IMA "Novimat Compact" Edgebander  Preview

Preview

Complete Shop Liquidation - Eugene, OR

Eugene, OR

Starts In remaining

Complete Shop Liquidation - Eugene, OR ( Preview #74895289 )

Commercial cabinet shop is closing and offering some GREAT machinery for auction. CNC with unload table, IMA edgebander, wide belt sander, vacuum lifts, beam saw, racks, tools, & finishing equipment.

-

Pick Up Location

91 S Danebo Ave, Eugene, OR 97402

-

Make

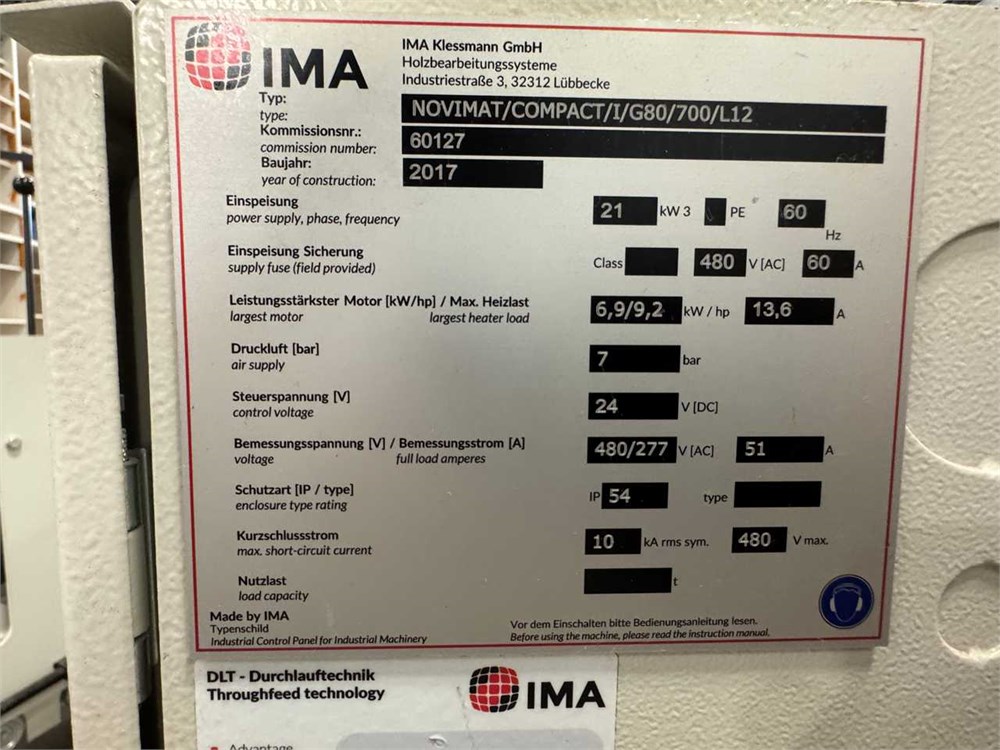

IMA

-

Model

Novimat/Compact/I/G80/700/L12

-

Serial Number

60127

-

Year

2017

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Buyer Inspection Period

Friday Sept 26th 9:00am - 3:00pm - Contact Jack for more info 503-806-4611

-

Load Out Period

Monday Oct 6th to Thursday Oct 9th by appointment. Text Mike 913-333-8396

-

Estimated Dimensions

30' x 5' x 8'

-

Estimated Weight

10,000 pounds

-

Seller Comment

Buyer responsible for prep, loading, and shipping or hiring a rigger to do so.

-

Load Fee

-

Lot Notes

See Video!

-

page views

26

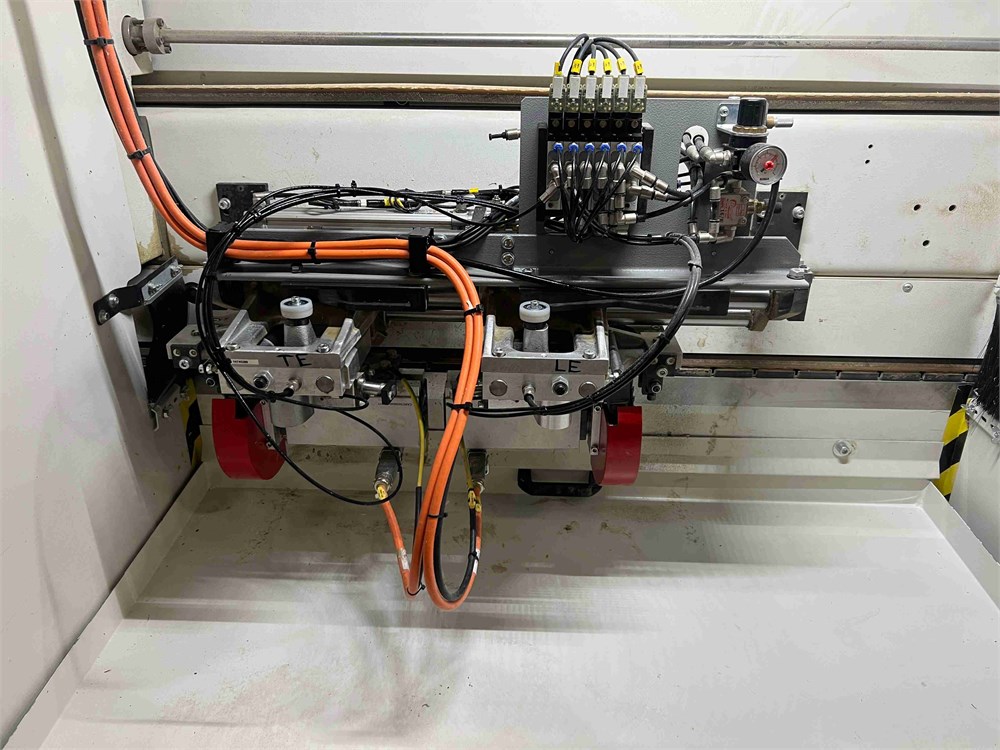

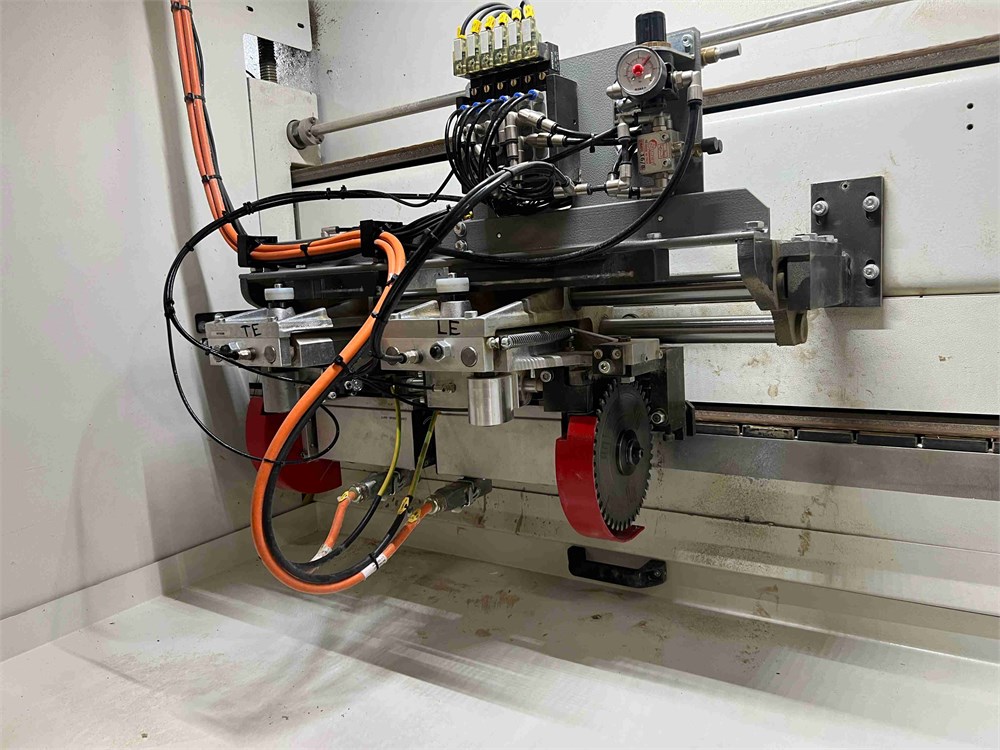

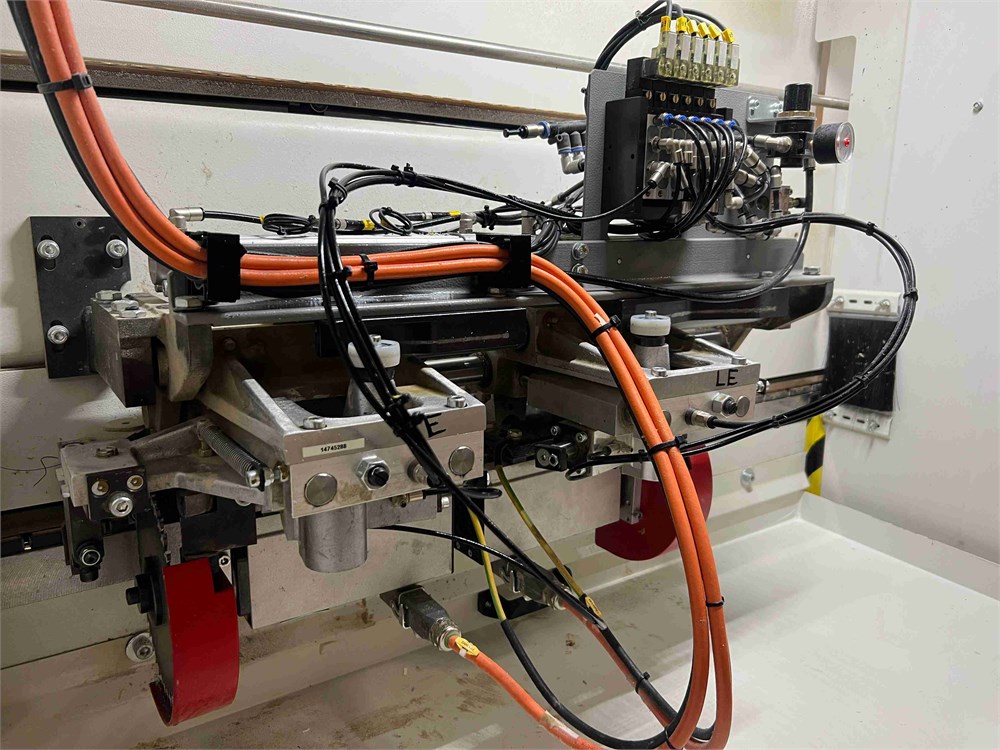

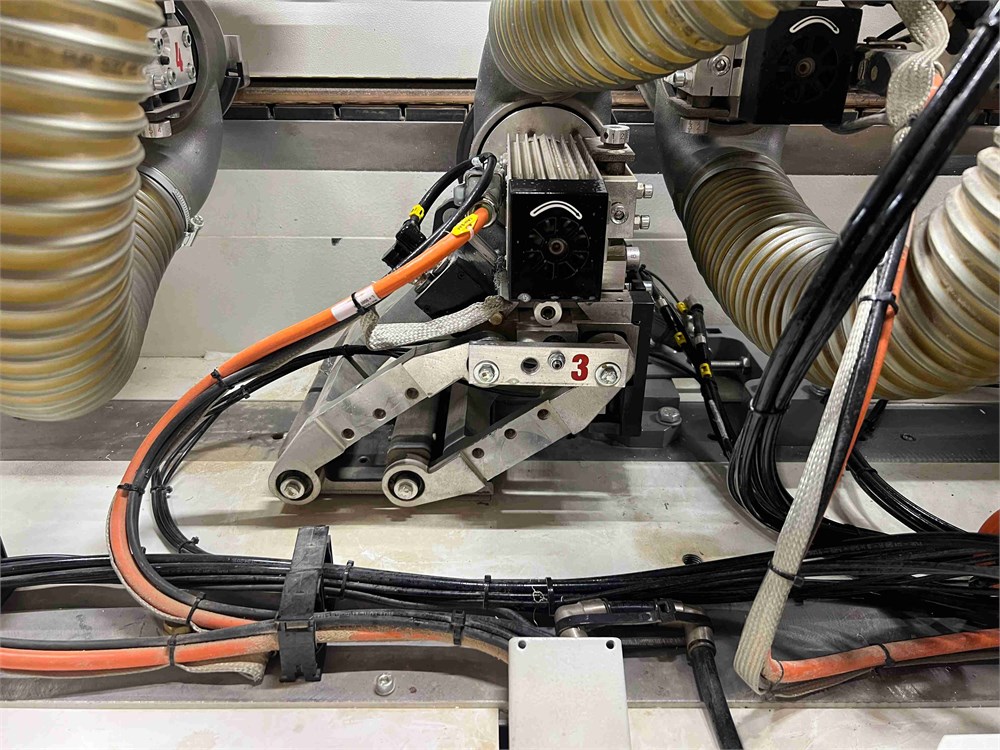

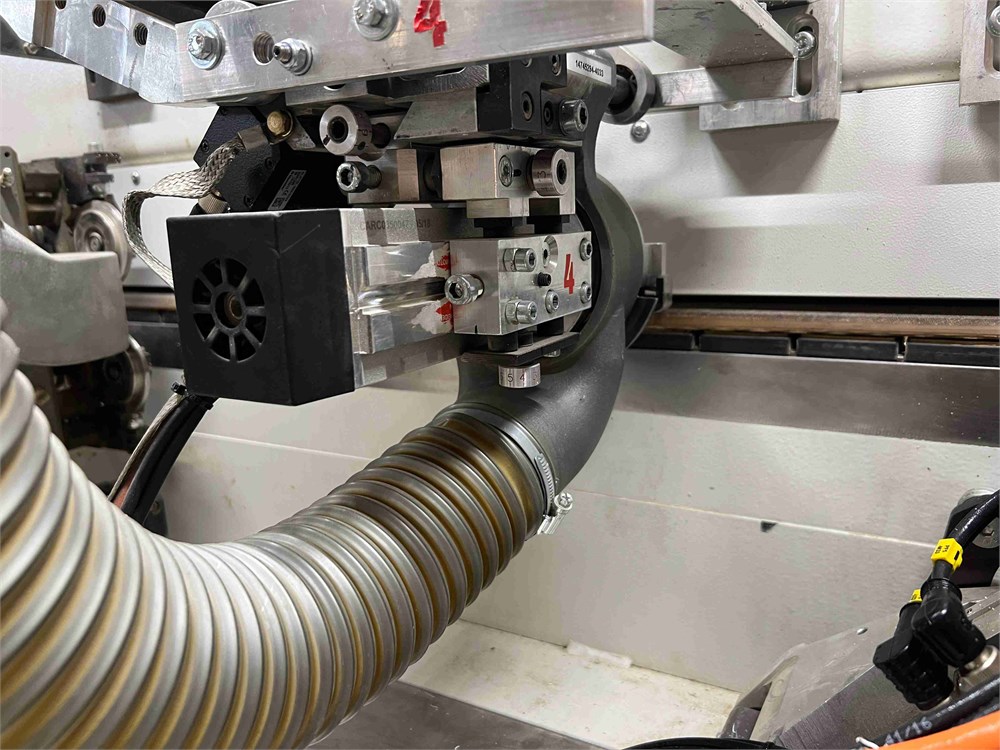

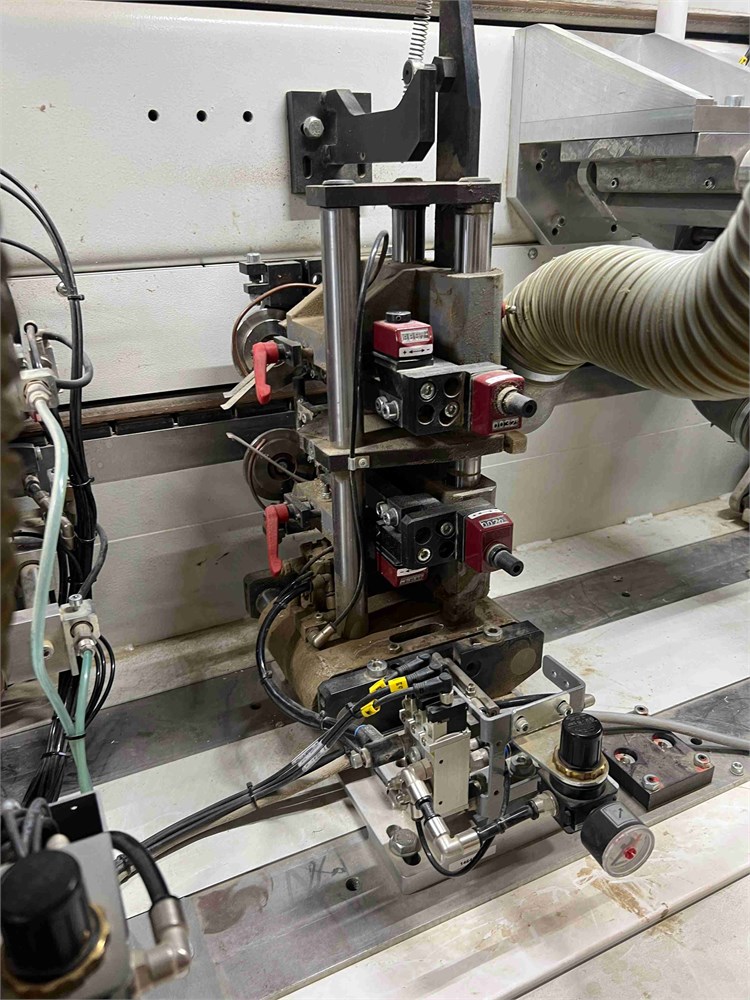

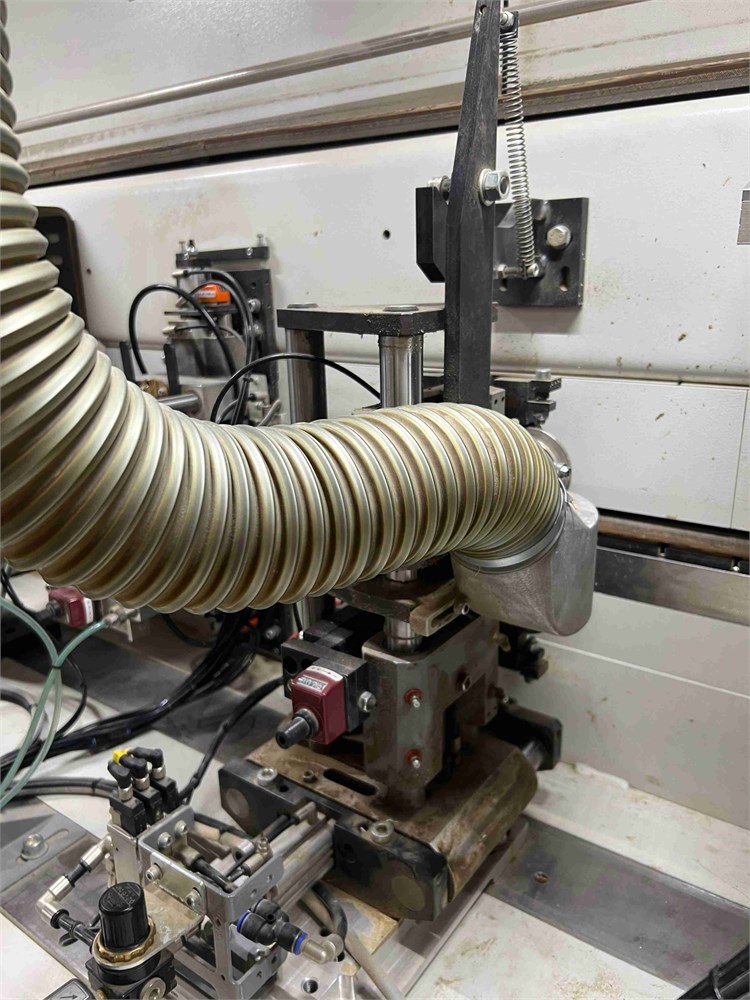

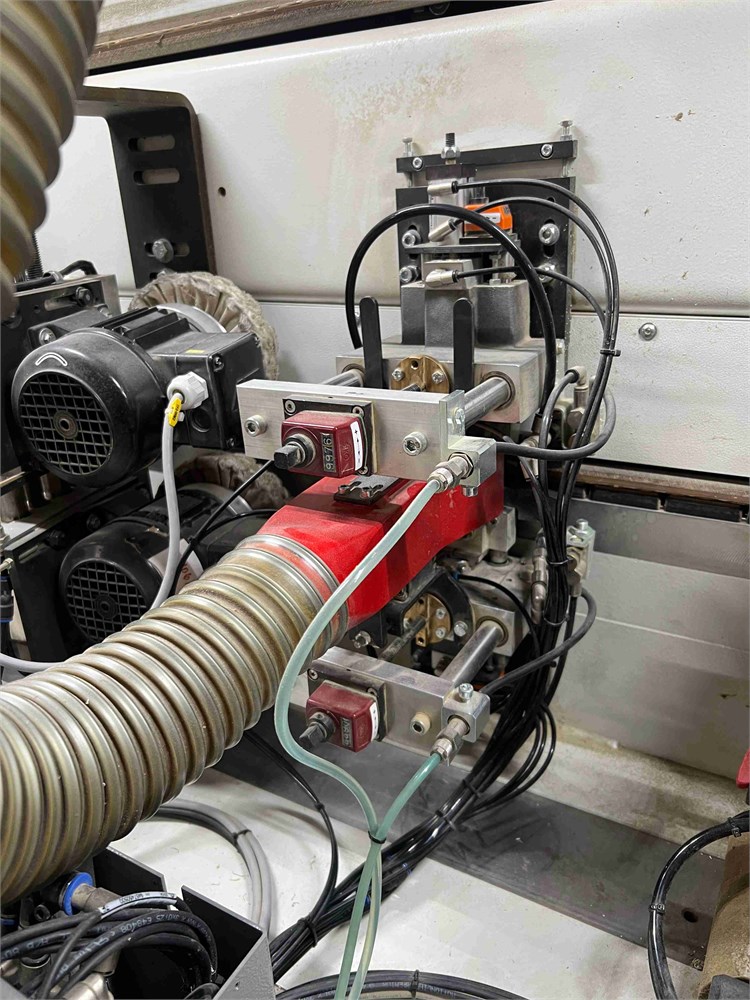

IMA "Novimat Compact" Edgebander

See video of machine.

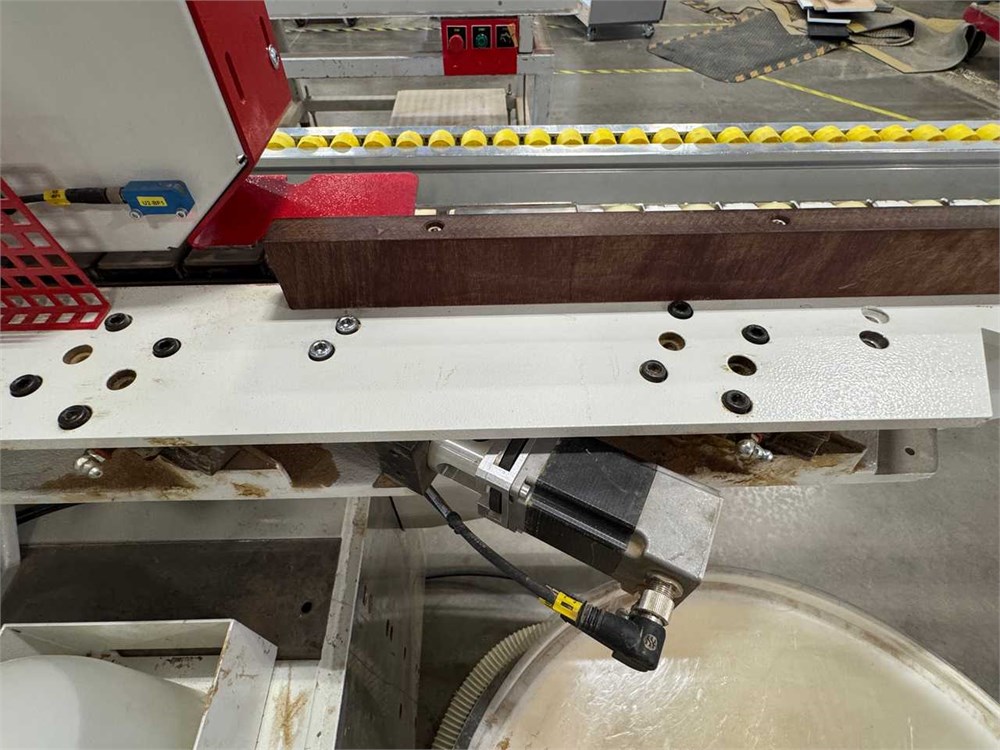

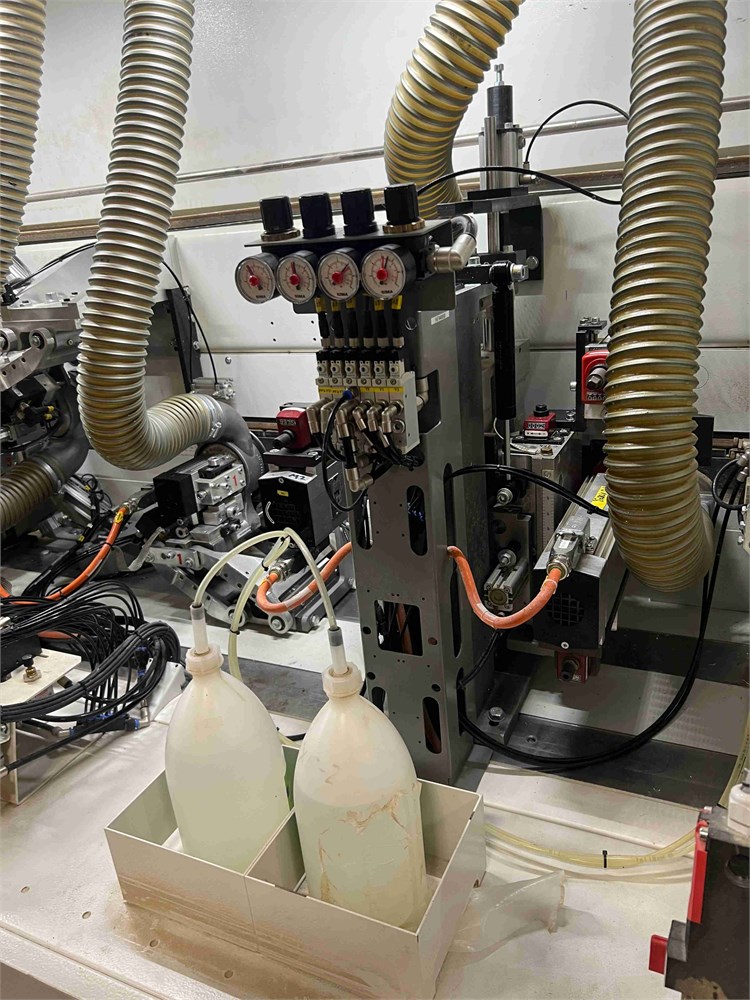

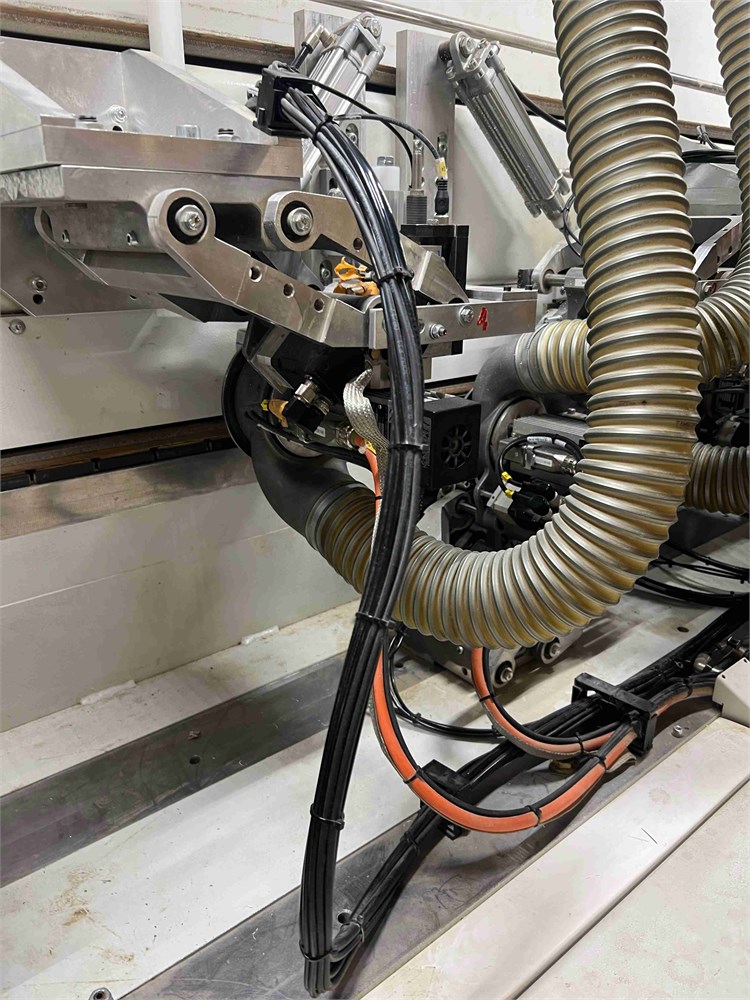

High Production Edgebander capable of processing panels at a rate of 25 MPM (82 FPM), even when using Corner Rounding Unit.

Edgebanding/Panel Capacity, 0.3 -3 mm (0.012 - 0.118"); Panel thickness min/max8 - 60 mm (0.315 - 2.362"). Variable feed speed 6 -25 MPM (20 -82 FPM).

Panel In-feed, extended hold-down beam section ~In-feed fence, adjustable by N.C. ~ Lamps to heat the work piece side.

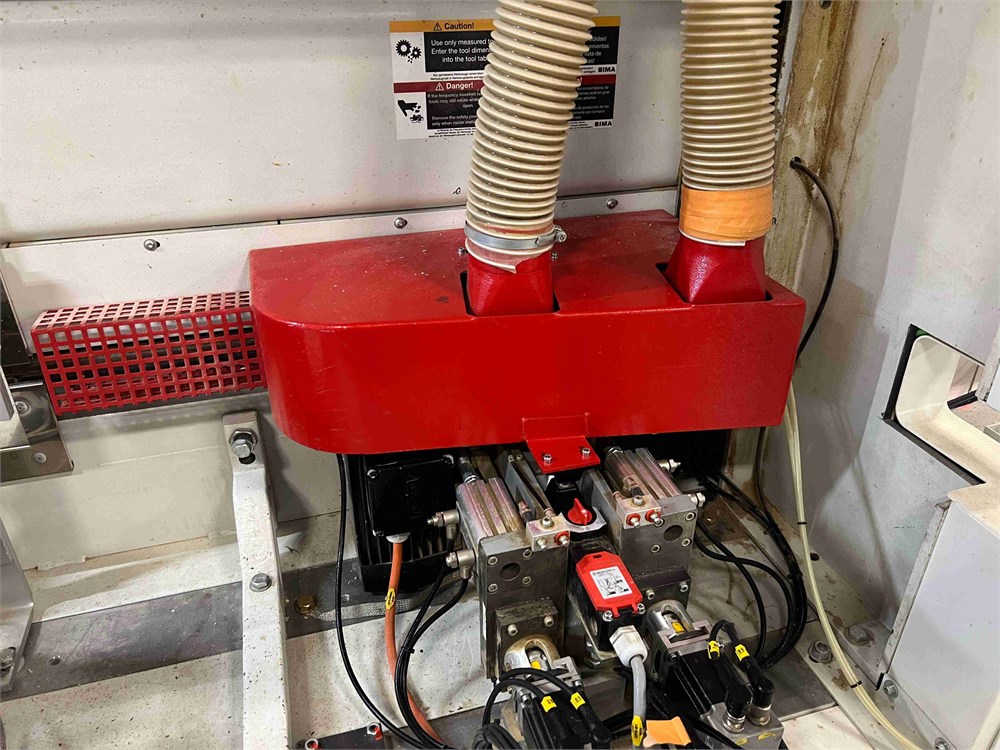

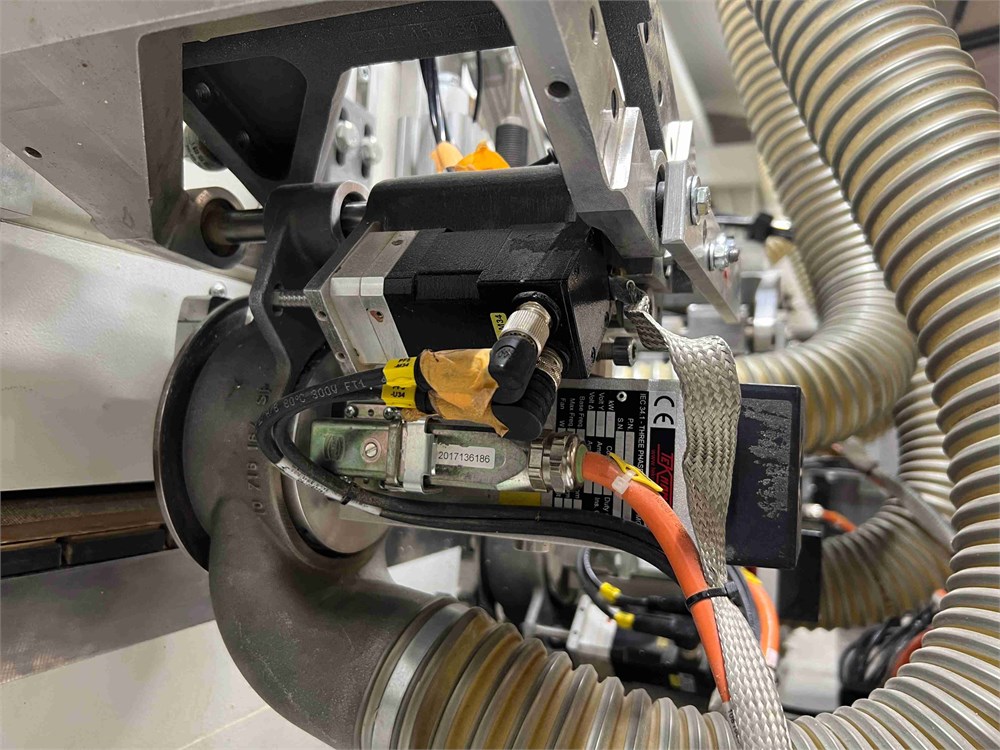

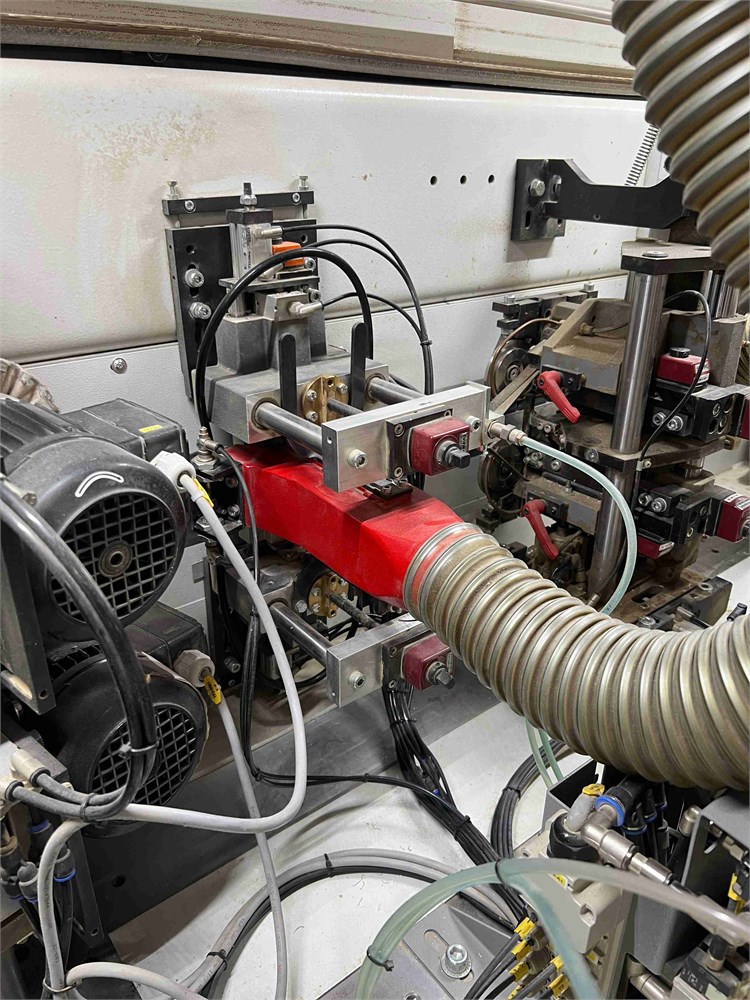

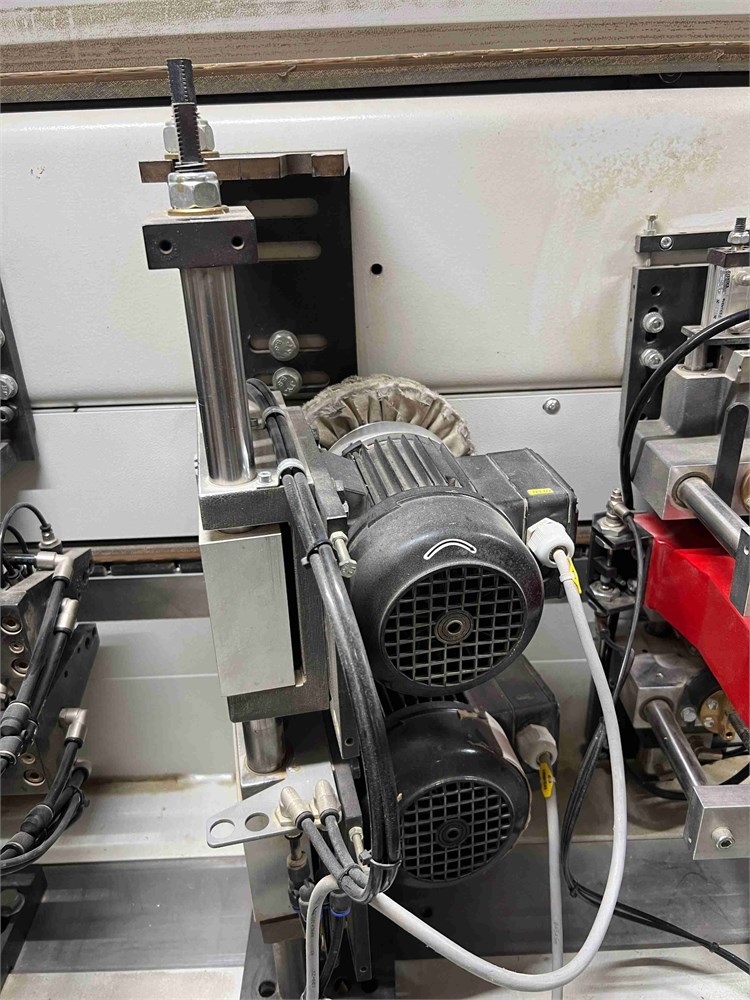

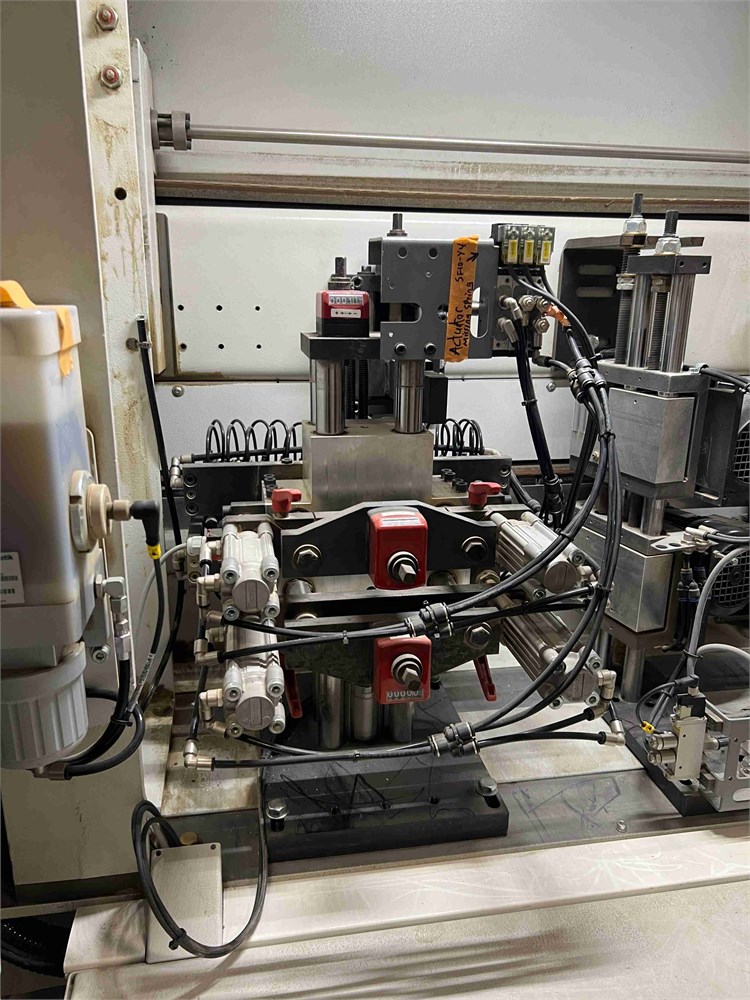

Pre-Milling Unit 08.378: KW 4.5 x 2 (HP 6x 2) vertical joining spindles, horizontal (y-axis) adjustable by N.C. servo motors,vertical (z-axis) SIKO digital readouts, particle & debris air jet blower.

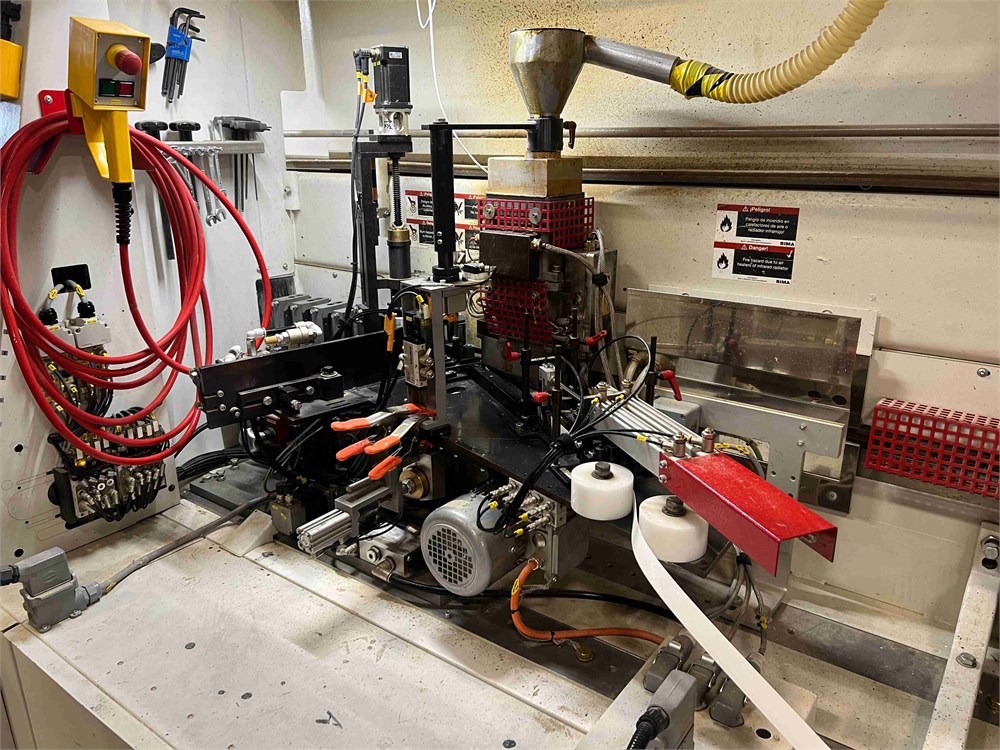

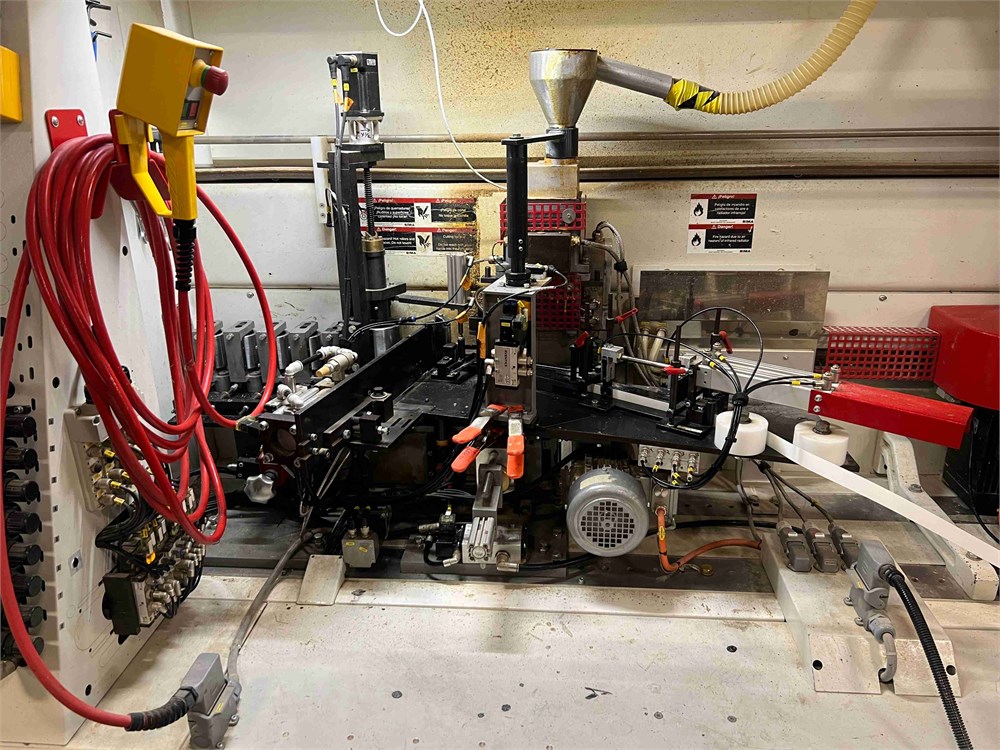

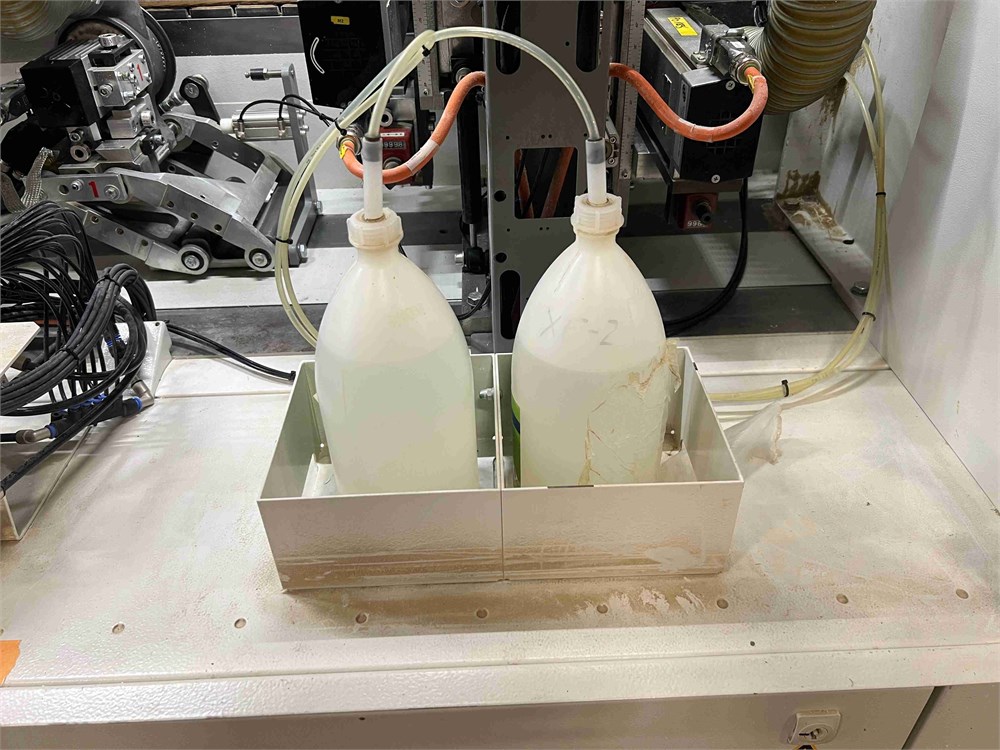

Glue System EVA: Hot Melt with Quick Melt overhead glue tank and vacuum granulate glue feed system directly from glue storage drum.

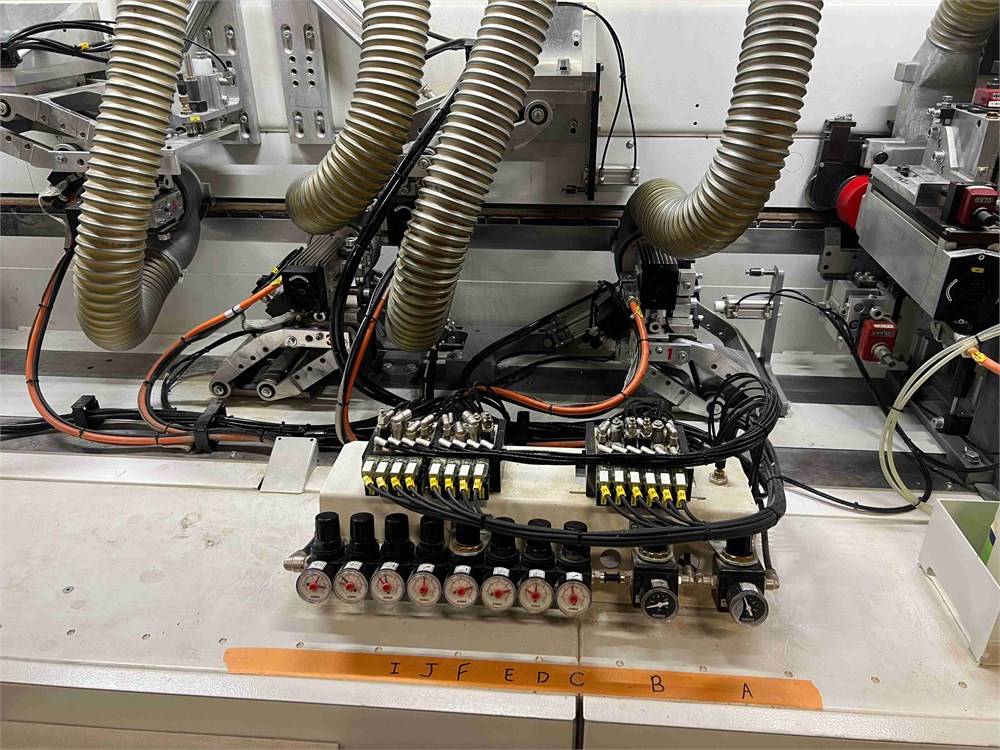

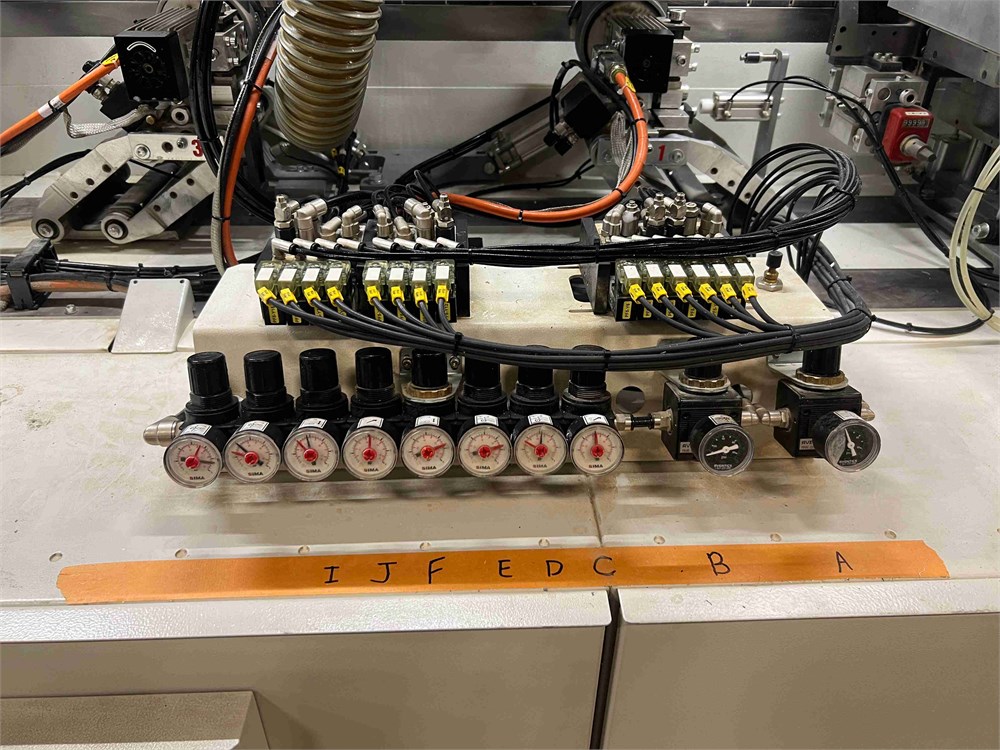

Side Pressure Section: N.C. controlled,pressure rollers w/individual pneumatic pressure.

Edge Magazine: Vertical (2) coils for quick change of edge-material and/or no down-time continuous operation.

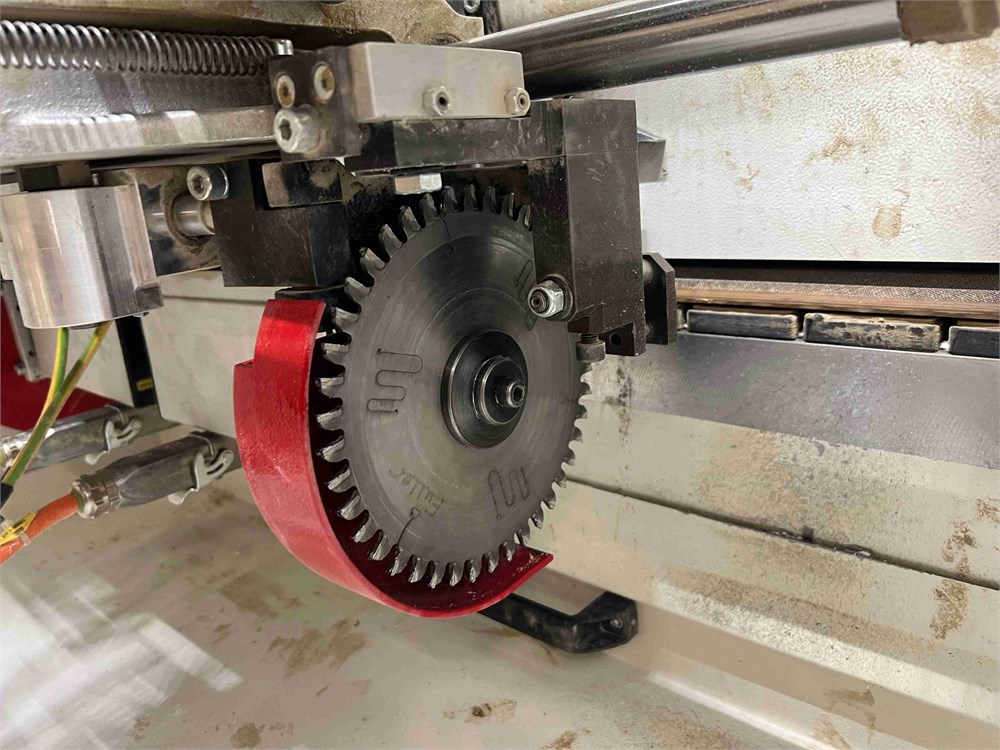

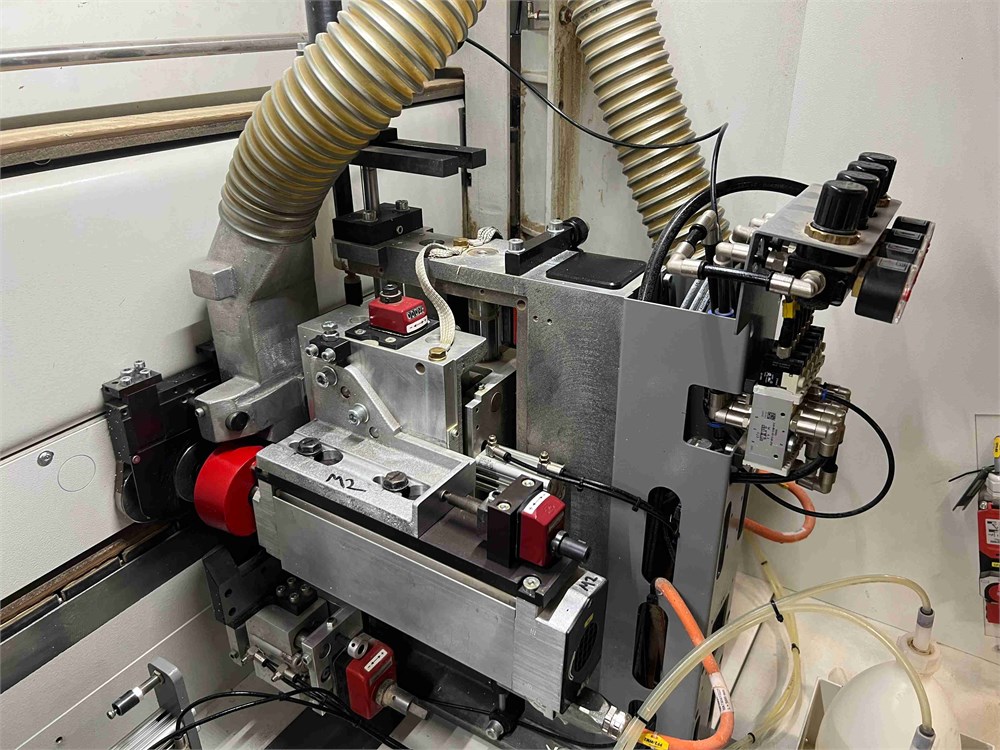

End Trimming Unit: High speed, double motor KW 0.66 x 2 (HP 0.88 x 2), automatic chamfer adjustment 0° - 25° for speeds up to25 m/Min (82 FPM).

Flush/Bevel/Radius Trimming Unit: Top & bottom,KW 1.0 x 2 (HP1.1 x 2)- 12,000 RPM motors, bevels 0°-30°, vertical & horizontal tracing wheels, digital read-outs for manual adjustments.

Corner Rounding Unit: 4-motor,kW 0,66(HP 0.88)for linear top/bottom edge trimming or vertical front/back corner rounding.

Glue Scraping Unit: Flat, top & bottom self-tracing glue scraper,with digital indicator set-up.

Profile Edge Scraping Unit: Top & bottom, multi profile scraper for up to 3 mm thick PVC banding, vertical & horizontal tracing wheels,digital readouts for adjustments,chip extraction system for scraping unit.

Spraying Unit: Top/Bottom for edge polishing/cleaning.

Buffing Unit:Top/Bottom,2 x kW 0.18(HP 0.25)- 3,000 RPM ea. motor.

Control System ICOS OPEN, Large color LCD display; displays stored data, on/off work station sequence, troubleshooting diagnostic; data input by alphanumeric keyboard. Microprocessor adjusts according to stored programs or input; pressure section position & pressure control, vertical positioning of all hold-down beam mounted workstations.

Heavy Duty feed chain with 80 mm wide x 60 mm long rubber pad inserts, central lubrication of transport chain.

Motorized central height adjustment of top pressure beam with double V-belt hold-down.

Dust plenum pictured included.

Return Conveyor is NOT included - see lot# 011

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available