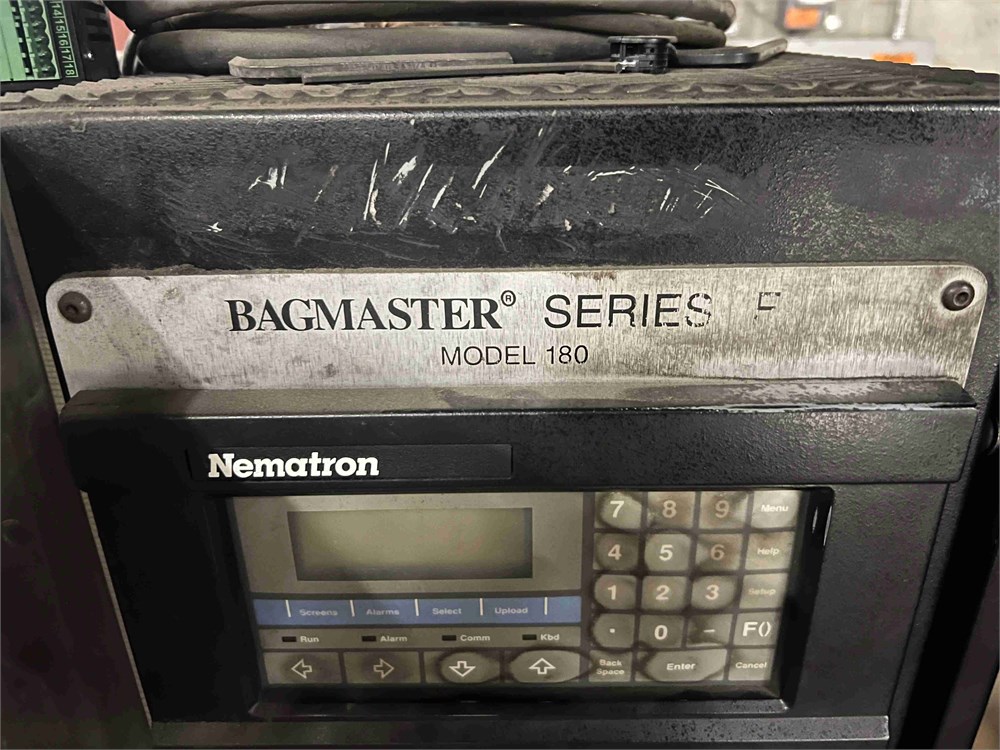

Bagmaster Series F "Model 180" Bagging Machine  Active

Active

DAY 1 of a 4-Day Sale

Tiffin, OH

- Current Price : $1,000.00 USD ( ) No Reserve

- 1 Bid(s)

- High Bidder: t****p

Dorel Home Furnishings - Ameriwood - Day 1 ( Active #73252952 )

Day 1 Features large selection of Woodworking machines including: Weinig Unit 23E Moulder, Holzma HPP350 Beam Saw, Harlan Creative Automation Laminating Line, 6 Forklifts, 200HP Torit Dust Collector, Edgebanders, CNC Routers, Creative Automation Angular Beam Saw, Roller Conveyors, Pallet Racing, plus much more!

-

Pick Up Location

458 2nd. Ave. Tiffin, OH 44883

-

Make

Bagmaster Series F

-

Model

Model 180

-

Serial Number

-

Year

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Buyer Inspection Period

September 16, 2025 8AM - 4PM & September 17, 2025 7AM - 11AM

-

Load Out Period

September 25 - October 9, 2025 By Appointment ONLY!

-

Estimated Dimensions

48' x 8' x 15'

-

Estimated Weight

10,000 pounds +

-

Seller Comment

Buyer responsible for disassembly, take down, packing & loading.

-

Load Fee

0.00

-

Lot Notes

-

page views

108

Bagmaster Series F "Model 180" Bagging Machine

This machine is designed to operate with plain flat film to form a maximum bag width of 6 inches. The width of the bag is determined by the forming tube diameter. The position of the film roll on its mounting determines the overlap centering on the forming tube.

The vertical jaw seals the overlap. Film is then drawn and the horizontal jaws close. The sealing bar is engaged to produce the upper horizontal seal of the current bag and the lower seal of the next bag. The cutting knife then separates the bags. Cooling air is applied to the seals. Horizontal jaws open and the process is repeated.

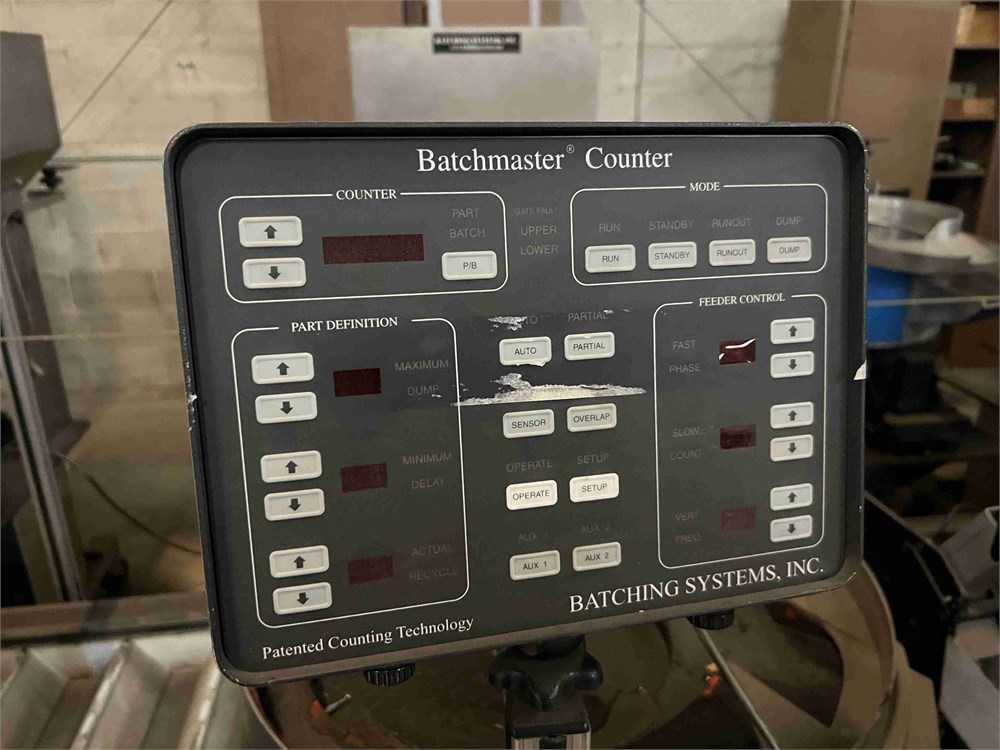

15 parts bins

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available