Holz-Her "Contriga 1368" Edgebander  Ended

Ended

Holz-Her "Contriga 1368" Edgebander - Salt Lake, UT

Murray, UT

- Winning Bid : $7,300.00 USD Sold

- 56 Bid(s)

- High Bidder: C****1

Holz-Her "Contriga 1368" Edgebander - Murray, UT ( Closed #73241682 )

Woodworking company in Salt Lake, UT is auctioning a Holz-Her edgebander no longer required for continuing operations.

-

Pick Up Location

4730 Riverside Dr. Murray, UT 84123

-

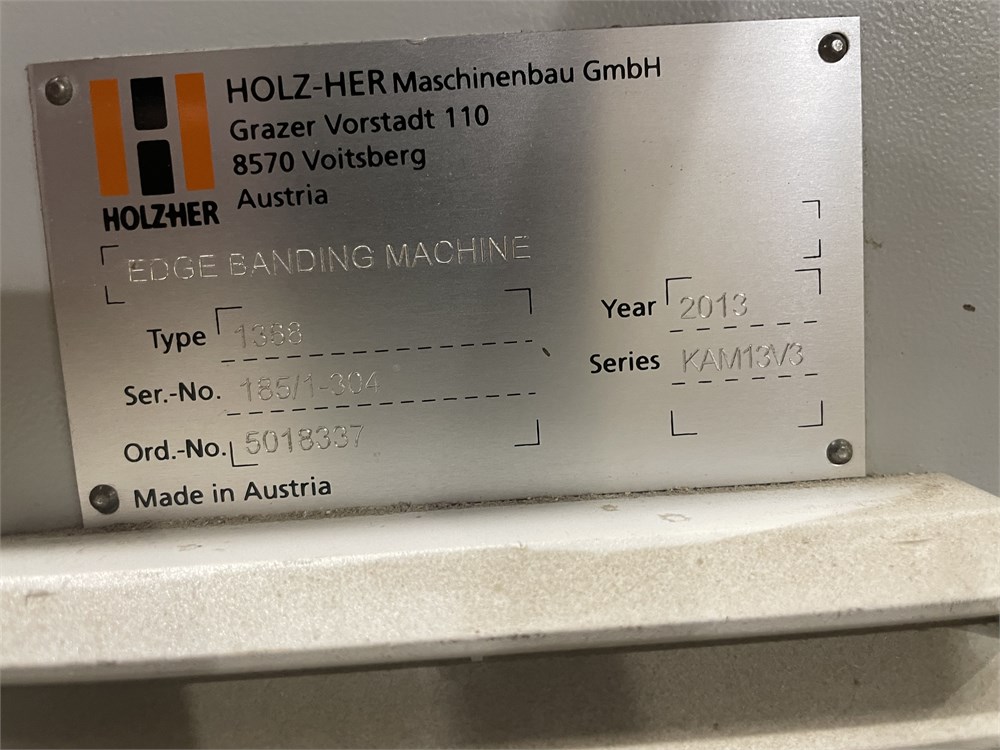

Make

Holz-Her

-

Model

Contriga 1368

-

Serial Number

185/1-304

-

Year

2013

-

Phase

3 PHASE

-

Voltage

220 VOLT

-

Buyer Inspection Period

By appointment only, contact Jack Ragan, [email protected], 503-806-4611

-

Load Out Period

September 8, 2025 (one day load out only)

-

Estimated Dimensions

360" L x 60" W x 90" H

-

Estimated Weight

-

Seller Comment

Seller will disconnect and load onto buyer's flatbed truck/trailer for non-negotiable loading fee. Palletizing, crating or other services may be available at an additional cost.

-

Load Fee

250.00

-

Lot Notes

-

page views

1493

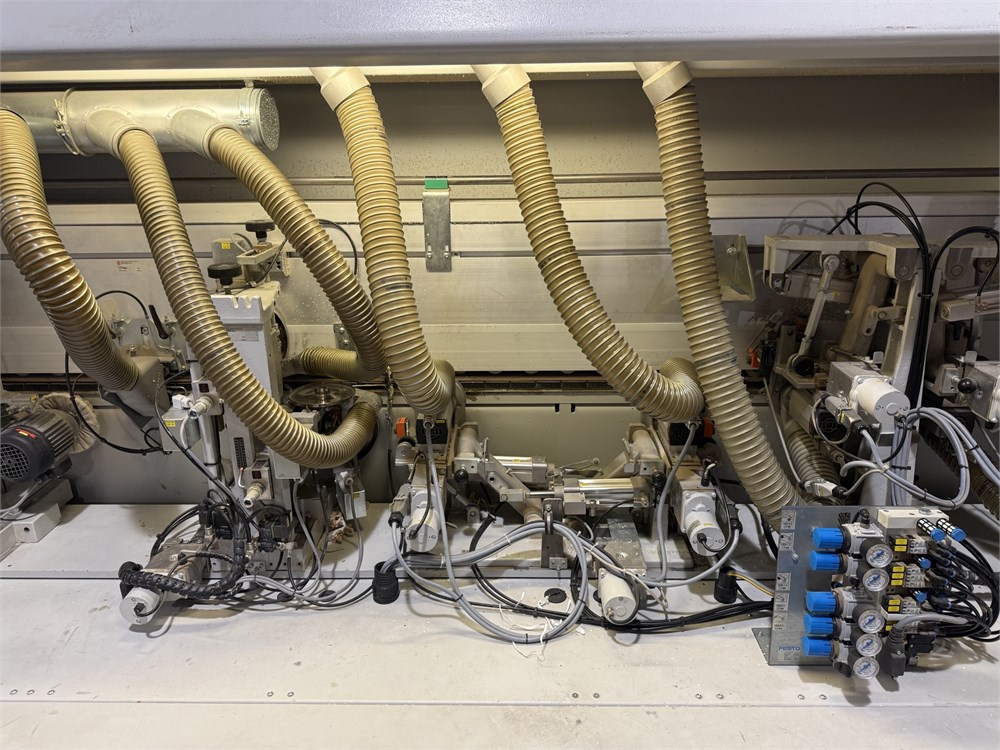

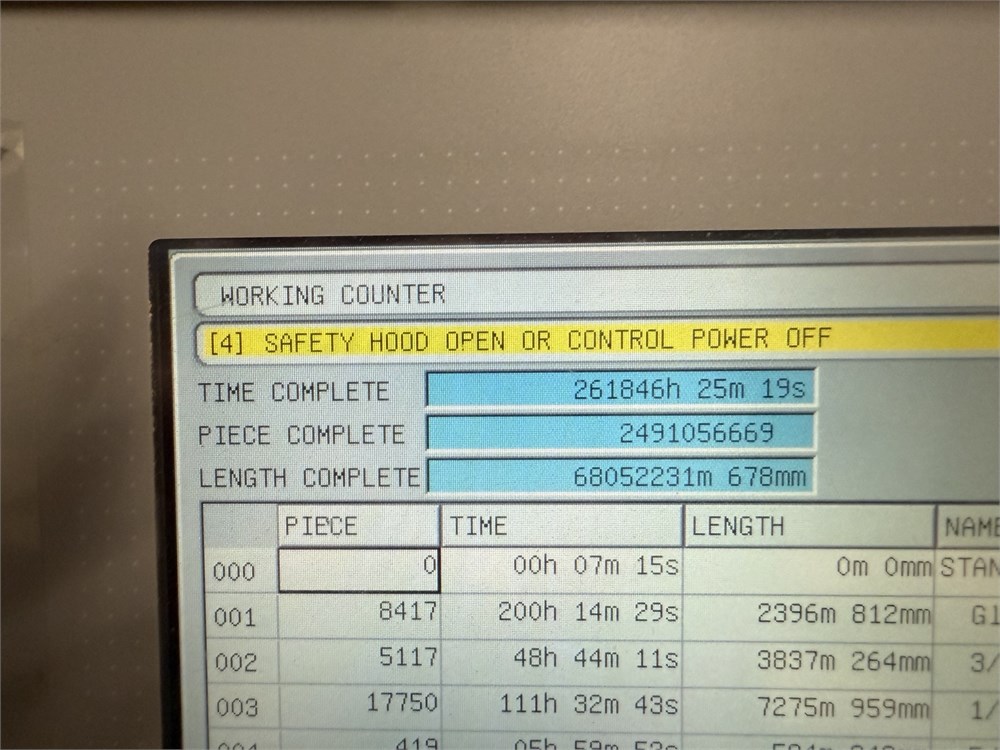

Holz-Her "Contriga 1368" Edgebander

3 mm PVC capacity

30 mm wood strip capacity (may require additional station setup, etc.)

2-3/8" maximum panel thickness

7" minimum panel length

Panel overhang beyond chain 35 mm (1.38")

Powered pressure beam height adjustment

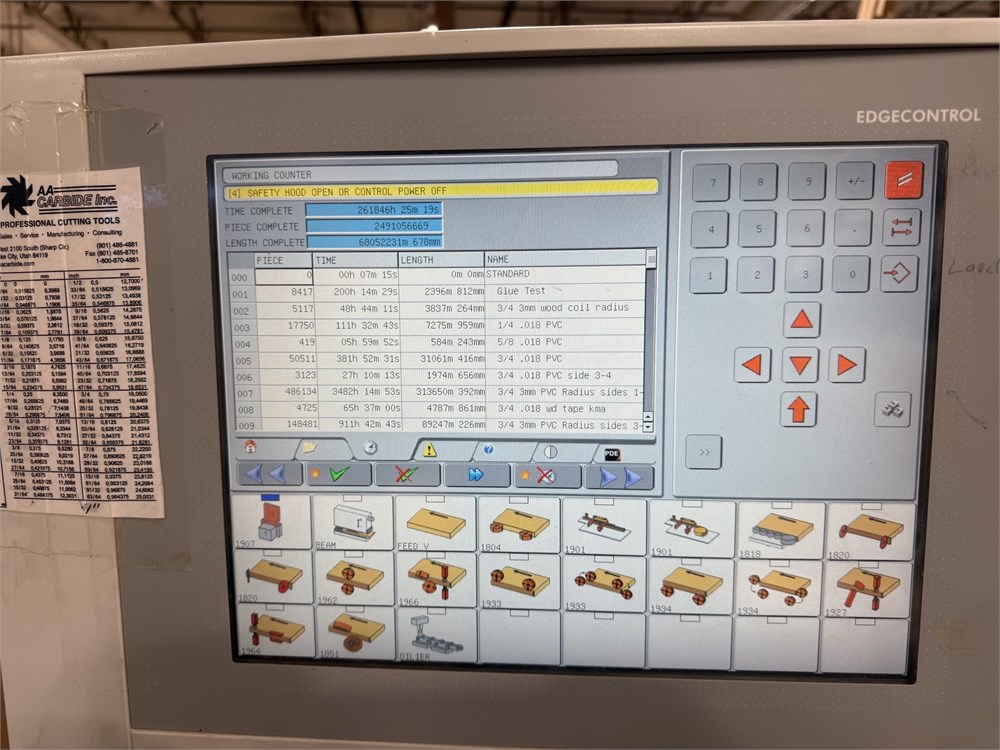

Variable feed speed up to 98 FPM

Automatic track pad lubrication

PC Controller; has the ability to program all functions including: panel thickness, edge feed, glue application, end trimming, radius/fine trimming, corner rounding, scraping and buffing. Virtually eliminates set-up time by selecting & loading program that automatically activates these functions simultaneously.

Edgebanding infeed table

Infeed fence

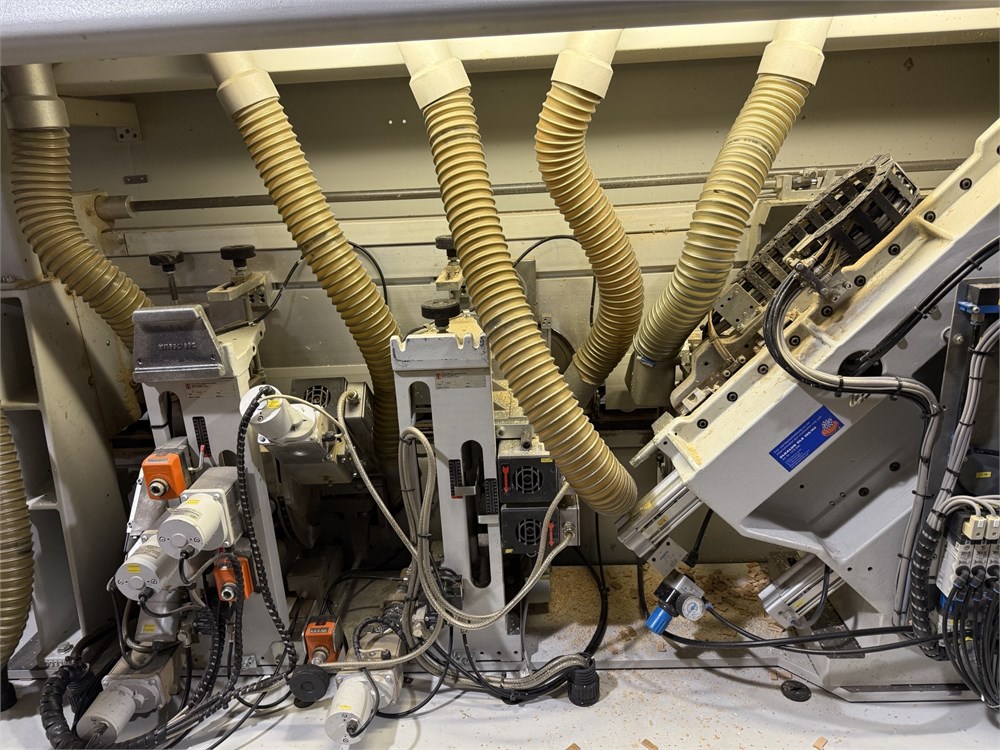

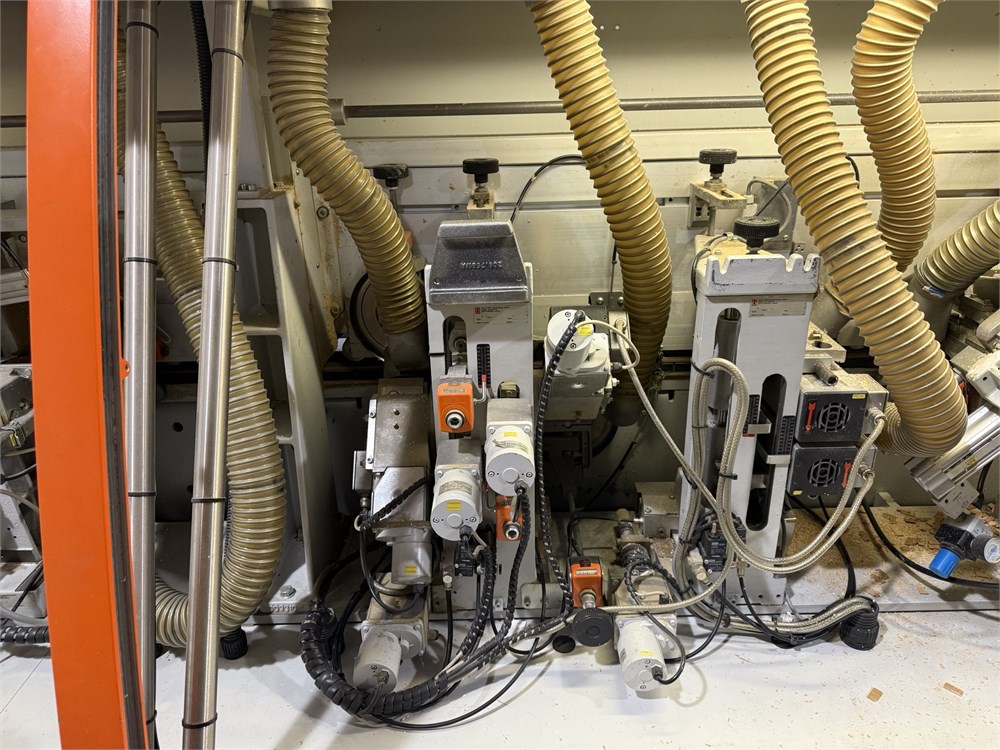

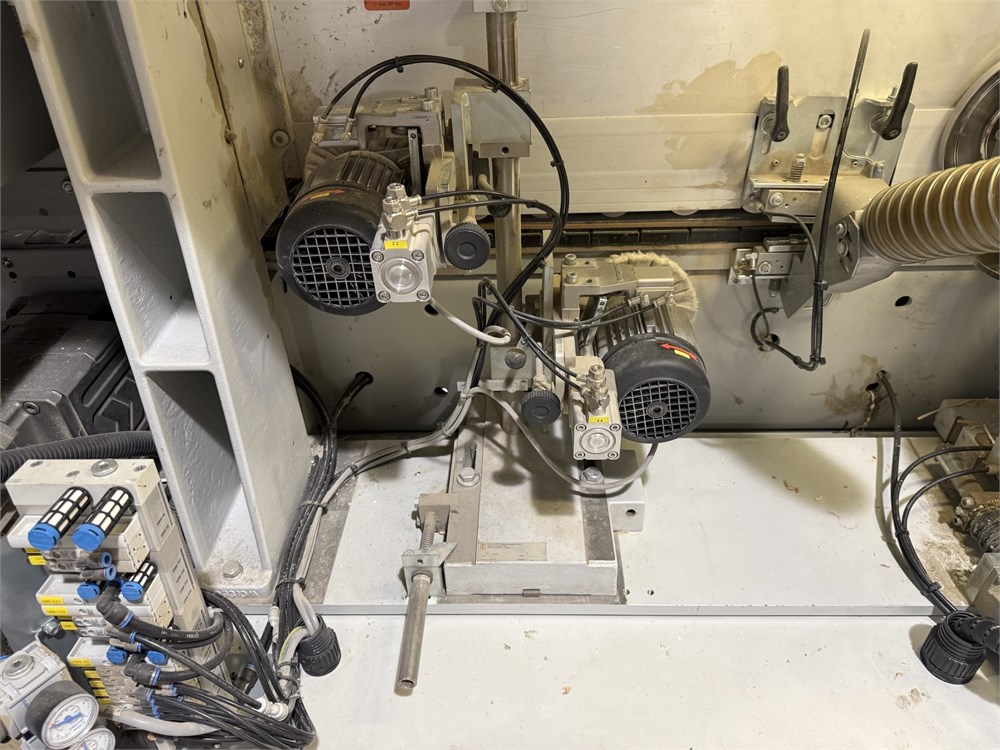

"1961" pre-milling station, PC controlled w/45 mm (1-3/4") milling height, 2-motors @ 2.6 HP - 9,000 RPM each.

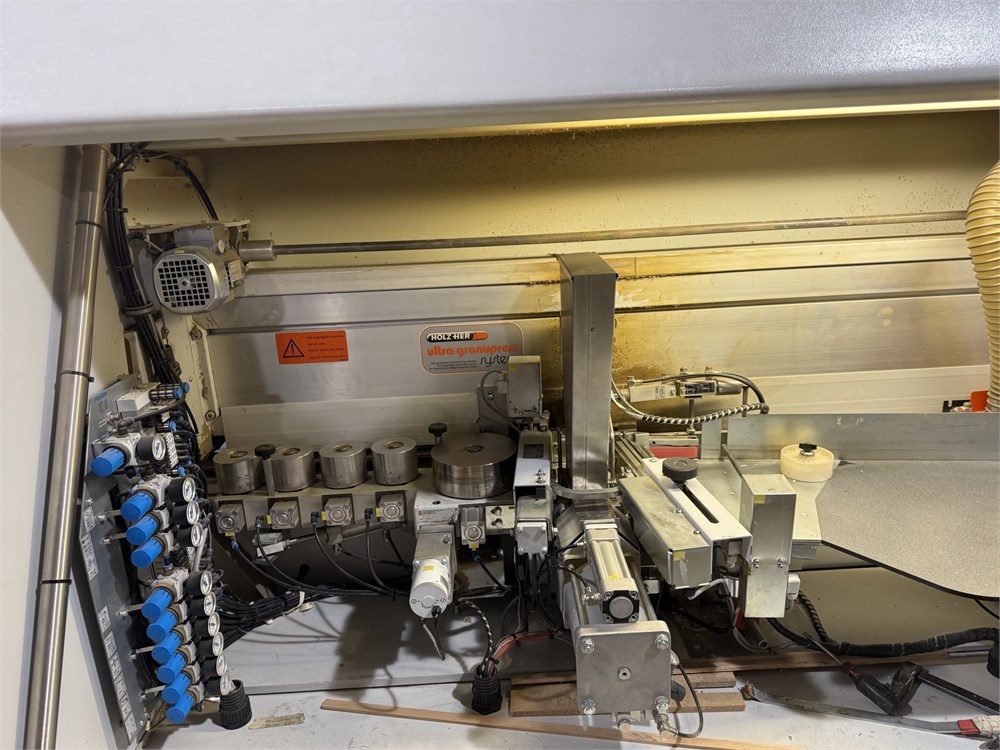

Granulate glue system with hopper system with "floating" applicator nozzle & "quick melt" feature.

"1914" Pressure section with one (1) driven roller and four (4) idle rollers, each w/individual pressure control

"1916" Double motor (1 HP - 6,000 RPM motor ea.) end trim units with "Uni-Point" swivel system, "quick change" from flush to 0° - 15° bevel from operator panel.

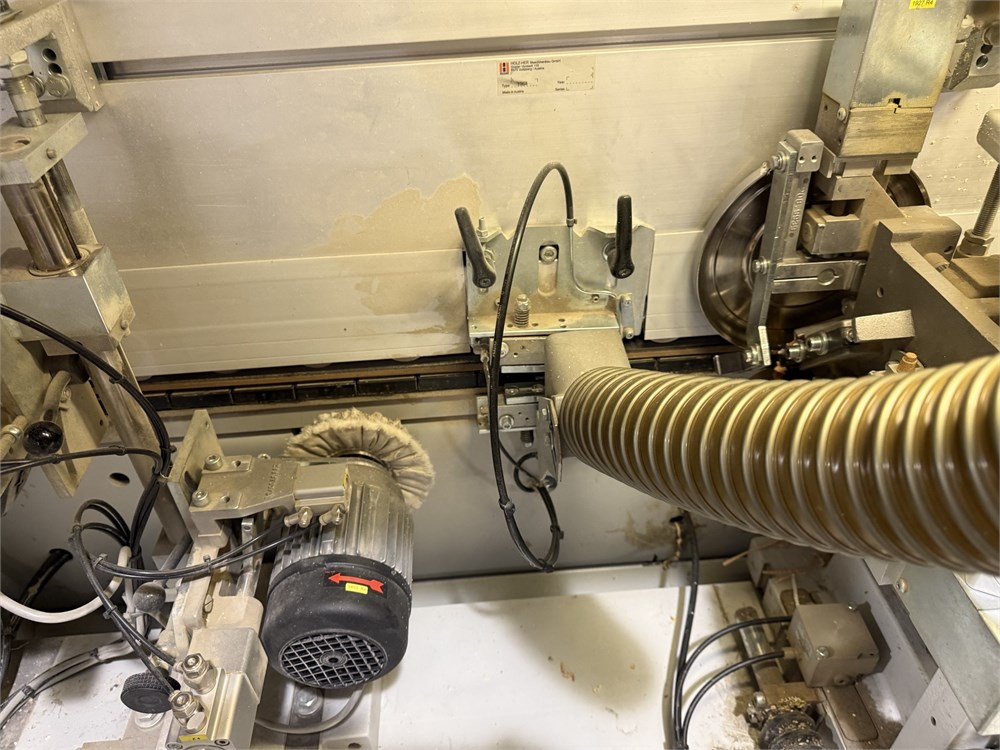

"1962" Top & bottom flush trim unit (2.6 HP motors), 12,000 RPM cutter speed; SIKO digital readouts; non tilt.

"1966" Top & bottom fine trim unit w/motorized positioning, (1.5 HP motors), 12,000 RPM cutter head speed, bevels 0° - 45°, SIKO digital readouts; all adjustments programmable through the PLC.

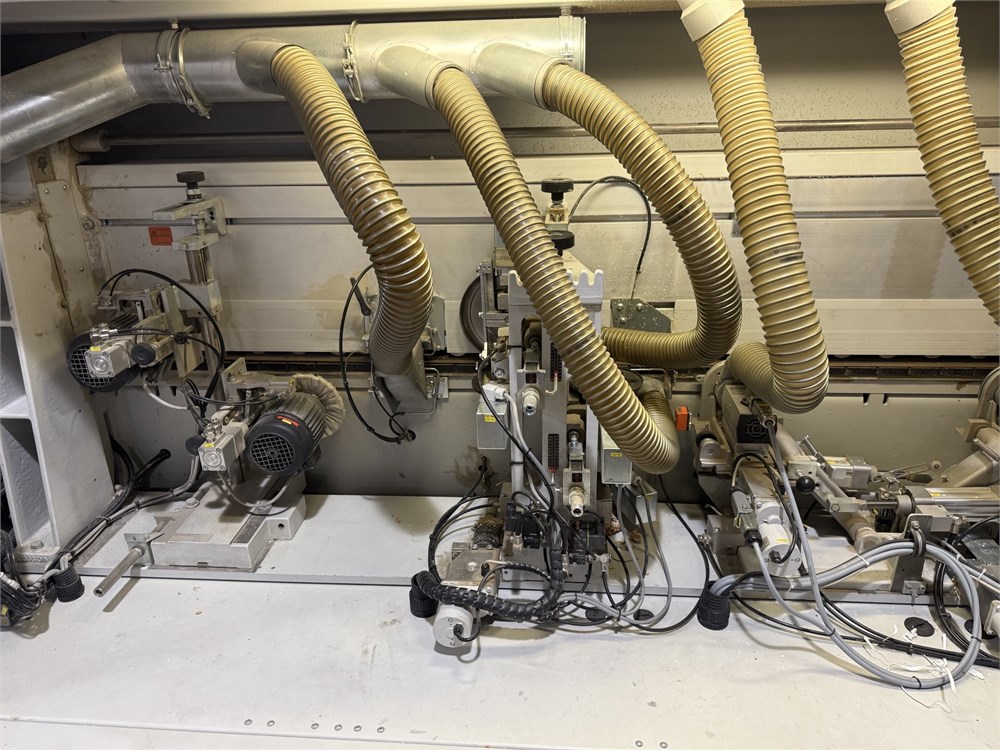

"1934" 2-Motor Corner rounding unit for top & bottom of leading & trailing corner when edgebanding all four sides (0.7 HP ea.), both motors with SIKO digital readouts as well as SERVO positioning from control panel; SERVO adjustment of entire unit (base).

"1927" Scraper Unit for finishing up to 5 mm thick PVC banding for radius range from 2 - 5 mm, vertical & horizontal tracing wheels, SERVO positioning enabled through "PC"; SERVO controlled in/out of base.

Top/bottom flat scraping unit

"1851" Jump buffing unit for cleaning & polishing of panel (two 0.25 HP - 1,440 RPM motors), tilts 0° - 45° vertically and 0 - 20° swivel on horizontal plane.

Sound enclosure

Outboard roller support

Return conveyor NOT included

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available