Holz-Her "Auriga 1308XL" Edgebander  Ended

Ended

Woodworking Machinery Warehouse Auction - Tracy, CA

Tracy, CA

- Winning Bid : $15,500.00 USD Sold

- 55 Bid(s)

- High Bidder: L****4

Woodworking Machinery Warehouse Auction - Tracy, CA ( Closed #72802701 )

All Assets Moved to Tracy CA warehouse for the convenience of buyers. Auction items include 2019 Omal HBD-1300 OF CNC Drill and Dowel, 2016 HolzHer 1308XL, 2016 Homag Brandt KDN 110 Edgebander, 2024 Demo Circle T Notcher machine, 2013 SCM SI400 Nova Sliding Table Saw, and much more. Over 20 Lot Items Up for Auction.

-

Pick Up Location

2203 N. MacArthur Drive, Tracy CA 95376

-

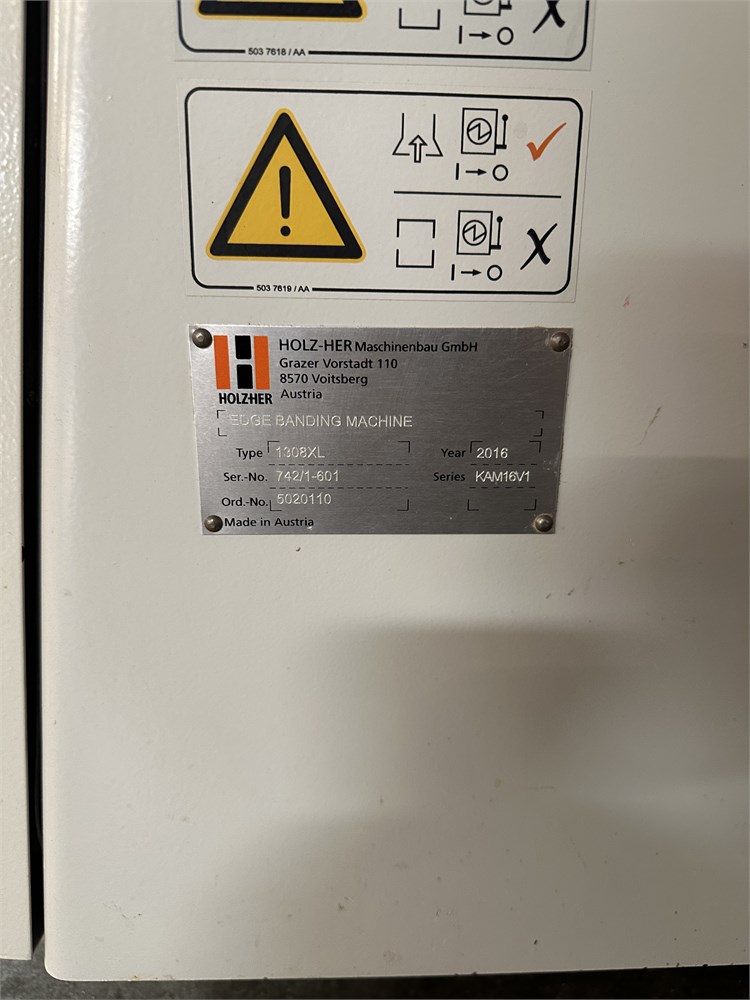

Make

HolzHer

-

Model

Auriga 1308XL

-

Serial Number

742/1-601

-

Year

2016

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Buyer Inspection Period

By appointment only, contact Kirk Gass, [email protected], 925-250-8248

-

Load Out Period

June 18th thru 23rd, By Appt. Only

-

Estimated Dimensions

192" x 60" x 60"

-

Estimated Weight

Approximately 4000 lbs.

-

Seller Comment

-

Load Fee

395.00

-

Lot Notes

-

page views

3140

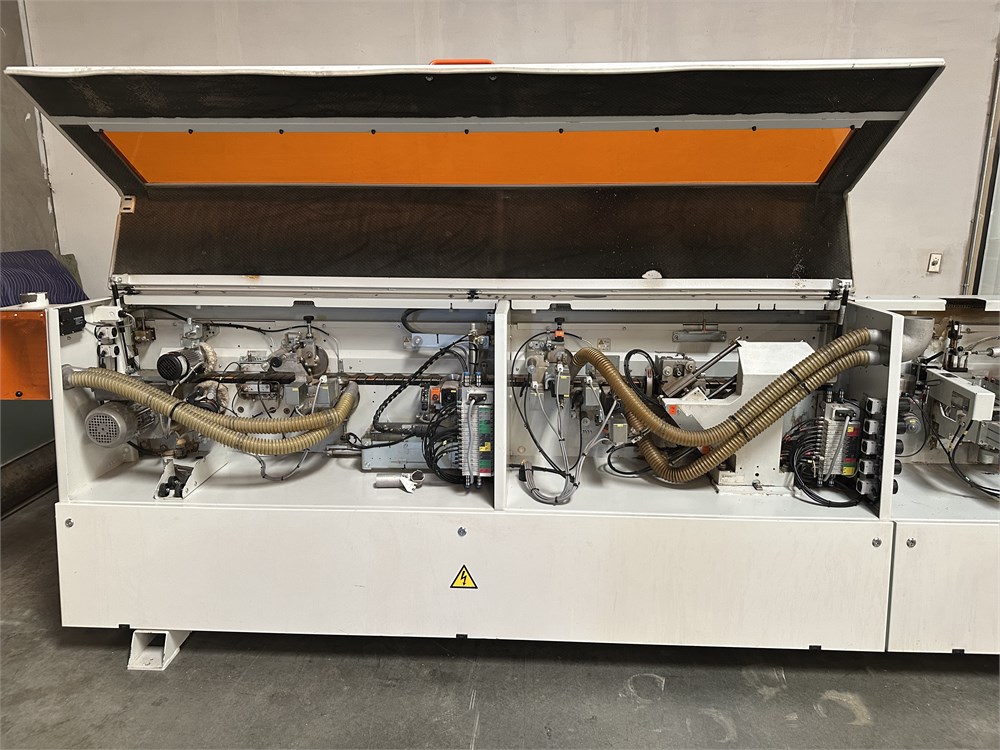

Holz-Her "Auriga 1308XL" Edgebander

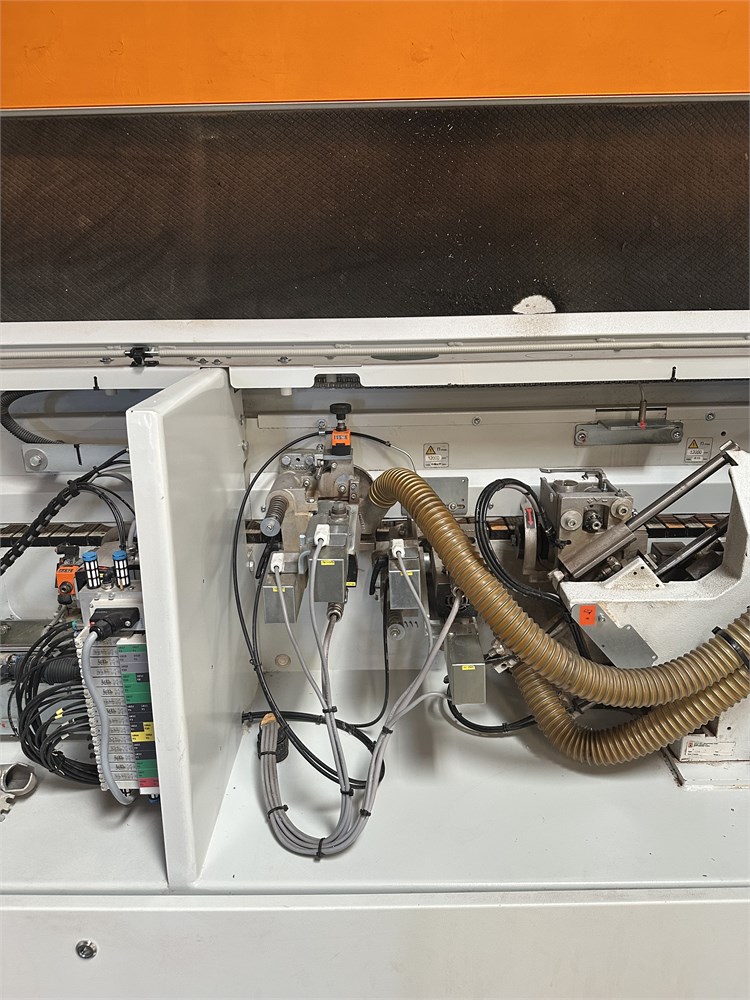

Edge thickness min./max. 0.4 - 3 mm (0.02 - 0.12"), coiled material, optional with flush cutters max. 6 mm (0.24"); Panel thickness 6 - 60 mm (0.236 - 2.362"), work piece width min. of 65 mm (2.559"); work piece length min. 160 mm (6.299"); Feed speed 10 MPM (33 FPM).

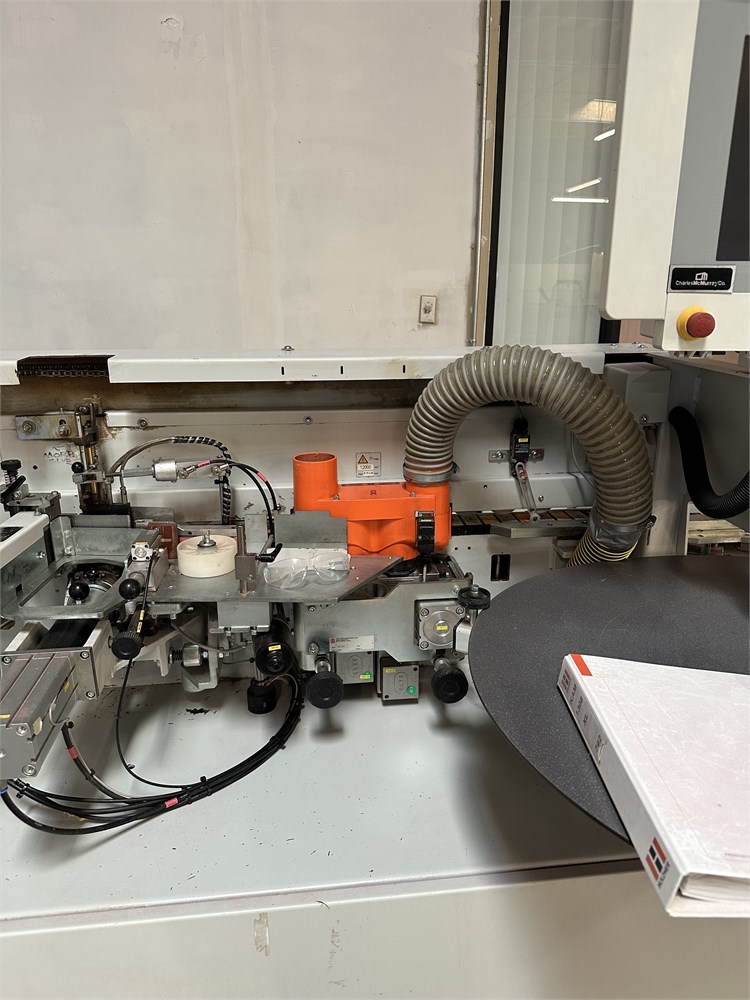

Pre-Milling Station "1801": 2 x 1.2 KW (1.6 HP) - 12,000 RPM motors; Diamond cutter-heads with ProLock quick clamping system. Quick-Lock adjustable in-feed fence with digital indicator.

Edge Magazine "1903": for coil and strip processing, utilizing motion detector to ensure accurate, trouble-free positioning of edge material; exclusive "Tractor-Belt feed System", edge guide equipped with automatic guillotine lock-out for safety, 3° approach angle allows easy feeding of solid wood edges.

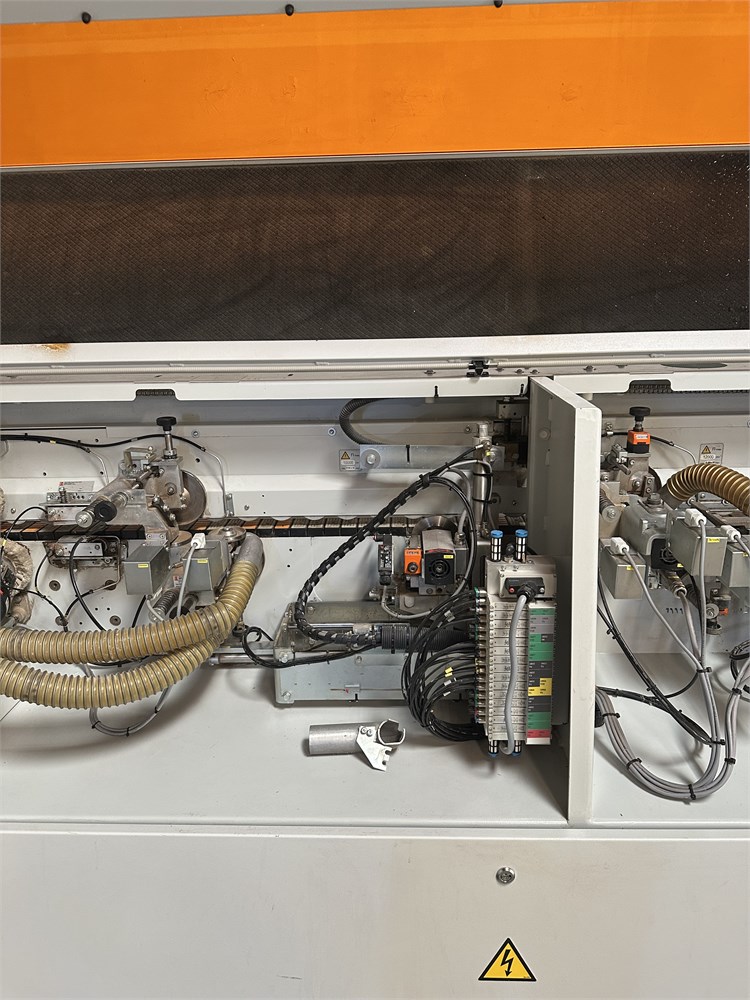

Pressure Section "1912-3": with (1) large driven (synchronized with feed-speed) roller and (2) cantered idle rollers, adjustable by hand wheel and scale.

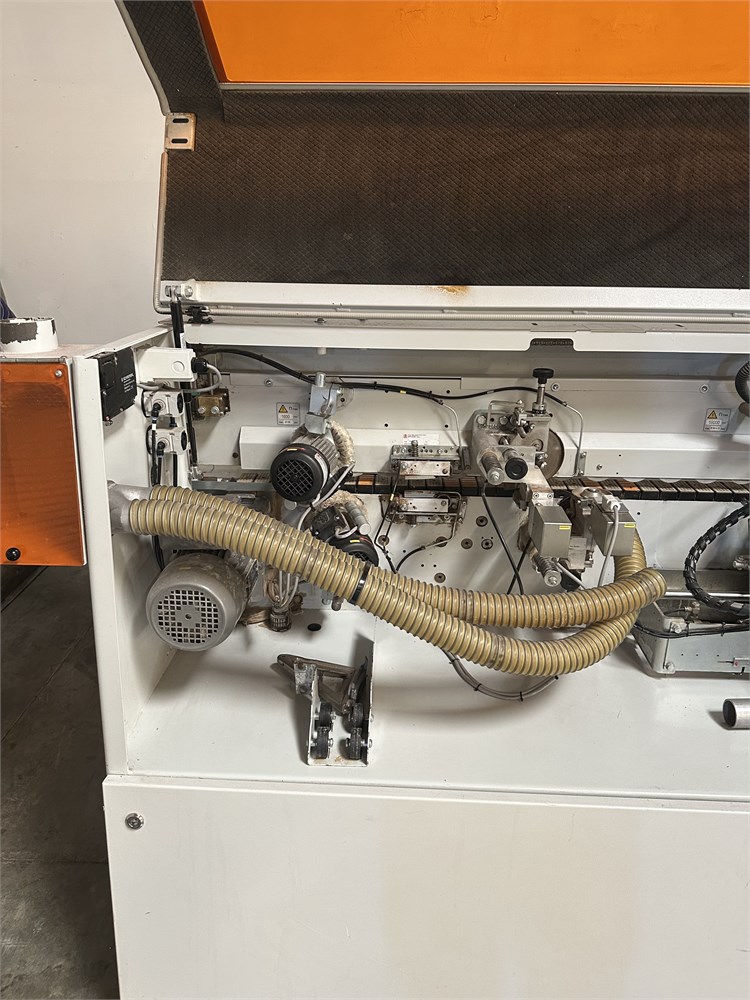

End Trimming Unit "1918P": Front & rear 2 x 0.45 KW (0.6 HP) - 9,000 RPM motor each, uni-point swivel-axis for no re-indexing when changing from flush to bevel end trim (0° - 10° bevel),"PCS" programmable pneumatic change-over from flush to bevel.

Flush/Bevel/Radius Combination Trimming Unit "1827 MOT4": Flush 6 mm, radius 3 mm trimming, servo controlled, 2 @ servo motors (1) for horizontal copy wheel & (1) for tool spindle position) programmable top & bottom unit 2 x 0.65 KW (0.88 HP) - 12,000 RPM each motor. Uni-Point design with no second adjustment, pneumatic, programmable tilt action for changing the degree of bevel, digital counters for vertical copy wheel position and pneumatic air cylinder for in/out pre-positioning of trimming motor.

Corner Rounding Unit "1832": (1) Motor 0.22 KW (0.30 HP) - 9000 RPM for up to 3 mm edge thickness and work-piece thickness min./max. 12 - 60 mm (0.473 - 2.362"), max. feed speed 10 MPM (33 FMP).

Glue Scraping Unit, Flat surface, top/bottom, ball bearing guided and pneumatic controlled. Reversible - replaceable knife inserts and blow-off nozzles. External collection box.

Buffing Station "1940": Top & bottom, 2 x 0.09 KW (0.25 HP) buffing motors with 150 mm ( 6.0") cloth buffing wheel diameter, adjusts in any direction (vertical tilt is 0° - 5°, horizontal swivel is 0° - 20°); 1,440 RPM wheel rotation.

Sound enclosure

Outboard roller support

PCC 221 Power-PC, Windows like interphase with large program storage capacity. Up to (10) individual users with password protection. USB connection and Ethernet network connections.

Flat Screen 8.4" VGA Color, dust-proof soft key input panel surface, programs can be easily created and recalled at will; Graphic interface makes programming easy, icon of each unit may be brought up on the screen to show the operator the status of the unit and the parameters which can be programmed; Edgebander can be operated manually when required, without the necessity to write a program.

Listed specifications were taken from manufacturer's published information and is assumed to be correct but not guaranteed. Bidder is encouraged to inspect the machine, call with questions or contact the manufacturer for more information.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available