SCM Group "Olimpic K560 ERT" Automatic Edgebander, Pre-Mill, Corner Round  Ended

Ended

Eco Step Complete Woodworking Shop Closure - San Leandro, Ca

San Leandro, Ca

- Winning Bid : $16,050.00 USD Sold

- 104 Bid(s)

- High Bidder: P****1

Eco Step Complete Woodworking Shop Closure - San Leandro, Ca ( Closed #72255012 )

Eco Step is closing its custom woodworking facility in San Leandro, Ca. over 135 lots featuring, SCM Pratix CNC Router, DMC SD60 wide belt sander, Komatsu Forklift, SCM F410 Jointer, Oliver Planer W/ Helical Head, SCM SI400 Move sliding table saw with Tiger Saw, Plus much more!

-

Pick Up Location

2124 Adams Ave San Leandro, Ca 94577

-

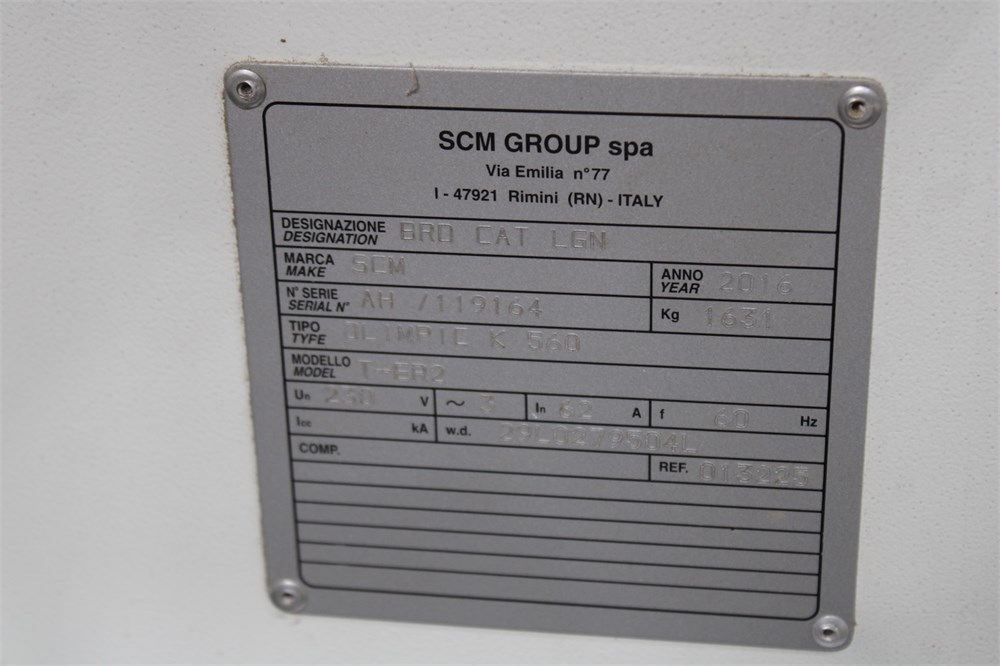

Make

SCM

-

Model

K560 ERT

-

Serial Number

AH/119164

-

Year

2016

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Buyer Inspection Period

By appt Only, Contact [email protected] or cell/text @ 925-250-8248

-

Load Out Period

June 3-4 2025

-

Estimated Dimensions

182” x 67” x 59”

-

Estimated Weight

4000 LBS

-

Seller Comment

Buyer responsible for prep, loading, and shipping or hiring a rigger to do so.

-

Load Fee

0.00

-

Lot Notes

-

page views

1305

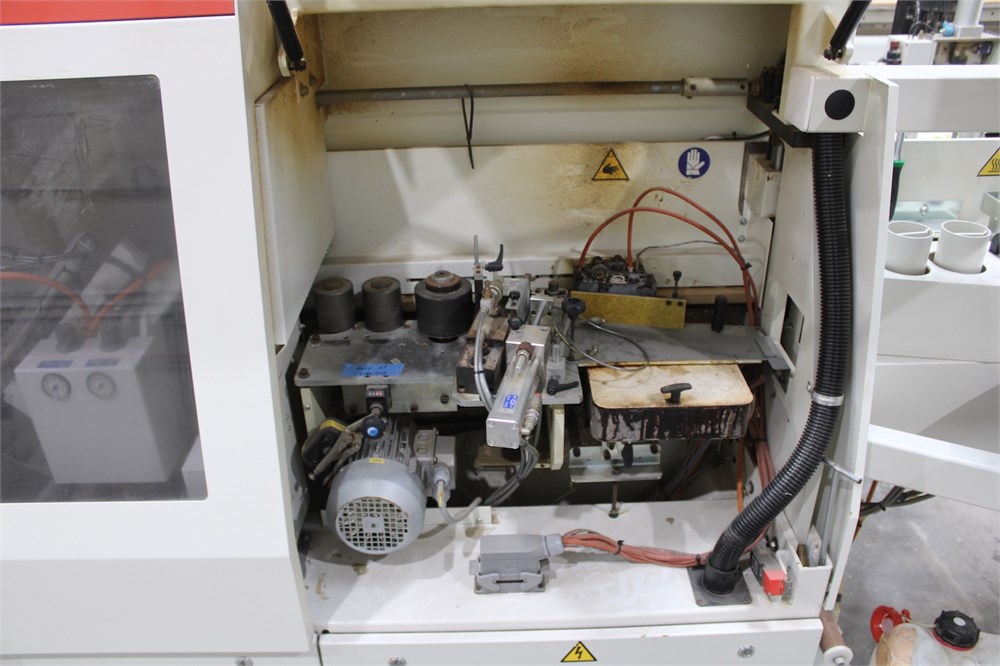

Automatic single sided edgebander designed to be used for edgebanding straight vertical profiles with coiled material (veneer and PVC) and with strips (high-pressure laminate and solid wood) with a maximum thickness of 8mm.

Machine Base

The machine base is made of a tubular steel structure and is designed to assure maximum stability and accuracy.

Electronic Positioning of the Top Pressure Beam

The height of the pressure beam is electronically positioned through the controller per the program. All operating units raise and lower simultaneously when the pressure beam is adjusted. No adjustment is required for the glue roller when changing panel thickness. The pressure beam has two rows of staggered pressure rollers with steel bearings.

Capacities and Speed

-

Edgebanding thickness: .4mm - 6mm (.016-1/4”)

-

Guillotine capacity: 3mm

-

Feed speed: 40/60 ft/min.

-

Panel height: 3/8” min – 2 1/8” max

-

Minimum panel length: 5 1/2”

-

Minimum panel width: 2 3/8”

-

Minimum distance between panels:

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available