Sorbini "01 BV 6000" Edge Roll Coater & UV Cure  Ended

Ended

Brochstein's Complete Shop Auction, Day 1- Houston, TX

Houston, TX

- Winning Bid : $2,300.00 USD Sold

- 17 Bid(s)

- High Bidder: W****X

Brochstein's Complete Shop Auction, Day 1- Houston, TX ( Closed #76325787 )

After 90 years in business, Brochstein's has ceased operations and is auctioning all assets in this two day event. Over 750 lots available in both days combined!

-

Pick Up Location

11530 S. Main St. Houston, TX 77025

-

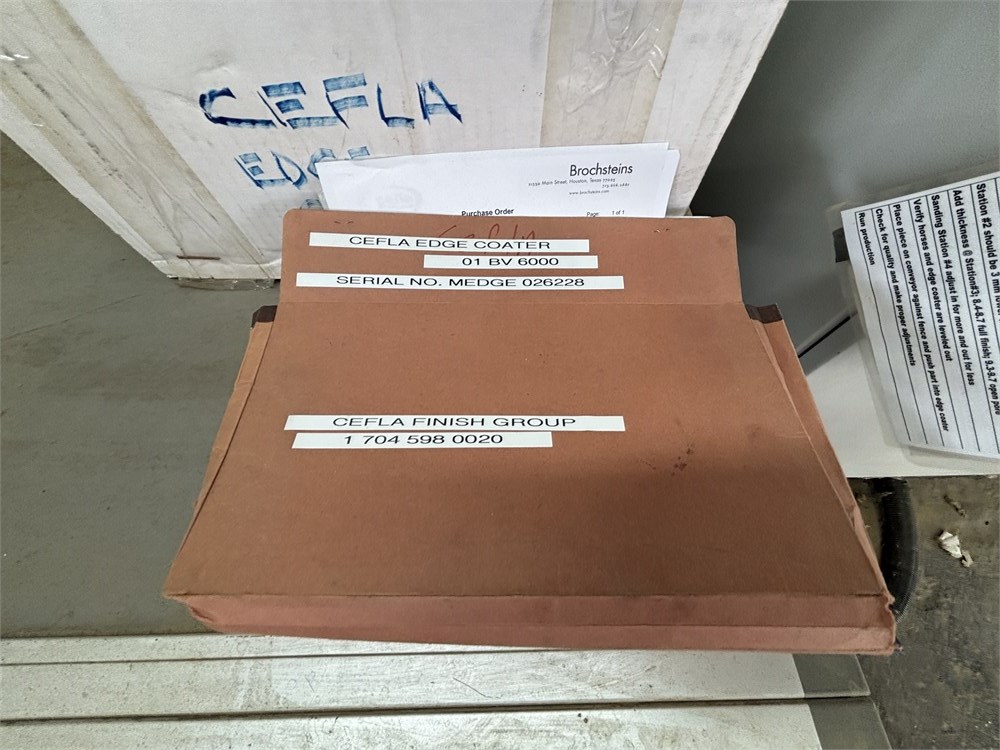

Make

Sorbini

-

Model

"01 BV 6000"

-

Serial Number

MEDGE026228

-

Year

2006

-

Phase

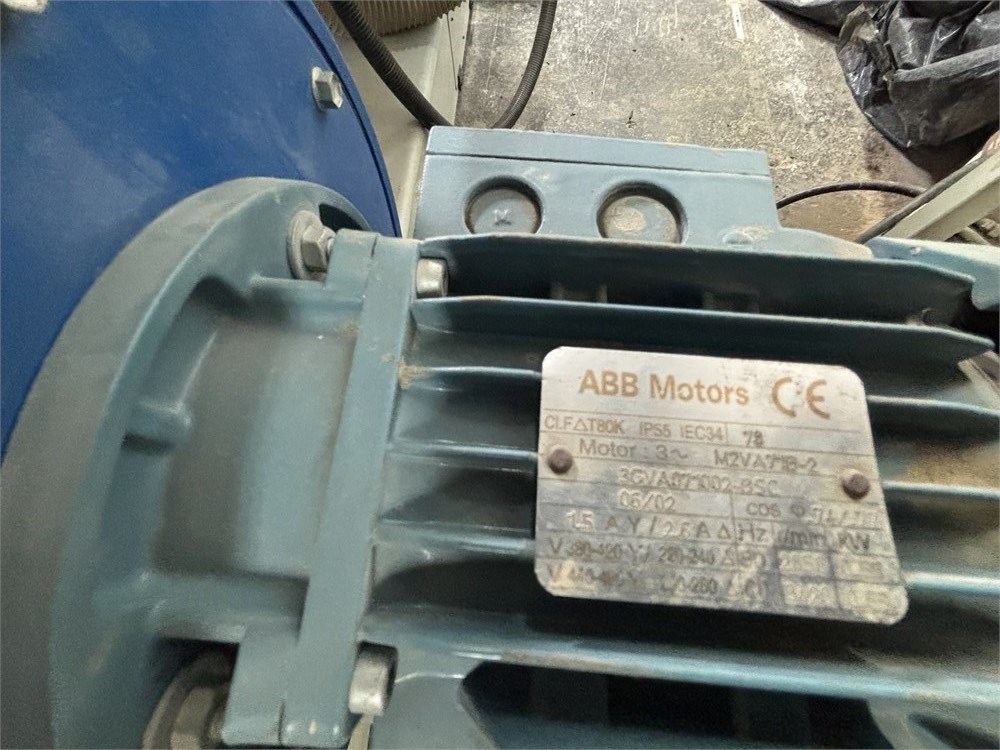

3 PHASE

-

Voltage

480 VOLT

-

Buyer Inspection Period

Tuesday December 9th & Wednesday December 10th, 2025 (9 am - 3 pm) Local Time. No appt. Needed!!

-

Load Out Period

December 12 - December 19, 2025 (by appointment only). For large machines requiring a rigger the loadout time is extended to January 9th. Text Joe for appointment (720) 273-1016

-

Estimated Dimensions

256" x 48" x 66"

-

Estimated Weight

7,500 Lbs

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal. By appointment ONLY!

-

Load Fee

0.00

-

Lot Notes

-

page views

242

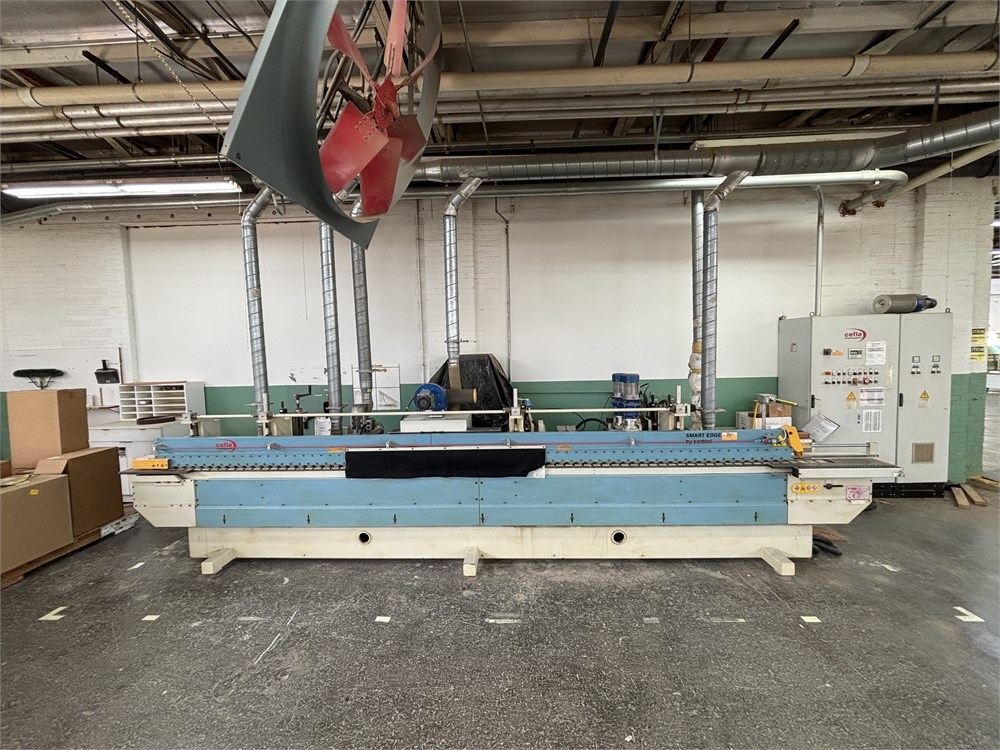

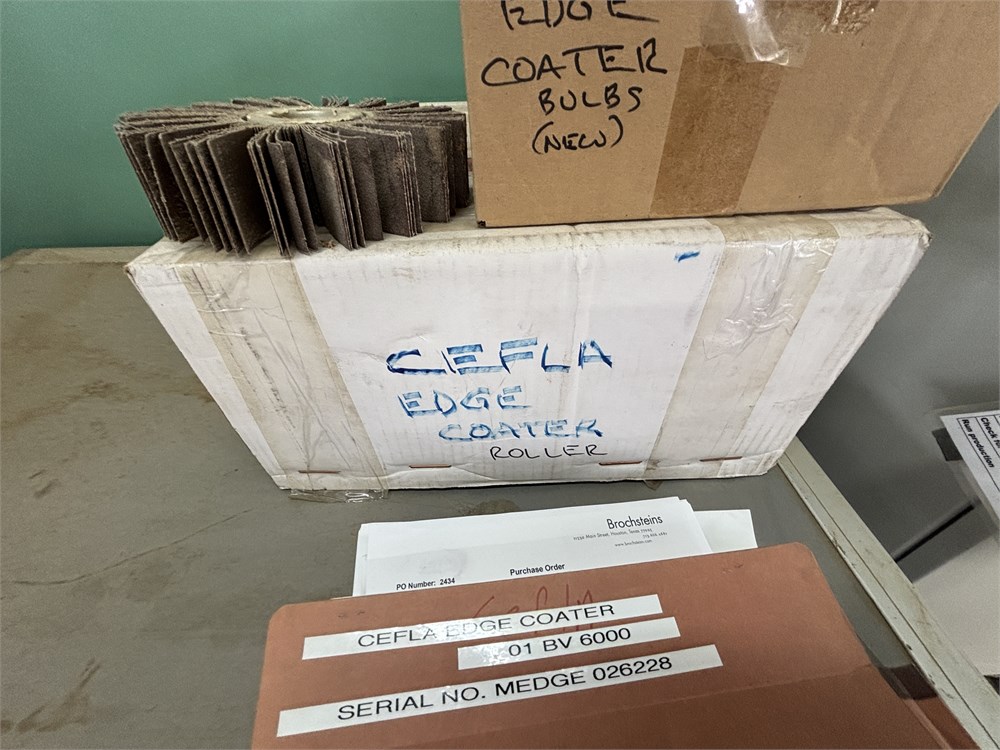

Sorbini "01 BV 6000" Edge Roll Coater & UV Cure

This is one of the most unique high production state-of-the-art Edge Finishing Systems that has ever been built; It uses a patented EDGE Roll COAT- UV Lamps cure the material.

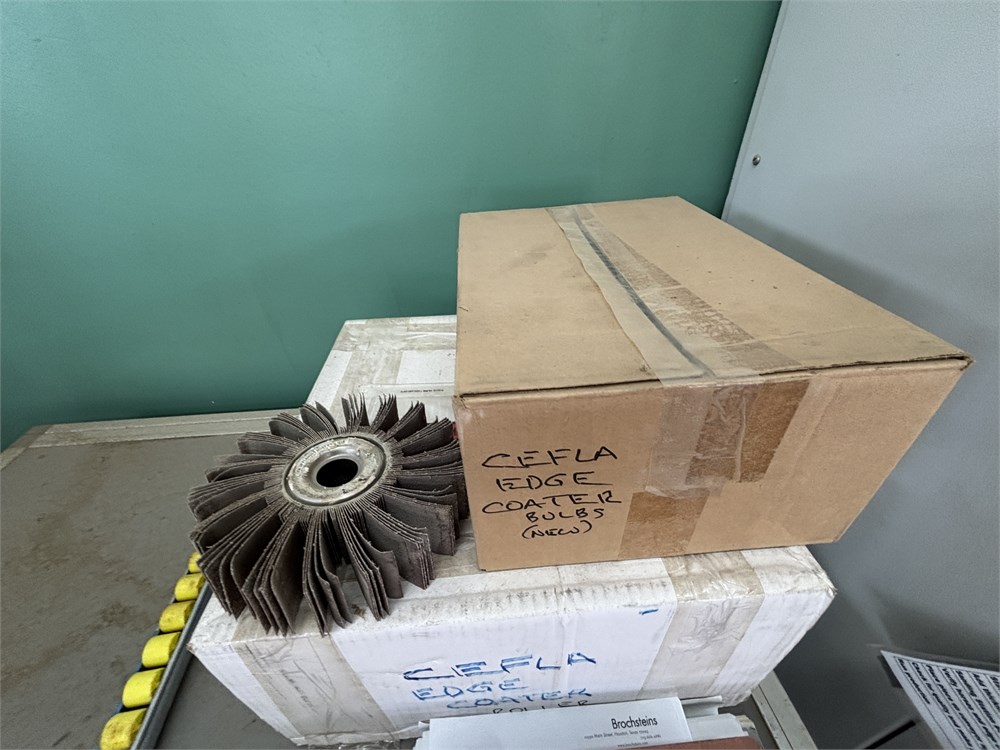

Configured with and as follows: Brush denib-sanding, Blow-off jet cleaning, Roller coatin application, Single lamp UV cure, Brush denib-sanding, Single lamp UV cure.

The stain & UV top coat units are attached to an Edgebander Conveyor, it allows the fnish of (1) side at a time. It uses a die system that is very precise as to where it will apply the finish on the product. Max. line speed of 98+ FPM; and it requires only (2) operators for entire line.

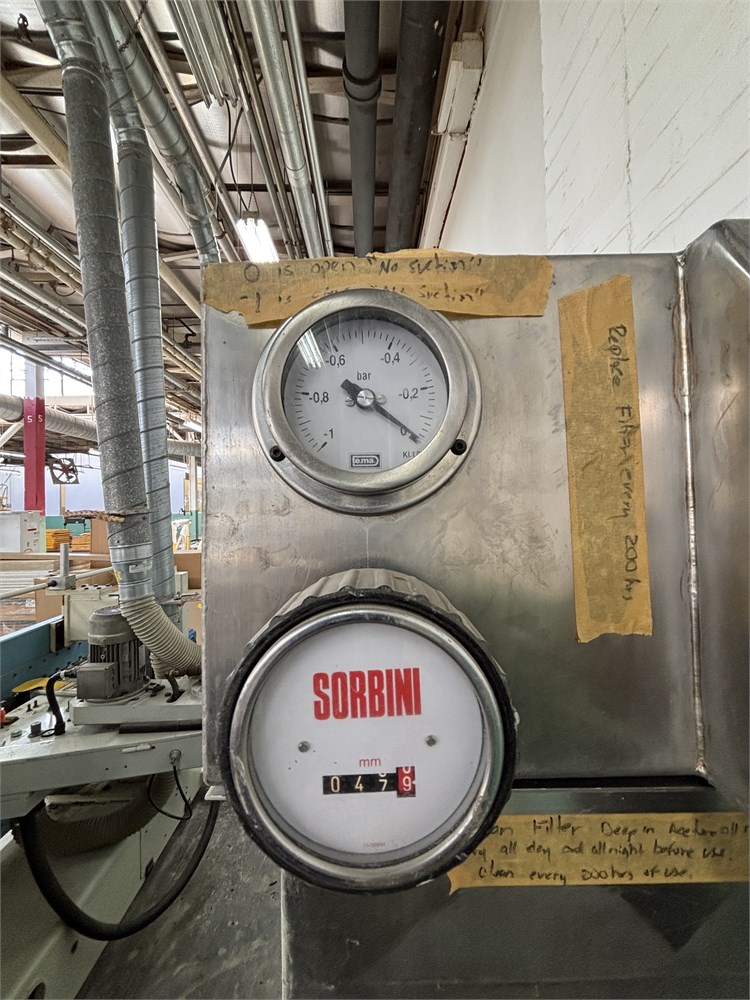

The EdgeCoater components consist of - Machine bed/Conveyor: Rubber caterpillar type feed chain, 80 mm wide, 4 kW motor/variator, adjustable feed speed; pressure bar with vulcanized rubber wheels; material thickness can be electronically adjusted (0.75 kW motor/variator power); movable side pressure guides with idle rollers for material support; 5,000 mm or 16'- 4" total length.

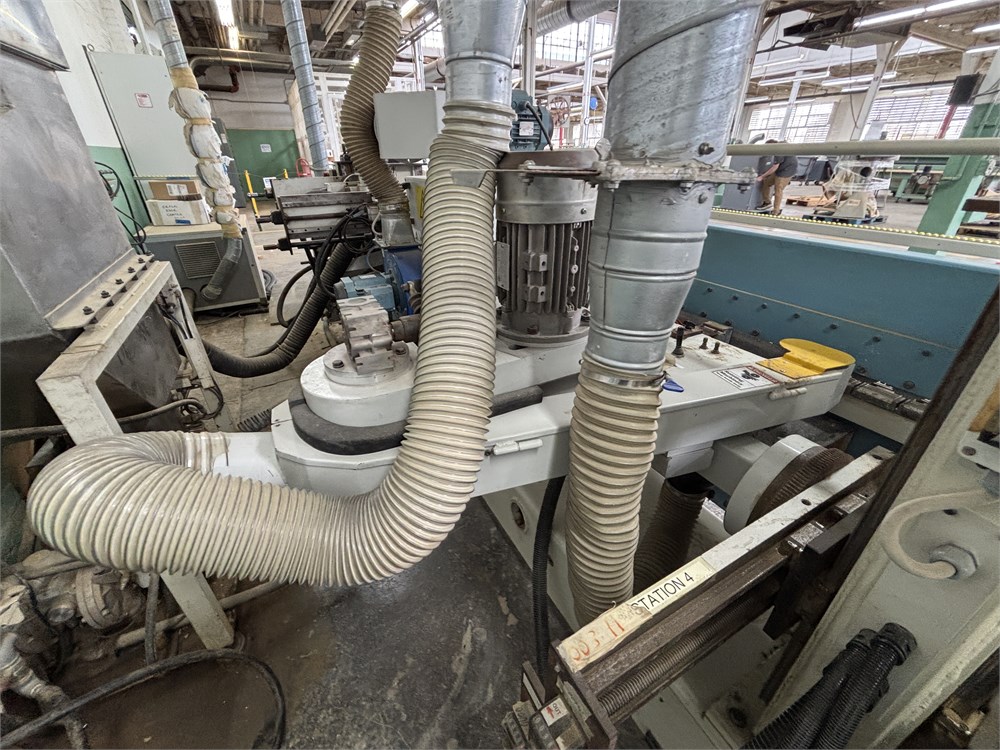

(1) Vertical Profile Station - Tiltable

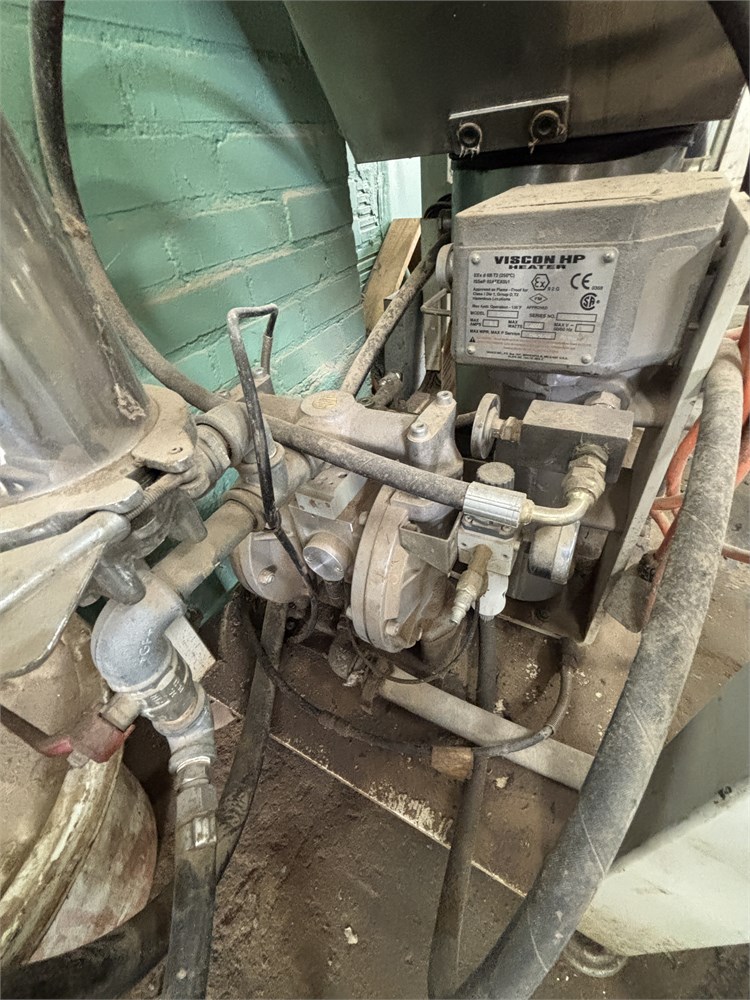

(2) Vertical Edge Roll Coat Application stations: one vertical application roller for for 90ø edges, (1) stainless steel vertical doctor roll, lauier filtering system, pneumatic supply pump, for stain or clear coat.

(2) Blow-off stations.

Section Air/Lacquer Filtering Unit: Double-membrane supply pump, filtering device, product recovery pump with stainless steel tank.

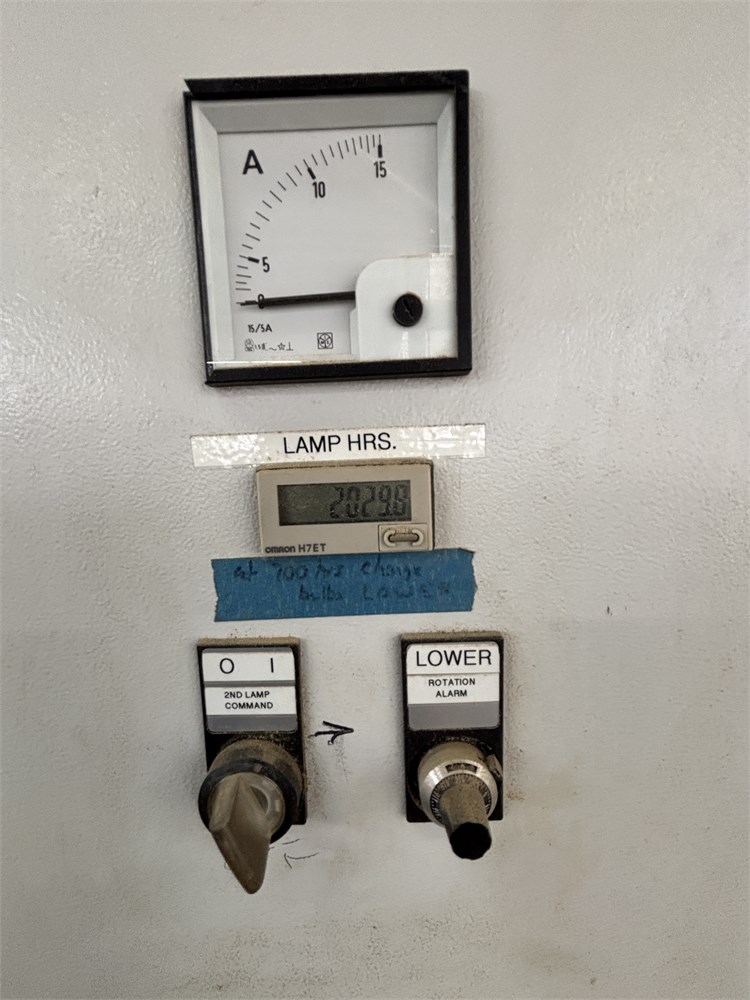

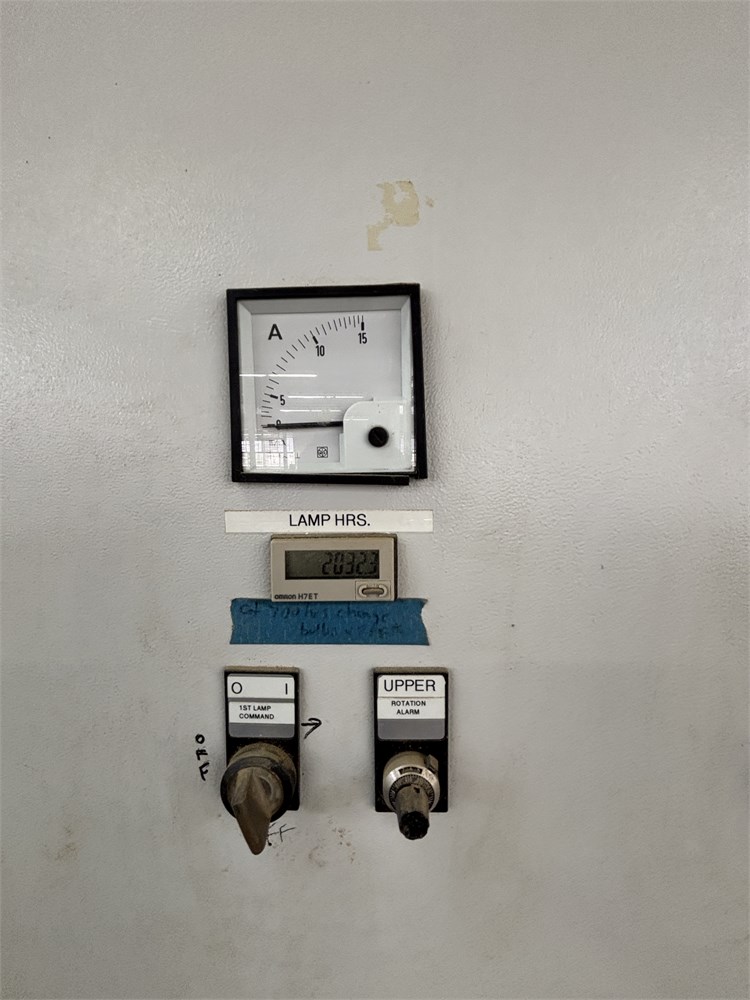

(2) UV Drying Hood Type "600/1": Hood is suitable to include up to (1) UV unit composed of (2) highly polished aluminiume reflectors with pertinent 600 mm lamps with an exhaust cooling fan.

(1) 3-Point tilting belt sander

(1) Vertical Profile Station - Tiltable

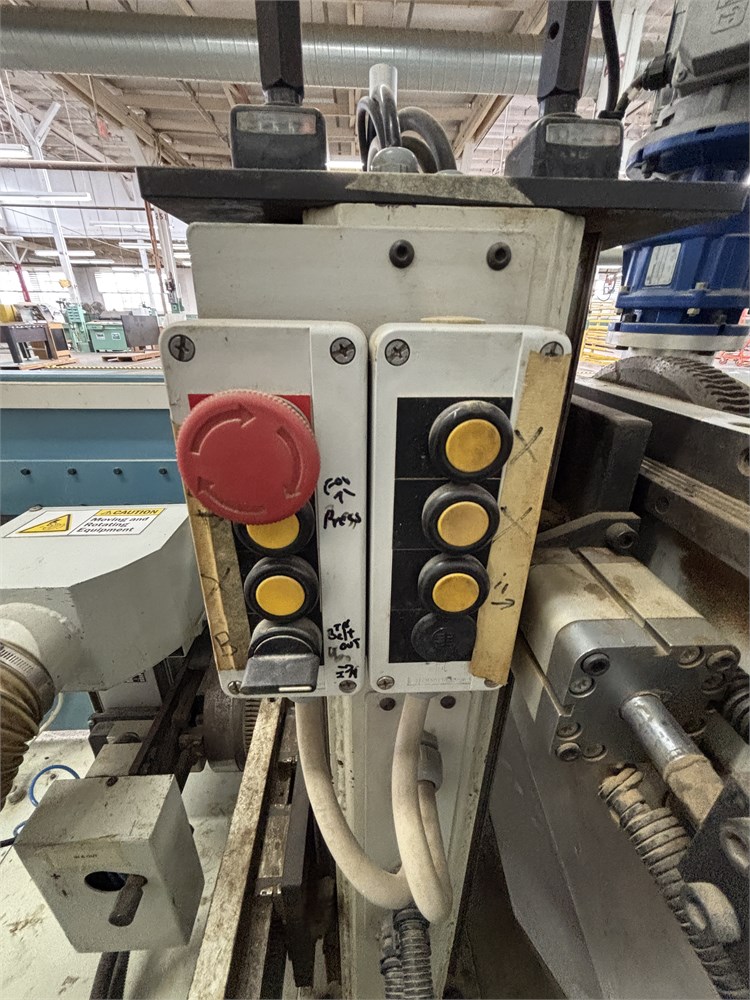

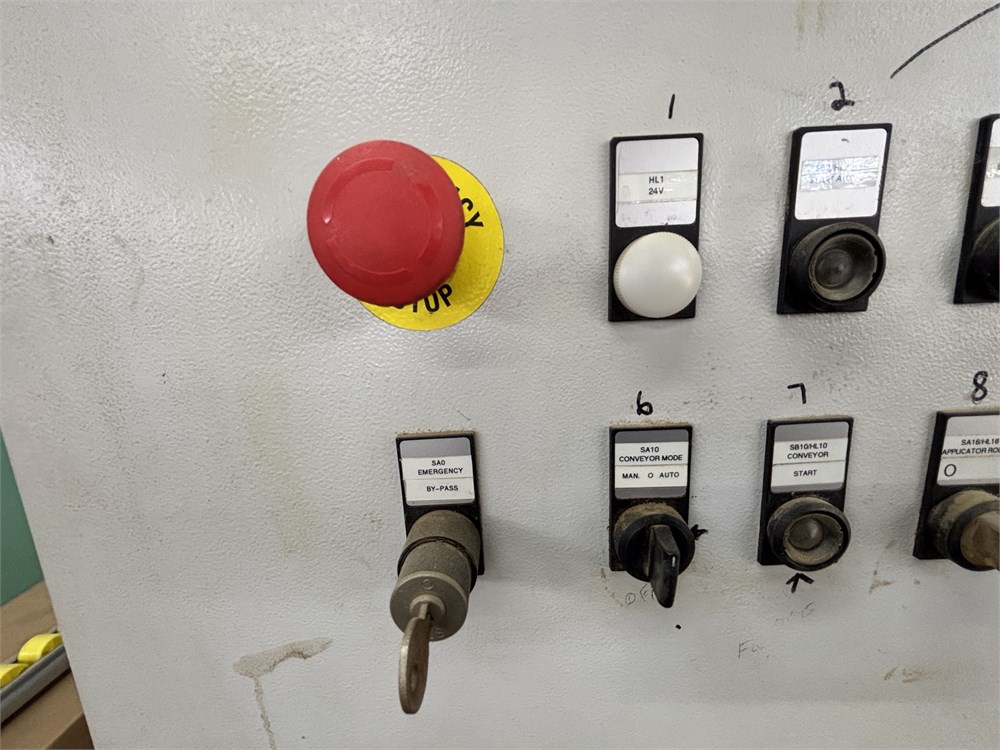

Electrical installation is in IP 55 protection class. The electrical power equipment, such as main switch, fuses, remote-control switch, and automatic thermal relays, etc., is contained in an electrical control cabinet, it is separate from the machine and connected by n electrical cable (standard length: 8,000 mm).

The control keyboard is fed with low tension voltage. The Machine in compliance with CE Safety Standards.

The min. length of part that can be run is 11.7" or 300 mm; Edgecoating systems over all approx. dimension: 18-1/2' x 6-1/4' x 6-1/4'.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available