Holz Her "Sprint 1329" Edgebander  Active

Active

Late Model Homag Machinery Auction Donna, TX

Donna, TX

- Starting Bid : $1,000.00 USD ( ) No Reserve

- 0 Bid(s)

Late Model Homag Machinery Auction Donna, TX ( Active #74452893 )

Shop in Donna, TX is offering these well kept late model machines they no longer need for production.

-

Pick Up Location

940 W I-2 Frontage Rd. Donna, TX 78537

-

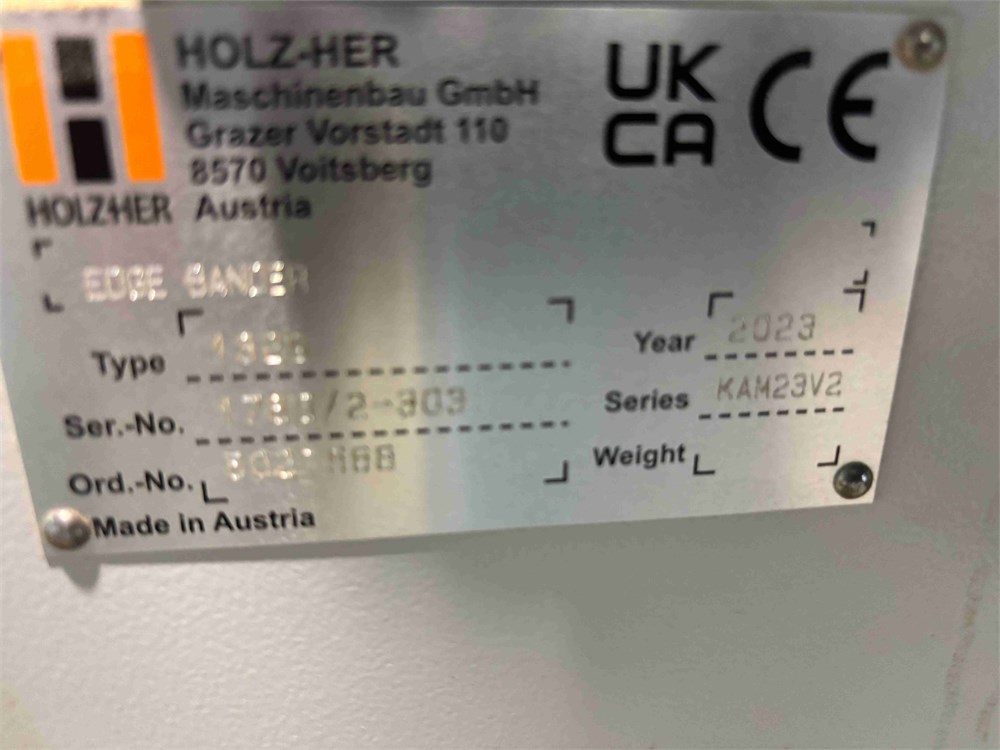

Make

Holz-Her

-

Model

Sprint 1329

-

Serial Number

1785/2-303

-

Year

2023

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Buyer Inspection Period

September 4th - September 18th, 2025 By appointment only

-

Load Out Period

September 18th - September 25th, 2025 By appointment only

-

Estimated Dimensions

18' x 4' x 5'

-

Estimated Weight

6,000 pounds

-

Seller Comment

Buyer responsible for prep, loading, and shipping or hiring a rigger to do so.

-

Load Fee

-

Lot Notes

-

page views

21

Holz Her "Sprint 1329" Edgebander

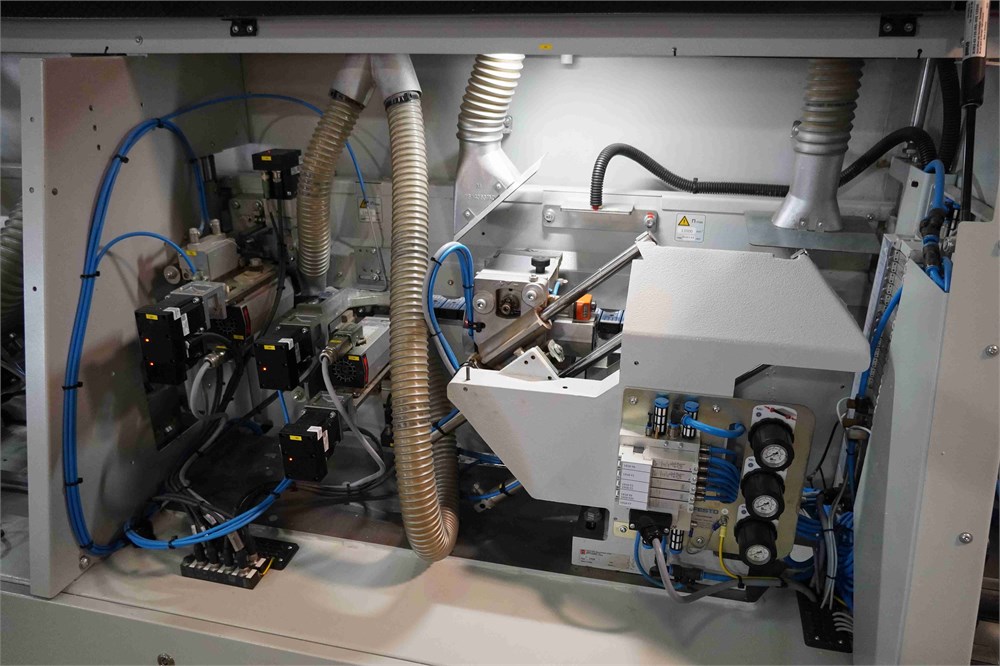

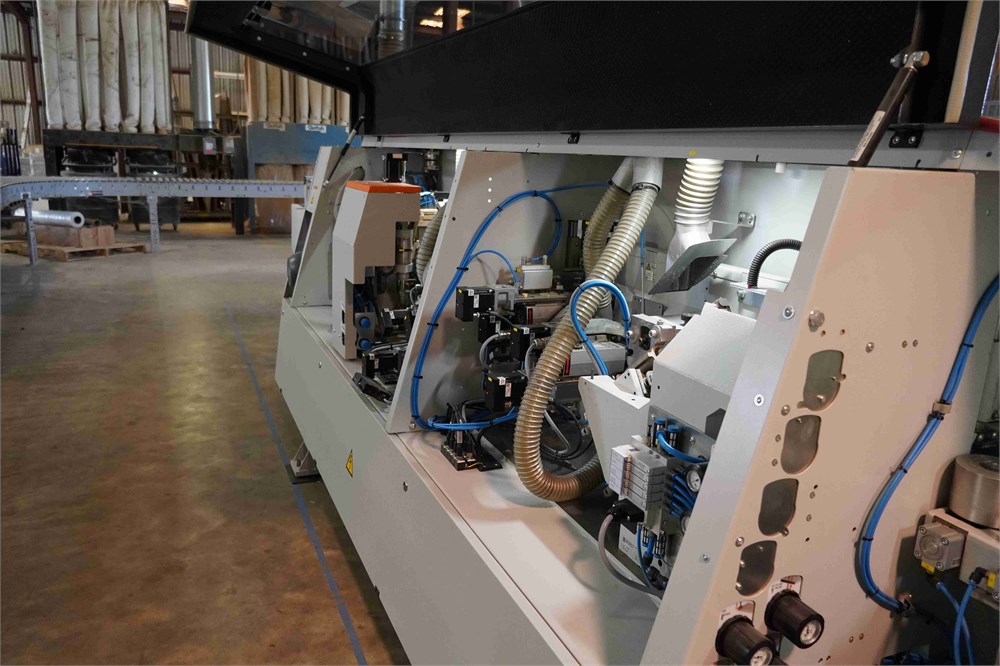

Edgebanding Capacity: edge thickness min./max. 0.4 - 15 mm (0.016 - 0.59"), coiled material 0.4 - 3 mm (0.016 - 0.157"); Panel thickness 8 - 60 mm (0.236 - 2.362"), workpiece width min. of 60 mm (2.36"); workpiece length min. 160 mm (6.29"); Feed speed 10 - 18 MPM (33 - 59 FPM).

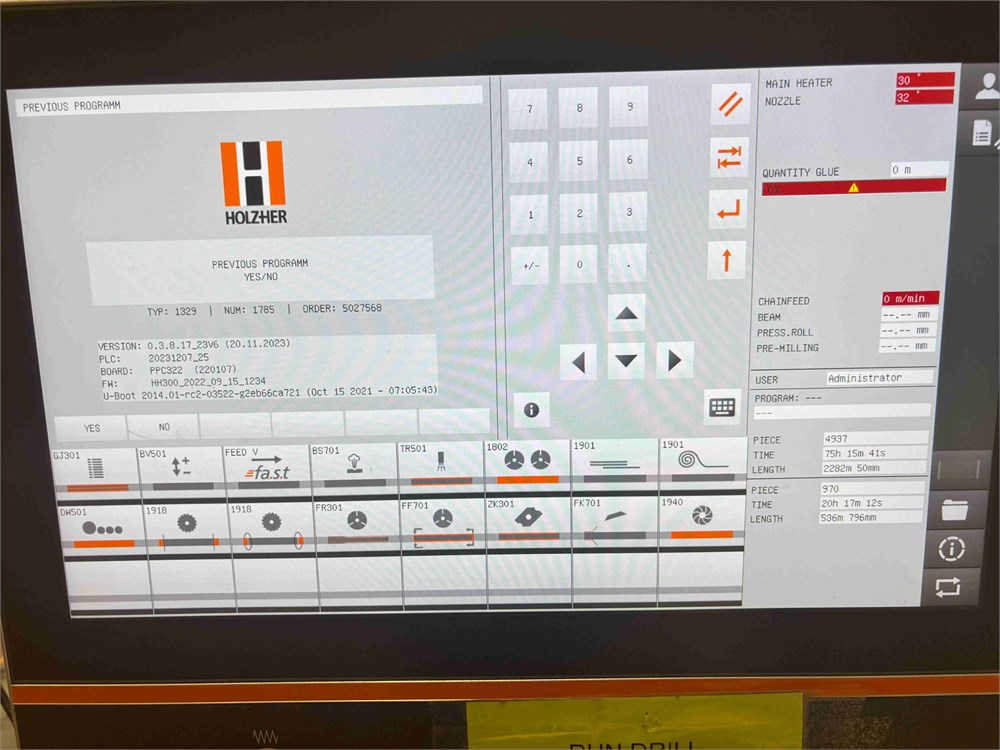

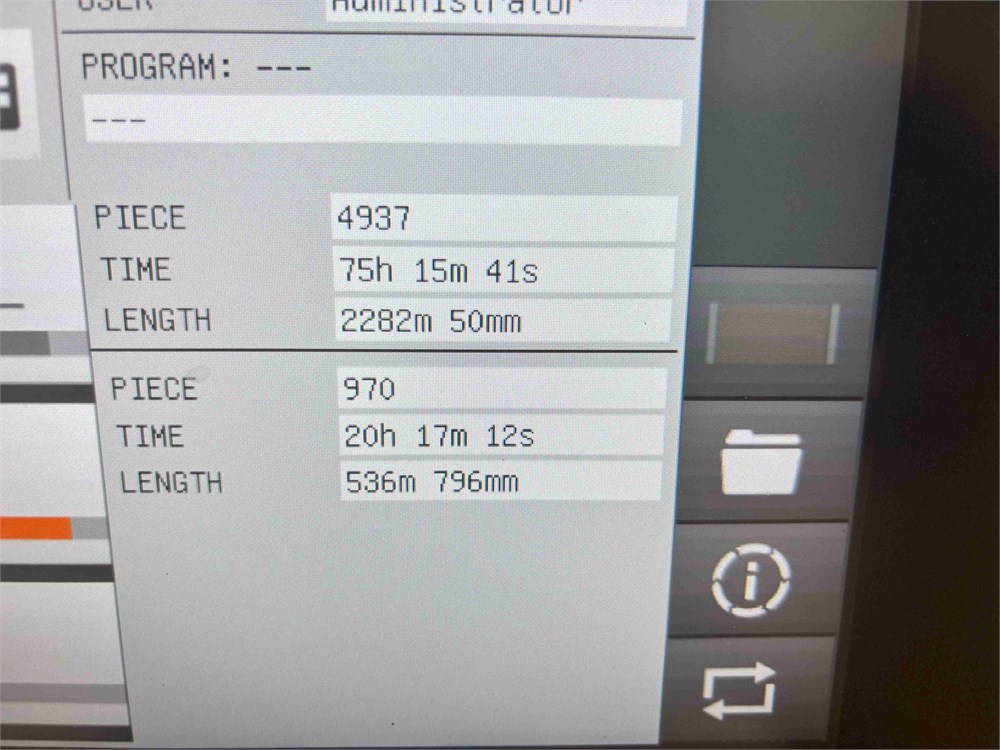

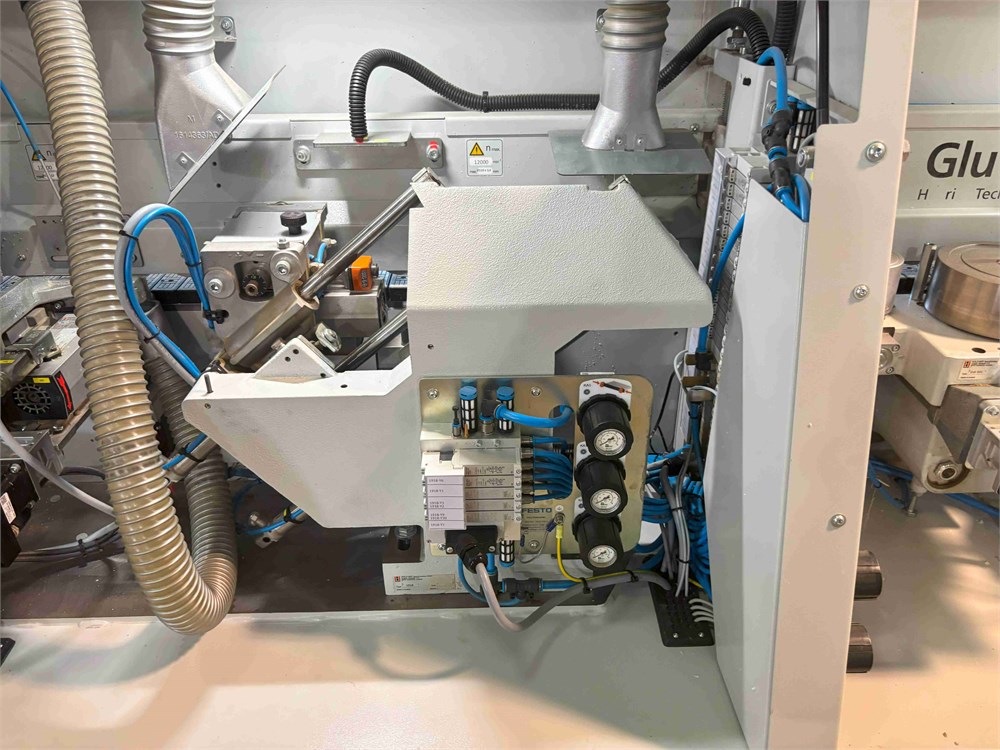

Programmable Logic Control (PLC) for Pre-Milling, edge feed, glue application, end trimming, flush trimming, radius trimming, scraping & corner rounding.

Holz-Her PPC 315 "EDGE CONTROL TOUCH" Electronically controlled set-up processes with 100% repetition accuracy.

18.5" Flat Touch Screen with Brilliant graphic display of machining process. Simple operation – rotating and swiveling control panel at eye height., programs can be easily created and recalled at will; Graphic interface makes programming easy, icon of each unit may be brought up on the screen to show the operator the status of the unit and the parameters which can be programmed.

Edgebander can be operated manually when required, without necessity to write a program.

Pre-Milling Station (1802): (2) 2.0 KW (2.68 HP) - 12,000 RPM motors; Equipped with "ProLock" quick-change flange including height adjustment for optimum utilization of cutters.

Edge Feeder Magazine: "SYNCRO" drive. The new magazine with its synchronous adaptation to the feed rate guarantees short intervals between work pieces & simultaneously optimizes edging protrusions. Small 3° feed angle thanks to nozzle design with easy feeding of coils, strips &up to 3 mm & solid wood edging up to 15 mm (.059"). Exclusive "Tractor-Belt feed System", edge guide equipped with automatic guillotine lock-out for safety.

Pressure Section: Servo controlled pressure section with (1) large driven roller and (2) cantered idle rollers. Straight and tapered pressure rollers for perfect glued joints.

GLUING SYSTEM (GJ301): "Glue Jet" thin film technology processes "EVA" or "PUR" Glue, motorized, programmable glue nozzle (upper glue line) height positioning.

End Trimming Unit (1918): Front & rear 2 x 0.35 KW (0.5 HP) - 9,000 RPM motor each, uni-point swivel-axis for no re-indexing when changing from flush to bevel end trim (0° - 10° bevel),"PCS" programmable pneumatic change-over from flush to bevel.

Multi-function Trimming Unit (1826): Servo controlled, .65 KW (0.87 HP) - 12,000 RPM each motor. Uni-Point design, pneumatic.

Trimming & Corner Rounding Unit (1833): For linear edge-trimming or vertical corner rounding with servo motor programmable positioning, (2) Motor 0.22 KW (0.30 HP) - 9000 RPM for up to 3 mm edge thickness and work-piece thickness min./max. 8 - 60 mm (0.31 - 2.36"), max. feed speed 18 MPM (60 FMP) up to 25 mm panel thickness, (16 m/min. 38 mm thickness, 12/m/min. 60 mm thickness).

Profile Scraping Unit (1939): knife position for PVC edges, reversible insert carbide knives, equipped with air-jet blowers and chip collector box.

Glue Scraping Unit (17 Scrape): Flat, top/bottom, ball bearing guided and pneumatic controlled.

Buffing Station (1940): Top & bottom buffing motors with 150 mm ( 6.0") cloth buffing wheel diameter, adjusts in any direction (vertical tilt is 0° - 5°, horizontal swivel is 0° - 20°); 1,440 RPM wheel rotation.

Return conveyor NOT included, listed in lot 005

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense).

Payment is due within 24 hours of auction close. For orders up to $1,500, the credit card on file will be charged. For orders over $1,500, payment must be made via bank wire transfer, unless the buyer chooses to use a credit card, in which case a 3% processing fee will apply. For payment-related questions, please contact Sabrina Correa at 209-839-7707. Sales tax exemption documents must be emailed to [email protected] at the time of purchase for tax exemption consideration.