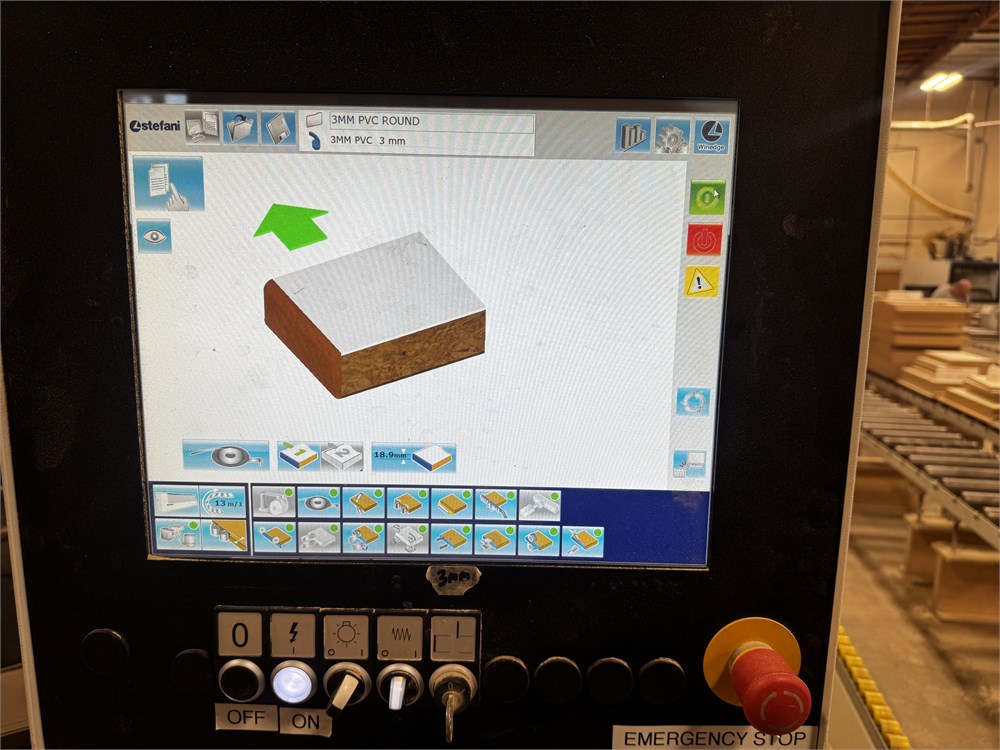

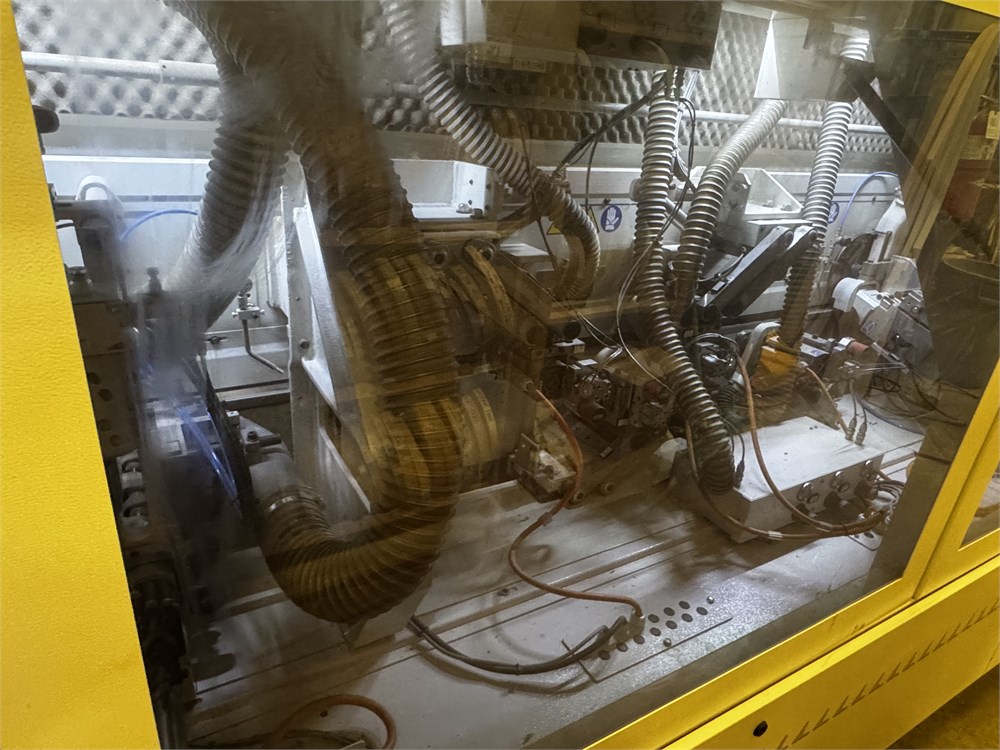

Stefani "Solution HD" Edgebander  Ended

Ended

Woodworking Machinery Auction - Fontana, CA

Fontana, CA

- Winning Bid : $30,500.00 USD Sold

- 135 Bid(s)

- High Bidder: e****s

Woodworking Machinery Auction - Fontana, CA ( Closed #76116626 )

A commercial cabinet manufacturer in the greater Los Angeles, CA area is auctioning a 2017 Stefani "Solution HD" edgebander, Blum hinge boring machine, SCM minimax e10 contour edgebander, and much more!

-

Pick Up Location

10860 Mulberry Ave. Fontana, CA 92337

-

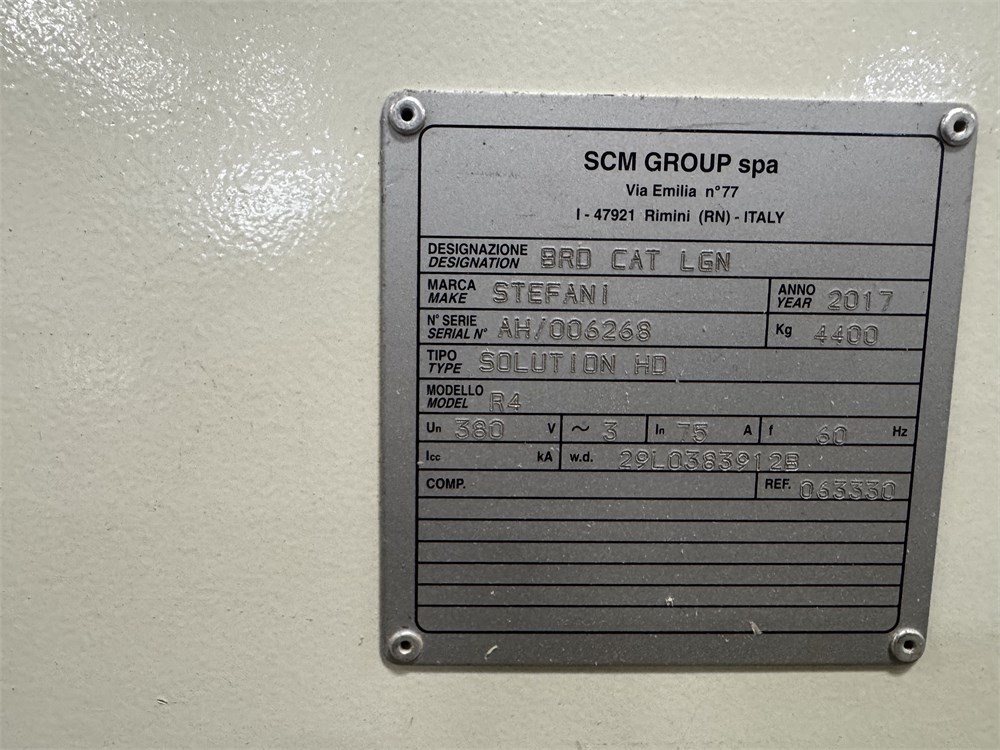

Make

Stefani

-

Model

Solution HD

-

Serial Number

AH/006268

-

Year

2017

-

Phase

3 PHASE

-

Voltage

208-230/460

-

Buyer Inspection Period

By appointment only, contact Thomas Aronson - [email protected] - 941-699-8717

-

Load Out Period

November 24 - December 10, 2025 (for lots 002 - 007 ), November 24 - November 26, 2025 (for lot 001)

-

Estimated Dimensions

27'L x 48"W x 72"H

-

Estimated Weight

10,000 Pounds

-

Seller Comment

This lots required a rigger, please see homepage for details

-

Load Fee

-

Lot Notes

-

page views

805

Stefani "Solution HD" Edgebander

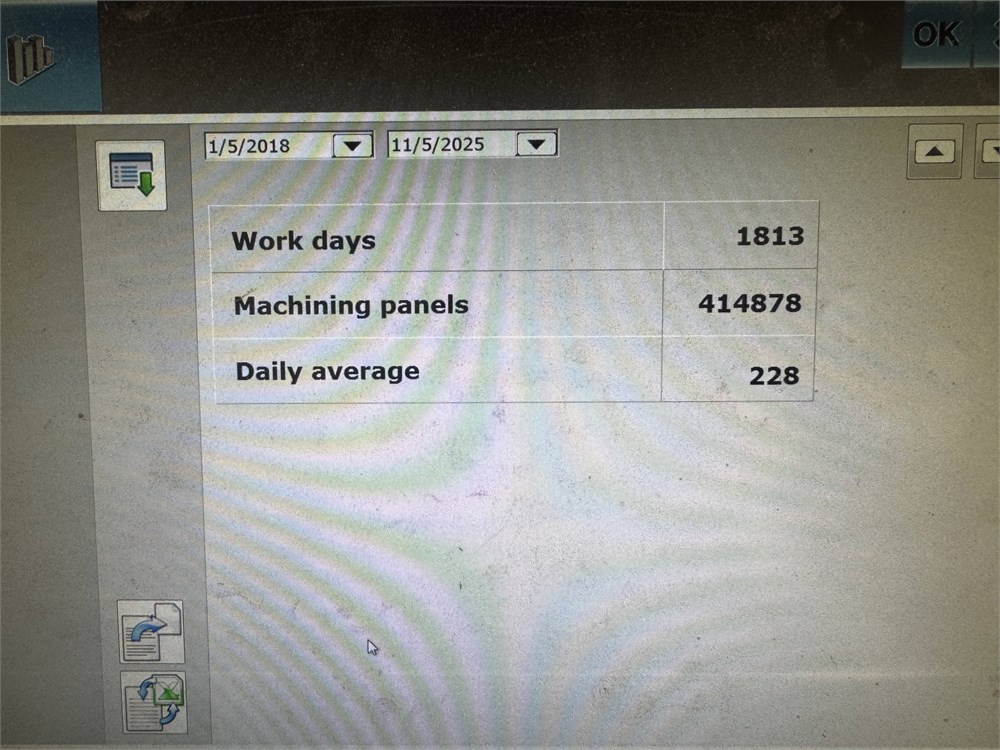

This machine has been in production less than 6 hours/day, 5 days/week. Low-usage for such a heavy-duty machine.

SEE VIDEO OF MACHINE

Minimum Panel Length: 140mm/5.5"

Working Height: 10 mm - 60 mm (3/8" – 2 3/8")

Edge Thickness: 0.4 mm/0.015" - 22 mm/0.87"

Minimum Panel Spacing: 630mm/24.8"

Minimum coil length: 230mm/9.0"

Minimum strips length (solid wood and HPL): 250mm/9.8"

Track speed (depending on edge thickness): 40 - 82 FPM

Controller

- PC Office Operating system: W XP

- Screen: 17" TFT

- 2 network card ETHERNET

- 6 USB ports - 2 PS/2 ports

- Bar code reader management

Automatic motorized positioning of the top pressure beam from the control. This system also automatically adjusts all work units to accommodate the new part thickness. Beam height is set in the programs to suit the application.

Panel spacing device

Two position infeed fence

Pneumatic two position of infeed guide

Top pressure belt

Anti-Adhesion Unit

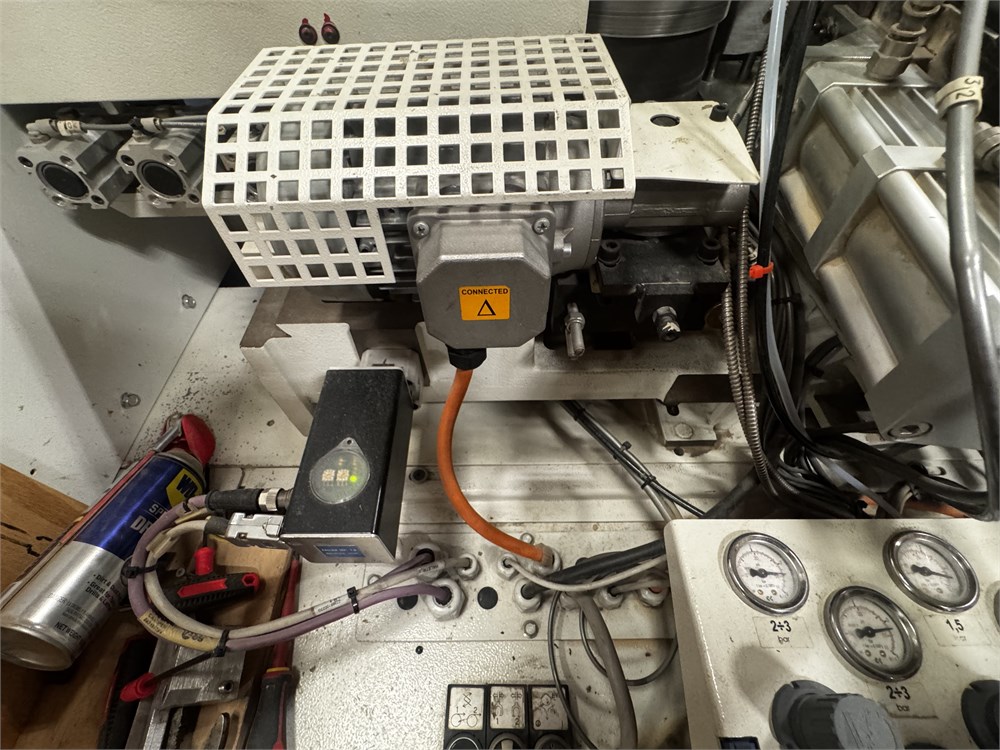

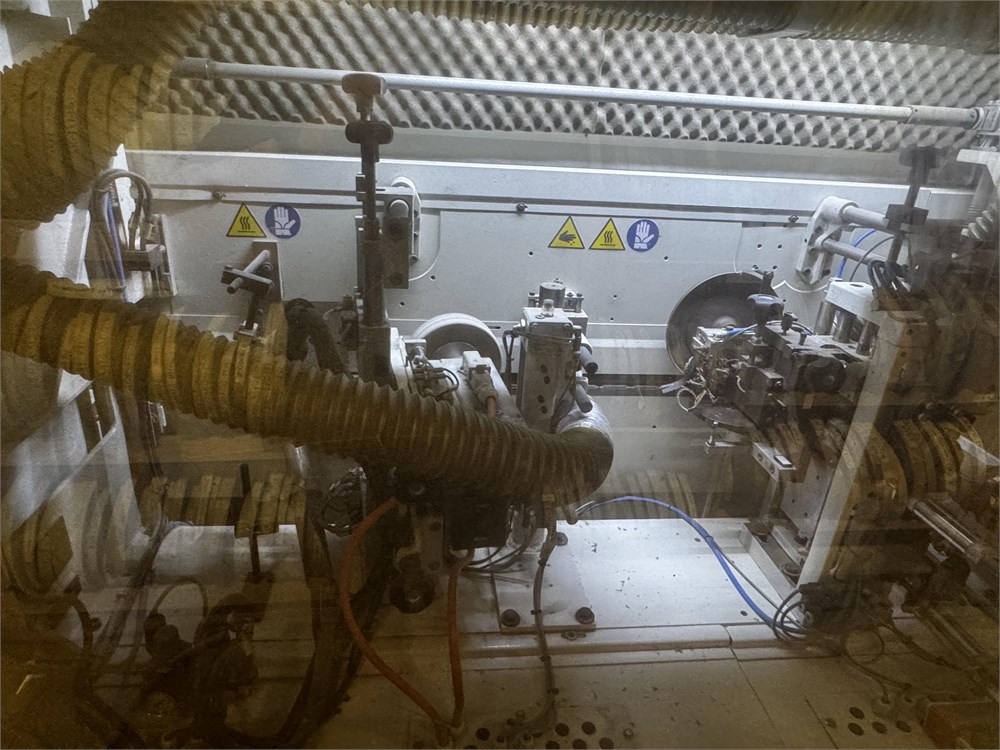

Pre-Milling Unit, 5.4 HP motors operating at 12,000 RPM

Panel Heating Lamps

Glue unit with hopper and application roller

- Precise control of the amount of glue on the panel edge

- Electronic control of the glue temperature

- Movement of the glue spreading roller, of the first pressure roller, and of the feed roller by motors

- Automatic temperature kick-down to avoid glue scorching

- Quick-melt system with pot for melting glue granules. This allows for a fast melt of the glue granules with controlled alimentation into on the spreading basin. The pump heated by resistors and complete with thermoregulators for the temperature control

- A smaller glue pot with electronic glue level monitoring replaces the standard glue pot to improve heating time.

Heavy duty guillotine for automatic tape trimming

Automatic loading of coiled material or strips

Pressure unit with one (1) motorized roller and three (3) idle rollers with opposing tilt. All rollers have “jump” capability. Electronic setting of the pressure unit by means of numerical controlled motor to set the position of the pressure rollers when changing edge thickness. This system is fully controlled by the PC program or manually adjusted on computer screen. Mounted on THK guides

YU/SP-750 Top Mounted End Trimming Unit

- Unit installed on the pressure beam

- Two motors with timed pneumatic movement

- Front, back feeler with automatic location

- Lateral feelers on linear ball recirculating guides with pneumatic intervention

- Motors with manual tilt up to 15°

- Automatic exclusion per application via the program

- Automatic Horizontal Blade Tilt

R Trimming Unit. For the rough trimming of thin and medium edges or for the finishing of solid wood edge:

- Top and bottom trimming motors with quick-release device

- Top motor connected to the pressure beam for automatic adjustment according to the panel thickness

- Large diameter, disc-shaped vertical copying device

- Numerical indicators for the horizontal and vertical shifting of the motors

- Automatic exclusion per application via the program

- 2.5 HP motors

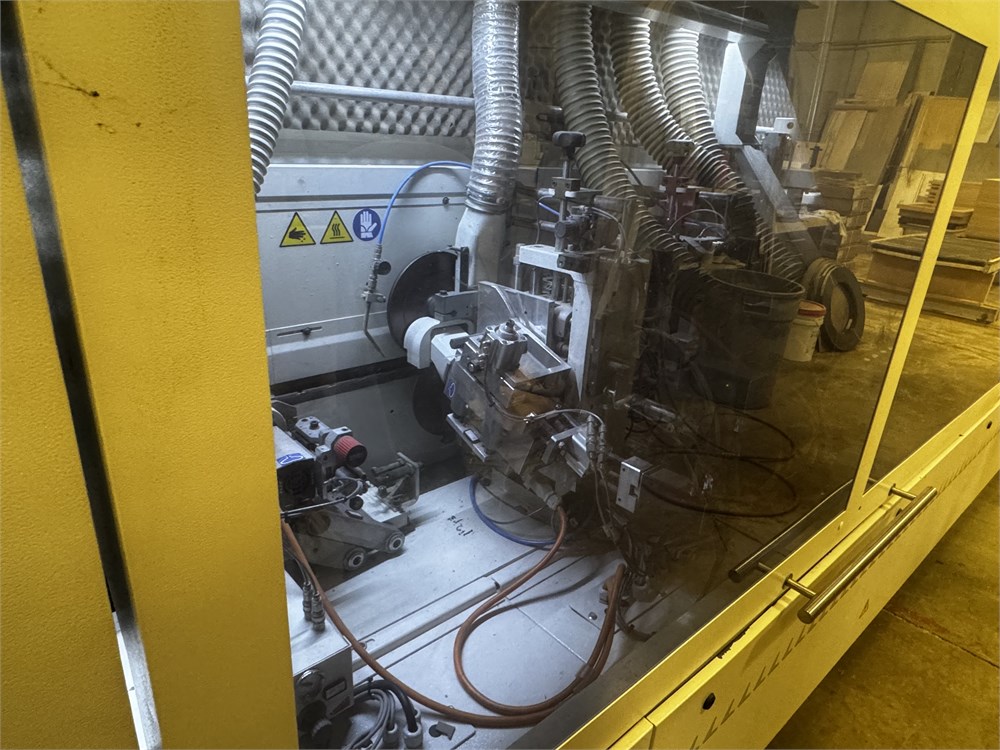

RSU Fine Trimming Unit. Automatic top and bottom trimming for thin edges or rough trimming on PVC/ABS edges:

- Two motors tilting up to 30° with quick-release system

- Top motor connected to the pressure beam for the automatic adjustment according to the edge thickness

- Large diameter, disc-shaped vertical copying device

- Horizontal and vertical automatic cut-off up to 10 mm.

- Electronic Positioning Of Feelers For RSU

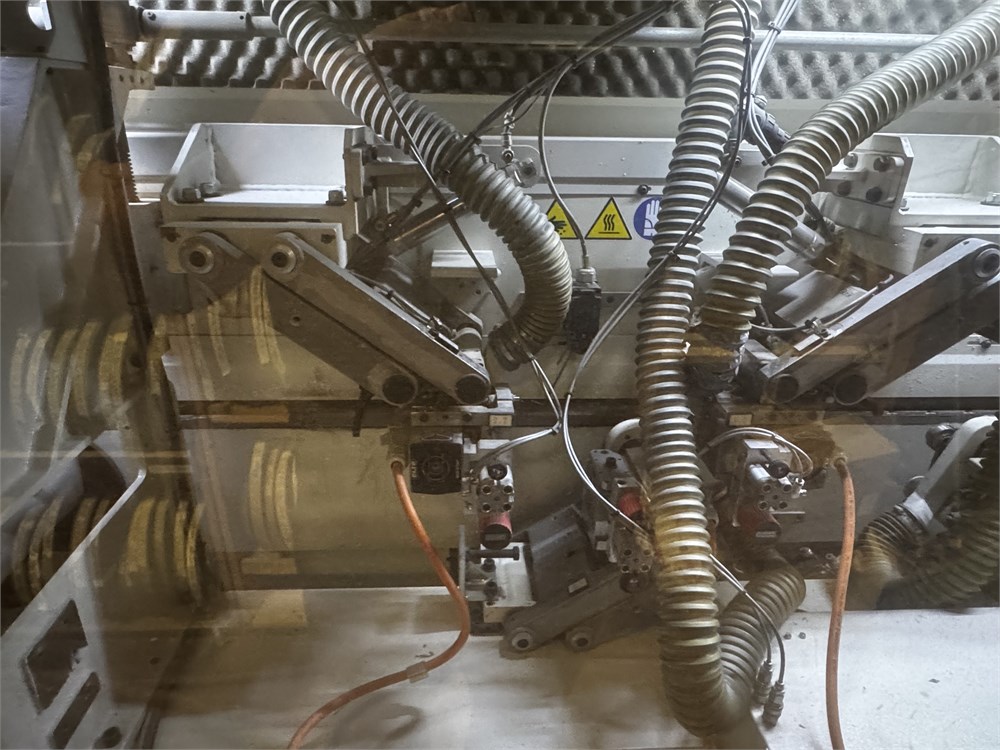

Corner Rounding Unit C1+C2 2P. This heavy-duty unit is designed to round the front and rear corners of work pieces with thick PVC edging. The four independent motors on this unit are equipped with front and lateral copying devices. In/out positioning is controlled through the PC. The unit is designed to change between 3mm PVC to thin tape via the PC.

- Four motors with quick-release system with motor blocks supported by a parallelogram supports that keep tool in perfect position independently from the geometry of the profile

- Motors equipped with 2 position automatic positioning to quickly change from thin tape to 3mm PVC.

- Separate processing sequences for each corner to avoid causing vibrations of the panel

- Four motors guarantee a tear out free finish when applying 3mm wood coil

- Copying system with bearing feelers and lateral feeler

- Automatic exclusion

- Pneumatic positioning of the cutter on 2 positions for processing 3mm or thin pvc

Edge Scraping Unit RAS/S. Top and bottom scraping for PVC/ABS material

- Quick release device for motor and tool which allows the fast and precise change over

- Vertical and horizontal shifting devices made of steel grounded bars with recirculating ball bearings

- Large diameter vertical and horizontal feelers

- Numerical indicators for the horizontal shifting

- Automatic exclusion

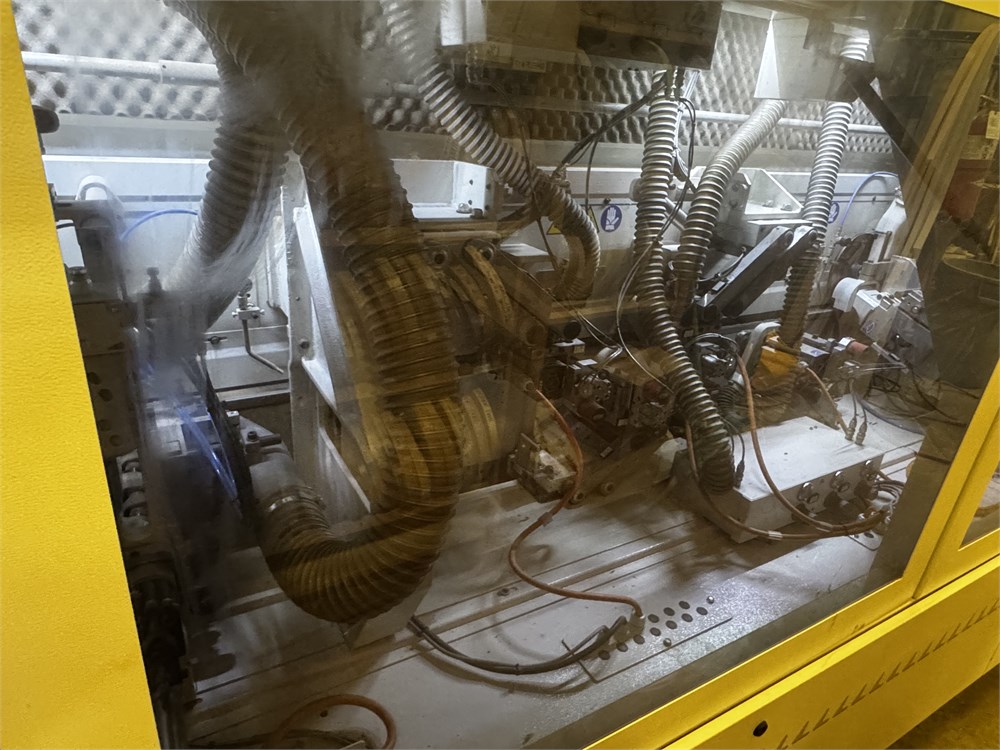

Glue Scraping RCA/2C. Removes possible excess of glue on the top and bottom side of the panel.

- Complete with two cutters

- Vertical copying device

- Two blowers cleaning the cutters

- Automatic start to assure the best processing of the starting and the ending side of the panel

- Automatic exclusion

Buffing Unit SPN. For the cleaning and finishing of plastic edges.

- Two (2) overlapped motors that tilt vertically.

- Pneumatic Cut-off and Oscillation

Sound enclosure

Outboard roller support

External electrical transformer

This machine must be loaded out by rigger November 24 - November 26, 2025. If a truck cannot be arranged the rigger listed on homepage can remove and store at his location for an additional price.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense).

Payment is due within 24 hours of auction close. For orders up to $1,500, the credit card on file will be charged. For orders over $1,500, payment must be made via bank wire transfer, unless the buyer chooses to use a credit card, in which case a 3% processing fee will apply. For payment-related questions, please contact Sabrina Correa at 209-839-7707. Sales tax exemption documents must be emailed to [email protected] at the time of purchase for tax exemption consideration.