Hansen & Hundebol "300/LS.4" Fladder System  Preview

Preview

World Renowned Shutter Manufacturer Sale #3

Lubbock, TX.

Starts In remaining

O'Hair Shutter Co. in Lubbock, TX ( Preview #75592428 )

In continuing efforts to improve and modernize their operations, O'Hair shutters is selling off a portion of their manufacturing equipment. Some machinery is still in operation and can be seen in operation during the "appointment only" Inspection period.

-

Pick Up Location

2001 N Ave P Lubbock, TX

-

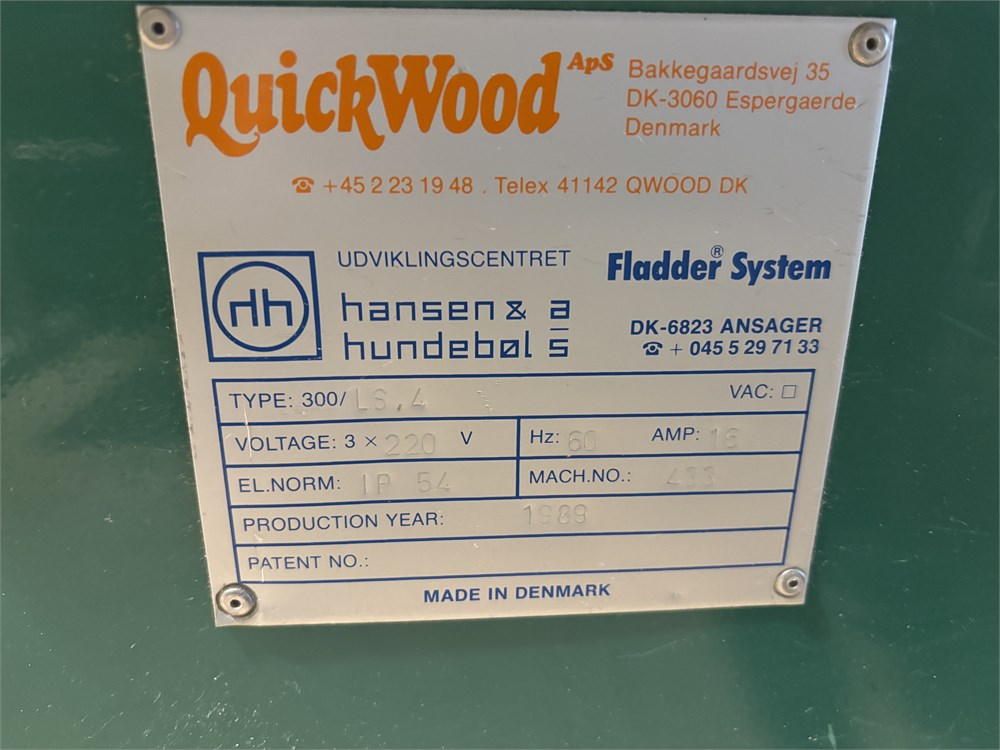

Make

Hansen & Hundebol

-

Model

"300/LS.4"

-

Serial Number

433

-

Year

1989

-

Phase

3 PHASE

-

Voltage

220 VOLT

-

Buyer Inspection Period

TBD

-

Load Out Period

Nov. 17th - Nov. 21st

-

Estimated Dimensions

137"x 36"x 60"H

-

Estimated Weight

3000 lbs.

-

Seller Comment

Buyer responsible for prep, loading, and shipping or hiring a rigger to do so.

-

Load Fee

-

Lot Notes

-

page views

12

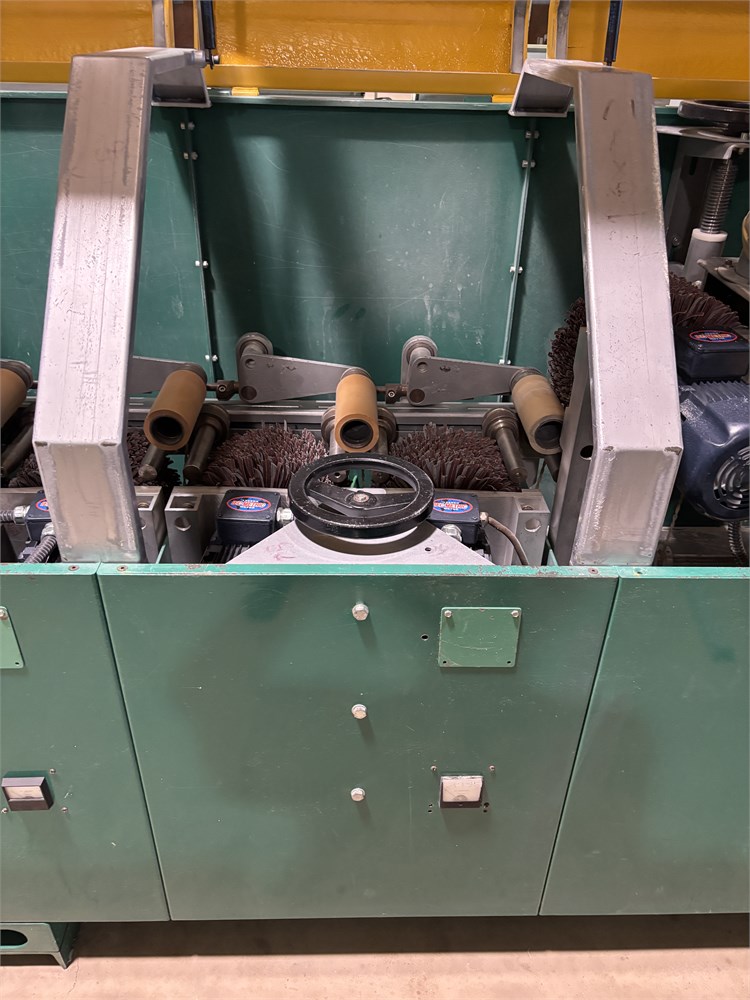

Hansen & Hundebol "300/LS.4" Fladder System

- Working height: 850 mm

- Maximum workpiece dimensions:

- Width: Ø 200 mm

- Height: Ø 200 mm

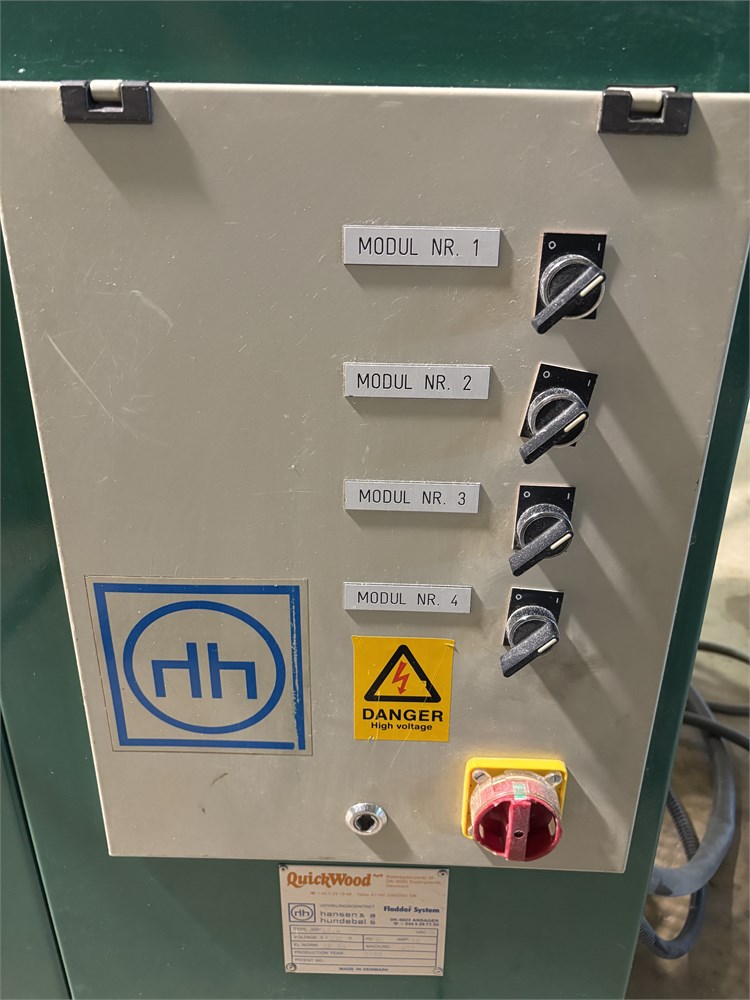

- Number of modules: The LS.4 configuration includes four sections, which can hold up to eight modules.

- Spindle modules: Each module contains two counter-rotating spindles that can accommodate flexible abrasive tools.

- Tooling system: The machine uses the patented

lock-itspindle system, which allows for quick tool changes and the use of partial abrasive brush segments. - Infeed speed: 0.3–25.0 meters per minute, adjustable via a frequency inverter.

- Versatile applications: Ideal for sanding and deburring various materials, including wood and metal profiles such as mouldings, window parts, skirtings, and extruded parts.

- Flexible finishing: The flexible, abrasive tools, mounted on counter-rotating and oscillating spindles, ensure a uniform finish on complex contours and shaped profiles.

- User-friendly operation: The machine is operated via a touchscreen and offers both manual and automatic modes.

- Robust construction: The machine features a solid, powder-coated body and large windows for easy maintenance and process viewing.

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available