Busellato "Jet Concept XXL" CNC Router - Pod & Rail  Ended

Ended

Friulmac Double End Tenoner and Busllato CNC Auction - Owensboro, KY

Owensboro, KY

- Starting Bid : $500.00 USD

- 0 Bid(s)

Friulmac Double End Tenoner and Busellato CNC Auction - Owensboro, KY ( Closed #76399687 )

A family-owned window supplier in the greater Louisville, KY area is auctioning a Friulmac "Idramat S/TC 4" Double End Tenoner and Busellato " Jet Concept XXL CNC Router no longer required for continuing operations. Please call me directly with any questions.

-

Pick Up Location

1515 E. 18th. St. Owensboro, KY 42303

-

Make

Busellato

-

Model

Jet Concept XXL

-

Serial Number

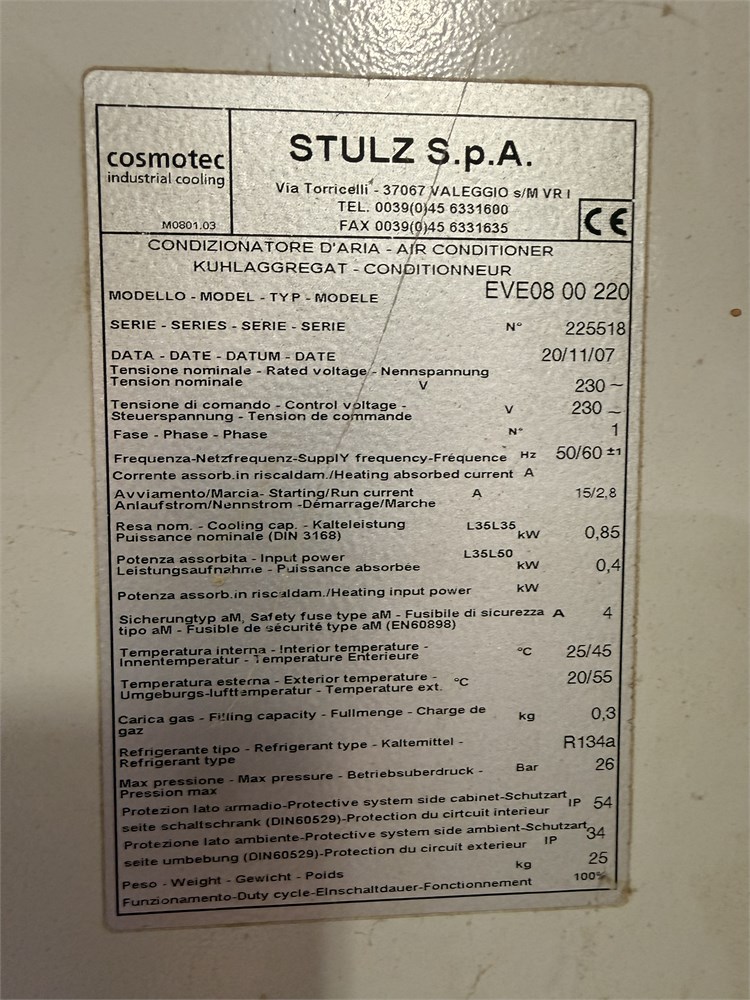

225518

-

Year

2008

-

Phase

3 PHASE

-

Voltage

208-230/460

-

Buyer Inspection Period

By appointment only, contact Thomas Aronson - [email protected] - 941-699-8717

-

Load Out Period

November 25- December 12, 2025 (by appointment only)

-

Estimated Dimensions

26' L x 8-1/2' W x 8' H

-

Estimated Weight

11,000 Pounds

-

Seller Comment

This lot requires a rigger, see home page for details.

-

Load Fee

-

Lot Notes

-

page views

814

Busellato "Jet Concept XXL" CNC Router - Pod & Rail

See attached quotation with additional details, note that not all quoted options necessarily apply

"X" Axis is 6,000 mm (236.2"); "Y" axis 1,345 mm (52.9"); "Z" axis stroke is 350 mm (13.7"), max. material thickness is180 mm (7").

"X" Axis 70 MPM (230 FPM); "Y" axis 60 MPM (197 FPM); "Z" axis 15 MPM (49 FPM).

The "X" axis (long axis) uses a helical rack & pinion system, "Y" & "Z" axis uses ballscrews, all axes are driven by digital, brushless AC Servo motors,

All motion components are maintained by an automatic lubrication system.

(8) Panel supports with double retractable backstops & (4) foot pedals that create (4) independent working zones in the "Y" axis;

(8) Digital readouts for panel support & pod locations according to the program required

(3) adjustable vacuum pods per panel support & (6) pneumatic lifting bars for heavy panels.

Scrap conveyor mounted under panel supports

16 HP electro spindle with HKS F63 adaptor, variable speed from 1,000 - 18,000 RPM, LH/RH rotation; c-axis/4th. axis

Eighteen (18) position rotary tool changer

(1) 14-position ATC tool changer mounted on the machine head for "on the fly" ATC (140 mm max. tool dia.).

7.5 HP horizontal router

Boring unit with twelve (12) vertical boring spindles; two (2) horizontal spindles in the "X" axis and one (1) horizontal spindle in the "Y" axis; grooving saw

Sound enclosure

Front safety mats

Centralized lubrication system

Vacuum pump

External electrical transformer

Control console

- PC with standard keyboard and mouse

- Windows operating system

- Busellato's Genesis software for programming and machine control

- Air conditioned

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense).

Payment is due within 24 hours of auction close. For orders up to $1,500, the credit card on file will be charged. For orders over $1,500, payment must be made via bank wire transfer, unless the buyer chooses to use a credit card, in which case a 3% processing fee will apply. For payment-related questions, please contact Sabrina Correa at 209-839-7707. Sales tax exemption documents must be emailed to [email protected] at the time of purchase for tax exemption consideration.