Morbidelli "N200-3615 Cell" CNC Machining Center with Auto Load/Unload  Ended

Ended

Complete Woodworking Shop Auction - Oakland, CA

Oakland, CA

- Winning Bid : $52,000.00 USD Sold

- 206 Bid(s)

- High Bidder: e****k

Complete Woodworking Shop Auction - Oakland, CA ( Closed #74452820 )

After decades in business East Bay Fixtures has ceased operations and is auctioning all assets. Morbidelli CNC router with load/unload system, Busellato CNC router, Omal CNC bore/dowel machine, edgebanders, forklifts, vehicles, raw materials and more.

-

Pick Up Location

941 Aileen St. Oakland, CA 94608

-

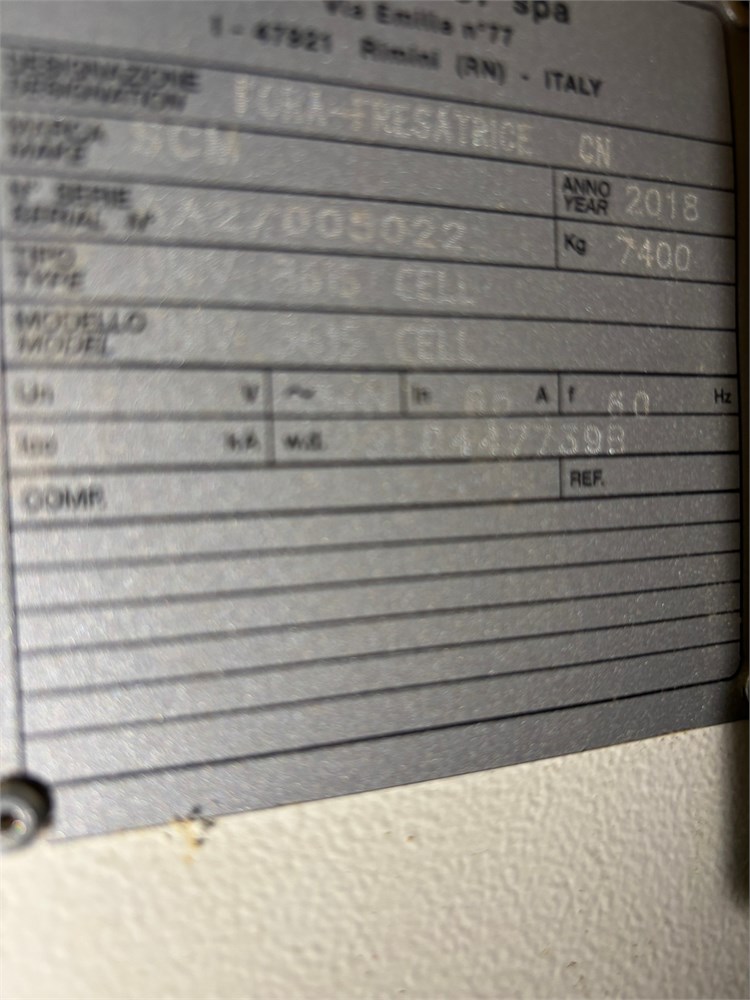

Make

Morbidelli

-

Model

N200-3615 Cell

-

Serial Number

AA2/005022

-

Year

2018

-

Phase

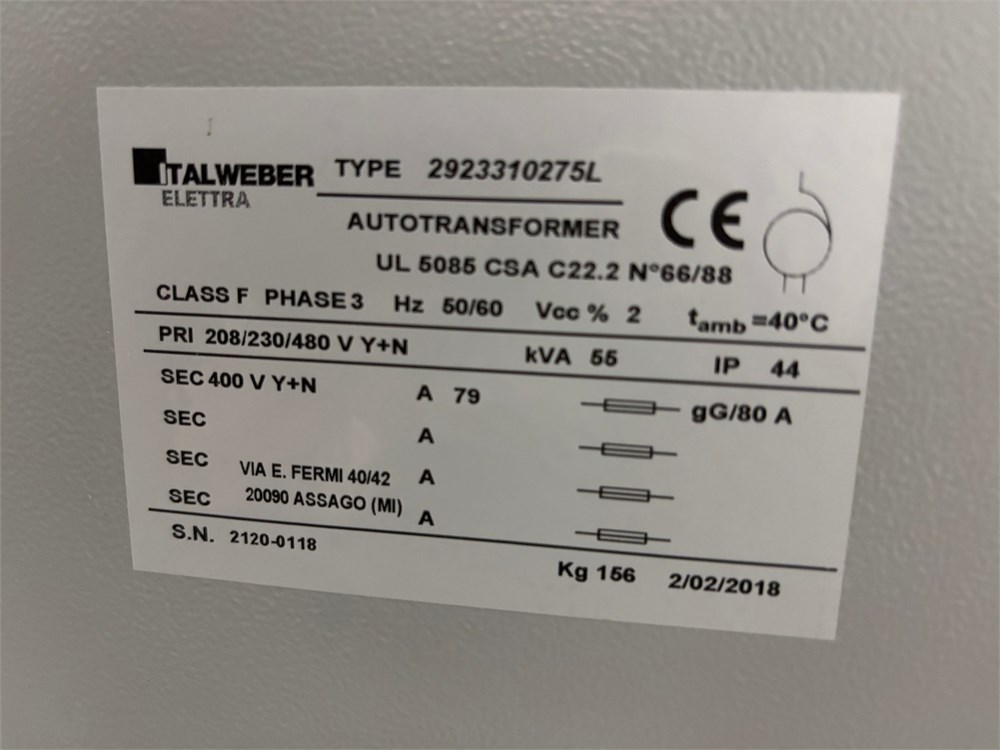

3 PHASE

-

Voltage

208-230/460

-

Buyer Inspection Period

Sept 9, 2025 (9 am - 3 pm) please contact Juan Fabian @ 209 -704-4305, [email protected] for details

-

Load Out Period

Sept 15 - 19, 2025 (By Appointment Only)

-

Estimated Dimensions

See photos and description

-

Estimated Weight

15,000 lbs

-

Seller Comment

Buyer responsible for prep, loading, and shipping or hiring a rigger to do so.

-

Load Fee

-

Lot Notes

This lot requires a rigger

-

page views

2219

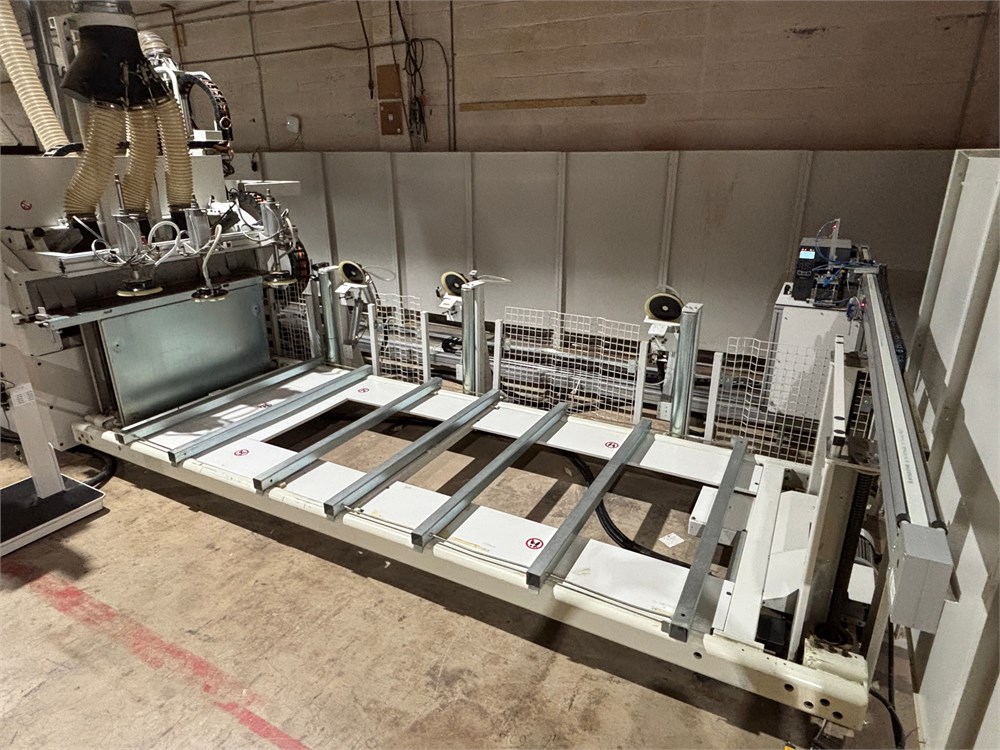

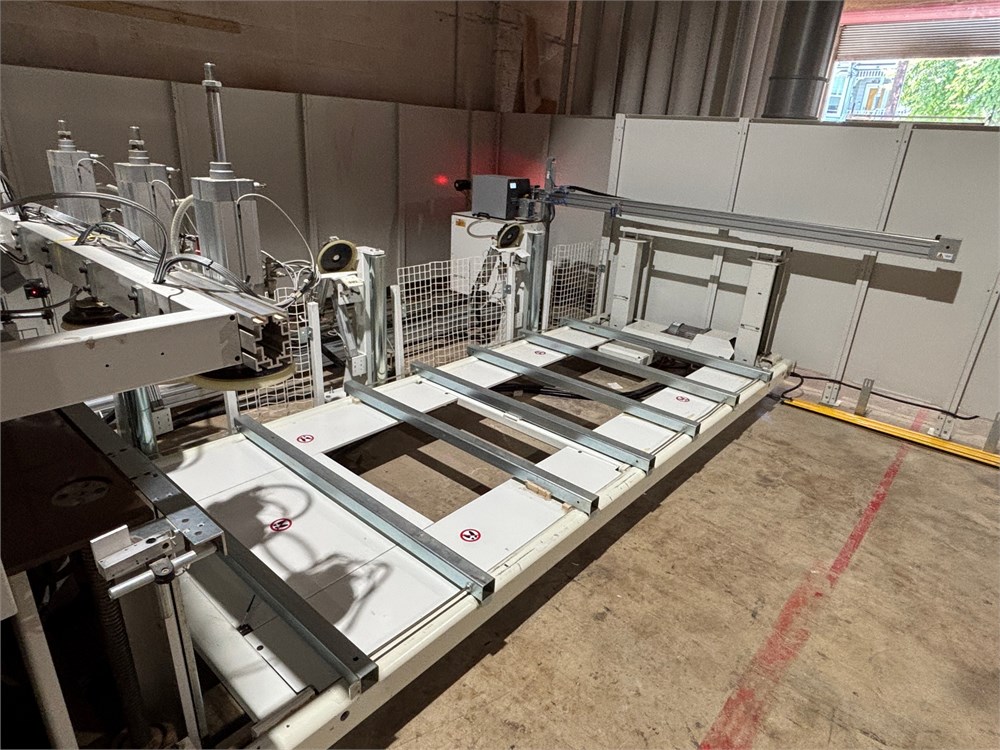

Morbidelli "N200-3615 Cell" CNC Machining Center with Auto Load/Unload

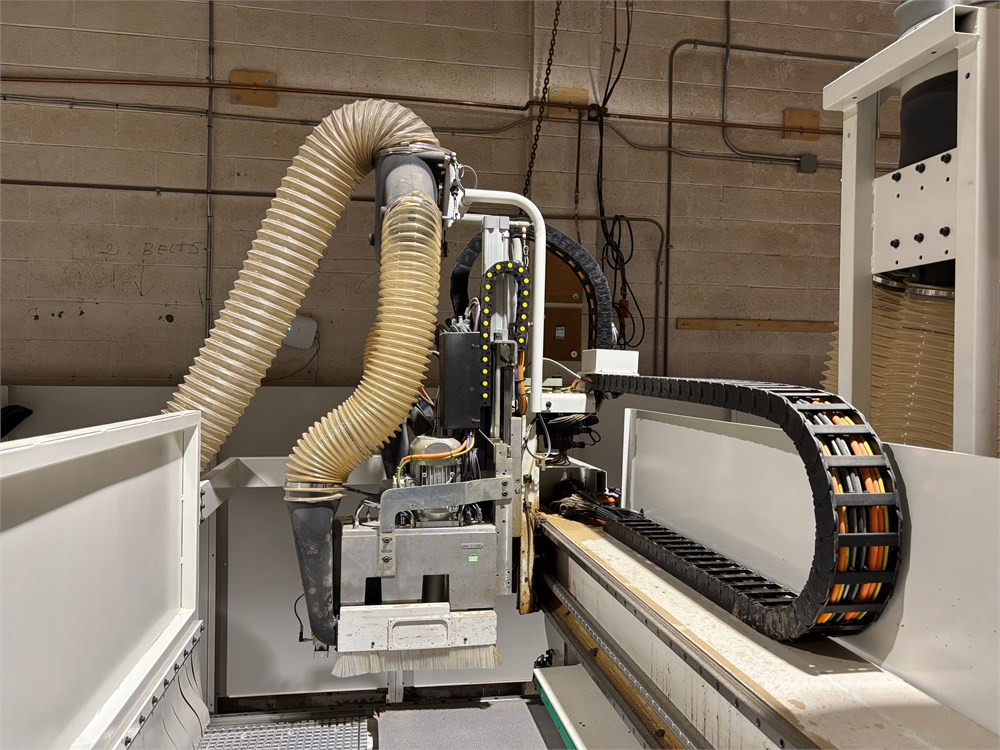

5' x 12' Traveling "Bridge Gantry", stationary aluminum grid "MATRIX" table with square grid pattern for fixturing parts; (8) vacuum zones controlled by electronic switches. 216" L x 96" W x 106" H overall dimensions.

Grid pattern allows use of vacuum pods or closed cell rope gasketing material and use of spoilboards for "nested base machining", part location pop-up pins mounted on the table perimeter.

"X" axis is 143.7" (3,686 mm); "Y" axis is 61.2" (1,555 mm); "Z" axis stroke is 9.4" (240 mm); max. material thickness 5.9" (150 mm) (5.1" / 130 mm when using off-loading system).

"X" axis 229 FPM (70 MPM), "Y" axis 197 FPM (60 MPM) ,"Z" axis at 49 FPM (15 MPM); closed loop AC servo drive system.

High precision "Rack & Pinion" system in "X" axis & ground ball screws in "Y" and "Z" axes; all axes ride on extra large precision profile linear guide-ways.

Foot pedal operation

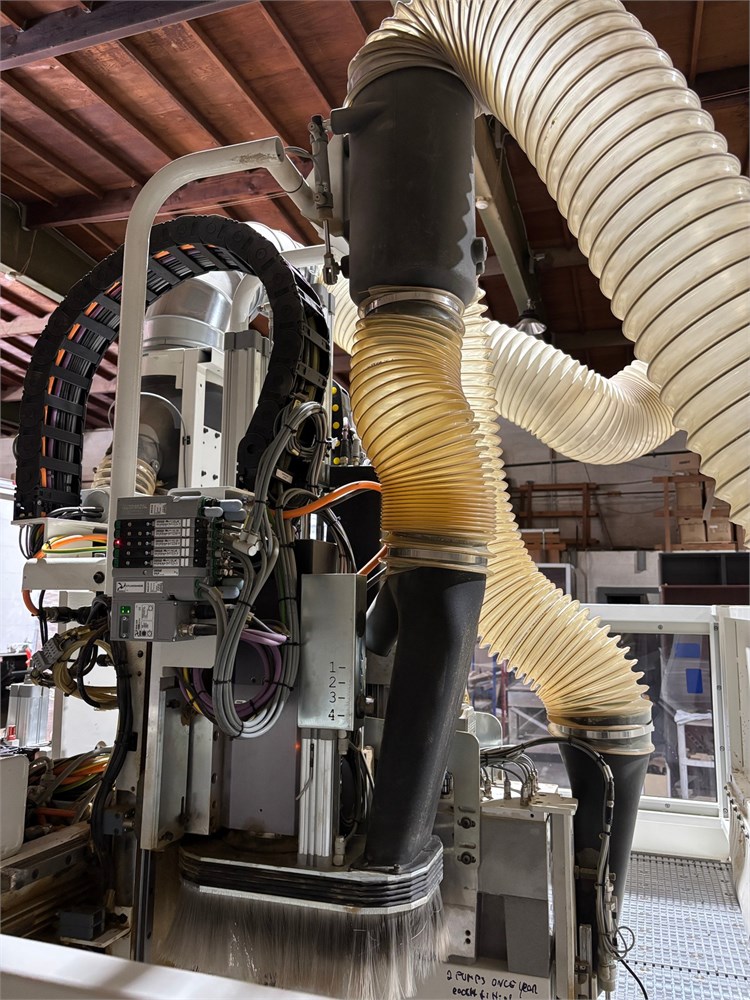

Drill unit

3 HP motor, variable speed from 1,000 - 6,000 RPM; (18) independent vertical spindles on 32 mm centers

(4) Horizontal spindles with (2+2) in "X" axis; (4) Horizontal spindles with (2+2) in "Y" axis; "X" axis grooving saw for max 120 mm dia blade.

One (1) 15 HP air-cooled electro spindle with HSK F63 adaptor; variable spindle speeds from 1,500 - 24,000 RPM;

Sound enclosure

Twenty (20) position lateral tool changer mounted on rear of machine

Air-conditioned electrical cabinet

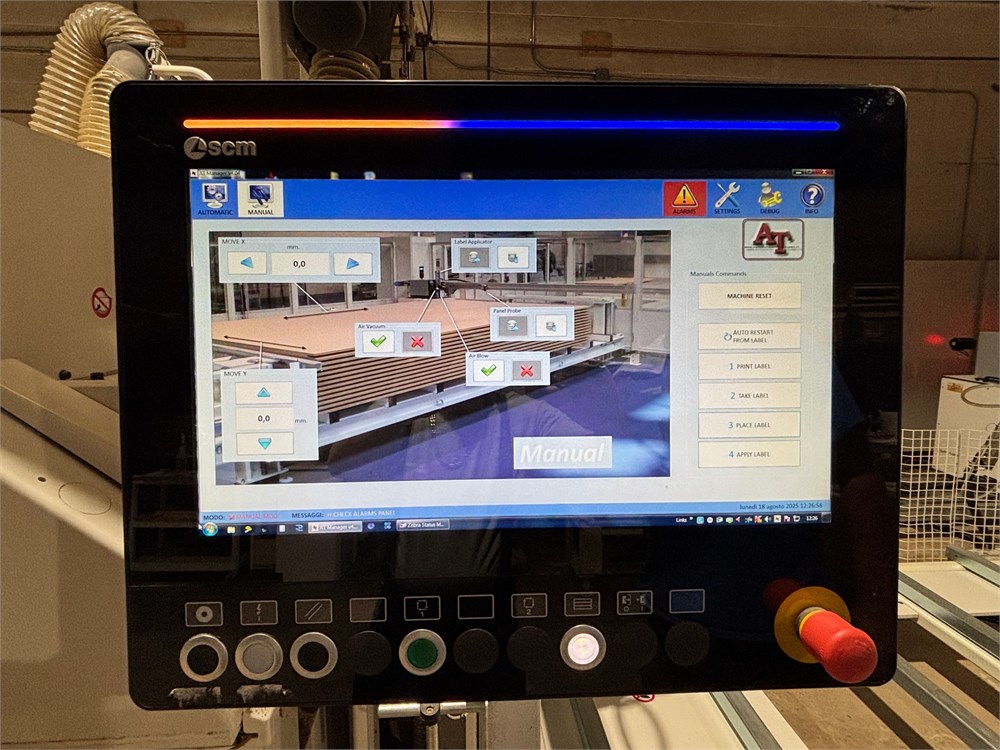

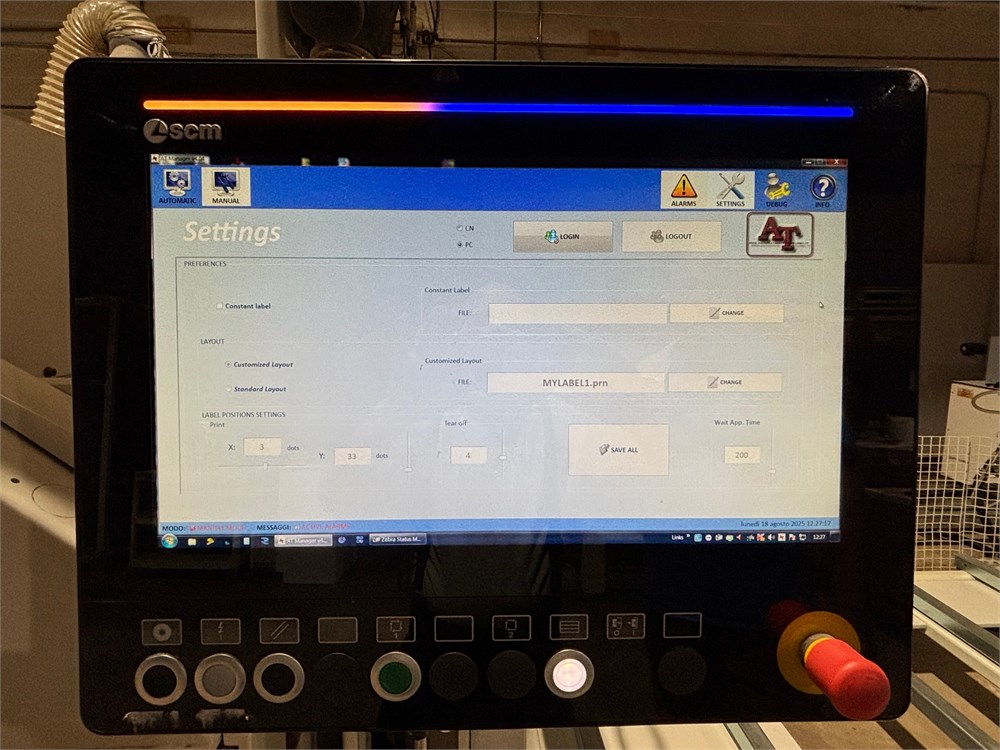

PC Front-End with: "XILOG Plus" + Windows "XP PRO" operating system;

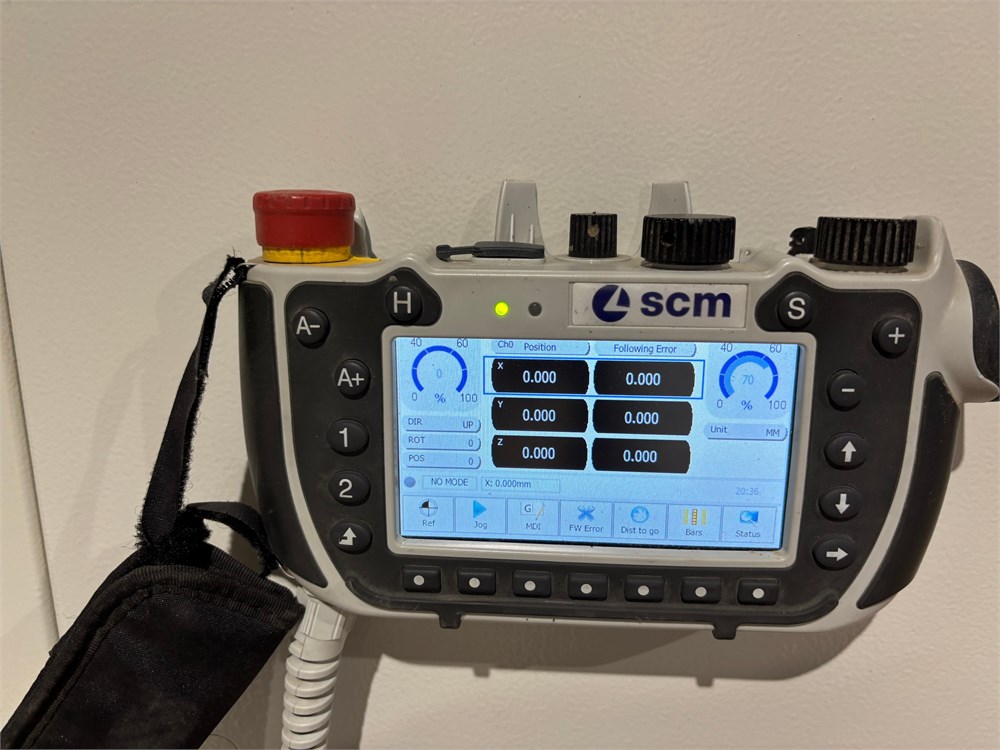

Remote control pendant

Standard keyboard and mouse

USB Ports, serial ports RS-232 & RS-242 & Ethernet adaptor; programs can be transferred via disk or downloading by wire is possible; all computer components are mounted on a mobile stand.

Centralized lubrication system

Front safety photo eyes

Safety fencing with interlocked access door

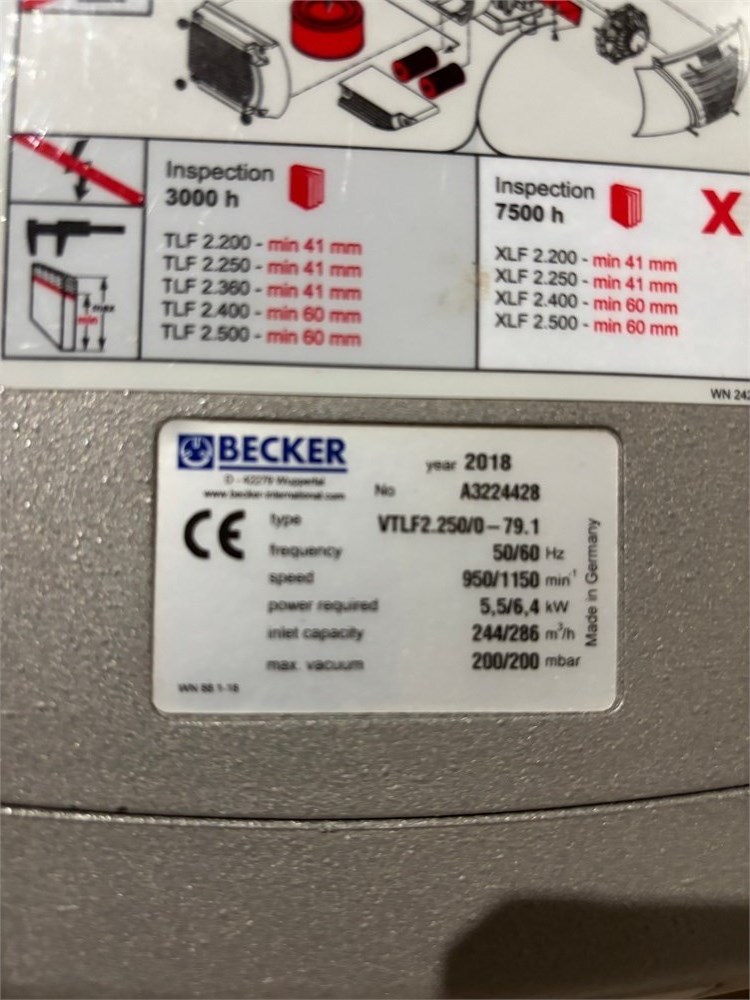

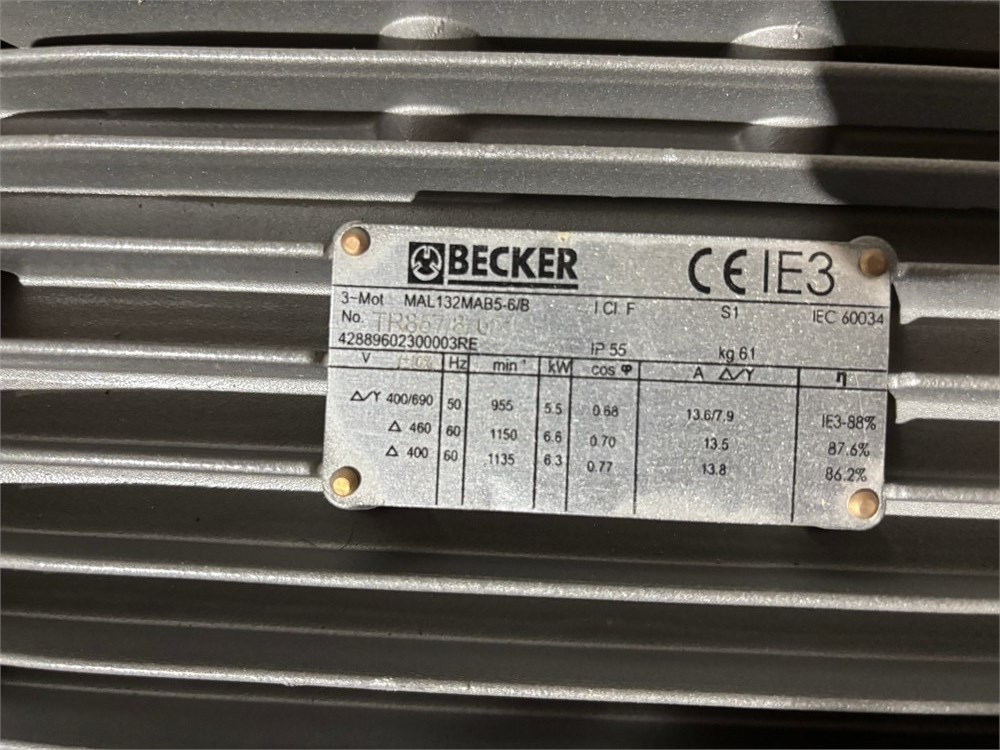

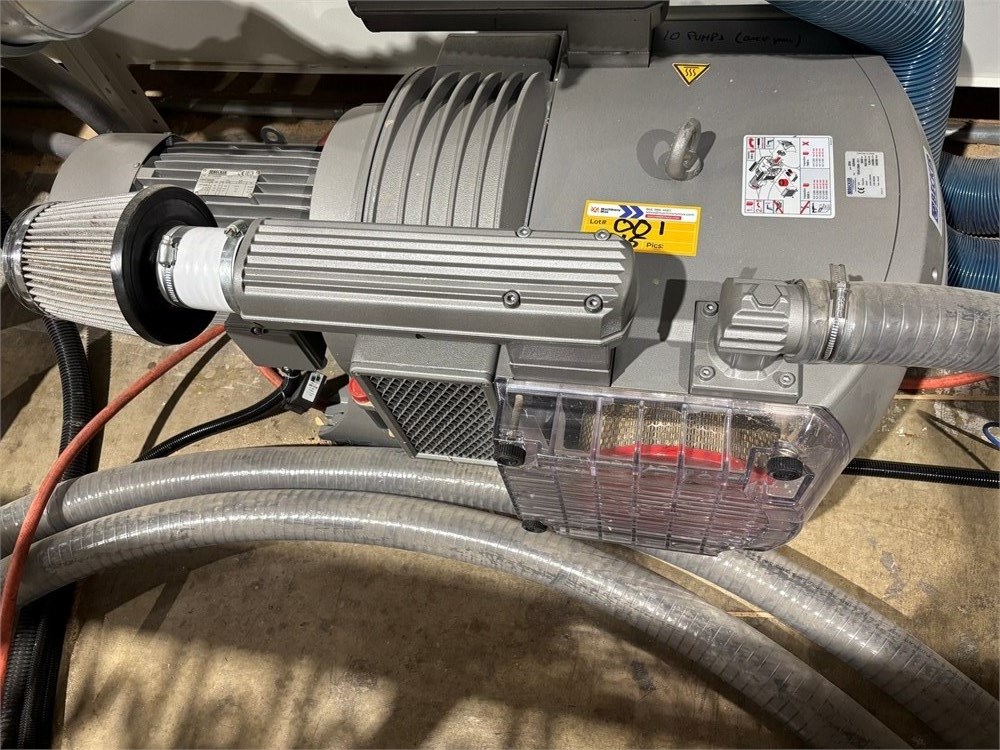

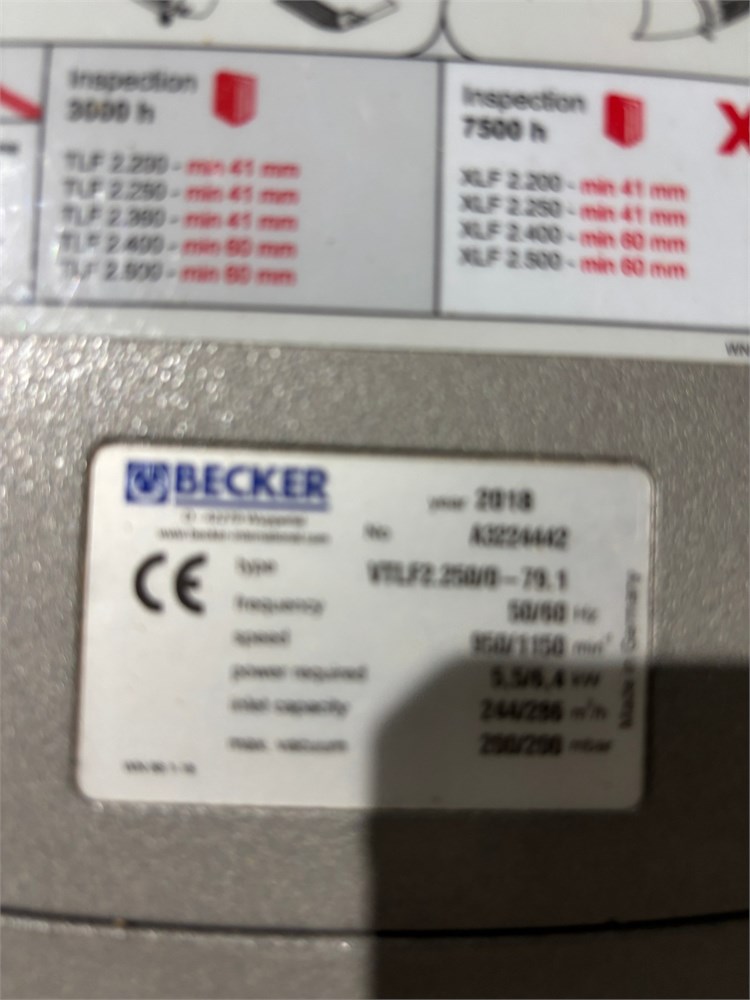

Two (2) Becker "VTLF-2.250/0-79.1" vacuum pumps, 8.5 HP (each), 286 m/hr. capacity (each)

External electrical transformer

Tool holders and tooling included

Manuals and accessories as photographed

Automatic infeed

176" L x 80" W x 72" H overall dimensions, Scissor lift, Photo eye at infeed onto machine. Three (3) side mounted vacuum cups and rollers, control box for manual or automatic operation.

Loading device with three (3) vacuum cups for loading panels onto machine, automatic dust blast gates to clean table in advance of next panel

Automatic labeling system

Automatic outfeed:

Pusher/rake device on machine to push cut parts onto outfeed conveyor

192" L x 65" W x 40" H overall dimensions, 62" belt width, photo eye at end of belt, side fences, control box for manual or automatic operation.

Bottom-mounted dust plenum

Overhead dust collection ducting

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available