Omec "650-A" CNC Dovetail Machine  Active

Active

All items located in Omaha, NE

Omaha, NE

- Starting Bid : $500.00 USD ( ) No Reserve

- 0 Bid(s)

Rip Saw, Door Machines, Dovetail Machines, Sanders & More - Omaha, NE ( Active #74368170 )

Custom door and drawer manufacturer in Omaha, NE is offering machines they no longer use for their production.

-

Pick Up Location

7050 N. 97th. Plaza Cir. Omaha, NE 68122

-

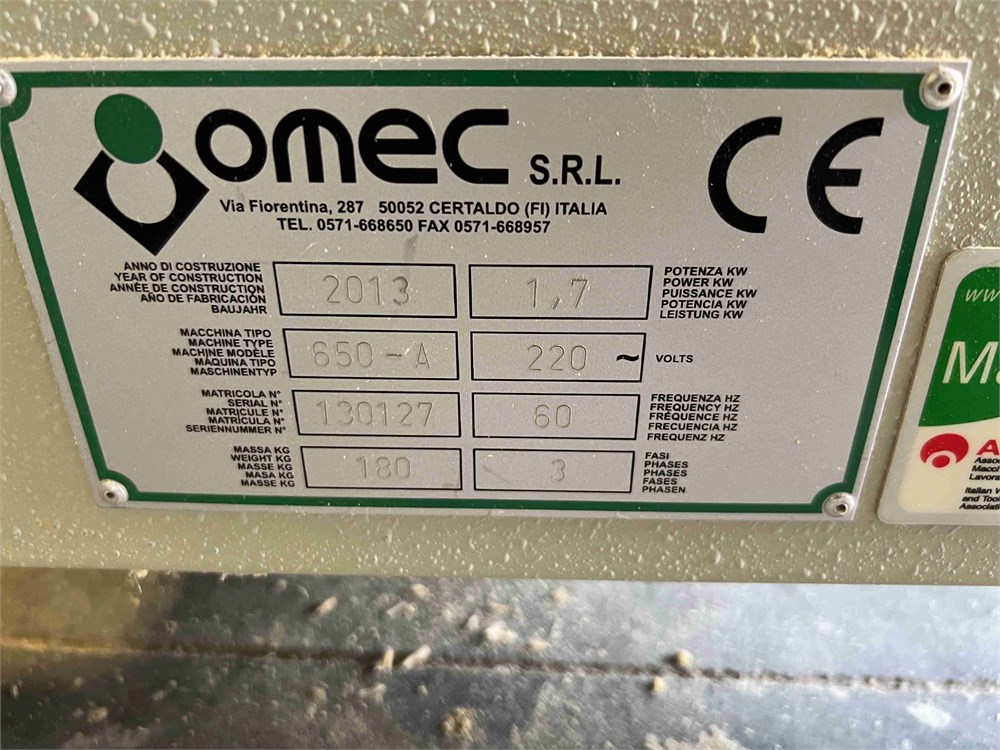

Make

Omec

-

Model

650-A

-

Serial Number

130127

-

Year

2013

-

Phase

3 PHASE

-

Voltage

220 VOLT

-

Buyer Inspection Period

By appointment only, contact Thomas Aronson - [email protected] - 941-699-8717

-

Load Out Period

End of auction through Sept 20, 2025 (by appointment)

-

Estimated Dimensions

40" x 28" x 50"

-

Estimated Weight

500 pounds

-

Seller Comment

A non-negotionable loading fee has been established. This includes loading onto a flat bed trailer. Requests for additional labor, crating or pallatization will be extra.

-

Load Fee

50.00

-

Lot Notes

-

page views

19

Omec "650-A" CNC Dovetail Machine

CNC Controlled Single Spindle cuts male & female dovetail (English type) in (2) joining drawer parts in (1) cutting cycle.

The New OMEC "650A" is now "Touch Screen" controlled, had added a scoring pass feature and can be programmed to store up to (40) separate dovetail drawer sizes.

Minimum: 7.87"L x 2.36"W x 0.33" dovetail cutout height; 0.31" drawer front thickness and 0.31" sidewall thickness.

Maximum: 59.06"L x 14.50"W x 0.63" dovetail cutout height; 2.36" drawer front thickness and 0.78" sidewall thickness.

This automatic milling machine is used to machine dovetails for drawers and various furniture elements. The machine is equipped with a mill spindle allowing adjustable height cutting; it can cut a single male workpiece, a single female workpiece, or both simultaneously.

Variable feed speed accommodates a variety of materials. X- & Y-Axis are servo-motor and ball screw controlled for a precision fit. Pin height, grove depth, groove location, machining speed, number of joints, and tool diameter (for tool compensation) are all controlled by the CNC from the operator control panel.

The lock-in (clamping) and release of the pieces is a pneumatically controlled operation linked to the CNC to allow the machine to work in two separate work zones. This allows loading of right or left side parts while the machine is milling parts on the opposite side. The safety interlock prevents movement of the router to areas where the clamps are open.

Motor Size: 2.3 HP, (1) spindle with 16,500 RPM; Center to center dovetail cutouts: 25 mm & 50 mm; Speed: 0 - 78 IPM (up to 40 boxes per hour).

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available