Biesse "Akron 1440A" Edgebander w/ Premill  Ended

Ended

Brochstein's Complete Shop Auction, Day 1- Houston, TX

Houston, TX

- Winning Bid : $32,900.00 USD Sold

- 154 Bid(s)

- High Bidder: J****2

Brochstein's Complete Shop Auction, Day 1- Houston, TX ( Closed #76325787 )

After 90 years in business, Brochstein's has ceased operations and is auctioning all assets in this two day event. Over 750 lots available in both days combined!

-

Pick Up Location

11530 S. Main St. Houston, TX 77025

-

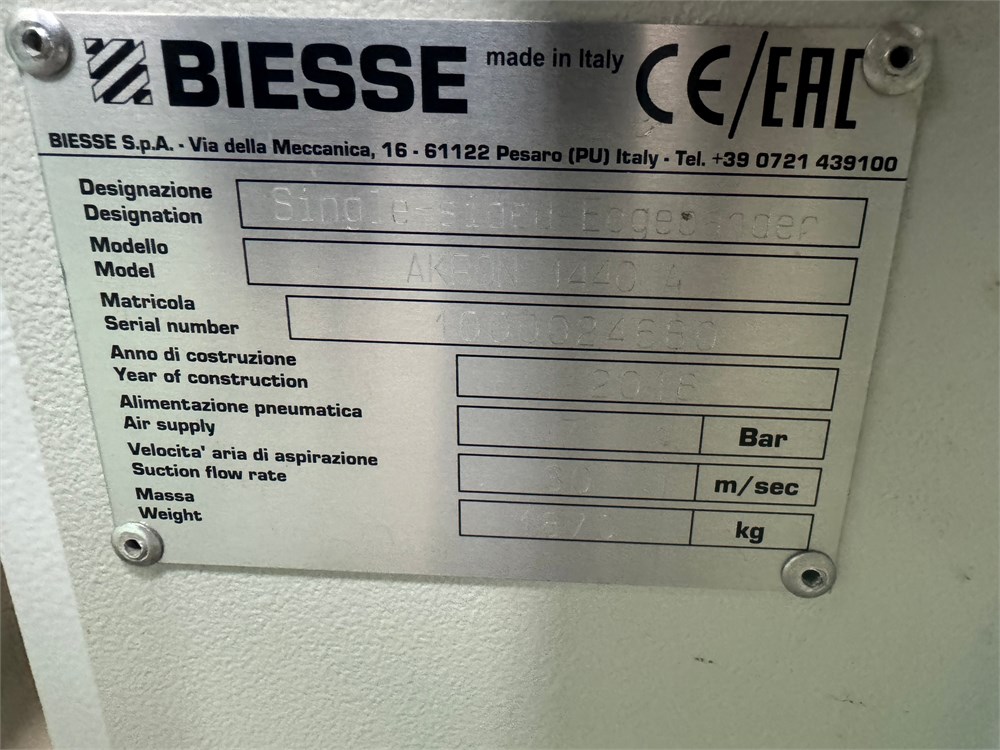

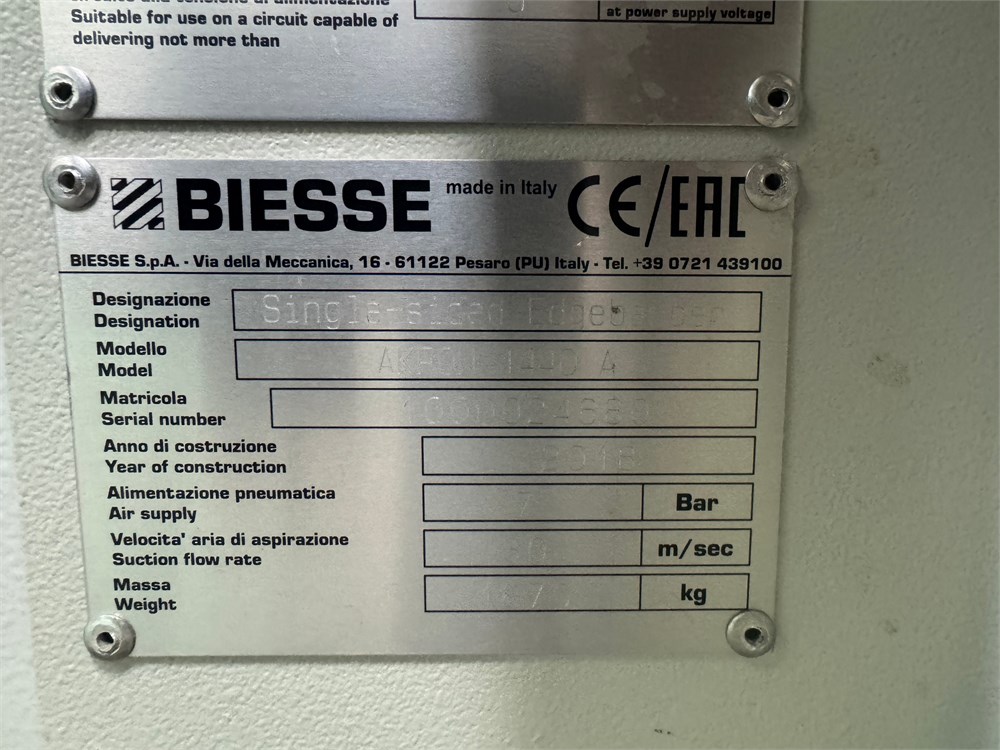

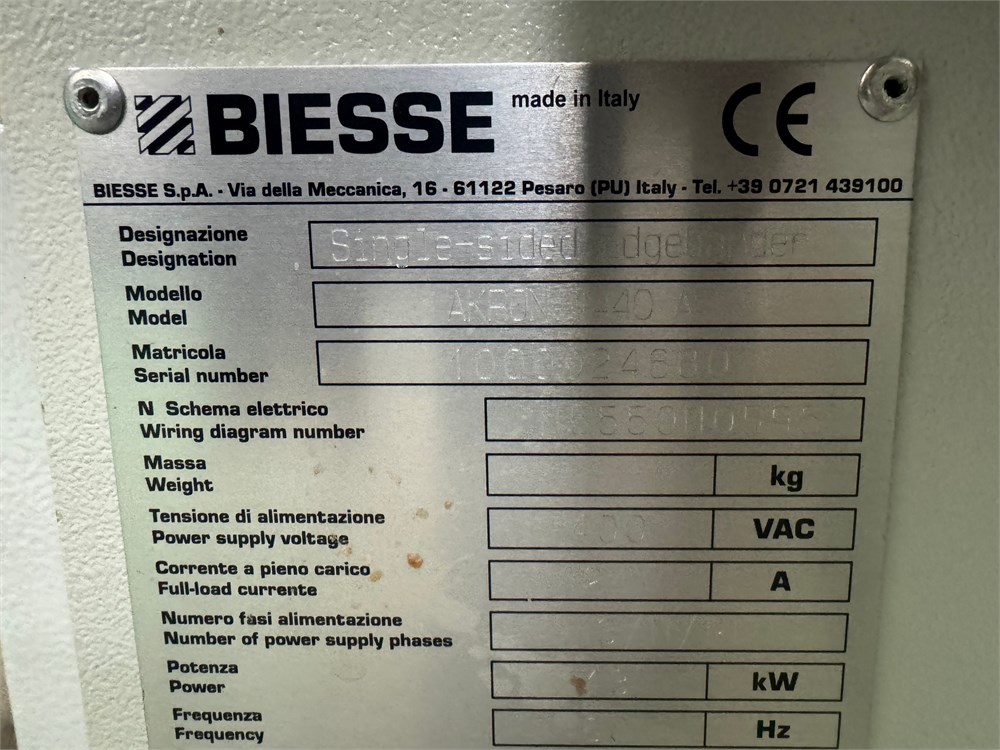

Make

Biesse

-

Model

Akron 1440A

-

Serial Number

1000024680

-

Year

2018

-

Phase

3 PHASE

-

Voltage

208-230/460

-

Buyer Inspection Period

Tuesday December 9th & Wednesday December 10th, 2025 (9 am - 3 pm) Local Time. No appt. Needed!!

-

Load Out Period

December 12 - December 19, 2025 (by appointment only). For large machines requiring a rigger the loadout time is extended to January 9th. Text Joe for appointment (720) 273-1016

-

Estimated Dimensions

18'x4'x6'

-

Estimated Weight

5,000 Lbs

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal. By appointment ONLY!

-

Load Fee

0.00

-

Lot Notes

-

page views

1385

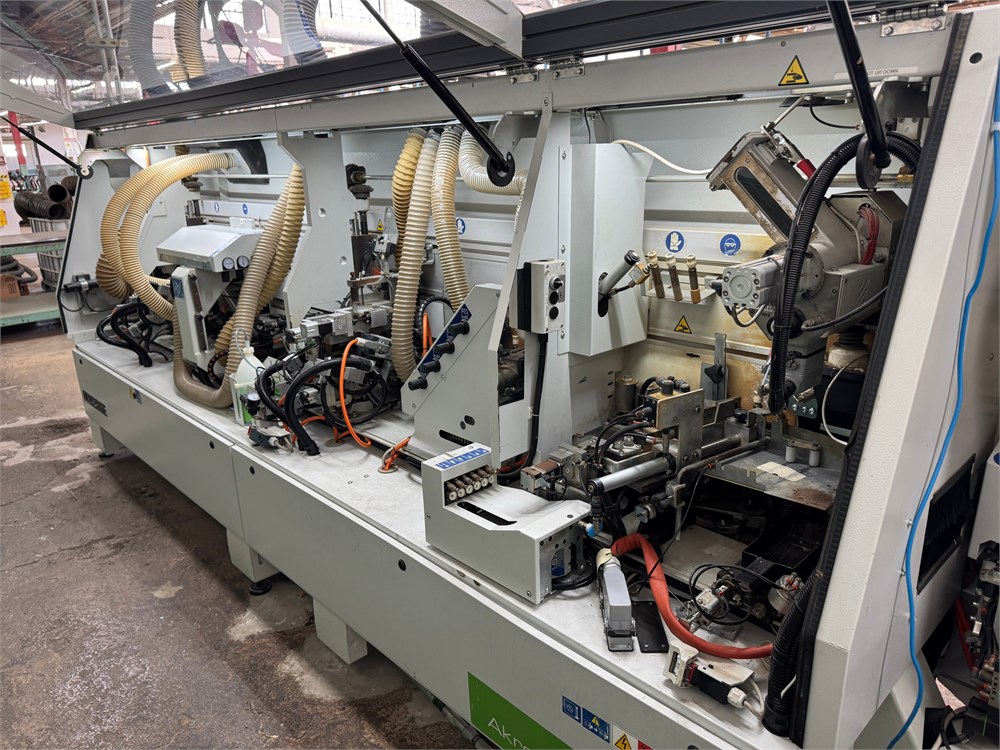

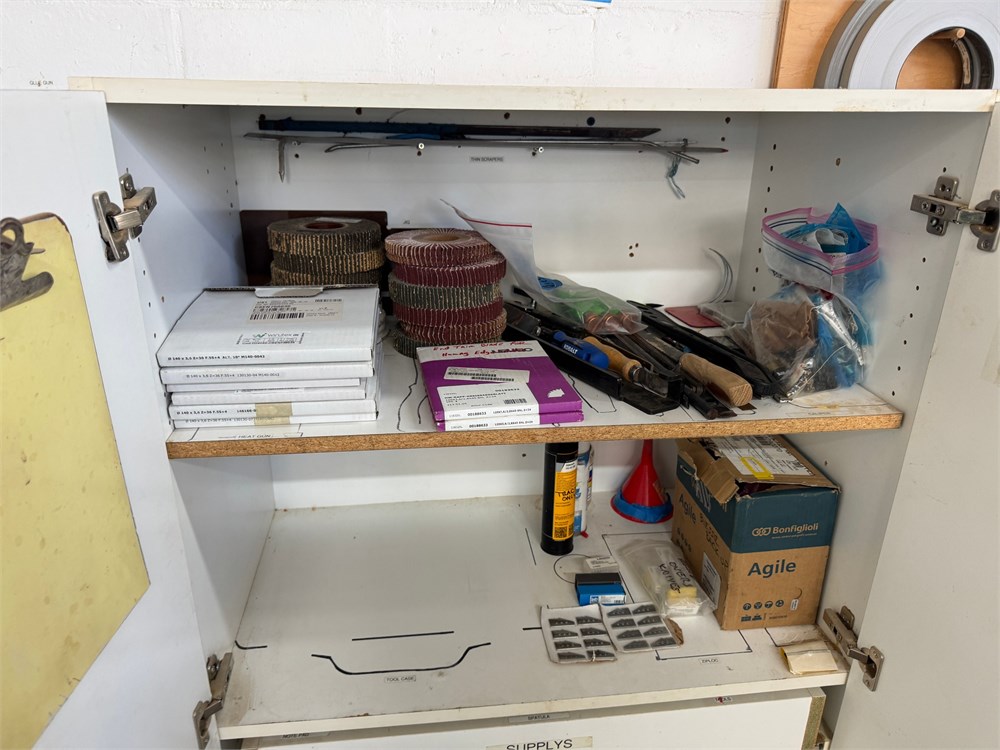

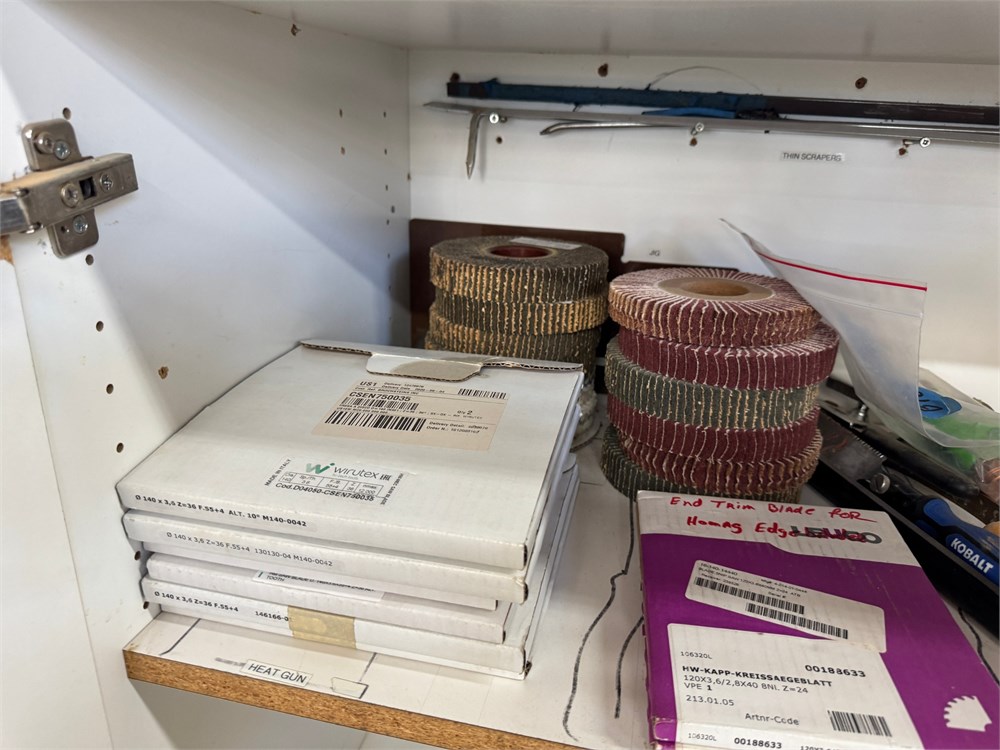

Biesse "Akron 1440A" Edgebander w/ Premill

Min. panel height: 10 mm;Max. panel height: 60 mm;Height of edgebanding material: 14 - 64 mm;Thickness of edgebanding material in rolls: 0.4 - 3 mm; Thickness of edgebanding in strips: 0.4 - 10 mm.

Min. panel protrusion from the track: 25 mm;Panel length: 140 - 3200 mm;Min. panel width (with length 140 mm): 85 mm;Min. panel width (with length 250 mm): 50 mm.

Multi-Feed speed 8-12-15 &18 MPM. (26, 39, 49 & 59 FPM)

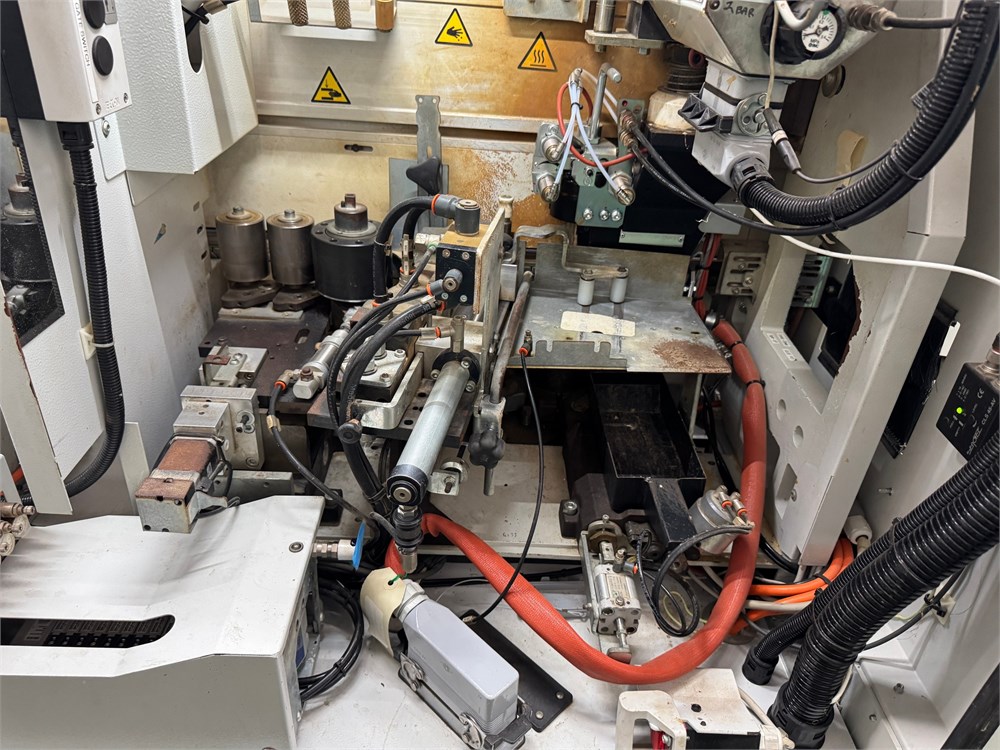

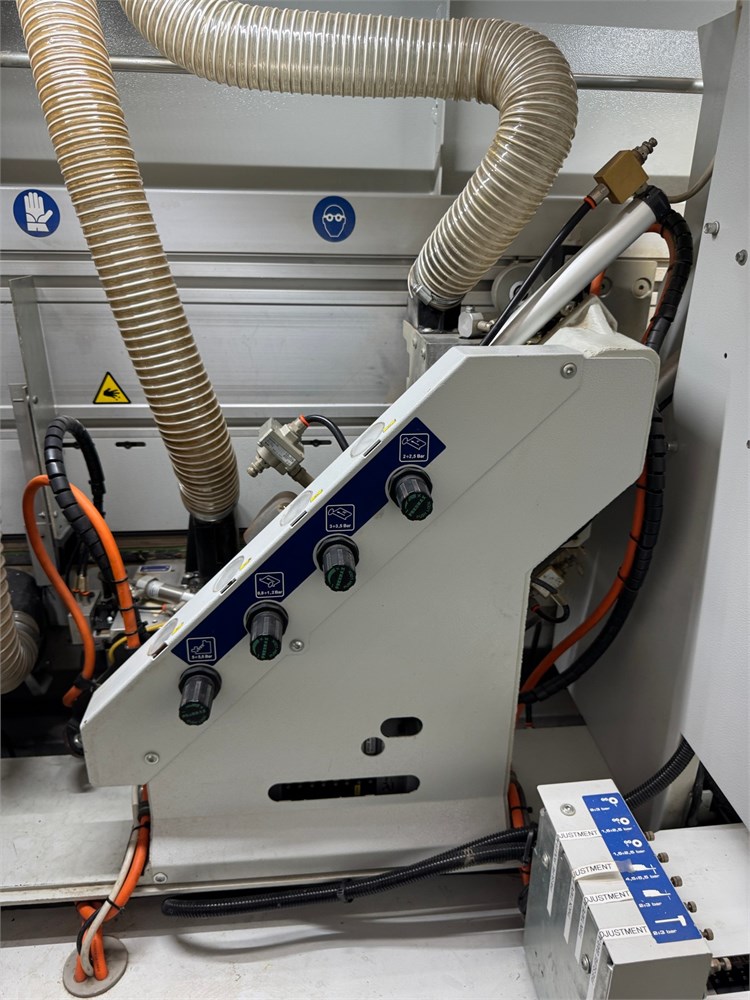

Glue & Pressure Section:

Infrared lamp IRL 700;Gluing unit Quickmelt QM 703 EVA melting glue. Special glue container for PU glue; Additionalglue container for EVA gluing unit with melting device;Automatic edge feed;Cutter knife;Pressure zone with 1-Drive & 2 pressure rollers.

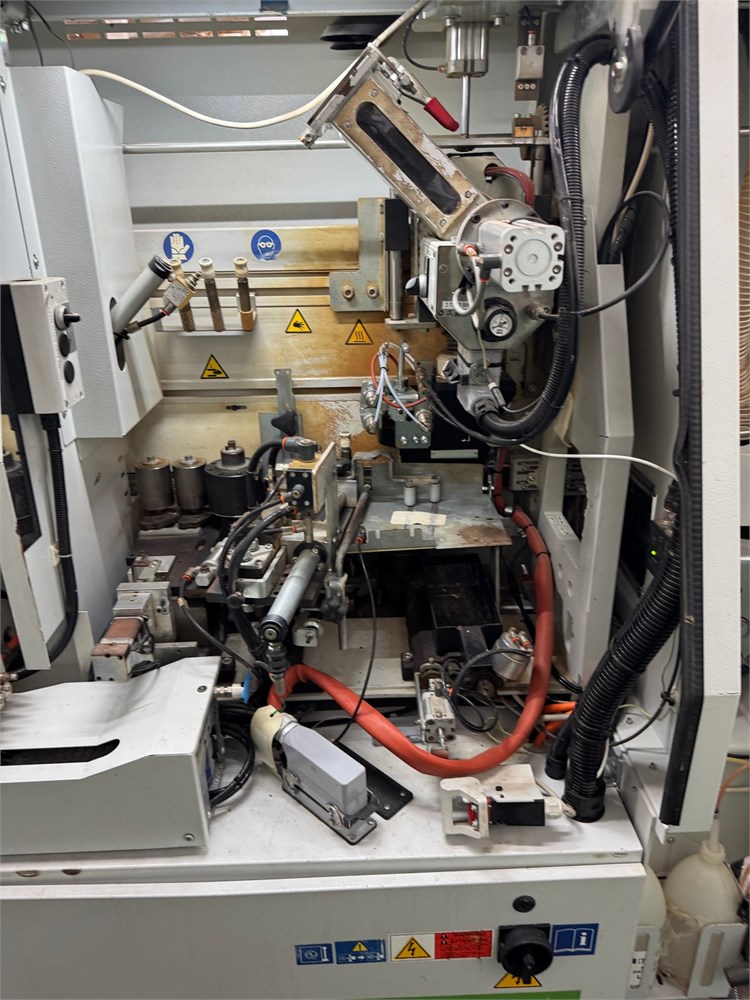

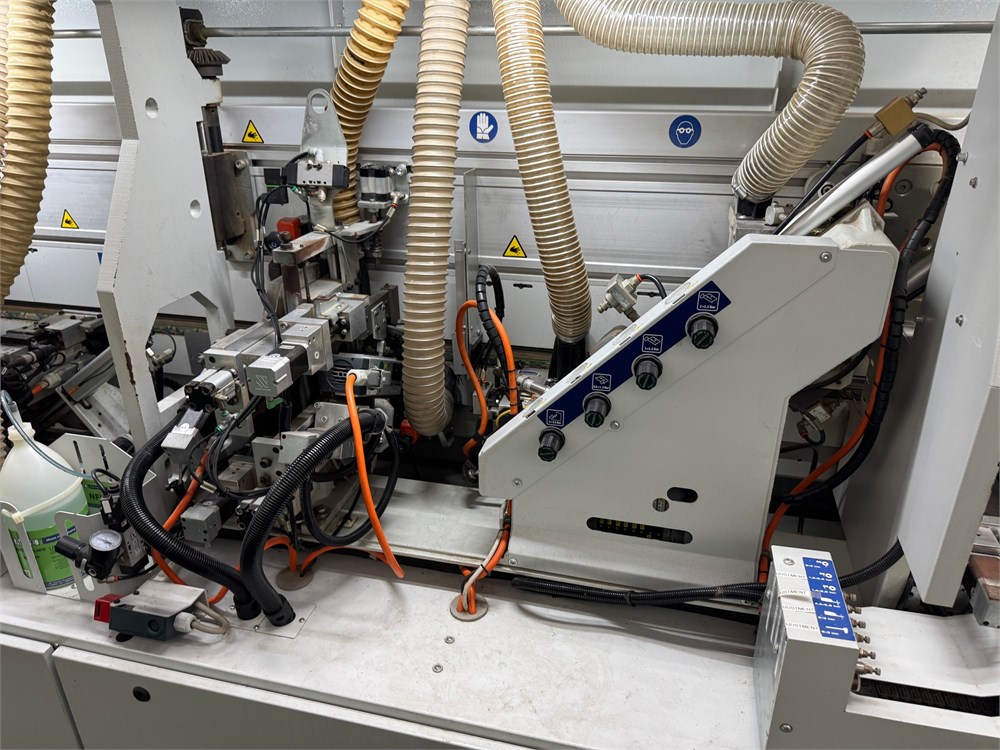

Working Units:

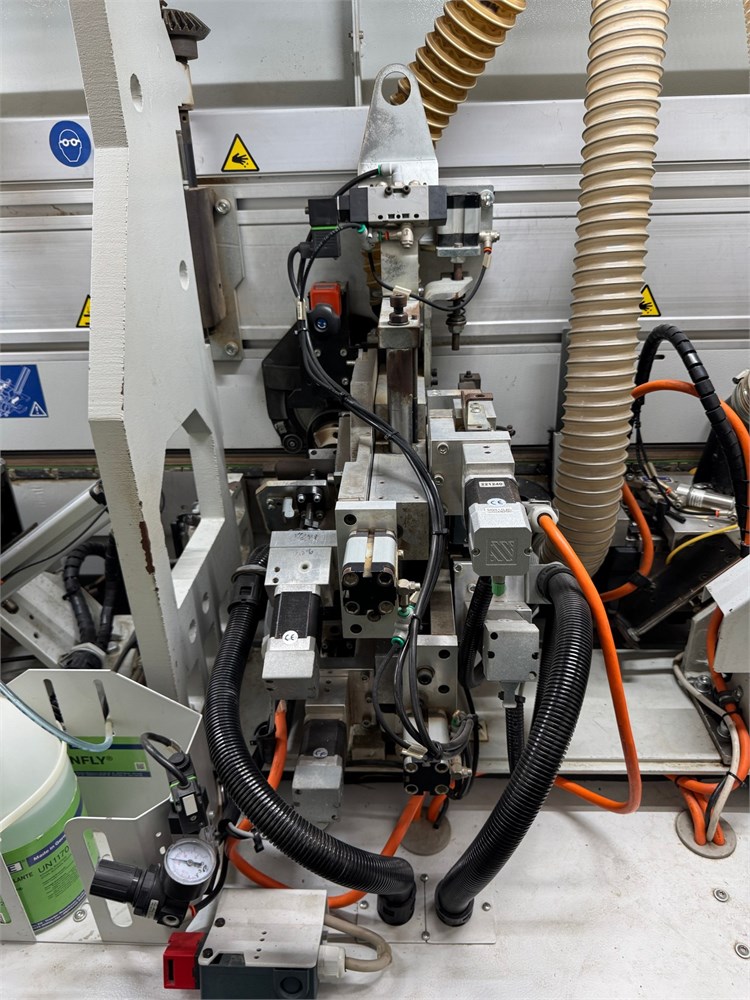

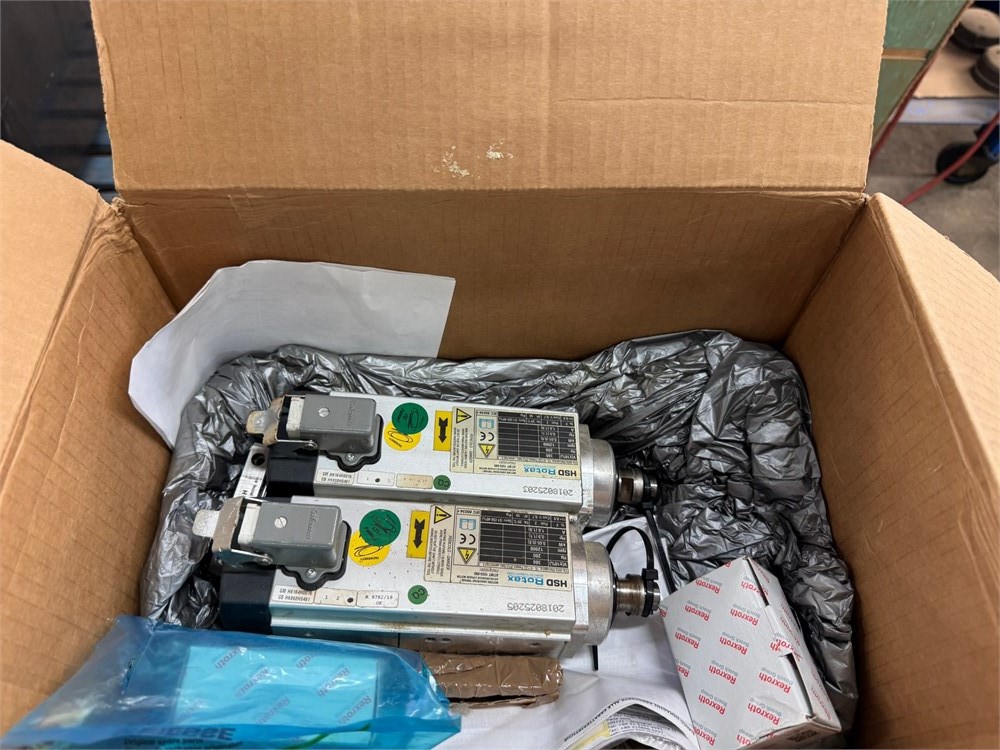

Pre-milling unit with 2 x 0,8 kW, 12000 RPM motors, front/rear inclination 0° -15°.

RT 02;Gluing, edge feeding, and pressing unit VC-511.

End trimming unit with 2 x 0,8 kW, 12000 RPM, front/rear, inclination 0° -15°.

Fine trimming unit 2 × 0,6 kW, 12000 RPM top/bottom.

(2) Multifunction Corner Rounding unit, 0,65 kW each, for Corner Rounding, Straight Work pieces, Post and Soft-Forming 90° -180° degrees.

Edge scraper unit; Glue scraper unit;Buffing unit 2 × 0,37 kW motors.

Cleaning unit LPT02 to apply a cleaning liquid of the glued edge, giving a perfect polishing of the edge.

Belt pressure beam. The top presser comprises a rubber belt with a stain-proof coating. The thrust exercised on the panel is provided by springs housed on techno polymer connecting rods.

Automatic track lubrication system with dynamic track absorption.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available