(2023) Morbidelli "X400C 510A" 5 Axis CNC Router with Load/Unload  Ended

Ended

(2023) Morbidelli "X400C 510A" 5 Axis CNC Router with Load/Unload - Tracy, CA

- 1 Unsold

-

Make

Morbidelli

-

Model

X400C 510A

-

Serial Number

AA10005761

-

Year

2023

-

Phase

3 PHASE

-

Voltage

208-230/460

-

Estimated Dimensions

See photos and description

-

Estimated Weight

See photos and description

-

Seller Comment

Seller will disconnect and load onto buyer's flatbed truck/trailer for non-negotiable $2,000 loading fee. Palletizing, crating or other services may be available at an additional cost.

-

Load Fee

2000

-

Lot Notes

-

page views

22377

(2023) Morbidelli "X400C 510A" 5 Axis CNC Router with Load/Unload

See video of machine in operation

See generic quote for this machine attached as PDF

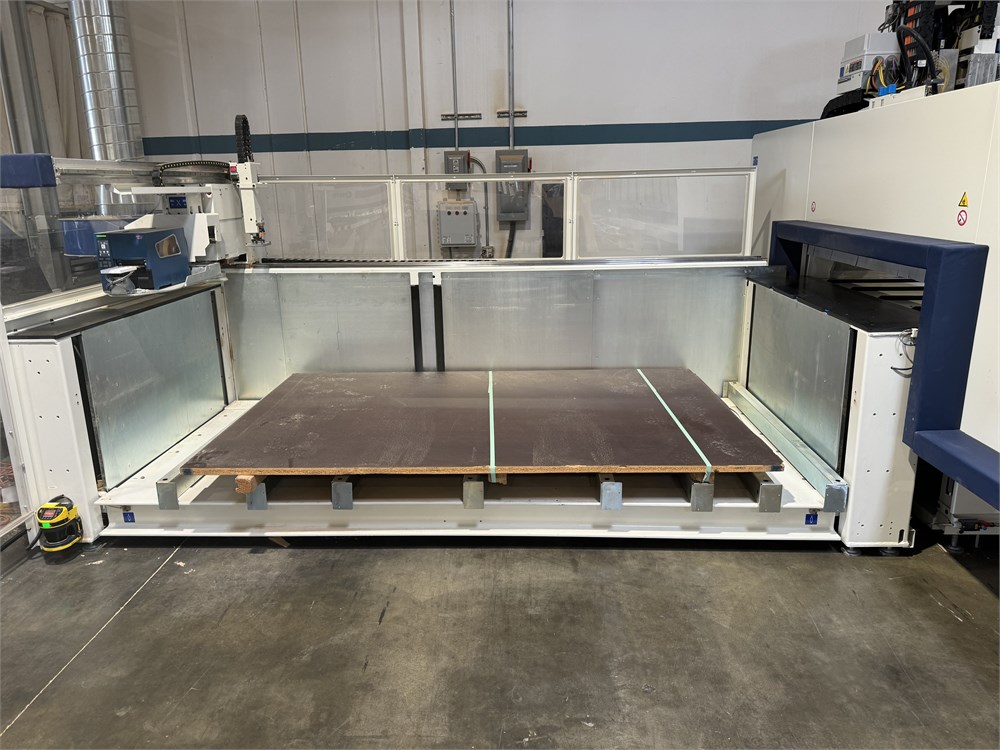

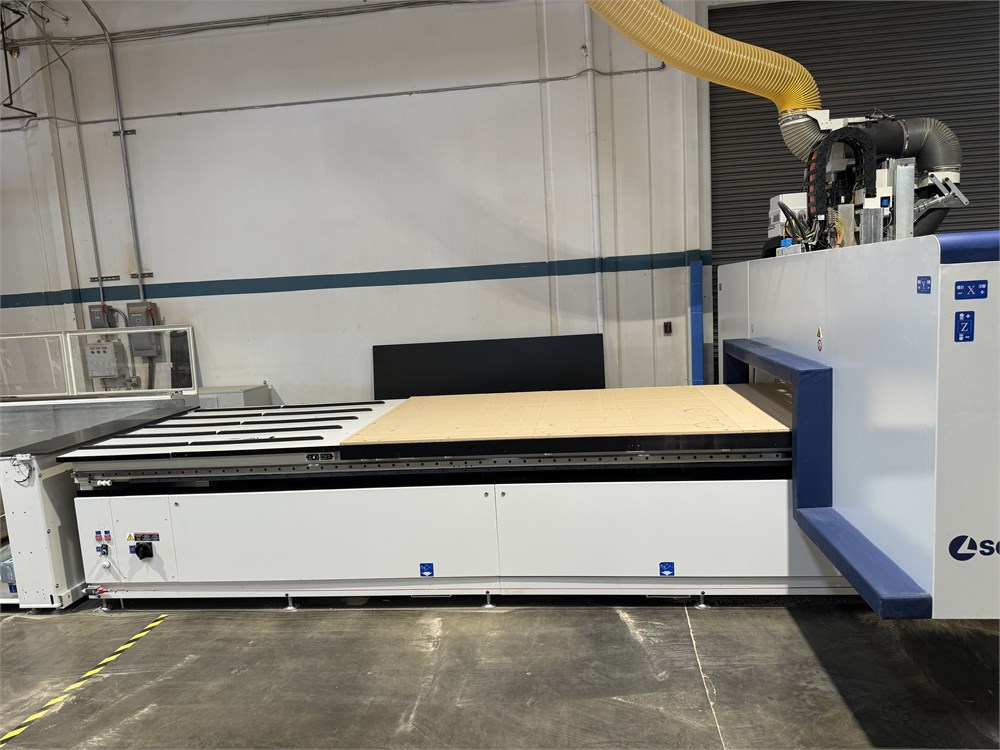

Automated CNC cell with panel loading, machining and unloading. System feeds from left to right. Gantry design with rack and pinion drive for x and y axes.

150 mm (5.9") z axis clearance

Infeed loading system

500 mm (19.7") x 1,600 mm (63") minimum panel size

3 mm (0.12") minimum panel thickness

30 mm (1.2") maximum panel thickness with slightly raised panel loading

60 mm (2.4") maximum panel thickness with dragged panel loading

330 pound maximum panel weight (with loading table)

440 pound maximum panel weight (without loading table)

700 mm (27.6") maximum panel stack height

Panel loading pods

Loading table

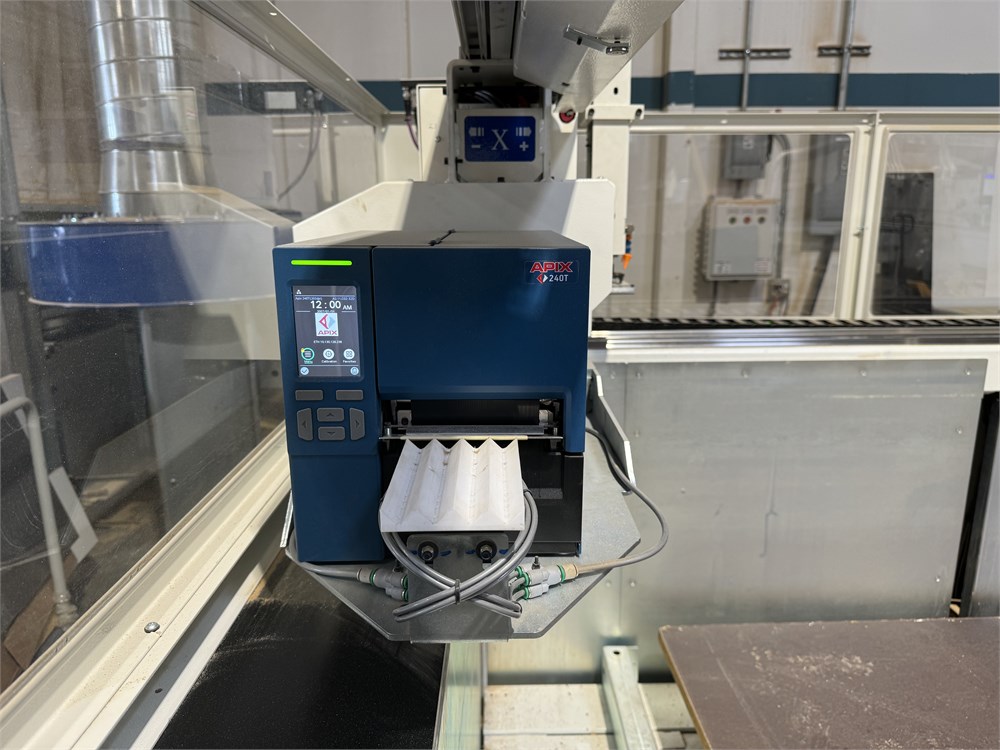

Automatic label printing system

Aluminum router table

Gridded on 20 mm (0.78") spacing for custom gasketing, fixturing and vacuum pods

Vacuum ports of 120 mm (4.72") pitch

Sixteen (16) selectable vacuum zones

Pneumatic reference stops

5 axis electrospindle router

13.6 HP with S1 rating at 12,000 + RPM

18.4 HP with S6 rating at 12,000 + RPM

HSK, quick-change

Variable speed, 1800 - 24000 RPM

B axis rotation, +/- 185 degrees

B axis speed rotation, 7,000 degrees/minute

C axis rotation, +/- 320 degrees

C axis speed rotation, 7,000 degrees/minute

Programmable left and right

Internal air blast system to insure proper fitting with tool holder

Liquid-cooled with external heat exchanger

Ceramic bearings

Variable feed speed based on spindle load

Dust extraction hood for 5 axis electrospindle

Fourteen (14) position tool changer

125 mm (4.9") position spacing

160 mm (6.3") maximum tool diameter

17.6 pound maximum weight per tool

92.4 pound maximum weight for entire changer

Extra tool loading station

Tool length measuring device

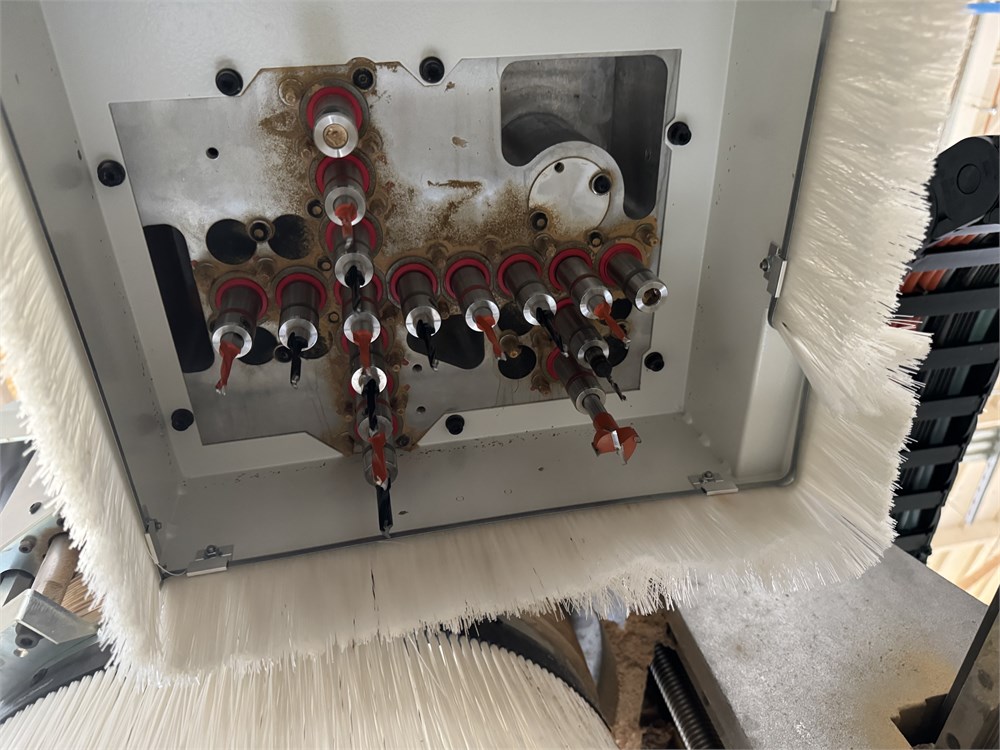

Drill unit

Sixteen (16) vertical spindles

5.3 HP motor

Variable RPM to up 8,000 RPM

Dust extraction hood for drill unit

Centralized dust collection manifold

Sound enclosure

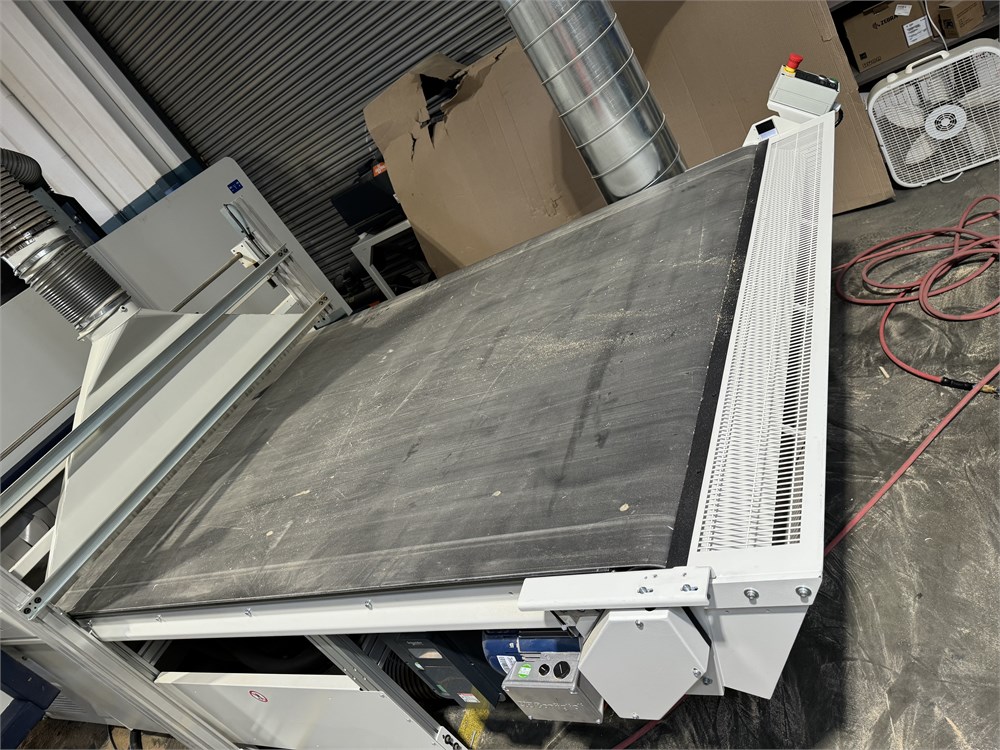

Off loading device (rake)

Integrated dust collection

Outfeed side rails

Bottom-mounted dust plenum

Top-mounted dust collection device

Outfeed conveyor belt

63" x 126"

Bottom-mounted dust plenum on outfeed end

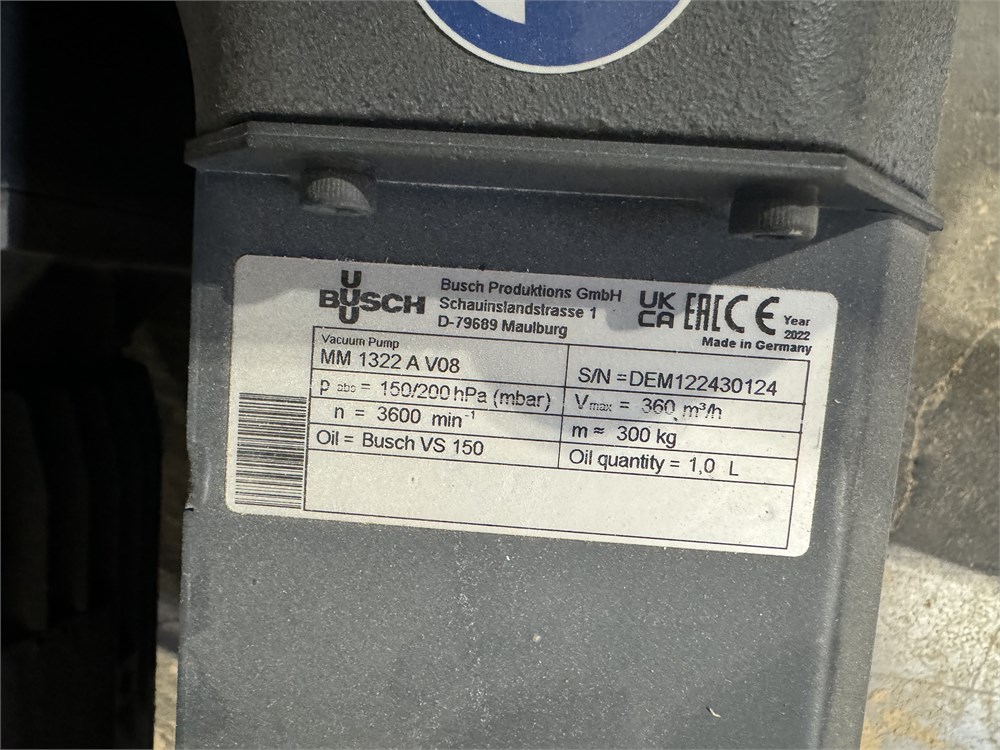

Three (3) Busch "Mink MM 1322 AV" vacuum pumps

360 m/hr. capacity (each)

Inverter

Air conditioned electrical cabinet

Centralized lubrication system

PC control stand

|

The Eye-M PRO is an interface console device connected to the CNC machine which allows the usage of the supplied SCM software. The integrated LED light bar allows the operator to check the state of the machine (emergency, operative, etc.) in real time without the need to be standing directly at the console itself.

It is equipped with an iPC with "fan-less" construction and IP53 grade external protection (IP65 on the front side). This robust solution grants the highest durability even in the worst environmental conditions.

The 21.5" LCD color display, with a 16/9 sized touch screen, allows for an unbeatable easiness and efficiency in controlling the main functions of the machine. Features include:

Maestro-Active interface software Maestro-CNC programming software |

Remote control pendant

External electrical transformer

Marketplace items are sold ‘as-is’ and ‘where-is’ without refunds or guarantees. Payment is due 48 hours after offer acceptance; buyer arranges freight within 7 days after offer acceptance.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view purchase history

LoginPlease log in to post a question

Login

There are no questions for this listing.