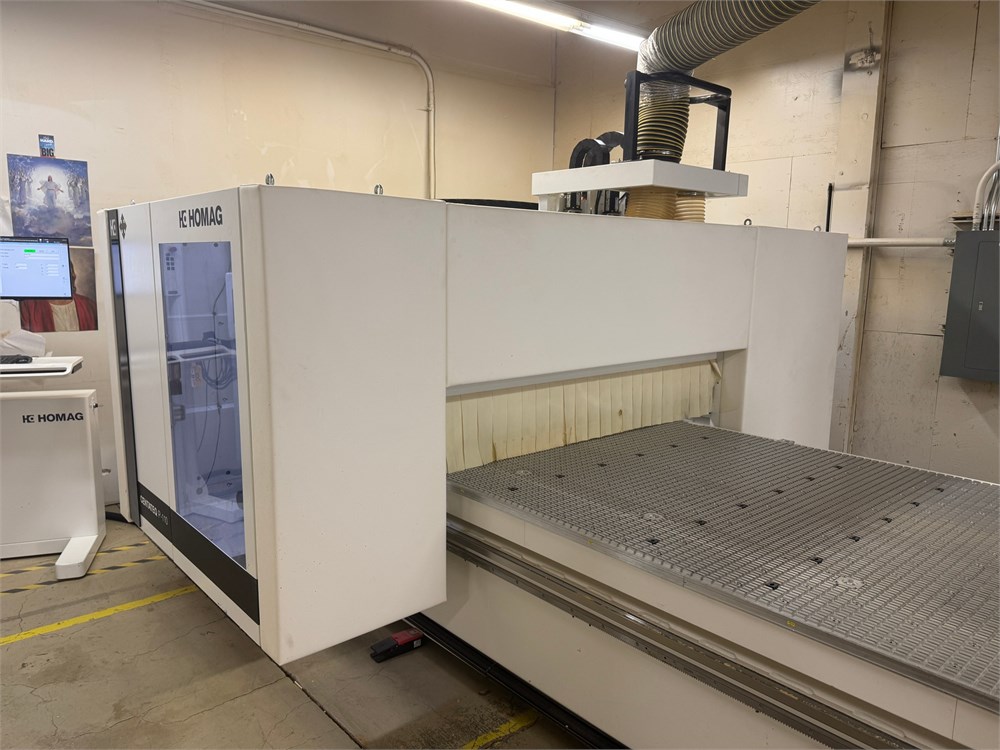

Homag "Centateq P-110" CNC Machining Center - C-Axis (2019)  Ended

Ended

Deseret Industries Complete Plant Auction (Day 1) - Salt Lake, UT

Salt Lake, UT

- Winning Bid : $30,250.00 USD Sold

- 103 Bid(s)

- High Bidder: C****Z

Deseret Industries Complete Plant Auction (Day 1) - Salt Lake, UT ( Closed #77413380 )

Deseret Industries has closed their plant and auctioning all assets. Day 1 of this auction includes Homag, SCM and other high-end machinery.

-

Pick Up Location

1665 S. Bennett Rd. Salt Lake, UT 84104

-

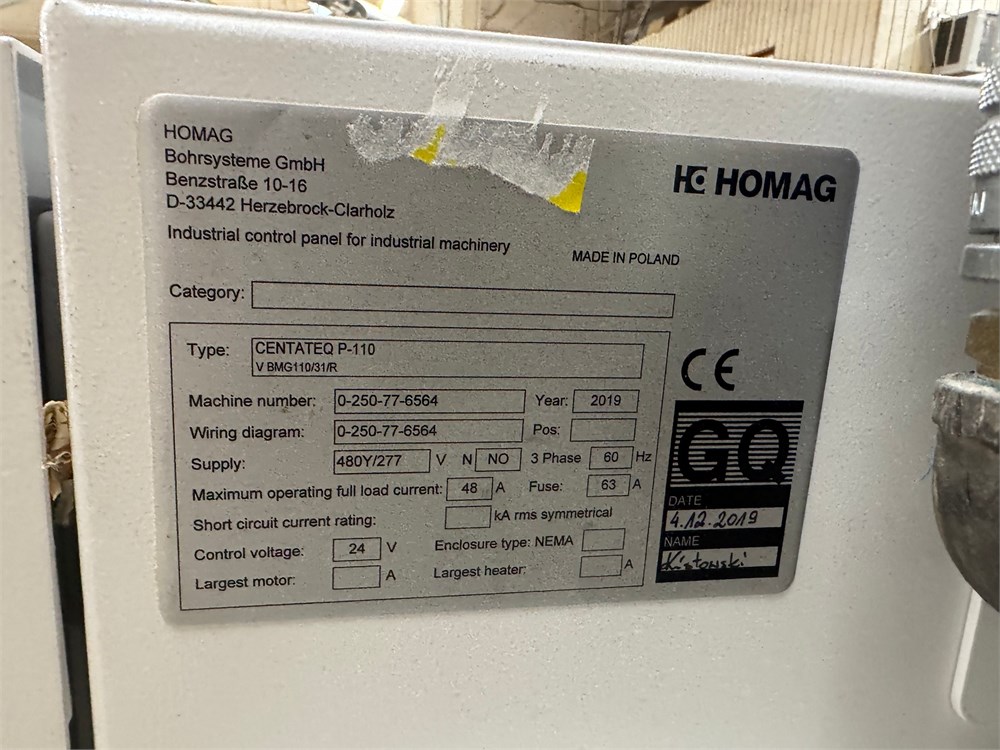

Make

Homag

-

Model

"Centateq P-110"

-

Serial Number

0-250-77-6564

-

Year

2019

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Buyer Inspection Period

January 27, 2026 (9 AM - 3 PM)

-

Load Out Period

February 2 - February 6, 2026 (by appointment). Lots requiring rigging have until February 27, 2026 for removal.

-

Estimated Dimensions

20'L x 144/102"W x 8'H

-

Estimated Weight

7,500 Lbs

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal. By appointment ONLY!

-

Load Fee

-

Lot Notes

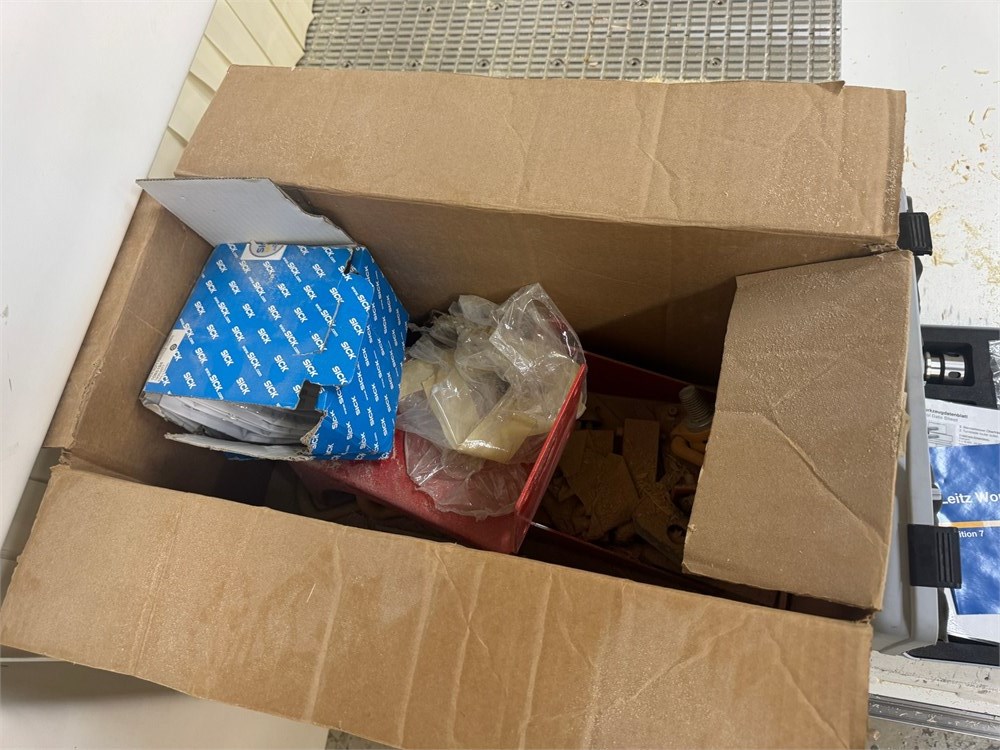

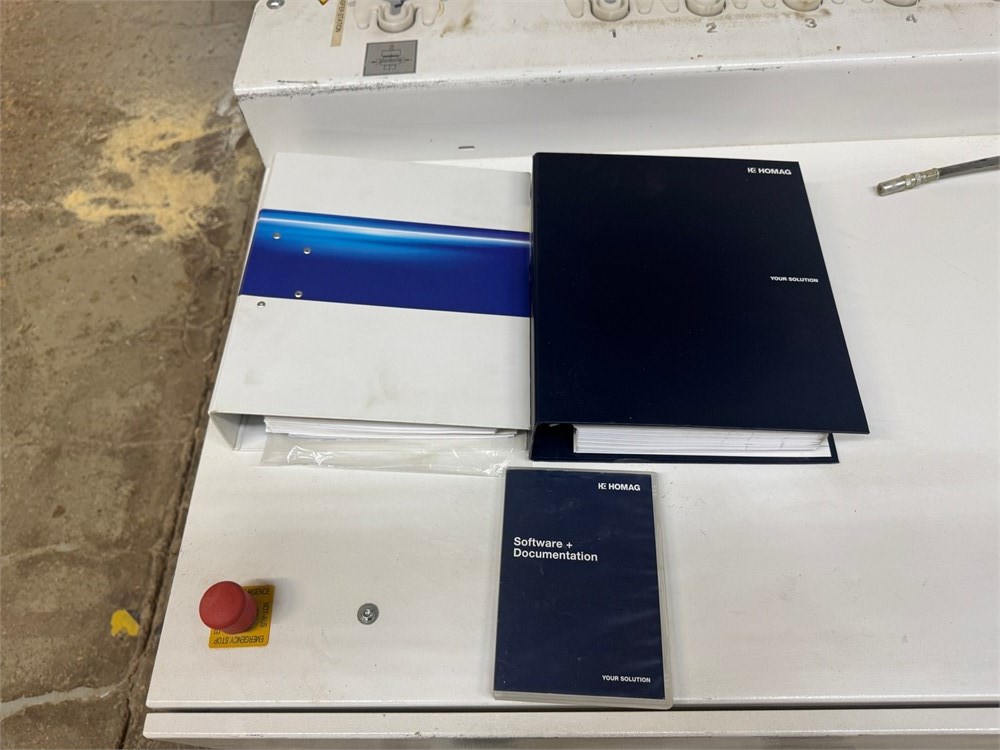

See Video - Manuals/Literature as picturerd included

-

page views

1938

Homag "Centateq P-110" CNC Machining Center - C-Axis (2019)

See Videos

Small to medium-sized carpenters and joiners benefit from the versatility and performance of this P 210 series. The machine concept is based on compact technology and a reduced footprint. Solutions for processing kitchen, office and solid wood furniture as well as for staircase, window and door construction pose no challenge for this machine.

Always in the right position: Effective extraction with low connected load thanks to optimized chip collection and removal. The hood can be adjusted in stages or optionally by motor and automatically adapts to the workpiece thickness.

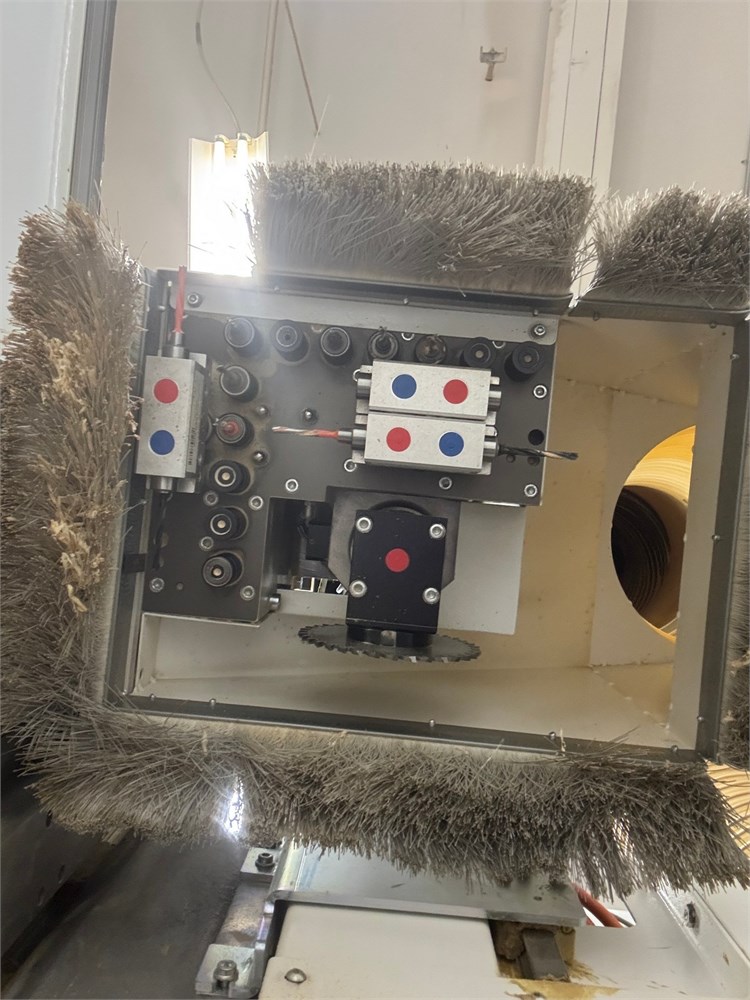

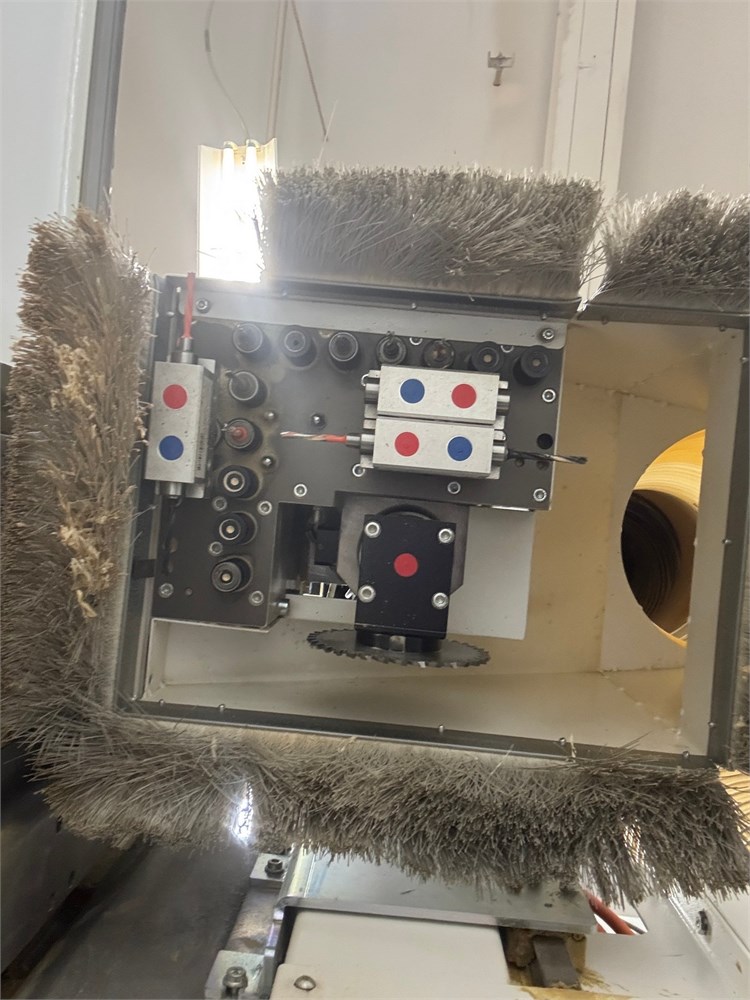

HOMAG routing technology: High-speed routing technology, clamping of the spindle and quick-change system for tools. Precise routing, fast cycles, maintenance-free and durable design. Additional optional attachment units extend the machine's range of applications.

Spindle sensor: Spindles with hybrid bearings offer a long service life.

Pneumatic interface: Patented interface with 3-fold support on all C-axes and optionally on the DRIVE5CS enables the use of traced units, e.g. for precise rounding at the top and bottom, regardless of thickness tolerances.

Speeds

- X axis, 35 MPM

- Y axis, 50 MPM

- X/Y vector, 60 MPM

- Z axis, 19 MPM

60" x 127" Aluminum Grid table

Variety of vacuum cups/pods

4 axis router, 15 HP

Rotary tool changer (8 positions)

Linear tool changer on RH side of machine (10 positions)

(7) Vertical boring spindles X-axis

(5) Vertical boring spindles X-axis

(2) Horizontal boring spindles (1+1) X-axis

(1) Horizontal boring spindles (1+1) Y-axis

Saw Aggregate fixed X-axis

Sound enclosure with safety-interlocked access door

Two (2) vacuum pumps

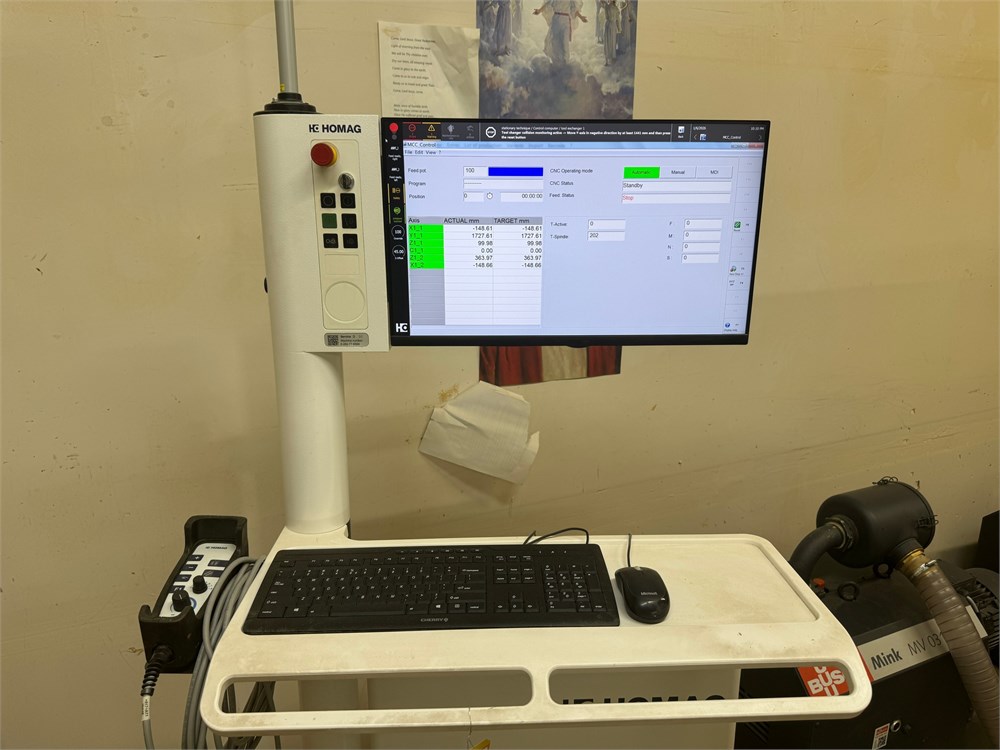

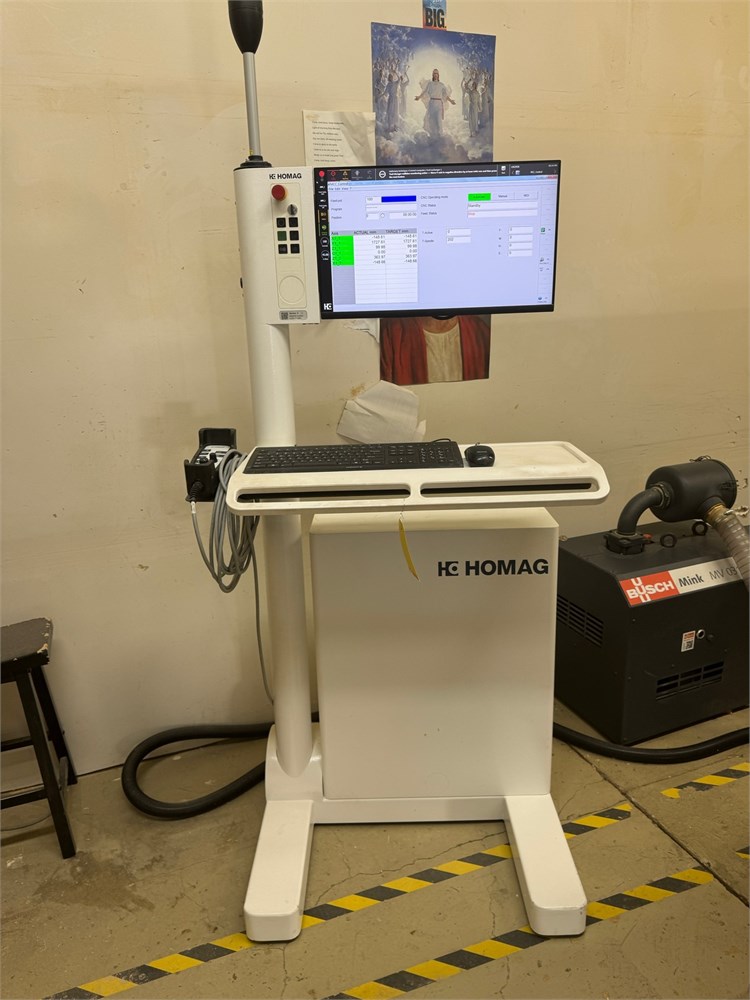

PC control console

- Windows operating system

- Standard keyboard and mouse

Tooling, tool holders in photos are in included

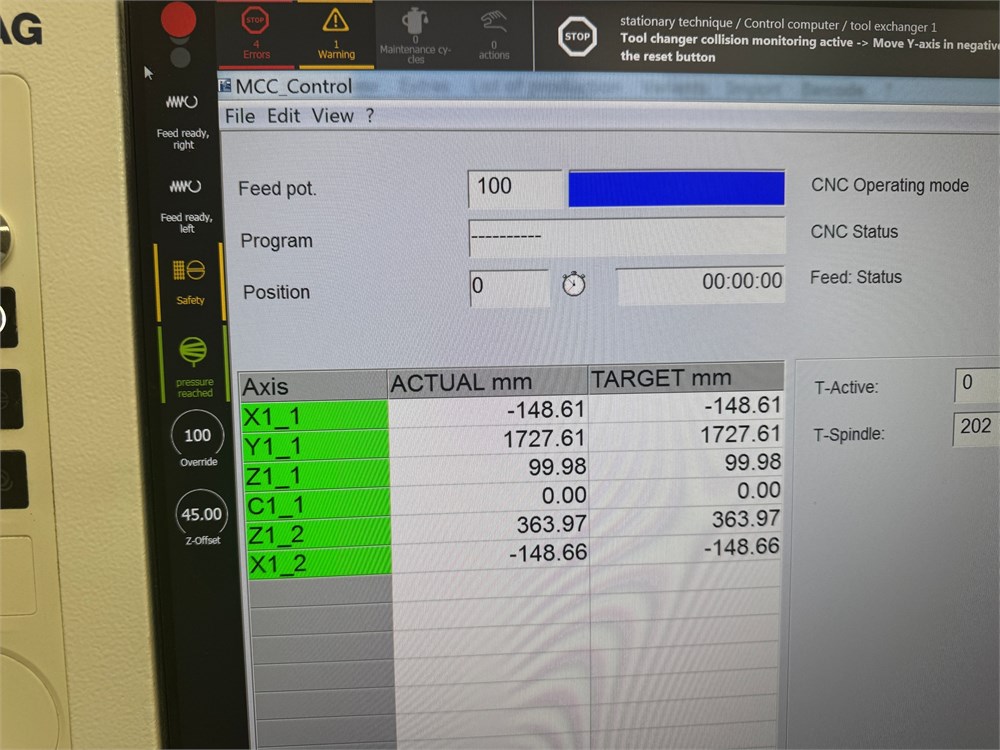

Seller states it needs re-calibrated in the Y-axis and Stiles has indicated a $5K repair. This is NOT due to a crash. Please contact Stiles directly for more information.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available