SCMI "Olimpic K230" Edgebander  Active

Active

Woodworking Machinery Auction - Kaufman, TX

Kaufman, TX

- Current Price : $1,900.00 USD ( ) No Reserve

- 36 Bid(s)

- High Bidder: P****l

Woodworking Machinery Auction - Kaufman, TX ( Active #75299353 )

Cabinet manufacturer in the greater Dallas/Ft. Worth, TX area is auctioning over 50 items no longer required for continuing operations.

-

Pick Up Location

2400 Tabor Pkwy. Kaufman, TX 75142

-

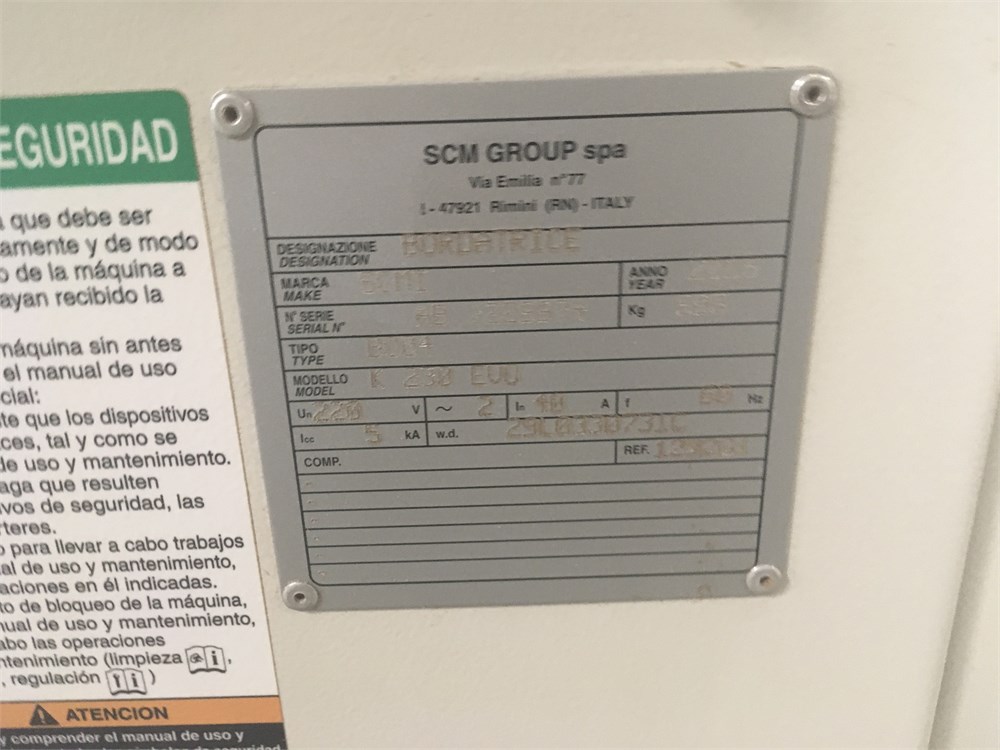

Make

SCMI

-

Model

Olimpic K230EVO

-

Serial Number

-

Year

-

Phase

1 PHASE

-

Voltage

230 VOLT

-

Buyer Inspection Period

By appointment only, contact Jack Ragan, [email protected], 503-806-4611

-

Load Out Period

October 22 - October 31, 2025 (by appointment)

-

Estimated Dimensions

125” x 42” x 58”

-

Estimated Weight

1,600 Pounds

-

Seller Comment

Seller will disconnect and load onto buyer's flatbed truck/trailer for non-negotiable loading fee. Palletizing, crating or other services may be available at an additional cost.

-

Load Fee

100.00

-

Lot Notes

-

page views

883

SCMI "Olimpic K230" Edgebander

Automatic single sided edgebander designed to be used for edgebanding straight vertical profiles with coiled material (veneer and PVC) and with strips (high-pressure laminate and solid wood) with a maximum thickness of 3mm.

Edgebanding thickness: .4mm - 3mm (.016-1/8”)

Guillotine capacity: 3.0mm

Feed speed: 30 FPM

Panel height: 3/8” min – 1 15/16” max

Minimum panel length: 5 1/2”

Minimum panel width: 2 3/8”

Minimum distance between panels: 22”

Controller

Edgebanding infeed table

Infeed fence

Guillotine

Glue pot with application roller

Pressure unit with one (1) driven roller and one (1) idle roller

End trimming unit. This unit is composed of two independent .25 hp motors mounted on THK guides. End trim utilizes a draw cut system for reduced blade projection on thick panels. The unit comes standard with pneumatic positioning of the unit from the control panel with two preset positions. The unit is also equipped with the “radius” edge feature that rounds over the vertical edge on the corners of a 3mm panel.

Top/bottom trimming unit. This unit is composed of two independent .5 hp motors operating at 12,000 rpm. The unit is equipped with a combination cutter that allows the operator to manually go from solid wood, to thin material, to a radius, all with the same cutter. All adjustments are carried out with mechanical digital readouts. The unit has top and bottom copy wheels and side copy shoes. The motors have quick release plugs to facilitate tooling changes.

Top/bottom profile scraping unit. Scraping station designed to remove knife marks from thick PVC. The unit is equipped with top and bottom copy wheel and side copy wheels, adjustments are made via mechanical digital readouts. The unit is positioned manually. The unit is also equipped with dust extraction and a collection bin.

Top/bottom buffing unit. The buffing unit has two .25 hp motors. It can also be tilted up to 12 degrees to provide a softer, more refined edge finish.

Sound enclosure

Outboard roller support

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available