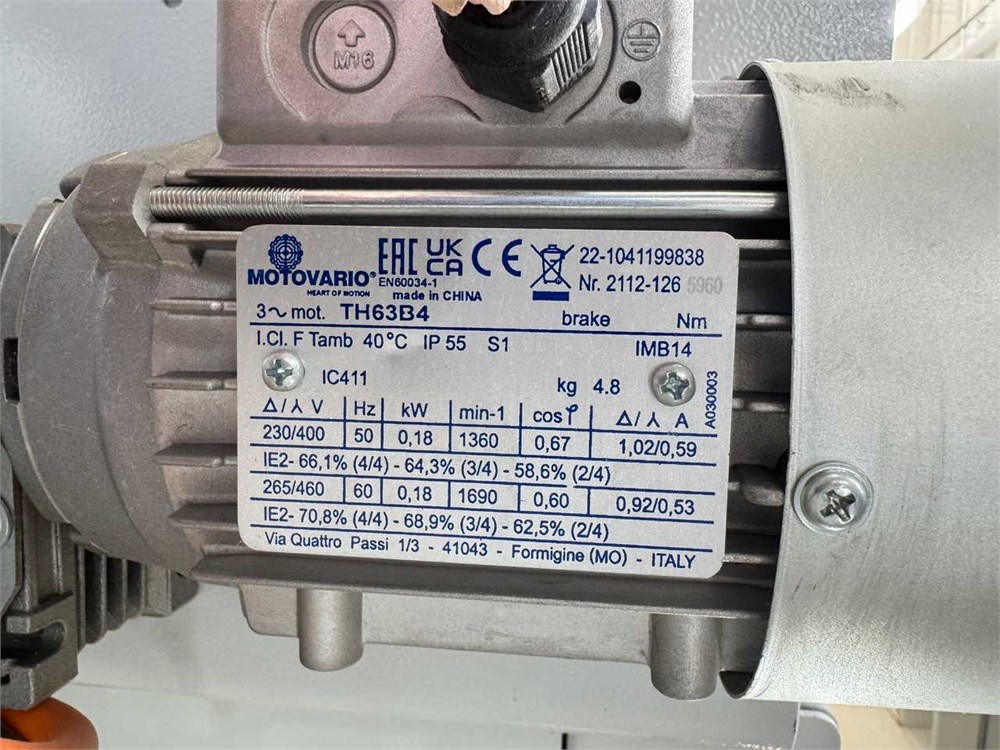

Phase

3 PHASE

-

Voltage

208-230/460

-

Buyer Inspection Period

March 3, 2026 (9 am - 3 pm, no appointment required)

-

Load Out Period

March 9 - March 13, 2026 (By Appointment Only)

-

Estimated Dimensions

240" L x 48" W x 68" H (96" H with dust manifold)

-

Estimated Weight

5,000 Lbs

-

Seller Comment

This lot requires a rigger, see home page for details.

-

Load Fee

-

Lot Notes

-

page views

20

Biesse "Akron 1440 A" Edgebander (2022)

Original purchase price was approximately $190,000

Panel length: 140 mm/5.5" - 3,200 mm/126"

Minimum panel width (with length 140 mm/5.5"): 85 mm/3.3"

Minimum panel width (with length 250 mm/9.8"): 50 mm/2"

Panel height: 10 mm/0.4" - 60 mm/2.4"

Panel protrusion from track: 25 mm/1"

Edgebanding height: 14 mm/0.6' - 64 mm/2.5"

Edgebanding thickness (rolls): 0.4 mm - 3 mm

Edgebanding thickness (strips): 0.4 mm - 12 mm

Touch screen controller

- Smart Touch 23 numeric control

- Windows operating system

- Biesse's "Sophia" software

- 23" color touchscreen

- Program and machine control

- Production data and machine diagnostics

- NC setup for infeed fence, pressure rollers, fine trimming unit, corner rounding unit and edge scraping unit

Edgebanding infeed table, 32" diameter

One coil automatic edge feeding (no need to open sound enclosure to introduce edgebanding)

Adjustable infeed fence

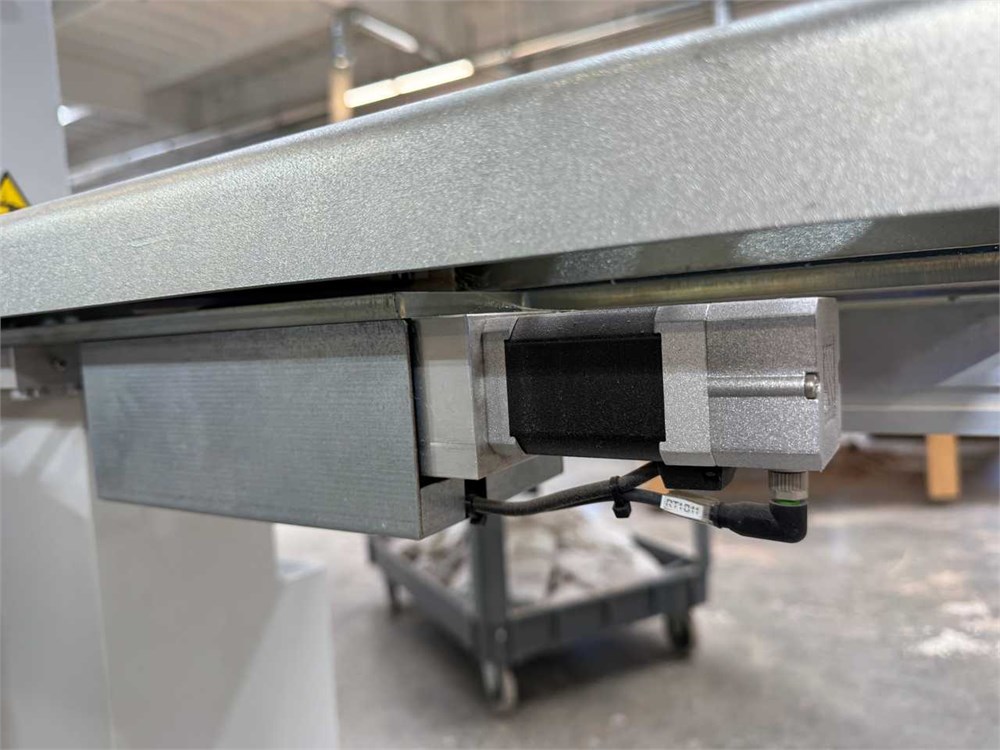

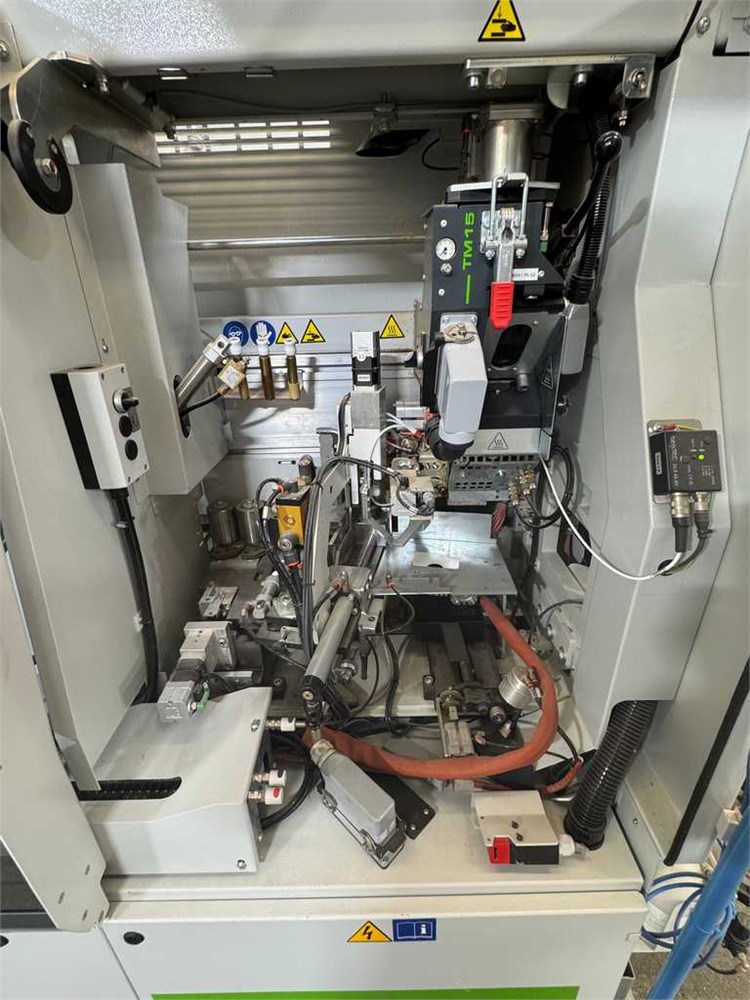

Pre-milling unit "RT02"

- (2) motors, 2.4 HP and 12,000 RPM (each)

- Auto set device

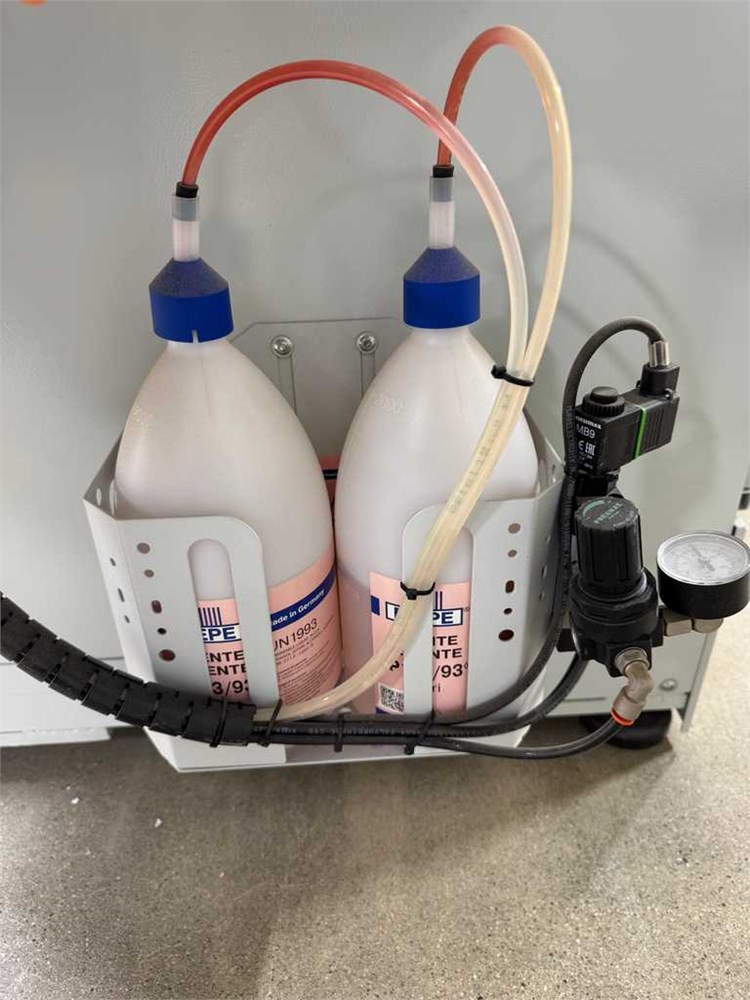

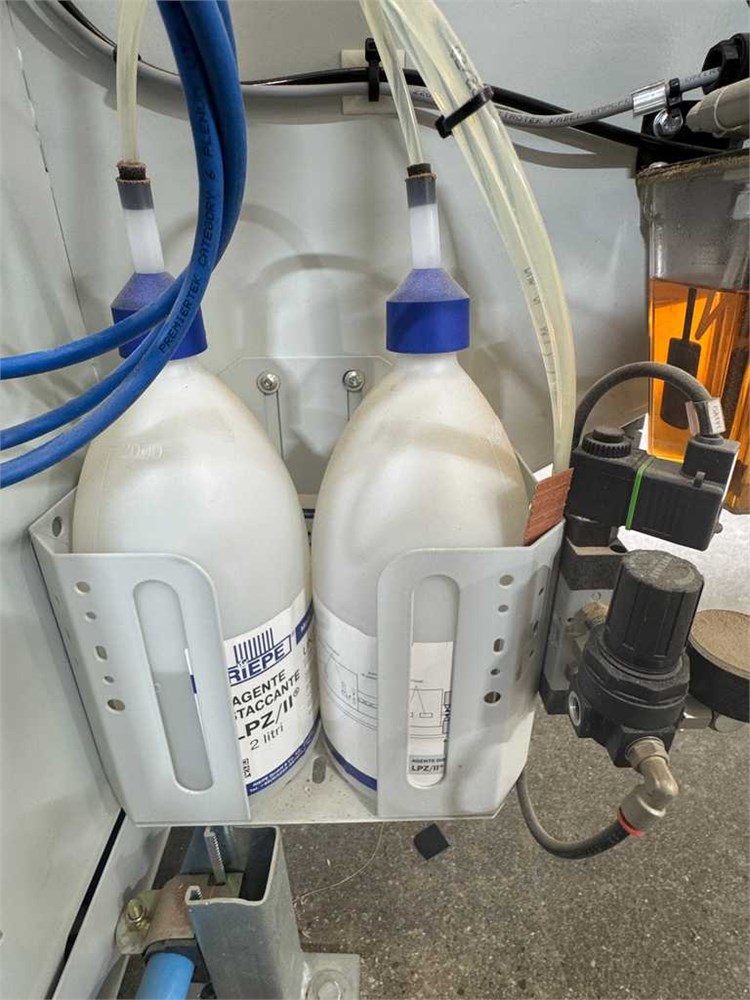

Anti-adhesive spray unit "ADZ02"

- Applies spray to top and bottom of panel

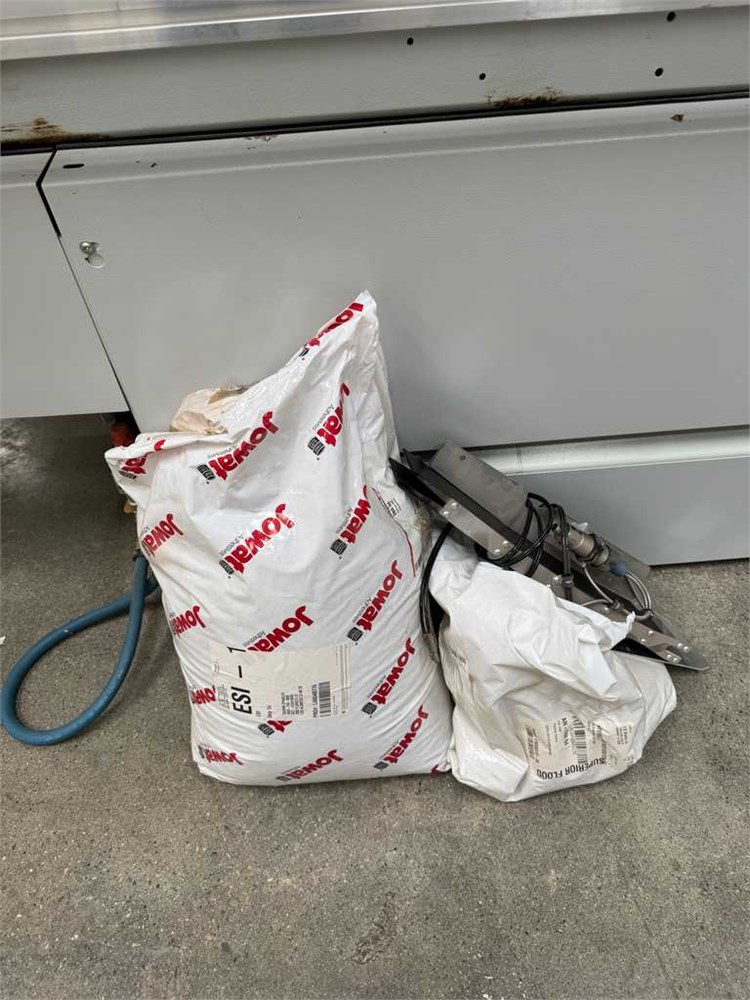

Infrared lamp (removed from machine, see photos)

Glue unit "VC-511"

- Capable of using EVA or PUR

- Glue pot with application roller and pre-melt hopper

- Application roller can operate CW/CCW

- NC glue flow control

- Quick-disconnect

- Controlled tilting of application roller

- Automatic pneumatic exclusion when track stops

- Pneumatic exclusion of the glue pot

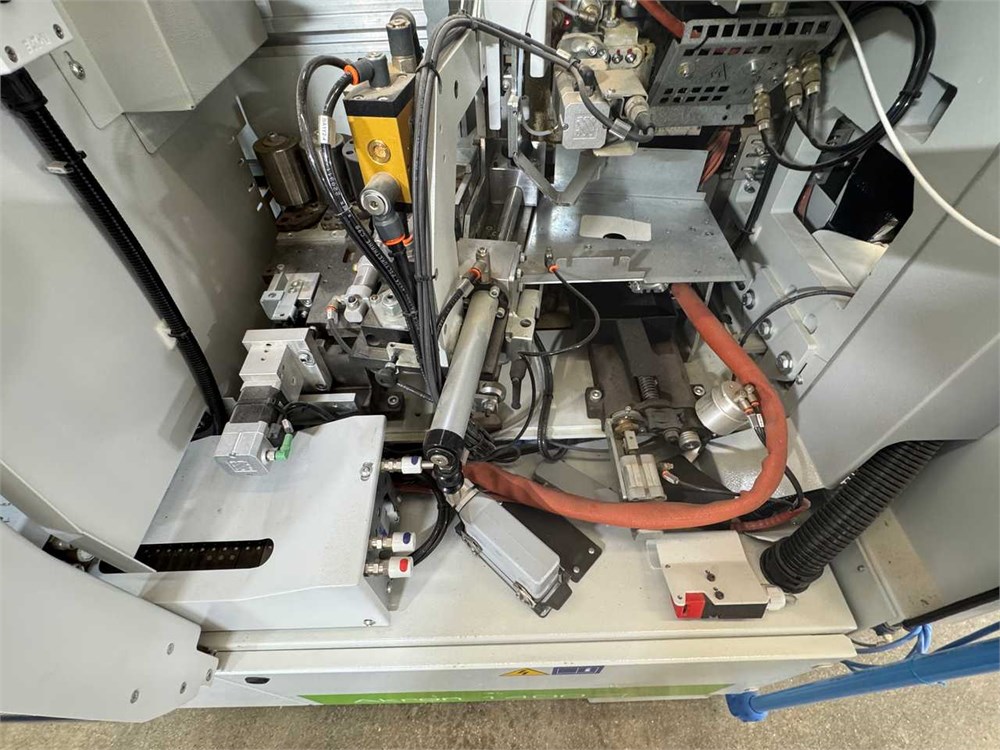

Guillotine

Pressure unit

- (1) driven roller, 100 mm/4" diameter

- (2) idle rollers, 60 mm/2.4" diameter

End trimming unit "IN-801

- (2) motors

- 1 HP and 12,000 RPM (each)

- (2) position (0/15 degrees) pneumatic tilt with selection from controller

Top/bottom fine trimming unit "RI-501"

- 0.9 HP and 12,000 RPM (each)

- NC pneumatic exclusion

- Tiltable, 0/25 degrees

- Pro nesting kit

Two (2) motor corner rounding unit "AR02E"

- 0.9 HP and 12,000 RPM (each)

Top/bottom profile scaping unit "RB02"

- NC exclusion

- Exterior collection box

- Pro nesting kit

Top/bottom glue scraping unit "RC02"

- Pneumatic exclusion

Top/bottom buffing unit "SZ02"

- 0.5 HP and 2,800 RPM (each)

- Misting unit

Hot air blower unit "PH-501"

Sound enclosure

Outboard roller track

Top pressure belt

Automatic track lubrication system with dynamic track absorption.

Motorized top beam positioning

Variable feed speed, 39 - 59 FPM

External electrical transformer

Dust manifold specific to the machine included, other ducting NOT included, but offered in lot 071

Manuals

Bags of adhesive

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available