Makor "Q-ONE" Flat Panel Spray Line & Rack Loader  Ended

Ended

Weber Widebelt Sander and Hyster Forklift - Houston, TX

Houston, TX

- Winning Bid : $900.00 USD Sold

- 25 Bid(s)

- High Bidder: b****s

Weber Widebelt Sander and Hyster Forklift - Houston, TX ( Closed #77465944 )

All remaining items including, 2 Schmalz Vacuum Lifts, Hyster Forklift, Weber Wide Belt Sander, plus much more!

-

Pick Up Location

11530 S. Main St. Houston, TX 77025

-

Make

Makor

-

Model

Q-ONE

-

Serial Number

8748/07

-

Year

2007

-

Phase

3 PHASE

-

Voltage

220 VOLT

-

Buyer Inspection Period

By appointment only, contact Jack Ragan, [email protected], 503-806-4611

-

Load Out Period

January 6 - January 9, 2026 (by appointment)

-

Estimated Dimensions

Makeover Spray Unit - 168"x136"x96"

-

Estimated Weight

15,000 Pounds

-

Seller Comment

This lot requires a rigger, see home page for details.

-

Load Fee

-

Lot Notes

-

page views

534

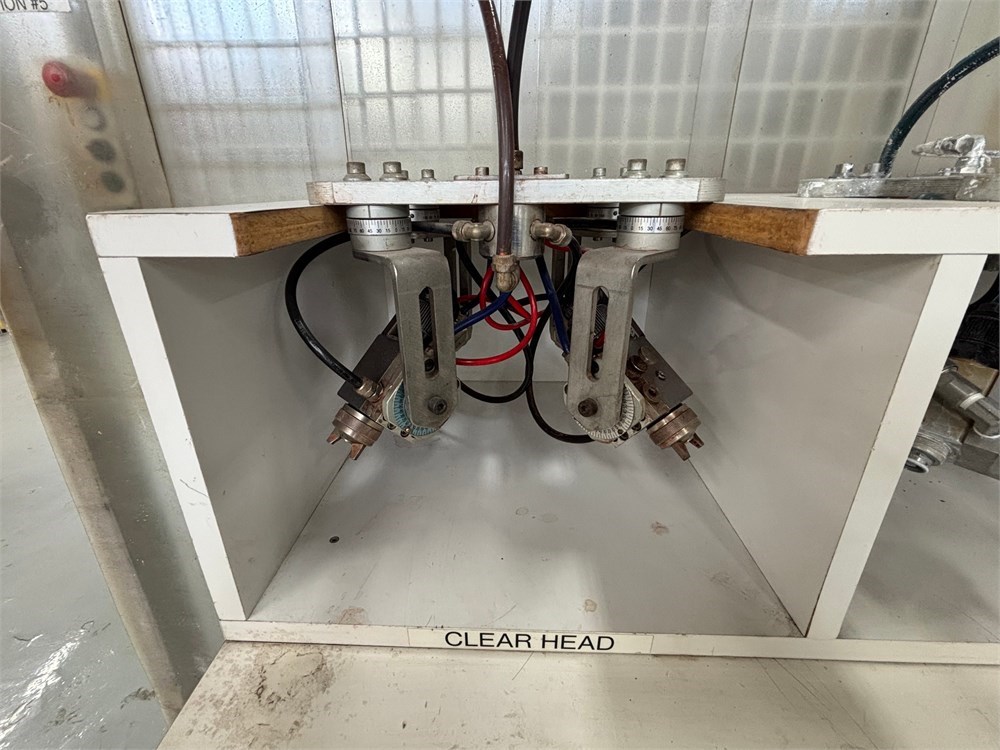

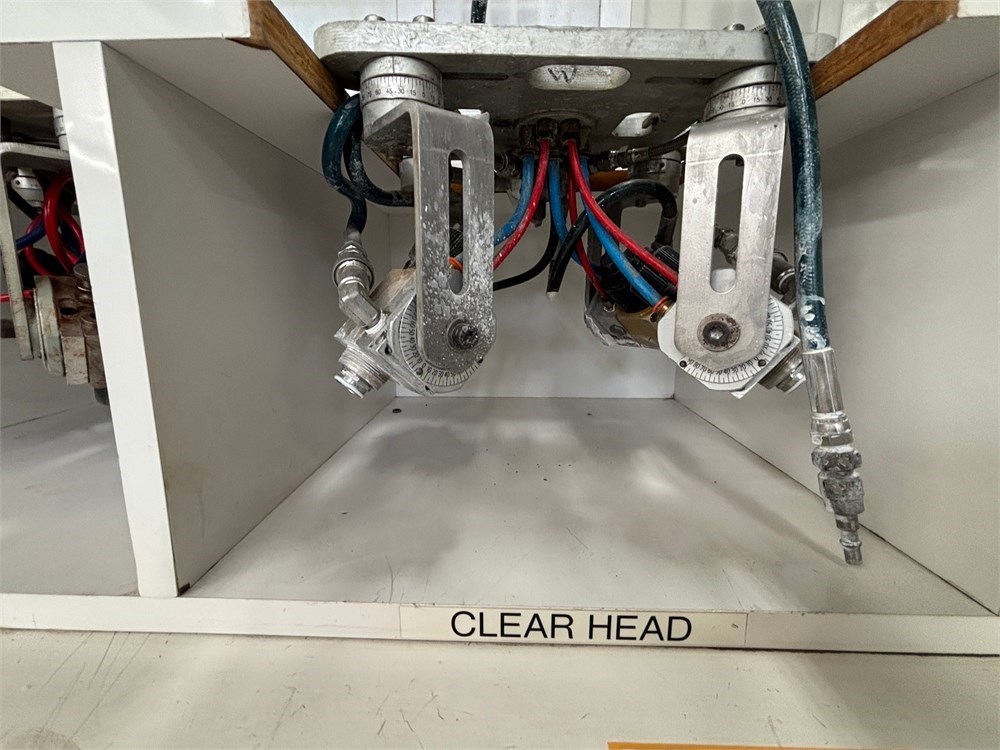

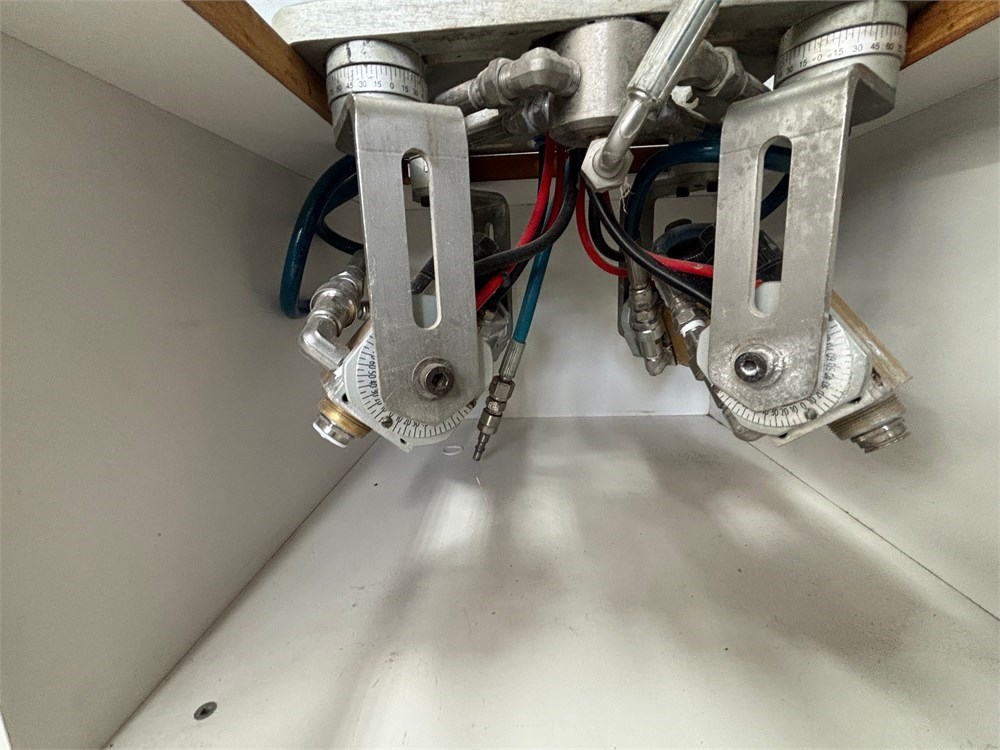

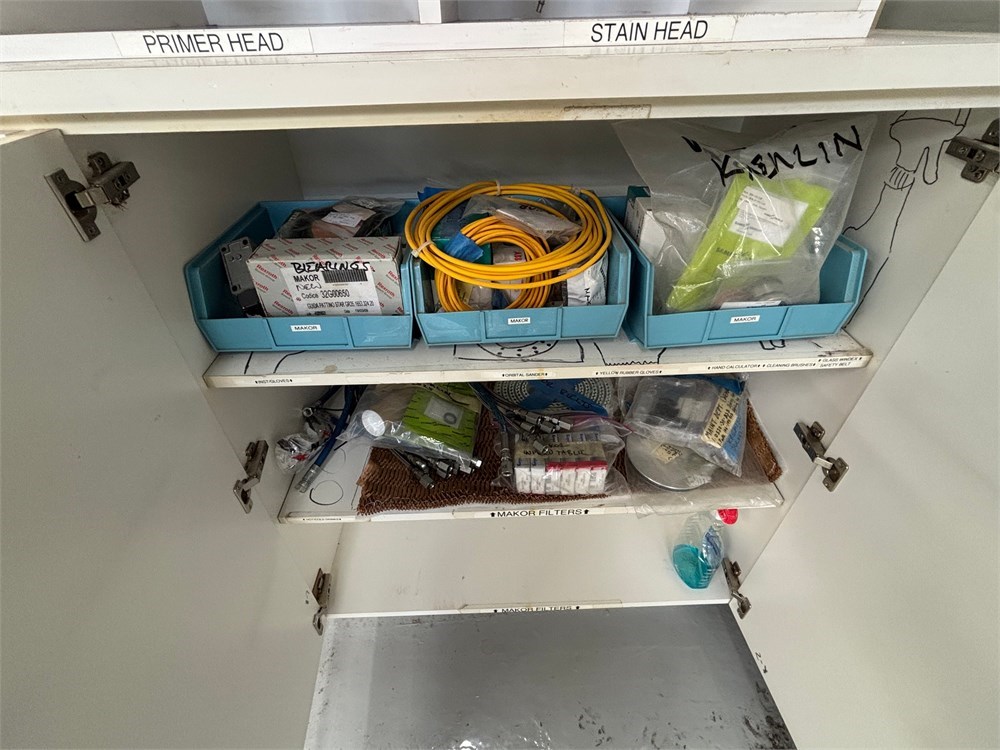

Makor "Q-ONE" Flat Panel Spray Line & Rack Loader

The Q-ONE sprayer is a single arm Reciprocating System with paper belt over spray collection;it combines productivity, flexibility, and quick change-over with a limited investment. This continuous belt conveyor system, combined with disposable paper promotes a "self-cleaning" machine & dramatically reduces clean-up & service time. Suitable for all types of conventional coatings from solvent to water base materials.

Conveyor advances only when parts are present. Conveyor system with a vacuum belt to secure & support the feeding of the disposable paper, ensuring proper tracking & automatic winding of the paper roll. The paper roll change-over time is only a few minutes. The panel lies flat on the belt which prevents the transfer of over-spray onto the bottom side.

Spraying enclosure is pressurized via (2) intake fans and filtered by means of dry filters. This system allows clean air & maintains a consistent air-flow throughout the Spray Cabin, also limiting the machine maintenance time to a minimum and produces an enhanced quality finish, control & containment of over-spray, resulting in significant material economy. Internal air flow is adjustable by means of inverters.

Spray system uses an inverter drive, variable speed reciprocating trolley which provides a consistent spray speed & pattern across the entire conveyor belt. Spray system with (4) spray guns, mounted on a "Quick-Change" gun support trolley.

PLC touch-screen for clear visual operator interface & a large memory storage of working programs, parameters, controls & diagnostic functions. Photo diode light bar reads the location and size of part to be sprayed.

Working Width: 0 - 1,300 mm (0" - 51"), Feed Motor: 0.75 kW, variable speed control from 2.5 - to 5 MPM (8 - 16 FPM), Vacuum Belt Motor: 1.5 kW(2 HP), Paper Rewind Motor: 0.18 kW. Paper Roll: Dia. 21.5" max. (approx. 9,500 lineal ft.)

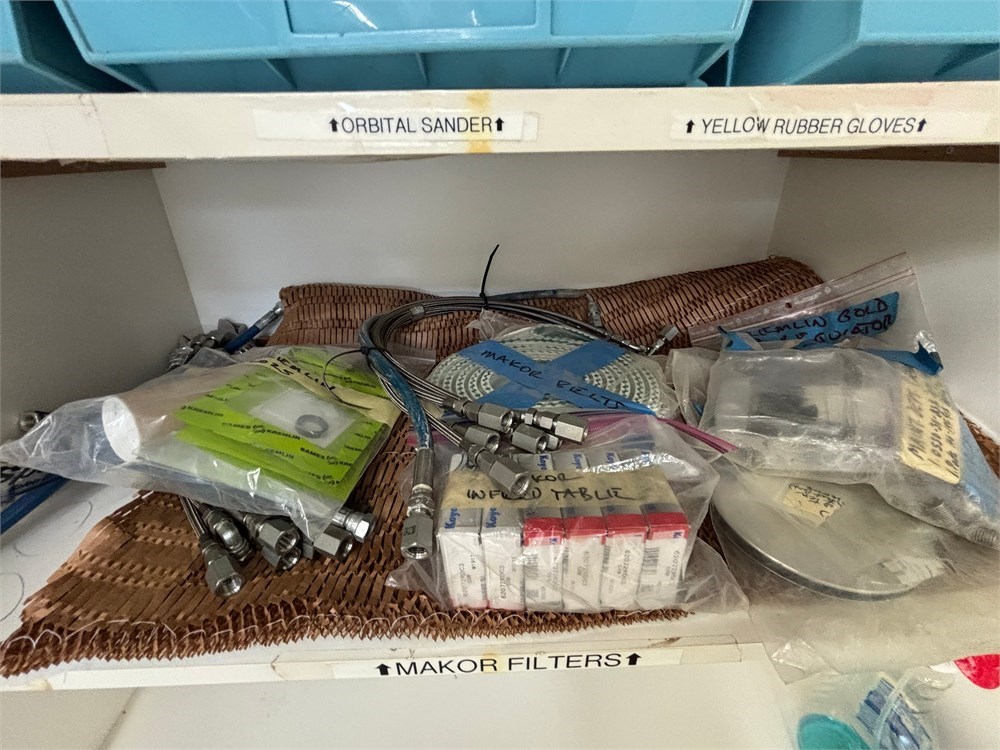

Makor "CP3000" Outfeed Conveyor & auto stacking system - 60" x 180" x 40"H (racks not included in this lot)

Infeed Table - 60" x 85" x 36"H

Makor "Rolly 3000" Infeed Conveyor - 72" x 80" x 38"H

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available