MB "Robatech 1300/DI" Rotational Belt Sanding Machine  Ended

Ended

Haas Cabinets - Building 2 Day 2

Sellersburg, IN

- Winning Bid : $26,350.00 USD Sold

- 85 Bid(s)

- High Bidder: J****l

Haas Cabinet liquidation of all Assets - Building #2 Day 2 of 2 ( Closed #71693823 )

Founded in 1939 and after 3 generations, HAAS cabinet is closing their doors and offering up all assets in this online only sale. This sale includes the assets from Building # 2 (260.000 Sq.'). This is Day (2) of a 2-Day sale. Some of the highlights included in this 1,000+ lot sale are: Late model Giardina Dualtech feed thru spray system, MB Roba Brush sander, Kaiser air compressor, plus much more!

-

Pick Up Location

4414 Bud Prather Road, Sellersburg, IN 47172

-

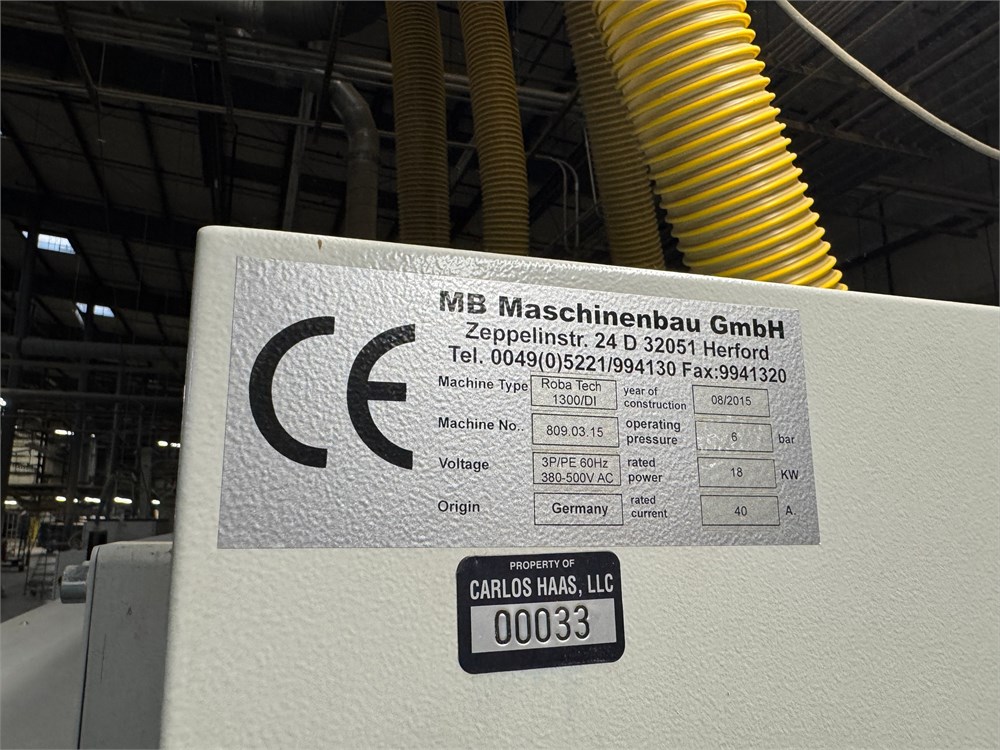

Make

MB

-

Model

"Roba SB 1300/DI"

-

Serial Number

809.03.15

-

Year

2015

-

Phase

3 PHASE

-

Voltage

230/460

-

Buyer Inspection Period

Wednesday May 21st 1-4PM & Thursday May 22nd 8AM-1PM

-

Load Out Period

June 2 - 12, 2025 By appointment ONLY! Text Adam for appointment (941) 916-7685

-

Estimated Dimensions

150"L x 102" x 84"

-

Estimated Weight

10,000 Lbs

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal. By appointment ONLY!

-

Load Fee

-

Lot Notes

Contact All-Ways Trucking 541-608-6532 - Aaron

-

page views

379

MB "Roba SB 1300/DI" Rotational Belt Sanding Machine

The Roba Split Belt principle is used for the sanding of flat and profiled surfaces, optimized for lacquer sanding.

The brush belt sanding system for optimal processing

in the areas of:

Intermediate lacquer sanding

White wood sanding

MDF sanding

Due to the innovative sanding method the Roba Belt Split offers for all these areas optimal prerequisites for best surface quality.

Sanding method

Lacquer sanding is a very difficult task in the field of production of furniture and furniture components.Many factors have an influence on a desired result and only the combination of the correct aggregate and abrasives configuration, in conjunction with certain programmable sanding parameters can offer a perfect result.

MB Maschinenbau has bundled many years of experience in lacquer sanding in the Roba Split Belt line and developed a machine that meets

these high expectations.

Based on the Roba Tech philosophy that only alarge sanding area provides enough performance for best results, MB developed the ?Split Belt" sanding aggregate. This combines the advantages of a large sanding area in contact with the work piece, while working in and against the part transport direction. An additional possibility to oscillate the split belt unit with up to 30 ? helps to optimize

the result. In conjunction with the for lacquer sanding optimized MB Superflex brushes, the Split Belt unit, placed at the machine exit, is responsible for the final finish in the longitudinal direction.

Since most work pieces need a cross processing to sand the millings transversal to the transport direction, as well as the right and left edges, two cross belt sanding units are placed at the machine

entrance. Having a processing width of 200mm each, the first cross unit works from right to left, while the second from left to right. This ensures a perfect sanding of all transversal grooves and longitudinal

edges. The combination of transverse and longitudinal sanding in one machine thus enables a smooth and effective processing in all areas.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available