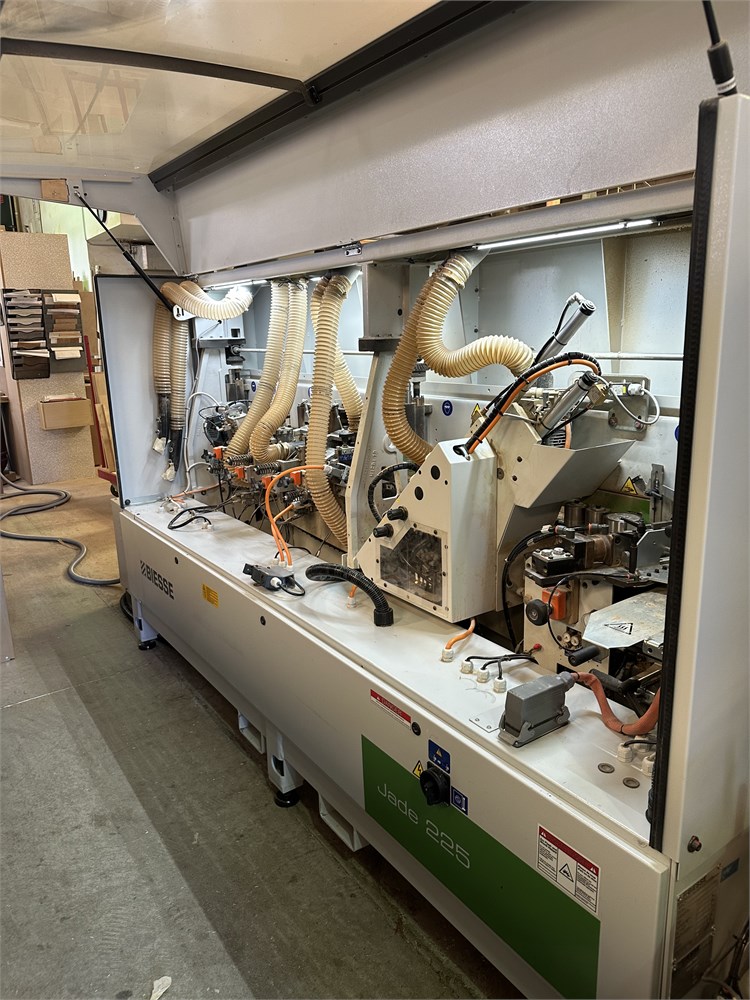

Biesse "Jade 225" Edgebander (2019)  Ended

Ended

Woodworking Machinery Auction - Sebastopol, CA

Sebastopol, CA

- Winning Bid : $7,100.00 USD Sold

- 10 Bid(s)

- High Bidder: n****e

Woodworking Machinery Auction - Sebastopol, CA ( Closed #72868407 )

Excess equipment no longer required for production from high-end kitchen cabinet manufacturer in the San Francico bay area. Items include Biesse Jade 225 Edgebander, Busellato CNC, and TigerStop gauge system.

-

Pick Up Location

350 Morris St., Suite F Sebastopol, CA 95472

-

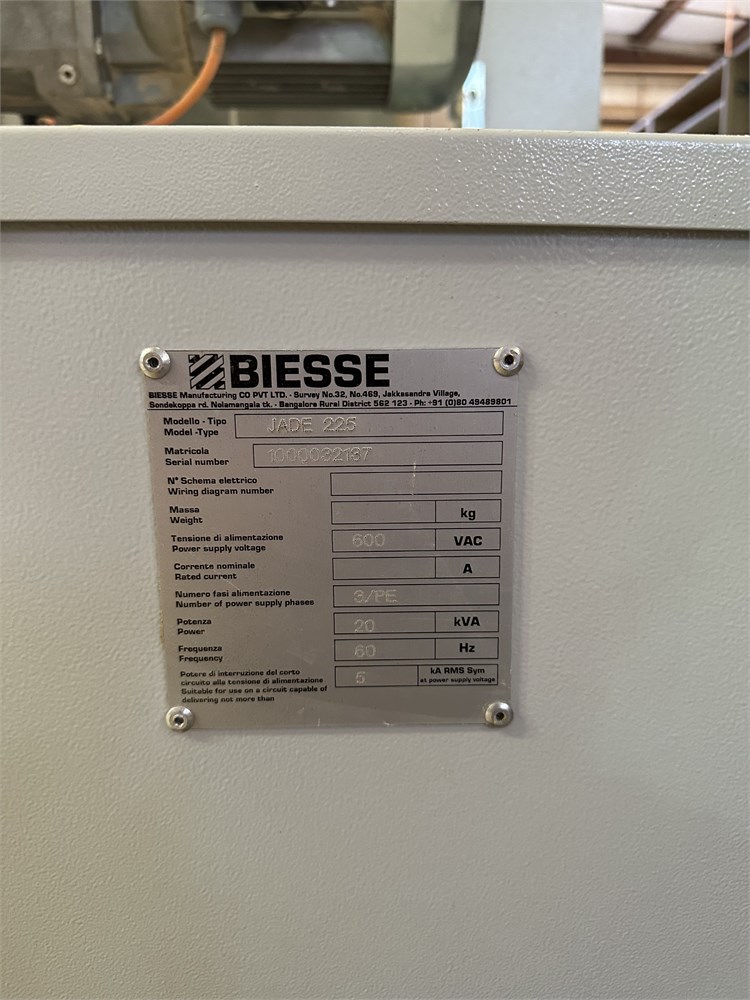

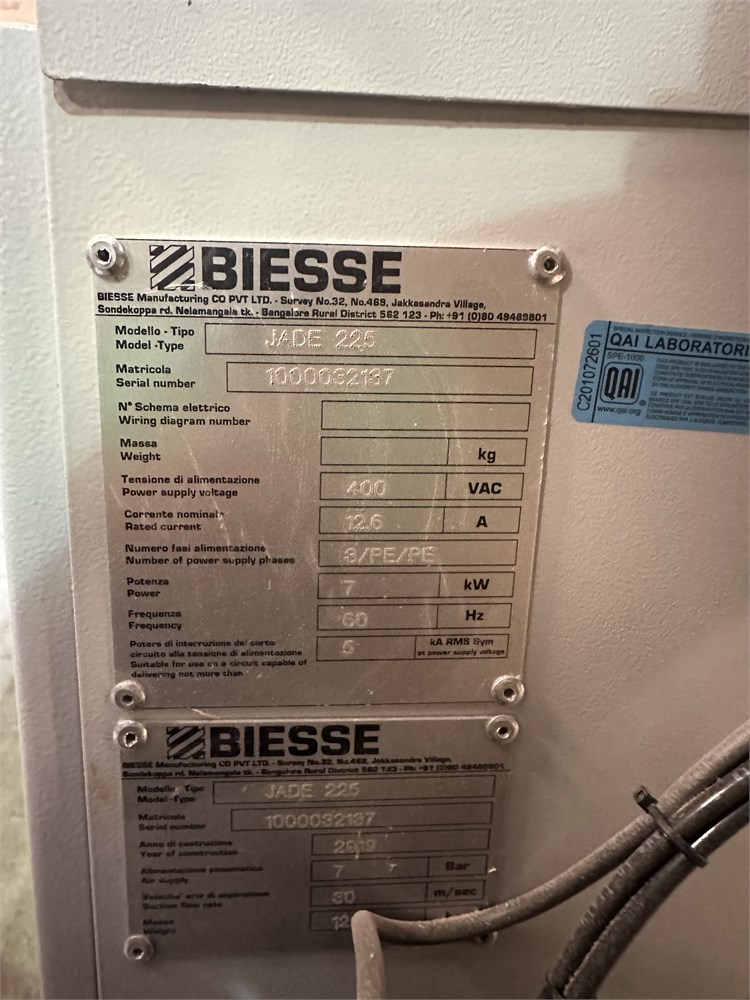

Make

Biesse

-

Model

Jade 225

-

Serial Number

1000032137

-

Year

2019

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Buyer Inspection Period

By appointment only, contact Kirk Gass, [email protected], 925-250-8248

-

Load Out Period

June 26 - July 3, 2025 (by appointment)

-

Estimated Dimensions

Length: 13' Width: 42" Height: 66"

-

Estimated Weight

2,800 Pounds

-

Seller Comment

Seller will disconnect and load onto buyer's flatbed truck/trailer for non-negotiable loading fee. Palletizing, crating or other services may be available at an additional cost.

-

Load Fee

495.00

-

Lot Notes

-

page views

744

Biesse "Jade 225" Edgebander (2019)

Edge and Workpiece Capacity: Edgebanding thickness 0.4 -8 mm (0.01" - 0.31"), min. panel width 85 mm (3.5"),min. length 150 mm (5.9"), max. panel thickness 10 -60 mm (0.39 - 2.36").

Touch screen PLC, rotating control panel

Edgebanding infeed table, 32" diameter

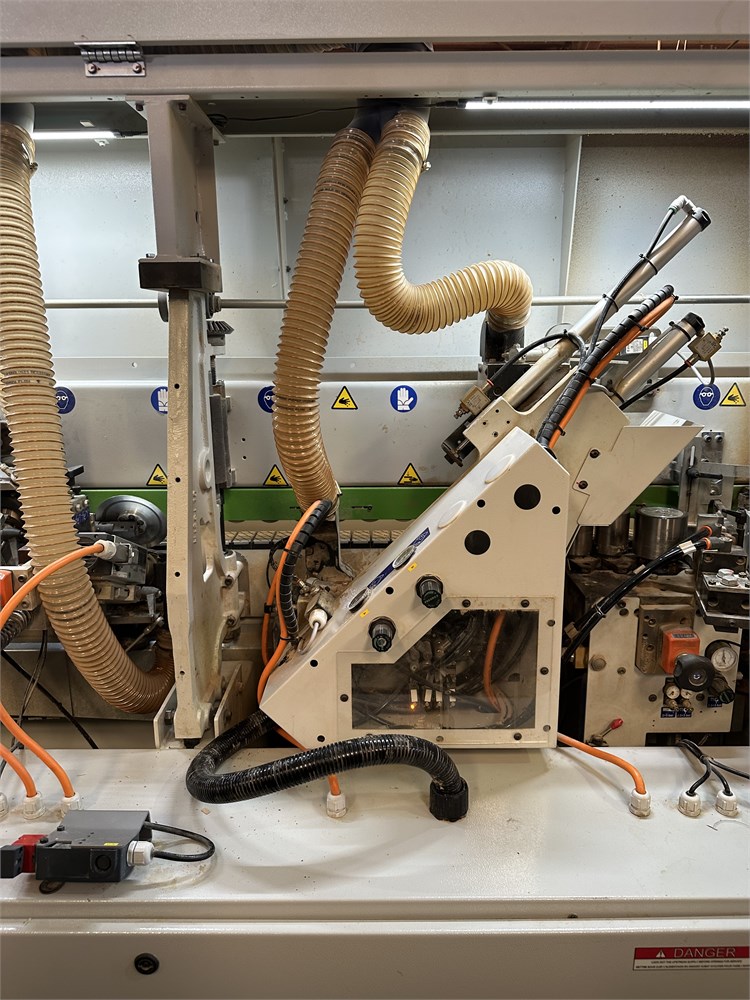

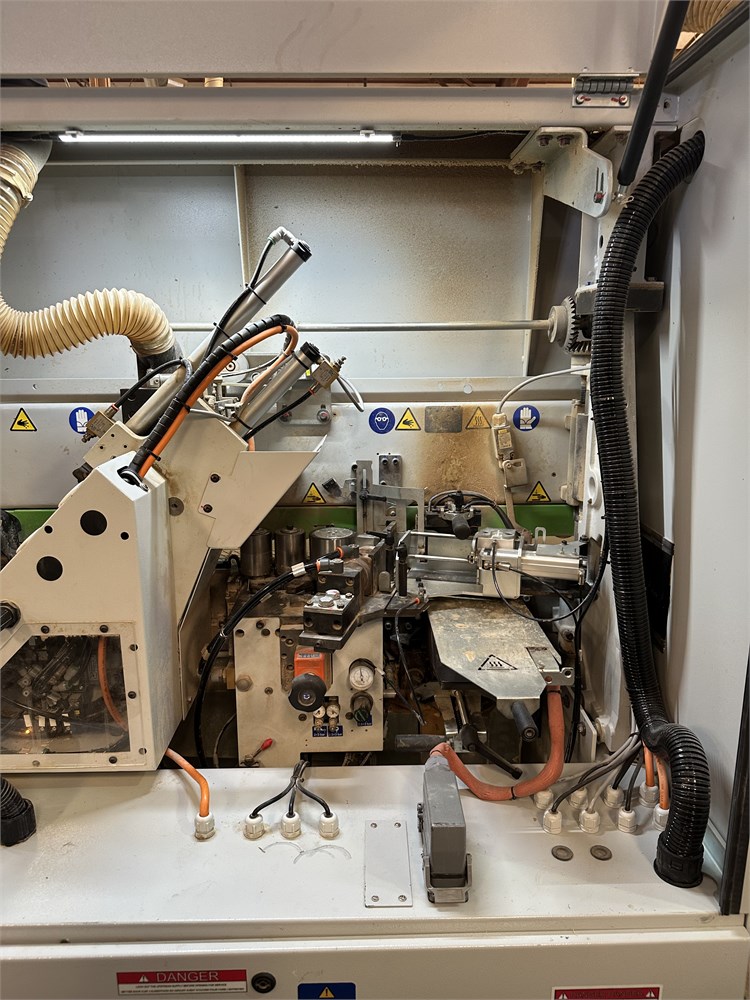

Automatic strip and coil feed magazine with "HD" shear type 3 mm PVC guillotine.

Infeed fence

Anti-Adhesive Unit: The unit applies an anti-adhesive liquid on the top and bottom surface of the panel.It is positioned before the pre-milling unit. The anti-adhesive liquid is applied with precision by means of injectors controlled by the machine control.

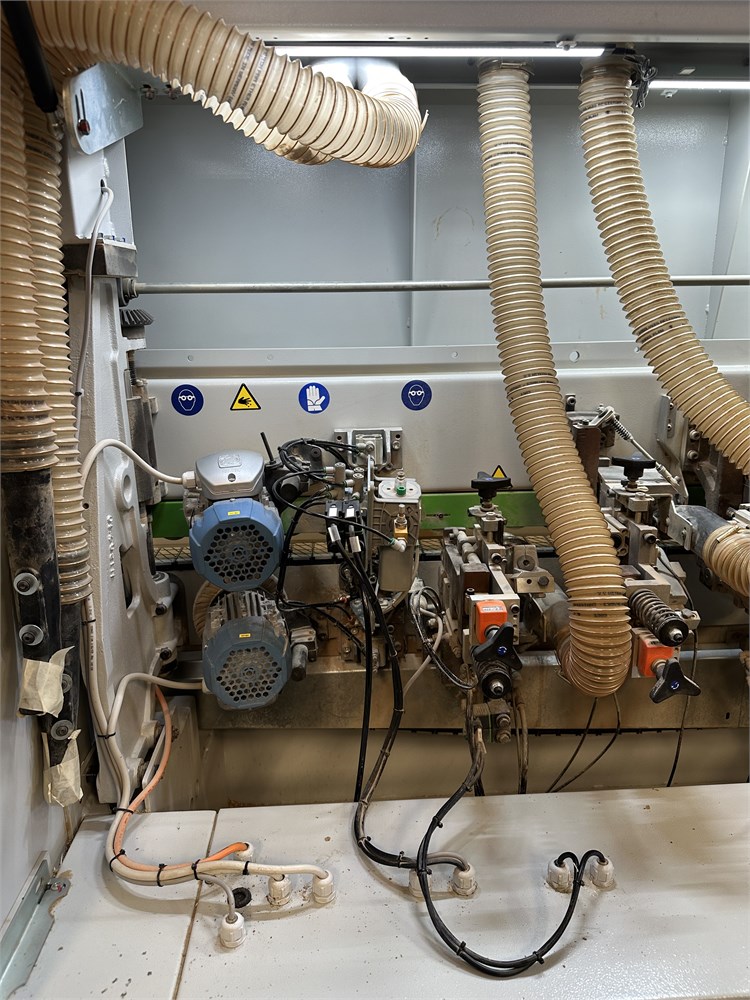

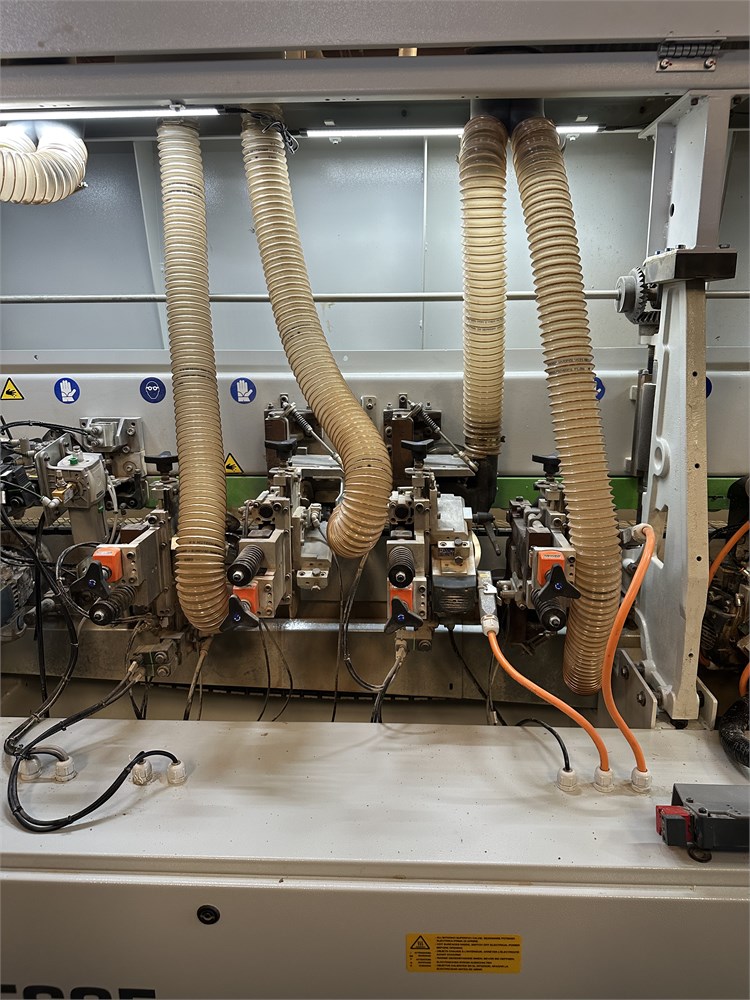

Pre-Milling Unit: (2) 2.4 HP motors operating at 12,000 RPM;"AUTO-SET" device ensures optimum positioning of the cutters according to the thickness of the panel being machined; numerical readouts, pneumatic exclusion when not needed.

Glue Unit: Teflon coated Hot Melt glue pot, digital thermostats with automatic kick down when machine is in idle mode.4.4 pounds capacity; "QMS" (quick melt - approx. 10 - 12 minute heat up time)

Pressure Section: (1) Large dia. "non-stick" coated drive roller and two (2) chrome plated pneumatic inclined pressure controlled idle rollers; horizontal adjustment w/ digital indicator.

End Trimming Unit: Front & rear end trim motors, 1.0 HP,12,000 RPM, motors travel on 45° slides and pneumatic tilt 0° - 15° form the control panel.

Top/bottom Trimming Unit: Top and bottom flush or bevel trims with "Quick Change" motors 0.8 HP, 12,000 RPM, digital readouts for easy setup.

Top/bottom Profile Scraping Unit: Finishing unit to eliminate previous machining imperfections; pneumatic exclusion from the machine control; external collection box.

Top/bottom Flat Scraping Unit: Top and bottom scrapers for 3 mm thick PVC banding.

Top/bottom Buffing Station: 0.5 HP, 2,800 RPM, units tilt 0° - 30°.

Top pressure beam & motorized feed track with "anti-slip" "Quick Change" snap on 80 mm wide x 60 mm long rubber pads, low friction nylon-graphite self-lubrication chain pads.

Lighted Sound Enclosure and Outboard Panel Support, over all trimming stations, industrial lights and viewing windows,extendible side panel support rail.

Fixed Feed Speed,39 FPM, 2 HP feed drive

External electrical transformer

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available