Morbidelli "UNIX KBT" CNC Feed-Thru Machining Center  Active

Active

DAY 1 of a 4-Day Sale

Tiffin, OH

- Current Price : $1,000.00 USD ( ) No Reserve

- 1 Bid(s)

- High Bidder: t****p

Dorel Home Furnishings - Ameriwood - Day 1 ( Active #73252952 )

Day 1 Features large selection of Woodworking machines including: Weinig Unit 23E Moulder, Holzma HPP350 Beam Saw, Harlan Creative Automation Laminating Line, 6 Forklifts, 200HP Torit Dust Collector, Edgebanders, CNC Routers, Creative Automation Angular Beam Saw, Roller Conveyors, Pallet Racing, plus much more!

-

Pick Up Location

458 2nd. Ave. Tiffin, OH 44883

-

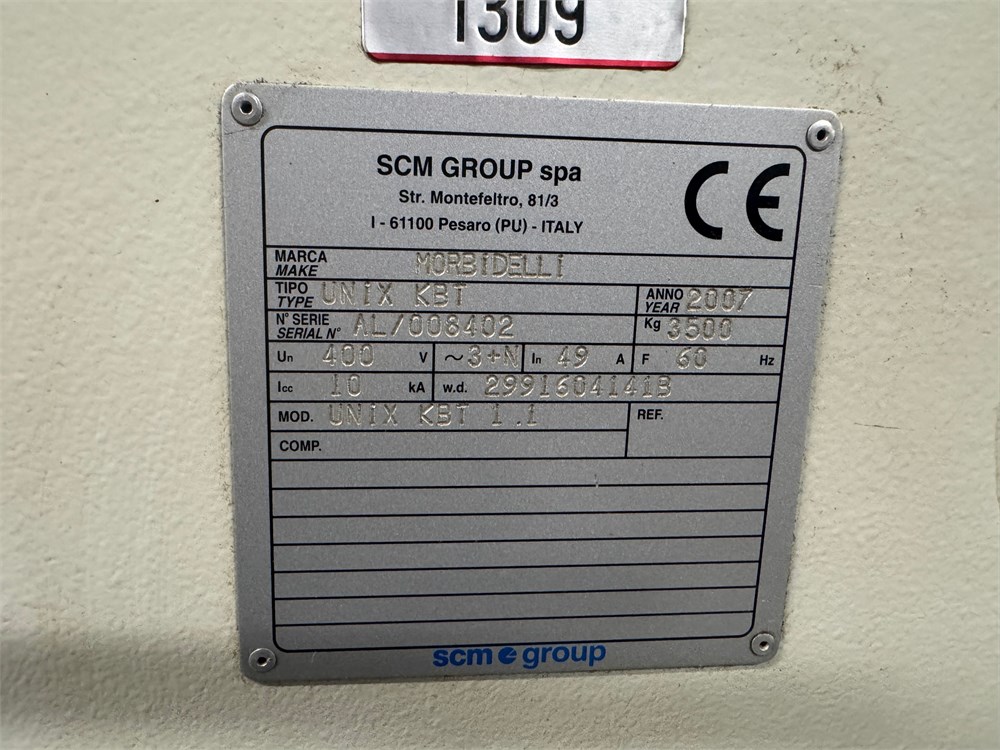

Make

Morbidelli

-

Model

"UNIX KBT"

-

Serial Number

AL/008402

-

Year

2007

-

Phase

3 PHASE

-

Voltage

460 VOLT

-

Buyer Inspection Period

September 16, 2025 8AM - 4PM & September 17, 2025 7AM - 11AM

-

Load Out Period

September 25 - October 9, 2025 By Appointment ONLY!

-

Estimated Dimensions

23'L x 102"D x 92"H

-

Estimated Weight

7,700 Lbs

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal. By appointment ONLY!

-

Load Fee

0.00

-

Lot Notes

Transformer is included

-

page views

428

Morbidelli "UNIX KBT" CNC Feed-Thru Machining Center

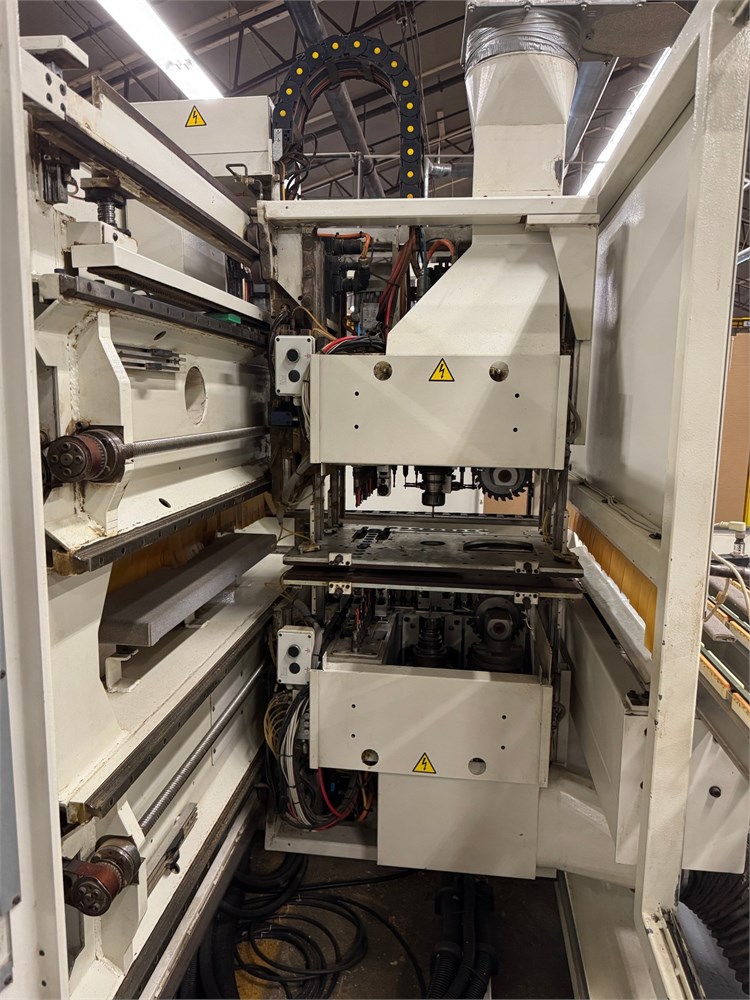

A flexible "TOP & BOTTOM" Machining Center that uses an innovative panel handling system.

Positioning speeds of 130 MPM in "X" axis, 80 MPM in "Y" axis & 50 MPM in "Z" axis with total safety, providing an unmatched working capacity.

Max. workable part size for "X" axis is 126" (3,200 mm), "Y" axis 48" (1,220 mm), max. material thickness 2.3" (60 mm).

Min. worktable part size for X-axis is 7.8" (200 mm), Y-axis 2.7" (70 mm), min. part thickness 0.157" (4 mm).

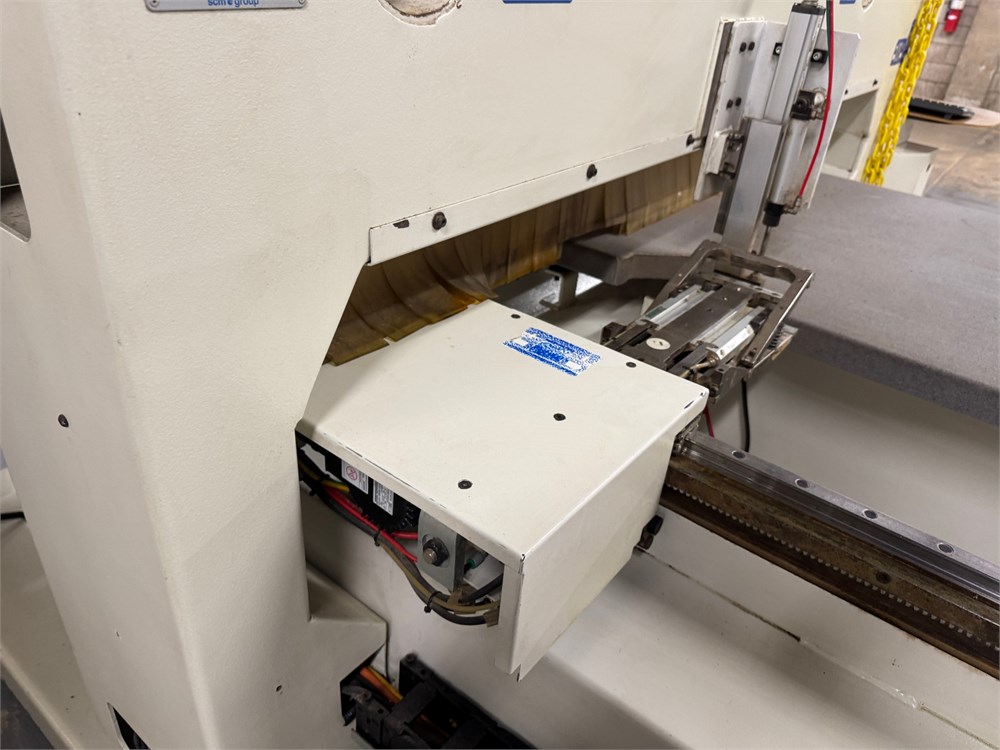

Automatic infeed table with gripper clamps; automatic outfeed transfer conveyor with belts; both infeed & outfeed are considered Robot ready.

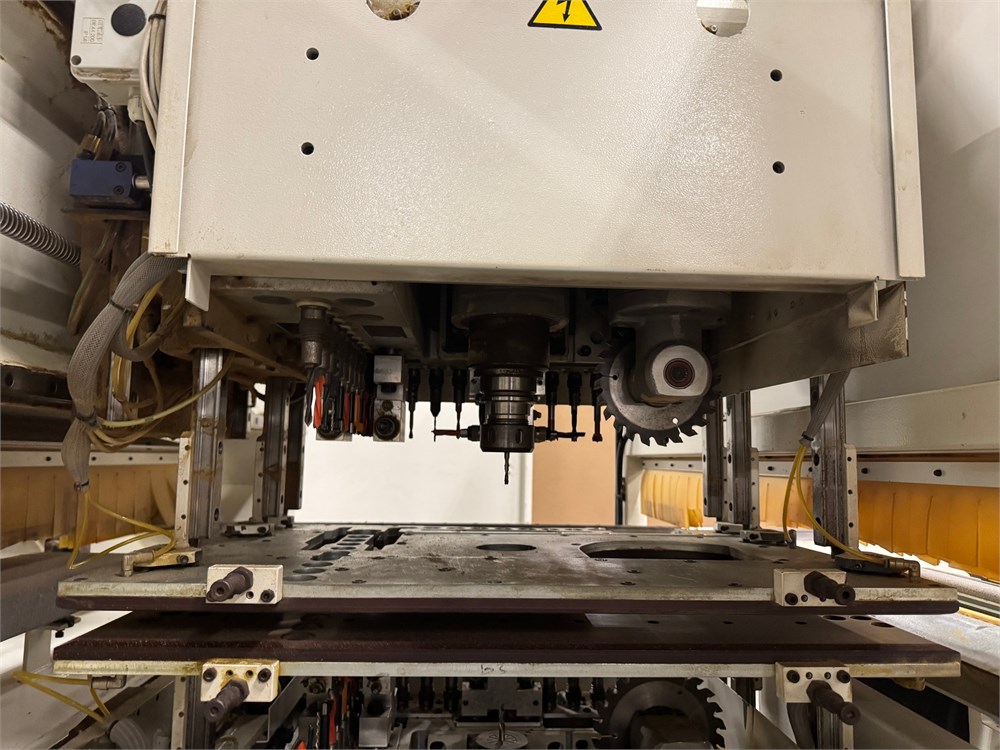

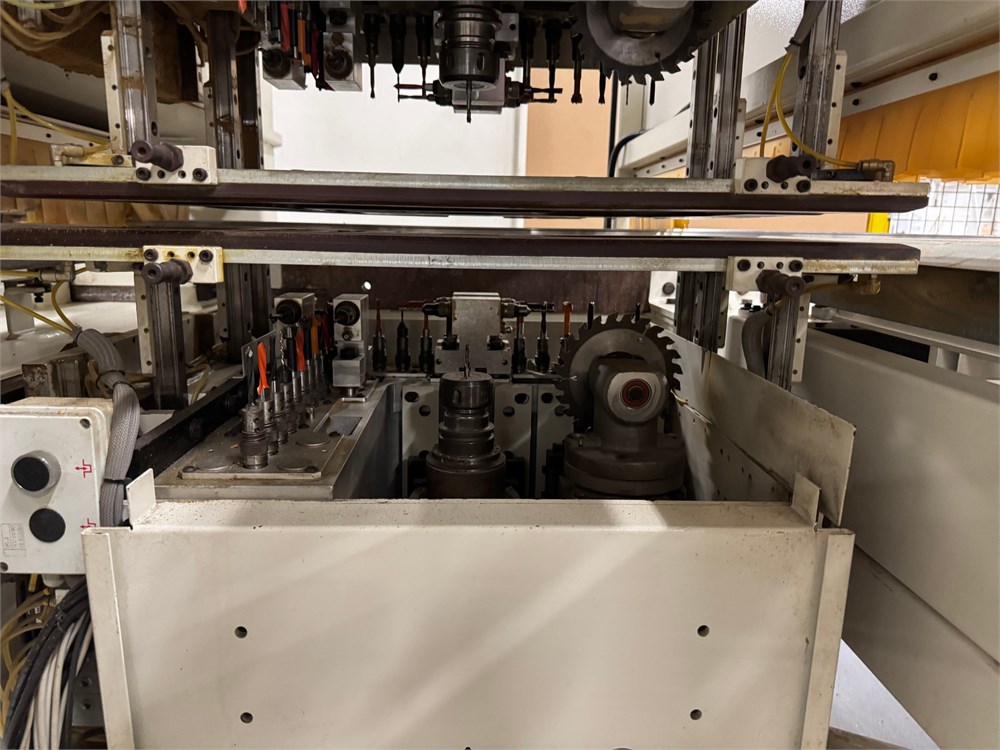

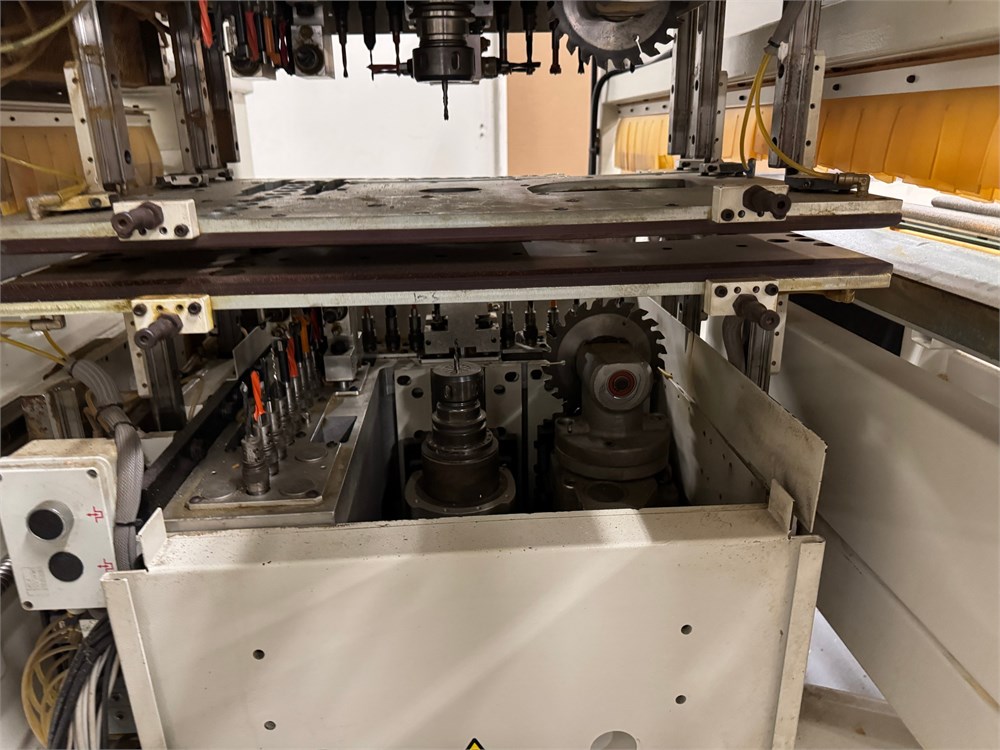

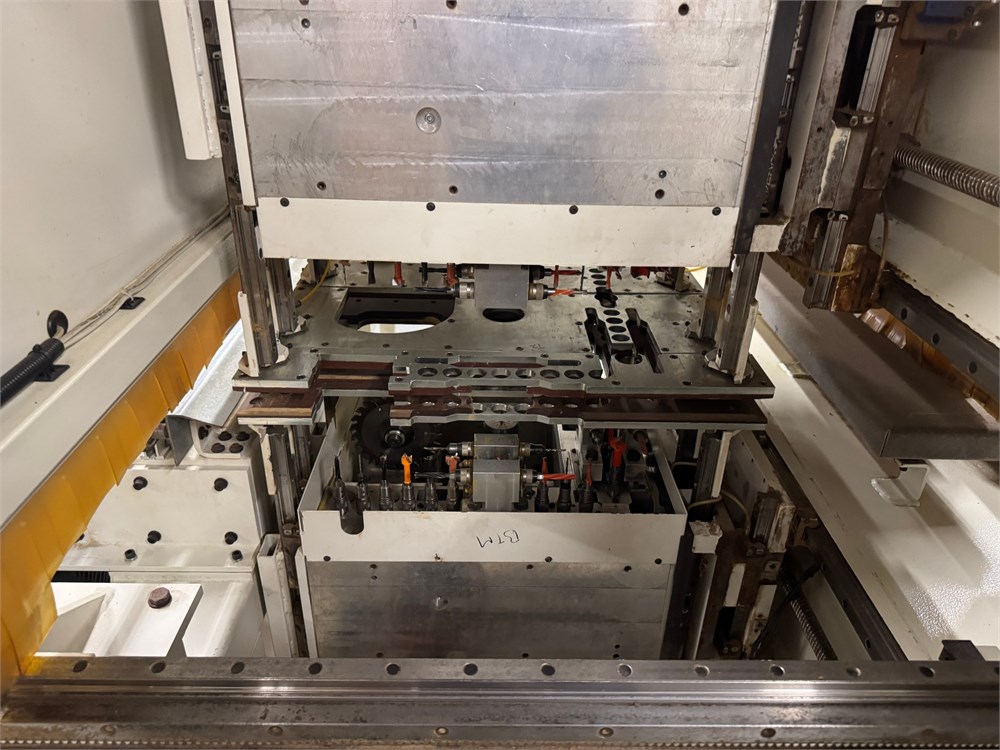

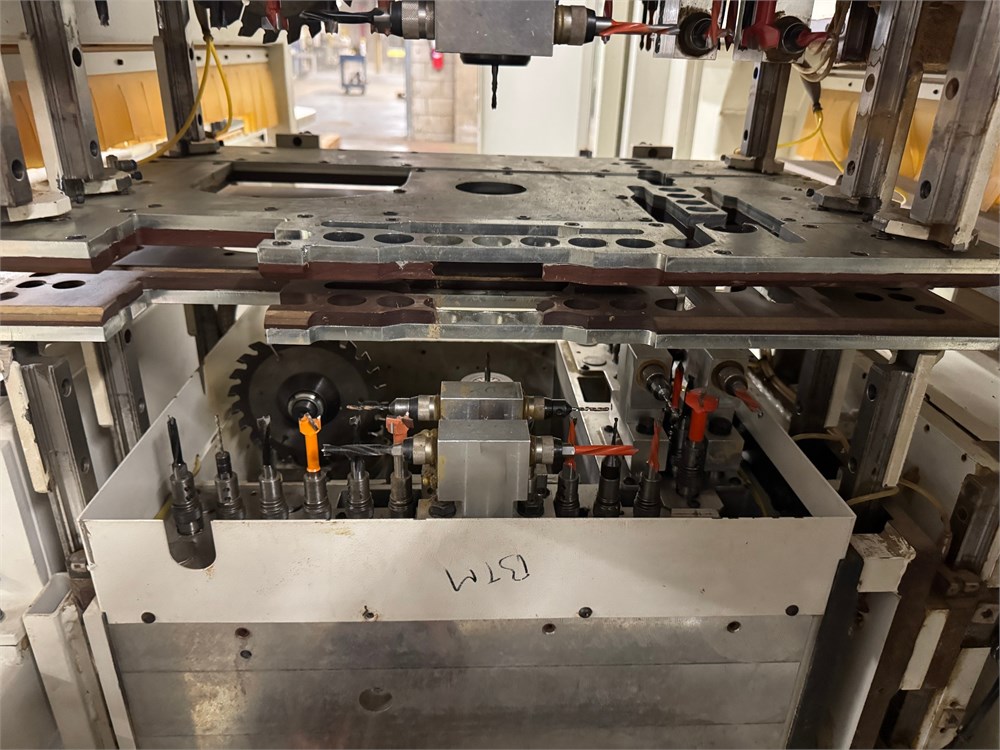

(1) Top mounted boring block, 4.2 HP (3 kW), variable speed from 1,500 - 7,500 RPM; (21) vertical spindles 12-spindles in "X axis & 9-spindles in "Y" axis; (6) horizontal spindles with (2+2) in "X" axis & (1+1) in "Y" axis; (1) 120 mm dia "X" axis grooving saw, 4.2 HP (3 kW), 9,000 RPM. (1) Bottom mounted boring block, 4.2 HP (3 kW), variable speed from 1,500 - 7,500 RPM; (21) vertical spindles 12-spindles in "X axis & 9-spindles in "Y" axis; (6) horizontal spindles with (2+2) in "X" axis & (1+1) in "Y" axis; (1) 120 mm dia "X" axis grooving saw, 4.2 HP (3 kW), 9,000 RPM.

(1) Top mounted 9 HP (6.7 kW) electro spindle with HSK D-50 adaptor, "ERC 32" tool holders & RC-32 collets, 1,500 - 24,000 RPM. (1) Bottom mounted 9 HP (6.7 kW) electro spindle HSK D-50 adaptors, "ERC 32" tool holders & RC-32 collets, 1,500 - 24,000 RPM.

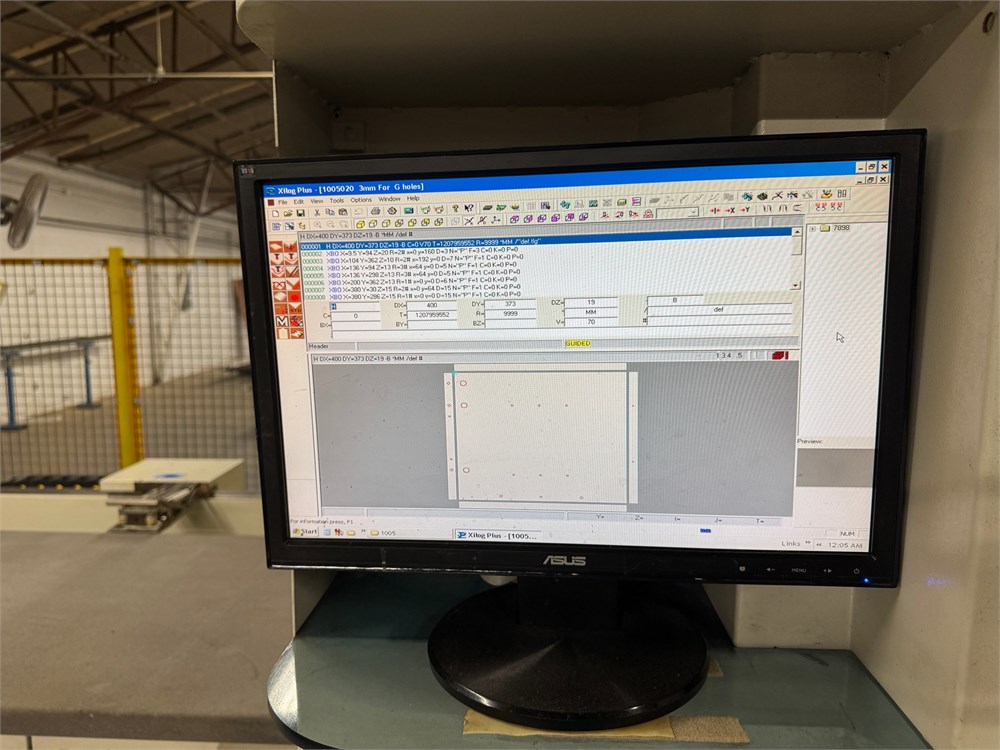

PC Front-end with: "XYLOG PLUS" + Windows operating system mounted in a separate control console.

Pneumatic part clamping devices; sound enclosure; safety mats.

The machine can work the panel from above & below at the same time and can produce (2) identical or mirrored panels per cycle with no difficulty.

The "UNIX KTB" can also machine porous materials since the pieces are held with grippers directly managed by the numerical control; it can even process small pieces and carry out "through" machining.

(4) Operating modes: at each cycle it can change automatically from: top machining to bottom machining, to top & bottom machining together, either on (1 or 2) stacked panels.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available