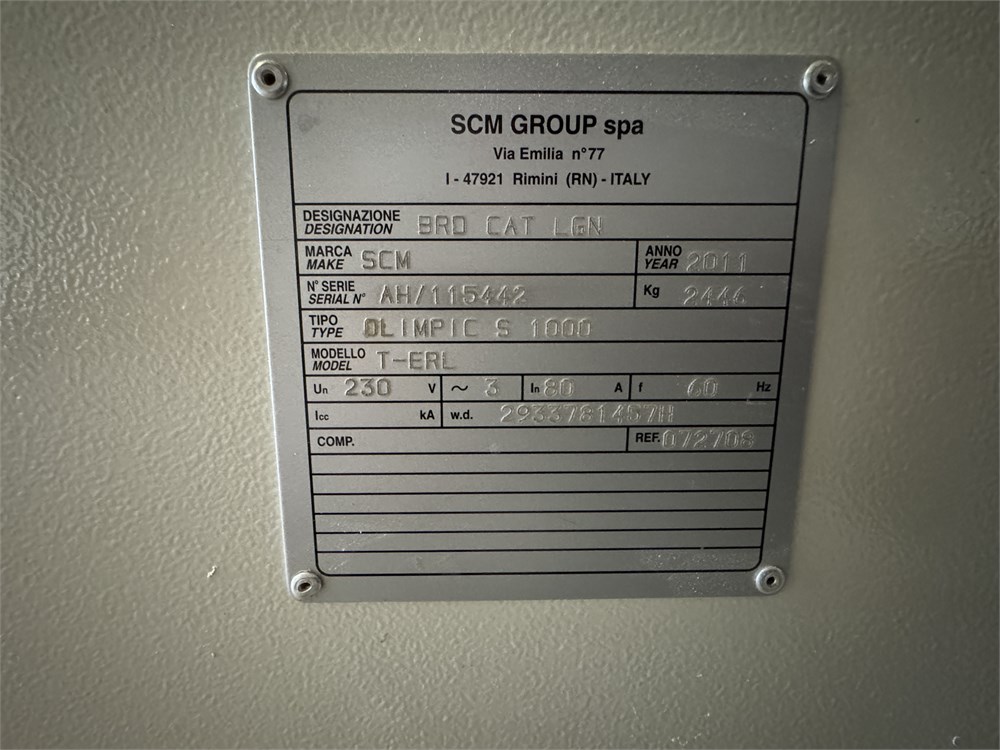

SCM "Olimpic S-1000-T-ERL" Edgebander  Ended

Ended

Woodworking Machinery Auction - Canby, OR

Canby, OR

- Winning Bid : $7,100.00 USD Sold

- 36 Bid(s)

- High Bidder: x****x

Woodworking Machinery Auction - Canby, OR ( Closed #75817051 )

Cabinet manufacturer in the Portland, OR area is auctioning several machines no longer required for continuing operations. SCM edgebander, Omga radial arm saw and more. Please contact me for more information and remember there is no sales tax for Oregon auctions.

-

Pick Up Location

505 NE 3rd. Ave. Canby, OR 97013

-

Make

SCM

-

Model

Olimpic S-1000-T-ERL

-

Serial Number

AH/115442

-

Year

2011

-

Phase

3 PHASE

-

Voltage

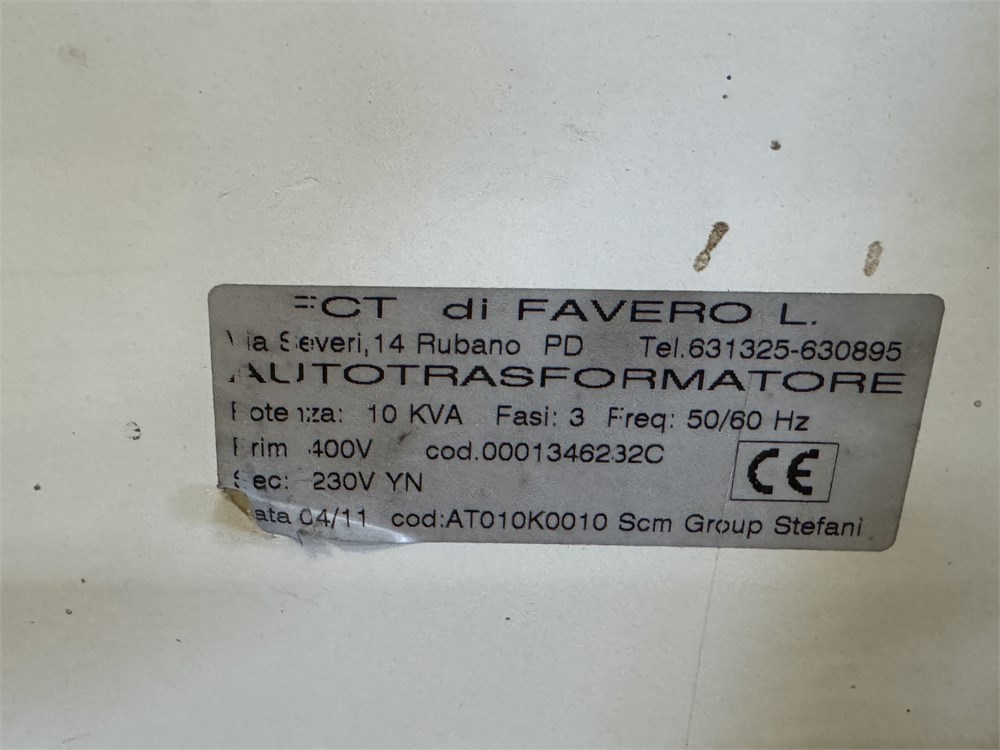

230 VOLT

-

Buyer Inspection Period

By appointment only, contact Jack Ragan, [email protected], 503-806-4611

-

Load Out Period

November 19 - December 5, 2025 (by appointment)

-

Estimated Dimensions

256" L x 42" W x 66" H

-

Estimated Weight

5,500 Pounds

-

Seller Comment

Seller will disconnect and load onto buyer's flatbed truck/trailer for non-negotiable loading fee. Palletizing, crating or other services may be available at an additional cost.

-

Load Fee

150.00

-

Lot Notes

-

page views

463

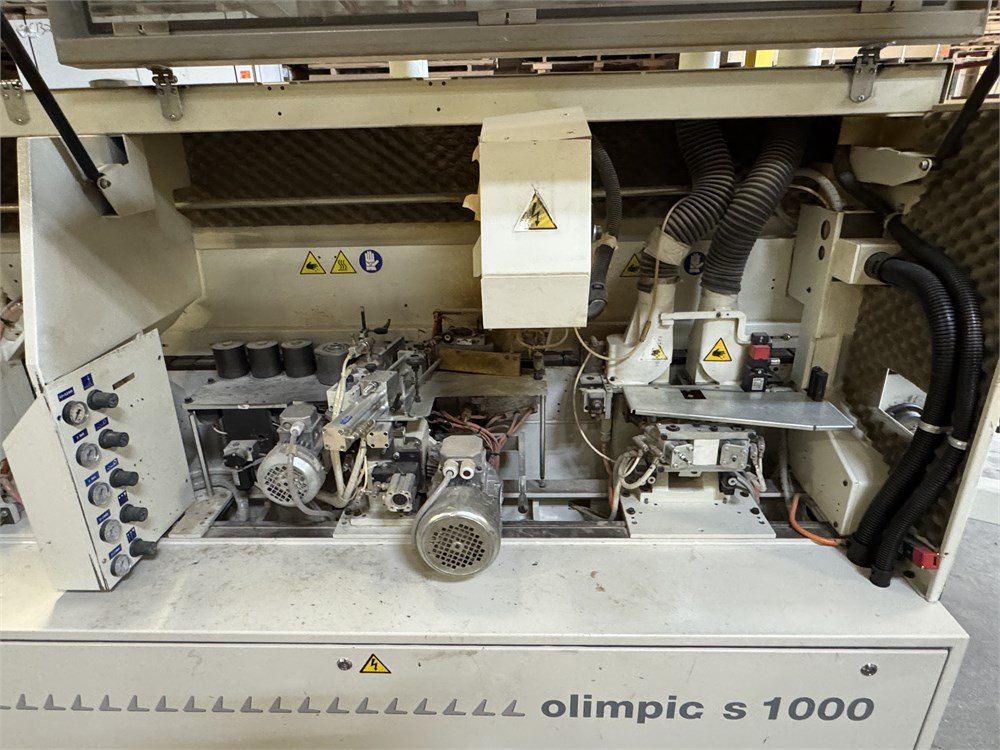

SCM "Olimpic S-1000-T-ERL" Edgebander

Edge Capacity, 0.4 to 15 mm (0.016 to 5/8") for strip feeding.

Panel minimum width 50 mm (2")

Panel minimum length, 140 mm (5-1/2")

Panel thickness, 8 - 60 mm (3/8" - 2-3/8")

Motorized top beam positioning

Centralized lubrication system

Touch screen controller

Edgebanding infeed table

Automatic Strip & Coil Feed Magazine: For straight edges and 3 mm guillotine for coils.

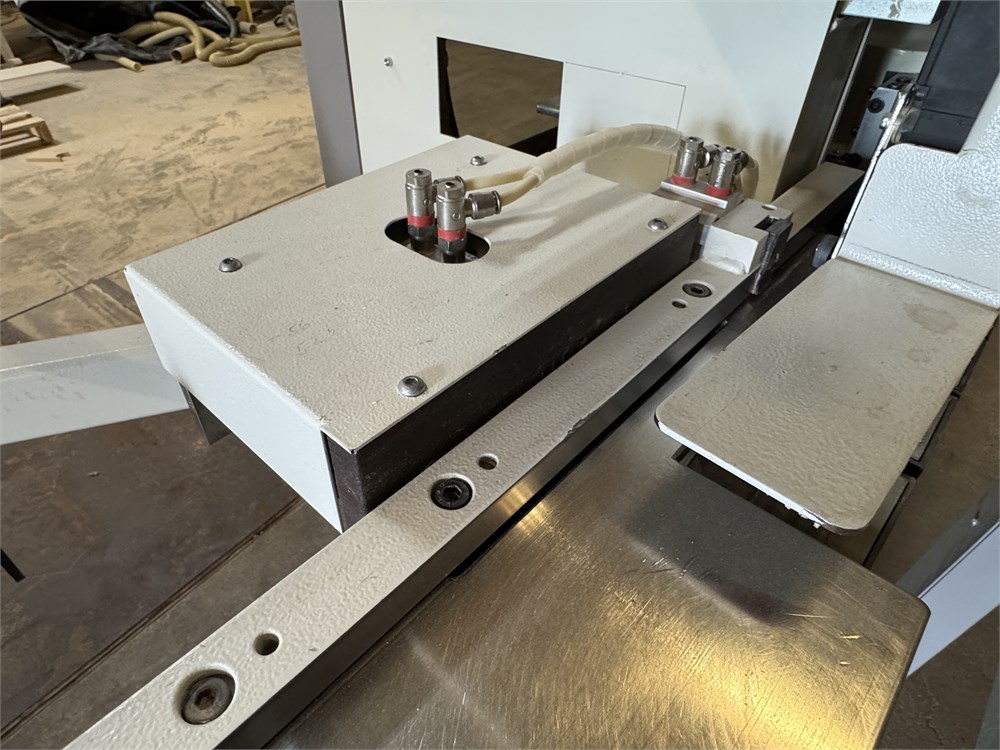

Adjustable In-feed Fence: Manually pre-set with digital indicator and pneumatic panel spacing device.

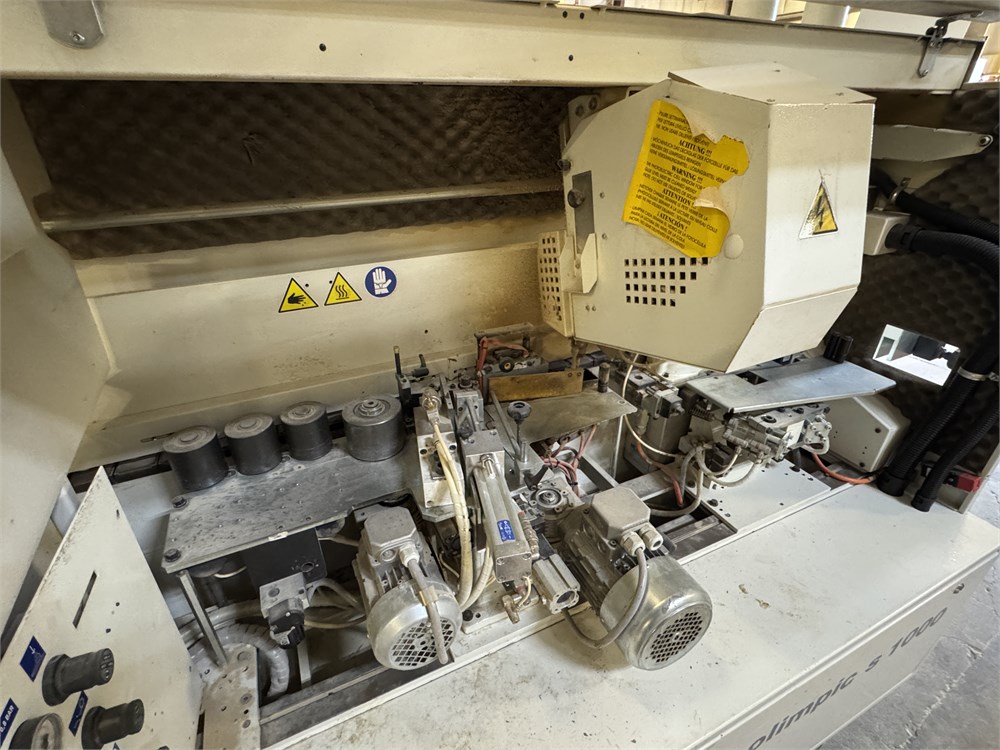

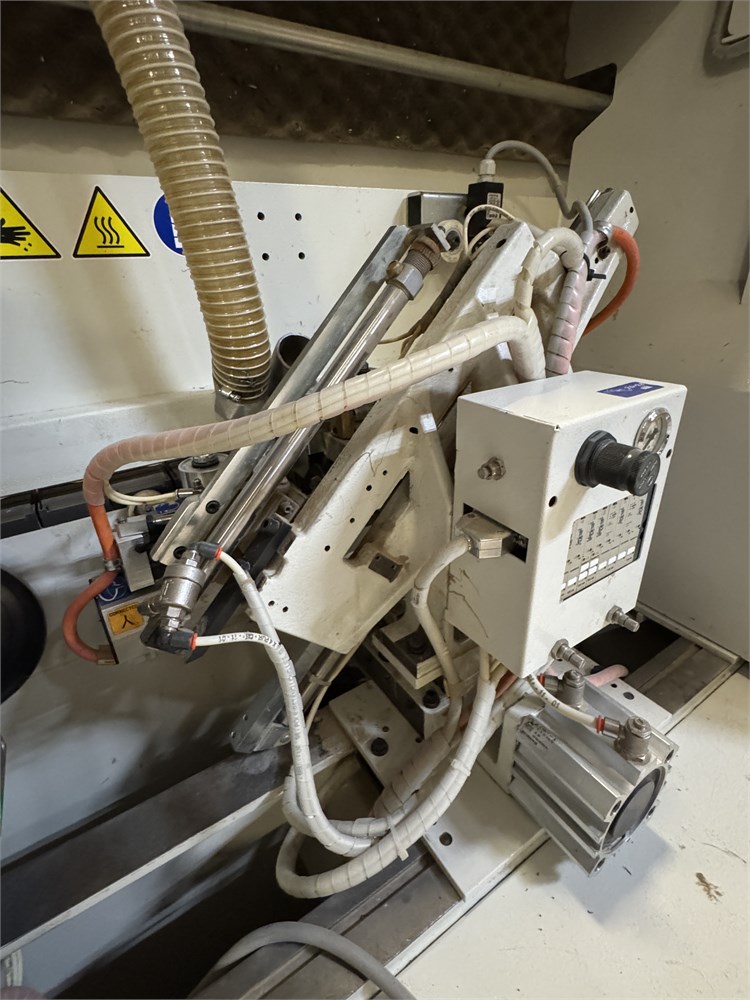

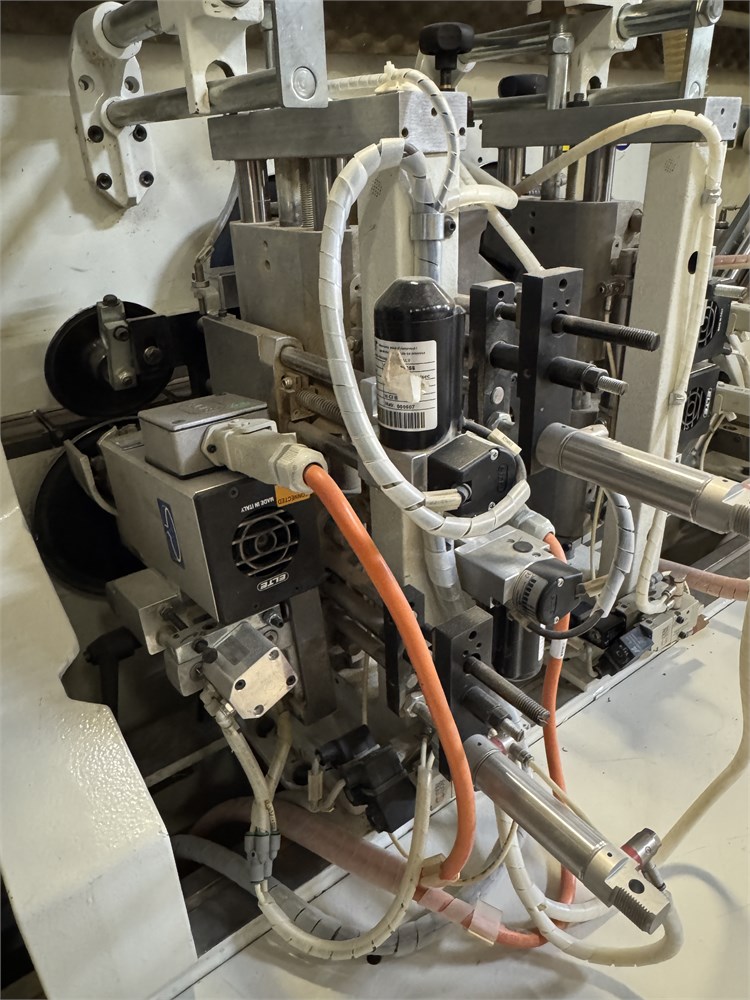

Pre-Milling Station, RT-E: Spindles 2 x 5.25 HP, 12,000 RPM, (1) with PLC controlled jump action and manual digital indicators positioning

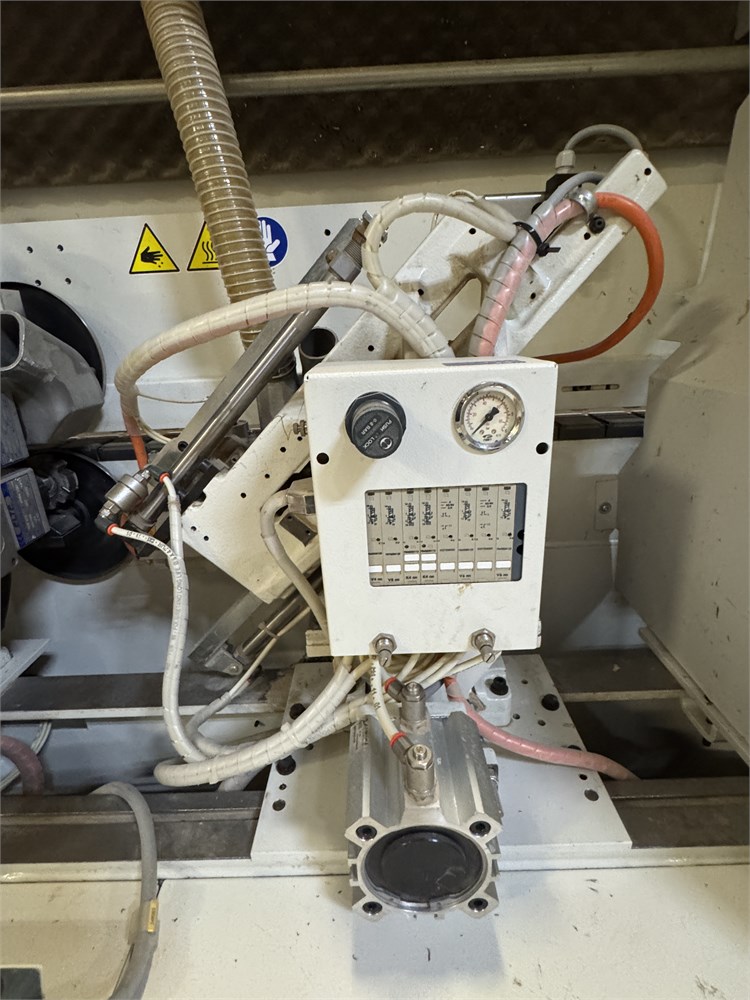

Gluing Station, Vc/1000: For EVA (Hot Melt) with Teflon coated glue tank and quick disconnect to change glue tanks fast if needed. Pre-melt hopper.

Pressure Section: Servo motor positioning, (4) pressure rollers, first larger, Teflon coated and powered.

End Trimming Station K-SEL: Front & rear 2 x 0.5 HP, 12,000 RPM motors mounted on THK guides, swivels 0° - 15°, rapid set up between straight and angled cutting with the automatic swivel cylinder.

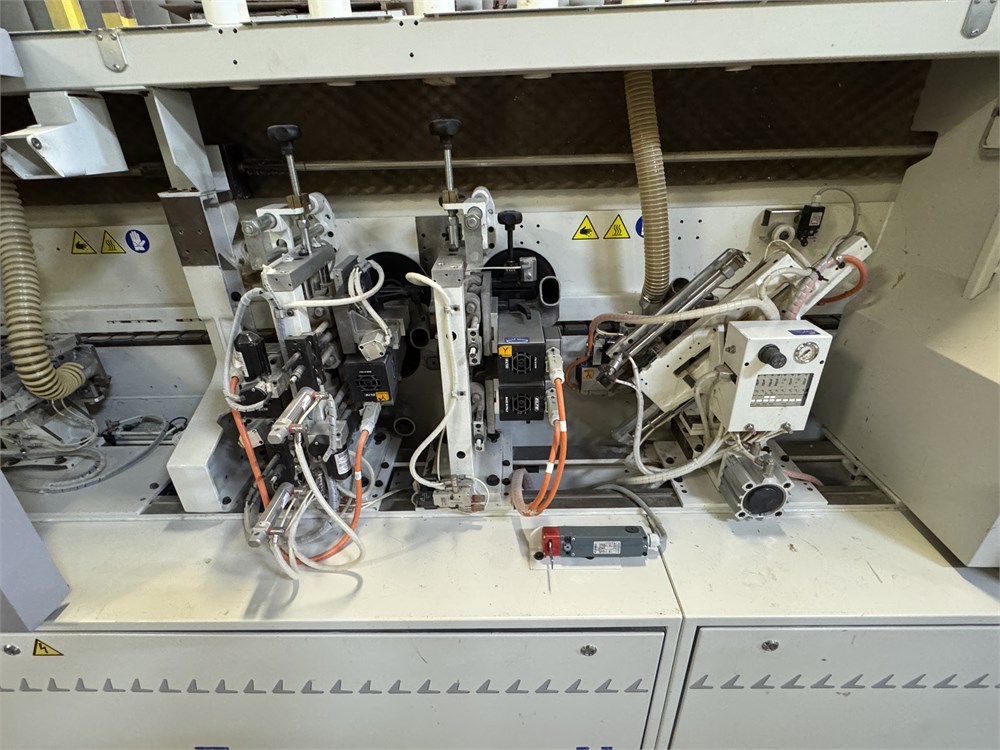

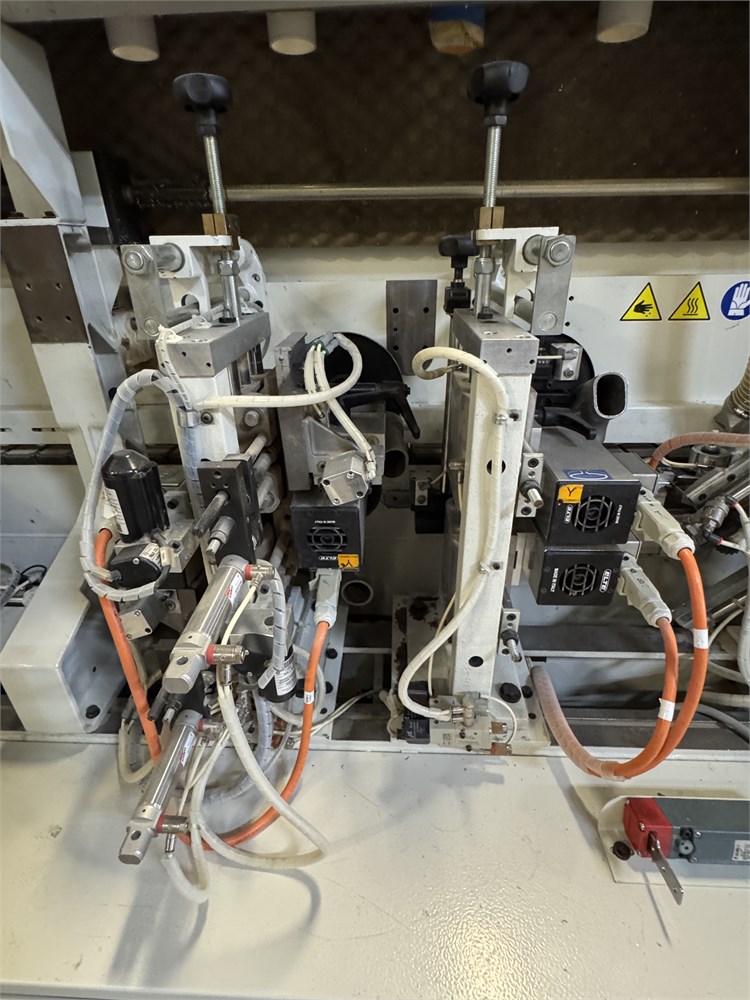

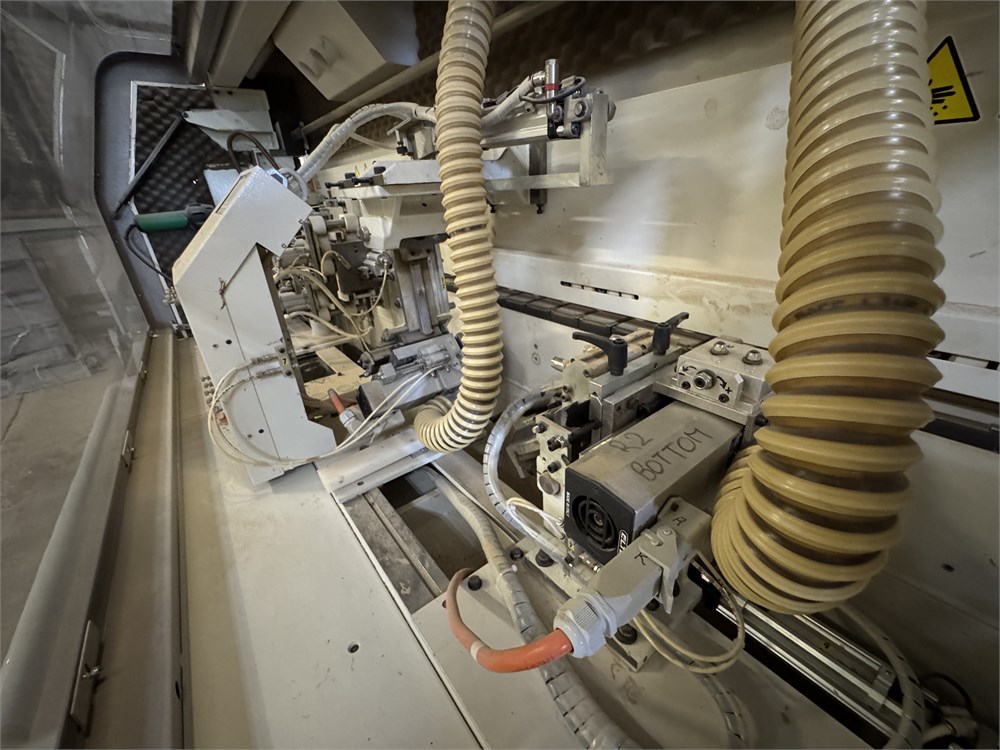

Flush Trimming Unit, Rsp: Top/Bottom, 2 x 1.5 HP, 12,000 RPM with 2 pre-set pneumatic positions, flush and overhang, remote pneumatic in/out positioning.

Bevel/Radius Trimming Unit, Ri/S: Programmable, servo motor positioning, 2 x 1.0 HP - 12.000 RPM motors for change-over on the fly.

Corner Rounding / Trimming Unit, Round-K: For additional top & bottom trimming of linear an/or vertical leading & trailing corner when edgebanding all (4) sides, 2 x 0.8 HP - 12,000 RPM motor. Comes with (2) pre-set pneumatic positions to allow to go from thick to thin pvc automatically.

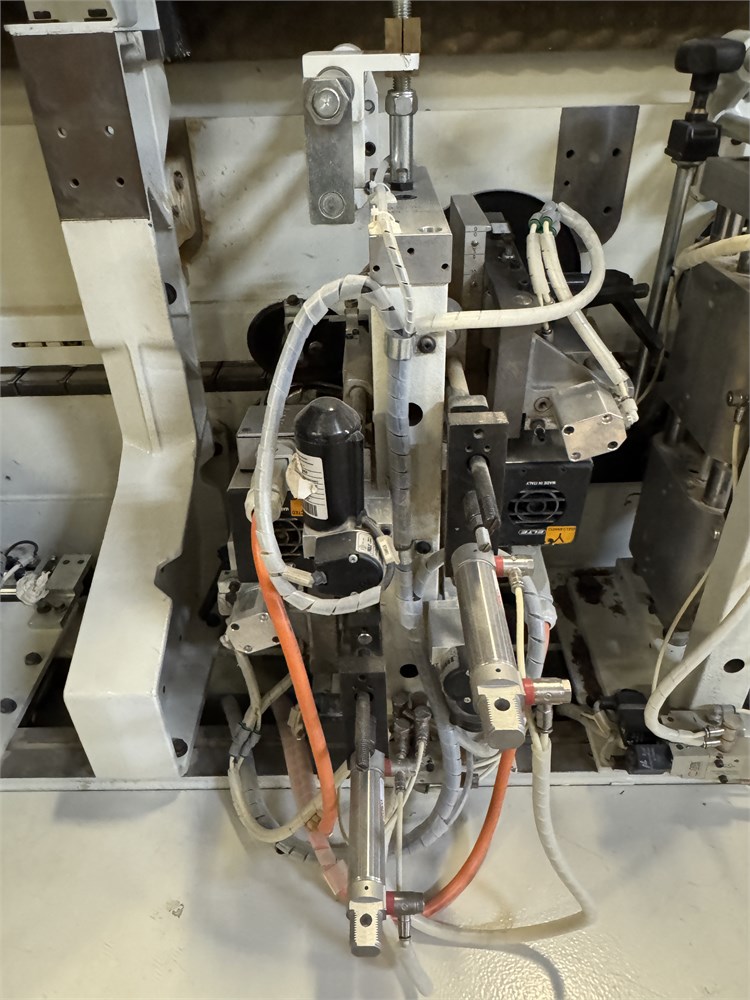

Profile Scraping Unit "RAS/1000": Top/Bottom with (2) indexed manual pre-sets. Large dia. copy wheels for max. accuracy and pneumatic in/out positioning.

Glue Scraping Unit, "Rca/2c": Top/bottom flat glue scraper with pneumatic positioning through controller and air-blow off nozzle to keep the knifes clean.

Buffing Unit "SPN": Top/bottom, oscillating 2 x 0.25 HP - 3,000 RPM motors, tilting up to 12°.

Hot Air Unit: Single blower with adjustable heat range and directional heat shield for top/bottom coverage. Restores color luster on thick pvc edging materials that may be lost during the edge scraping process.

Sound enclosure

Outboard roller support

External electrical transformer

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available