Biesse "Akron 1440A" Edgebander w/ Premill (2024)  Ended

Ended

RCS Innovations Complete Shop Closure (Day 1 of 2) - Milwaukee, WI

Milwaukee, WI

- Winning Bid : $75,007.00 USD Sold

- 260 Bid(s)

- High Bidder: T****r

RCS Innovations Complete Shop Closure (Day 1 of 2) - Milwaukee, WI ( Closed #76078693 )

RCS Innovations a fully integrated custom display fixtures and digital solutions company is closing it's doors and liquidating all assets. Late model Biesse machinery! Over 500 lots!

-

Pick Up Location

7075 W. Parkland Ct., Milwaukee, WI 53223

-

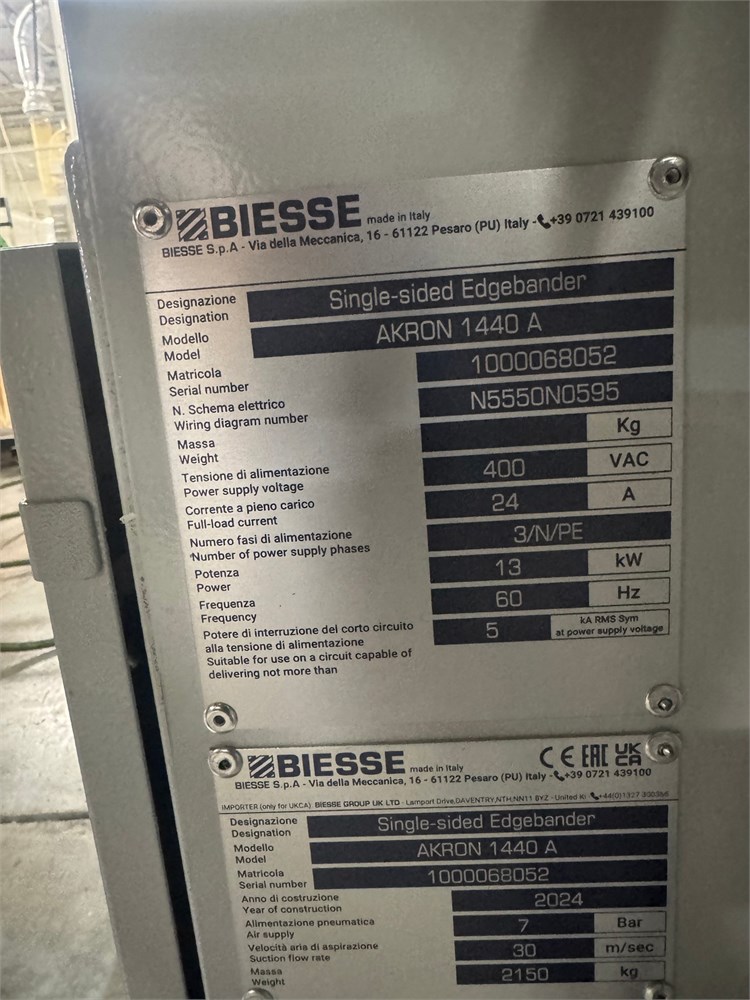

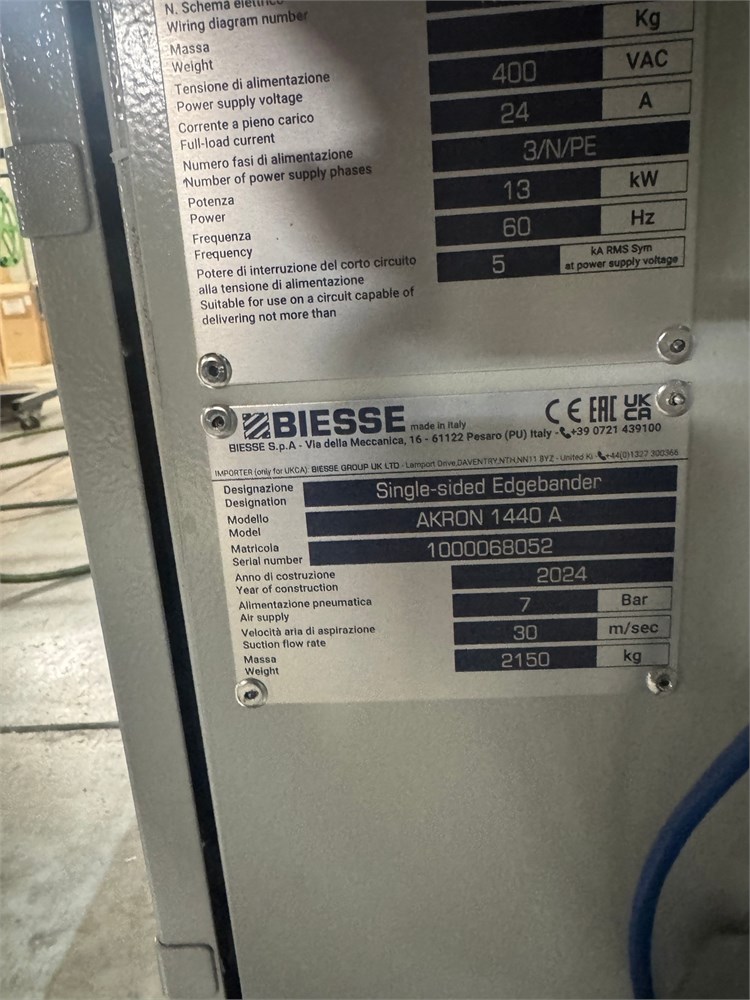

Make

Biesse

-

Model

Akron 1440A

-

Serial Number

1000068052

-

Year

2024

-

Phase

3 PHASE

-

Voltage

208-230/460

-

Buyer Inspection Period

Tuesday December 2nd 8AM - 3:30PM & Wednesday December 3rd 8AM to 11AM...No appt. needed.

-

Load Out Period

December 8- December 15, 2025 8:00am - 4:00pm (by appointment only). For large machines requiring a rigger the loadout time is extended to December 18th. Text Mike for appointment 913-333-8396

-

Estimated Dimensions

18' x 4' x 6'

-

Estimated Weight

5,000 Lbs

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal. By appointment ONLY!

-

Load Fee

-

Lot Notes

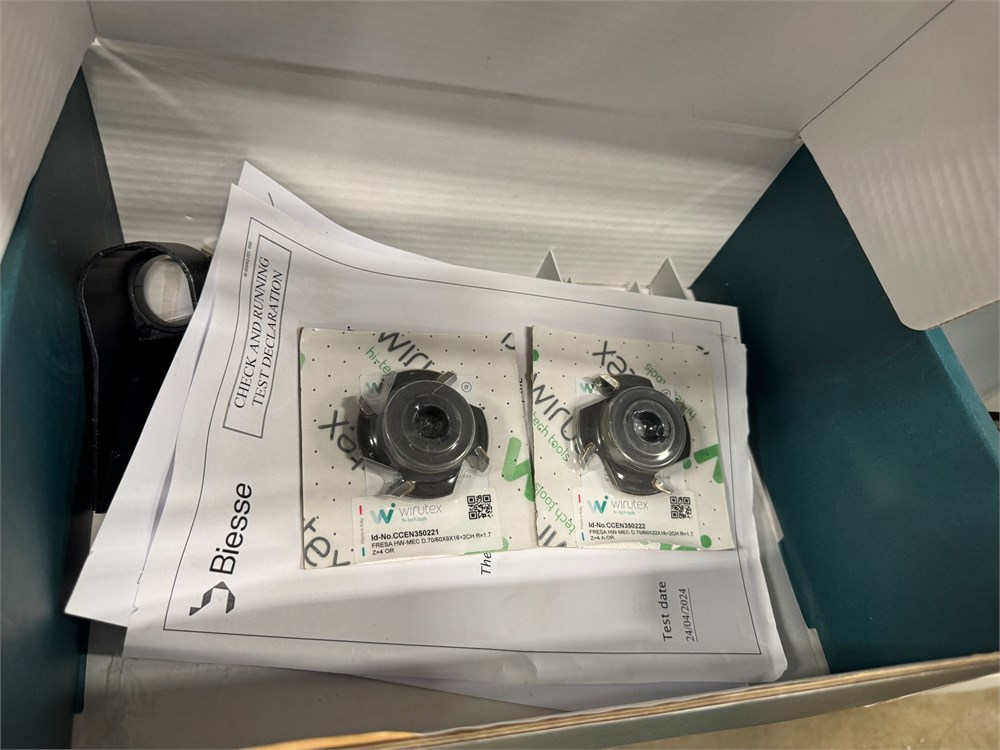

Installed March 2025!!! Replacement cost...$249,900

-

page views

1888

Biesse "AKron 1440A" Edgebander w/ Premill (2024)

Latest Technology combines productivity, efficiency, and flexibility for all types of edgebanding material.

Environmentally friendly providing a “clean - green” technology that eliminates glue and fumes, which becomes timely & important.In addition, it features a conventional EVA (Hot Melt) Gluing System to cover the full range of edgebanding processes in use today!

Min. panel height: 10 mm;Max. panel height: 60 mm;Height of edgebanding material: 14 - 64 mm;Thickness of edgebanding material in rolls: 0.4 - 3 mm; Thickness of edgebanding in strips: 0.4 - 10 mm.

Min. panel protrusion from the track: 25 mm;Panel length: 140 - 3200 mm;Min. panel width (with length 140 mm): 85 mm;Min. panel width (with length 250 mm): 50 mm.

Multi-Feed speed 8-12-15 &18 MPM.

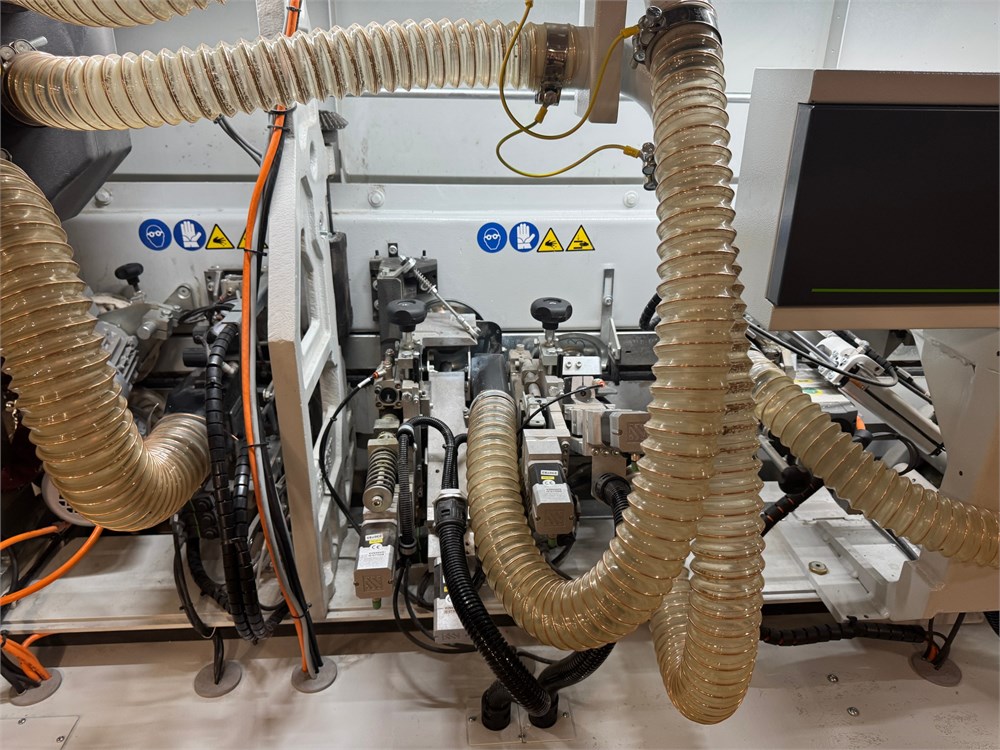

Glue & Pressure Section:

Infrared lamp IRL 700;Gluing unit Quickmelt QM 703 EVA melting glue. Special glue container for PU glue; Additionalglue container for EVA gluing unit with melting device.

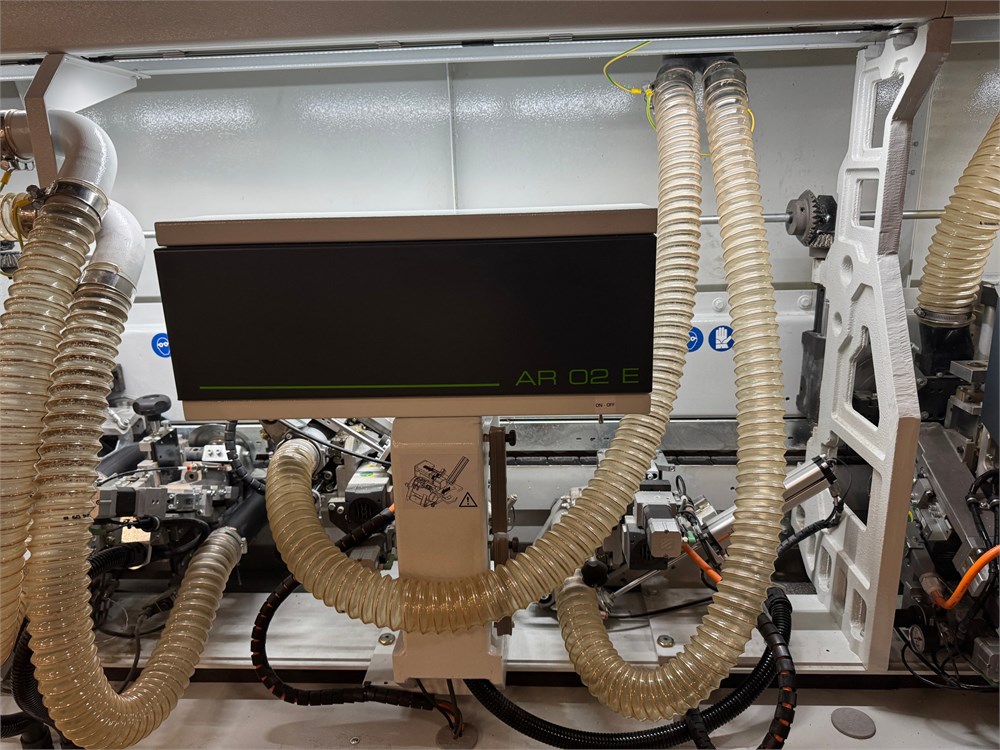

Additionally equipped with the AirForce "VC-710", High pressure, hot air system to reactivate special precoated edge material (commonly referred to as laser edge.

Automatic edge feed;Cutter knife;Pressure zone with 1-Drive & 2 pressure rollers.

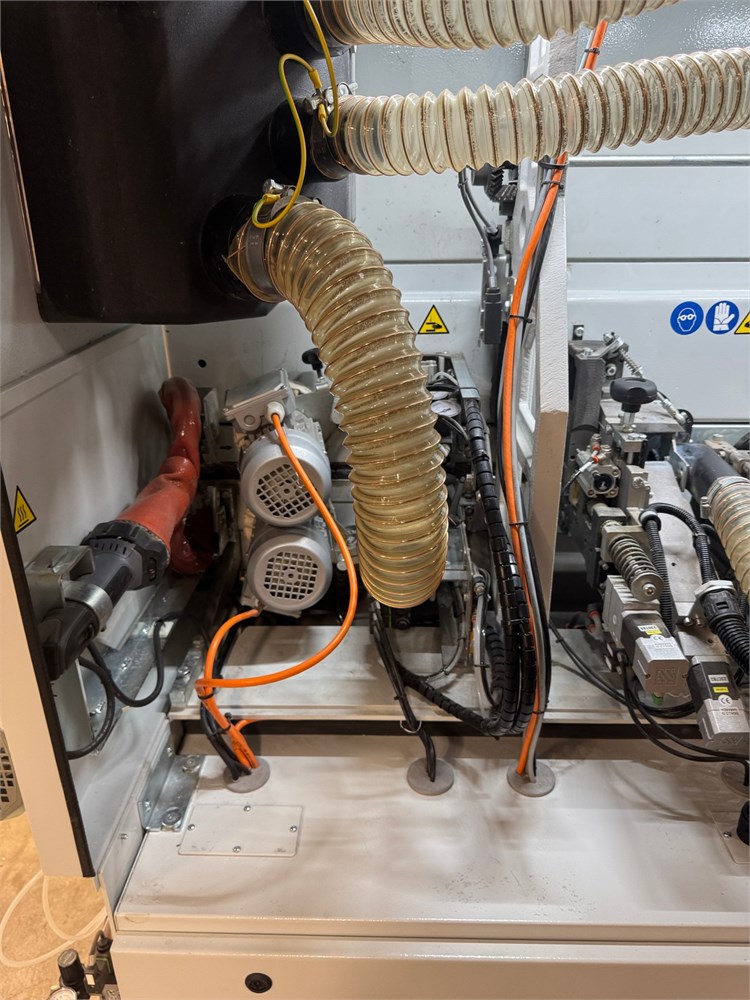

Pre-milling unit with 2 x 0,8 kW, 12000 RPM motors, front/rear inclination 0° -15°.

RT 02;Gluing, edge feeding, and pressing unit VC-511.

End trimming unit with 2 x 0,8 kW, 12000 RPM, front/rear, inclination 0° -15°.

Fine trimmingunit 2 × 0,6 kW, 12000 RPM top/bottom.

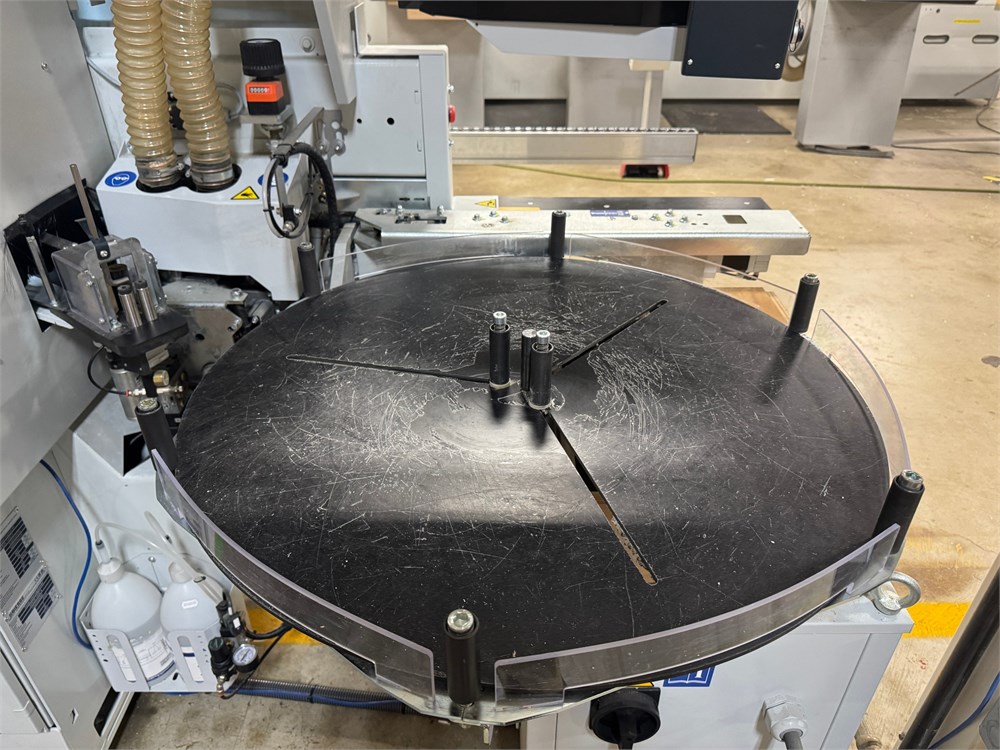

(2) Multifunction Corner Rounding unit, 0,65 kW each, for Corner Rounding, Straight Workpieces, Post and Soft-Forming 90° -180° degrees.

Edge scraper unit;

Glue scraper unit;

Buffing unit 2 × 0,37 kW motors.

Machine Features:

Belt pressure beam. The top presser comprises a rubber belt with a stain-proof coating. The thrust exercised on the panel is provided by springs housed on techno polymer connecting rods.

Automatic track lubrication system with dynamic track absorption.

Manual infeed system for narrow pieces.

One coil automatic edge feeding.

Hybrid gluing head for granulated EVA and Polyurethane glue.

Pre-Melter TM10 for Polyurethane glue in cartridges. On-demand top-loading pre-melter for PUR glues.

Adaptive infra-red lamp to heat up the panel side before the glue application, in order to optimize the adhesion process.

Independent pneumatic exclusion of the top/bottom fine trimming unit.

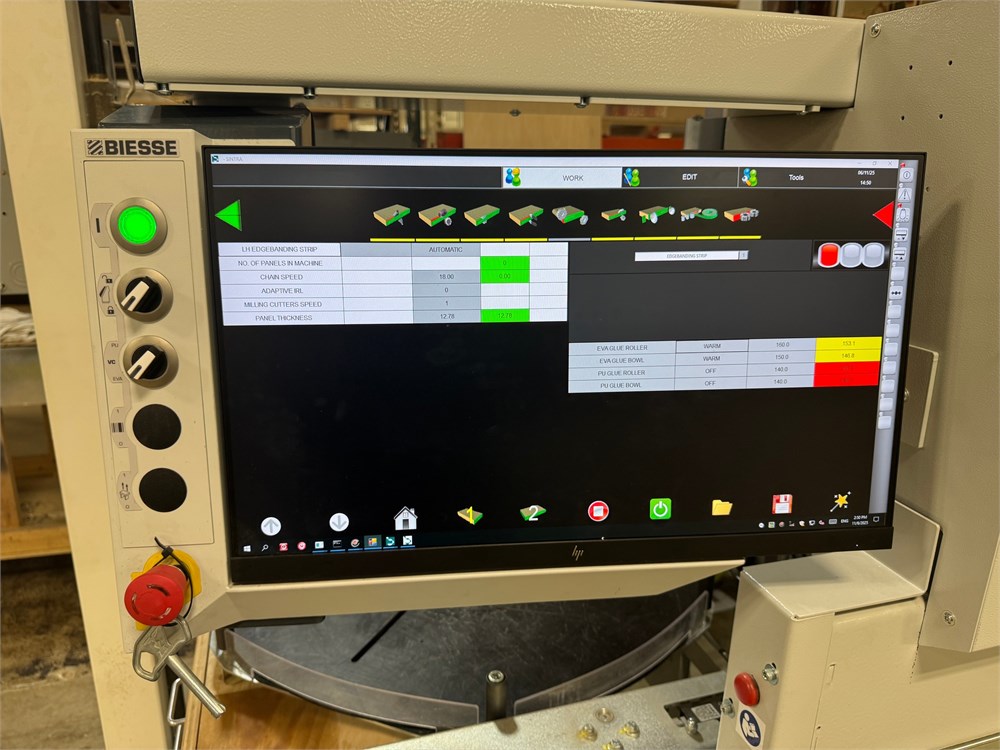

Operator & Machine Control:

Biesse, Windows-based "SMART TOUCH" control & operating system.

Easy program management and usability. Rapid transition from one machining operation to the next. Modern, intuitive graphic interface.

Sliding unit for corner rounding unit, for the application of sliding liquid before the corner rounding unit.

Cleaning unit LPT02 to apply a cleaning liquid of the glued edge, giving a perfect polishing of the edge.

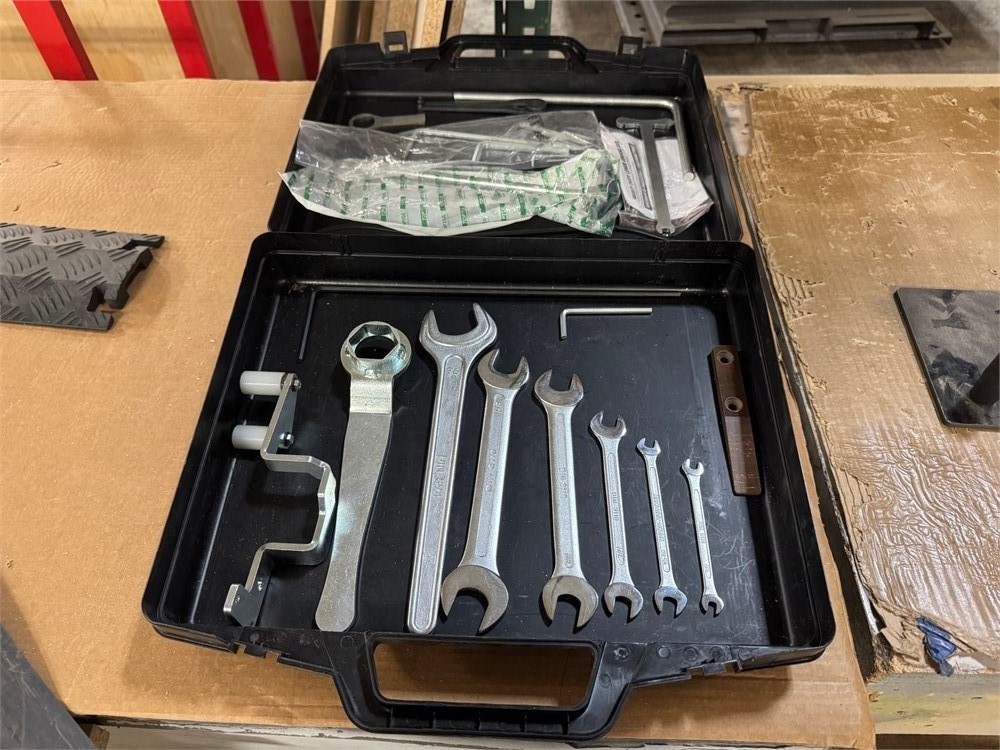

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense).

Payment is due within 24 hours of auction close. For orders up to $1,500, the credit card on file will be charged. For orders over $1,500, payment must be made via bank wire transfer, unless the buyer chooses to use a credit card, in which case a 3% processing fee will apply. For payment-related questions, please contact Sabrina Correa at 209-839-7707. Sales tax exemption documents must be emailed to [email protected] at the time of purchase for tax exemption consideration.