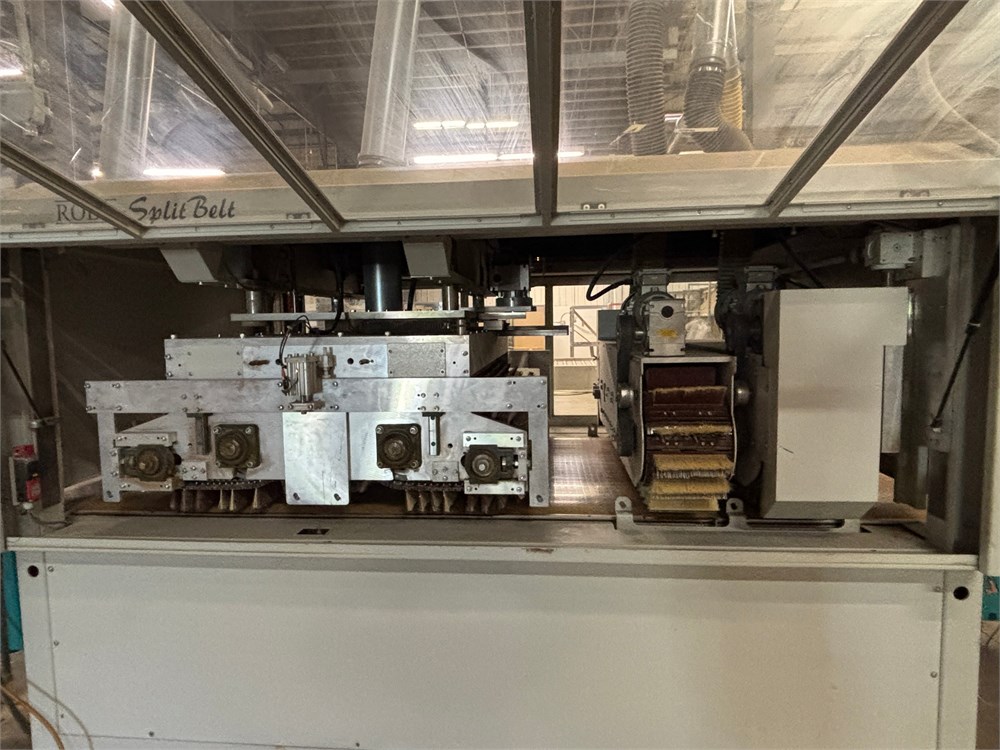

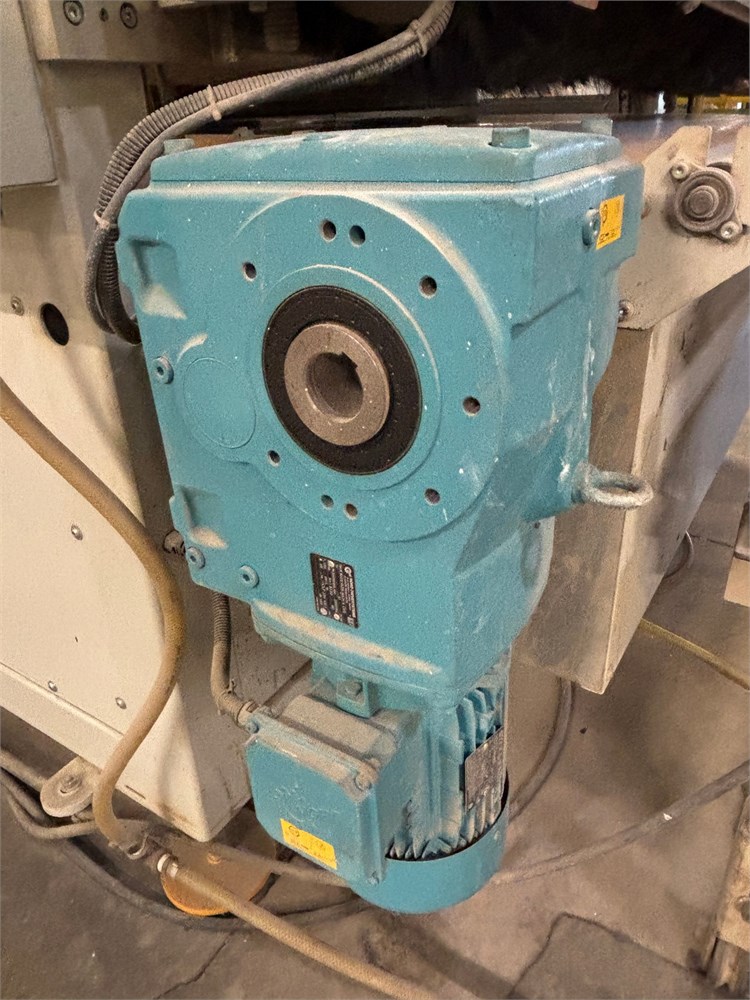

MB "Roba SB 1300/CB" Split Belt Brush Sanding Machine  Ended

Ended

Haas Cabinets - Building 2 Day 2

Sellersburg, IN

- Winning Bid : $30,350.00 USD Sold

- 92 Bid(s)

- High Bidder: J****l

Haas Cabinet liquidation of all Assets - Building #2 Day 2 of 2 ( Closed #71693823 )

Founded in 1939 and after 3 generations, HAAS cabinet is closing their doors and offering up all assets in this online only sale. This sale includes the assets from Building # 2 (260.000 Sq.'). This is Day (2) of a 2-Day sale. Some of the highlights included in this 1,000+ lot sale are: Late model Giardina Dualtech feed thru spray system, MB Roba Brush sander, Kaiser air compressor, plus much more!

-

Pick Up Location

4414 Bud Prather Road, Sellersburg, IN 47172

-

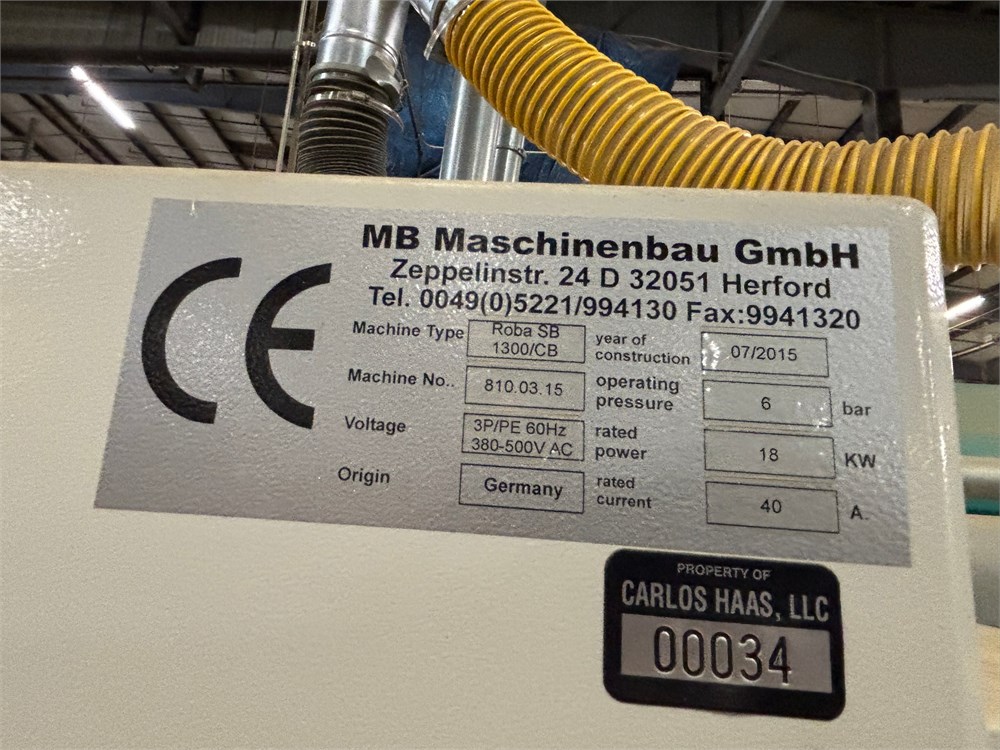

Make

MB

-

Model

"Roba SB 1300/CB"

-

Serial Number

810.03.15

-

Year

2015

-

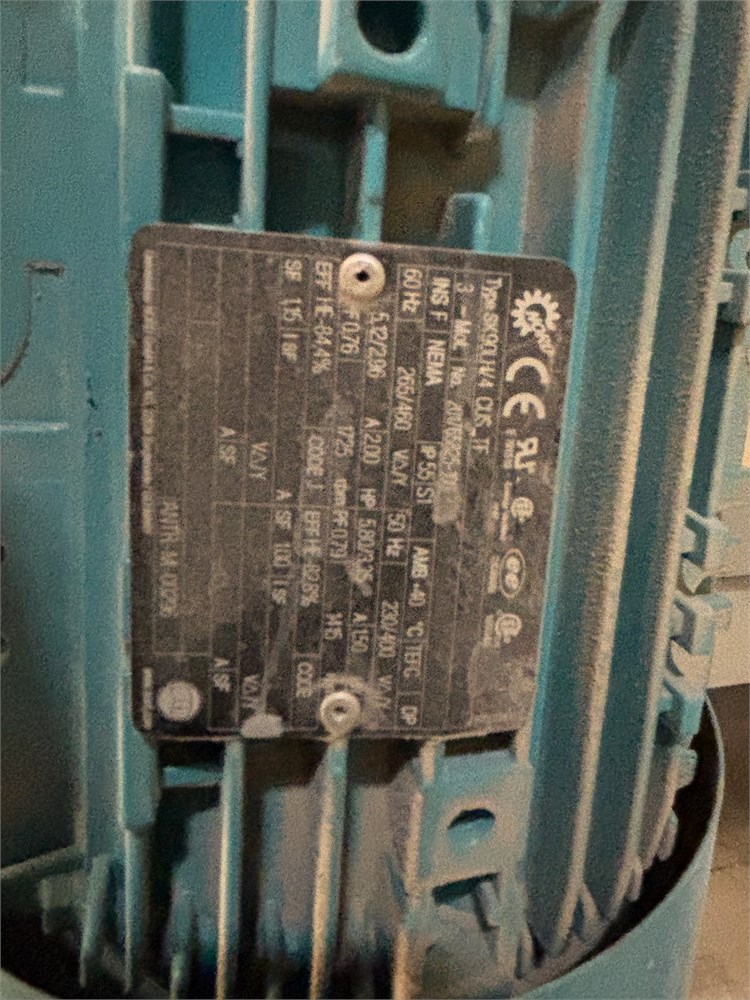

Phase

3 PHASE

-

Voltage

460 VOLT

-

Buyer Inspection Period

Wednesday May 21st 1-4PM & Thursday May 22nd 8AM-1PM

-

Load Out Period

June 2 - 12, 2025 By appointment ONLY! Text Adam for appointment (941) 916-7685

-

Estimated Dimensions

108" x 162" x 84"

-

Estimated Weight

12,000 Lbs

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal. By appointment ONLY!

-

Load Fee

-

Lot Notes

-

page views

443

MB "Roba SB 1300/CB" Split Belt Brush Sanding Machine

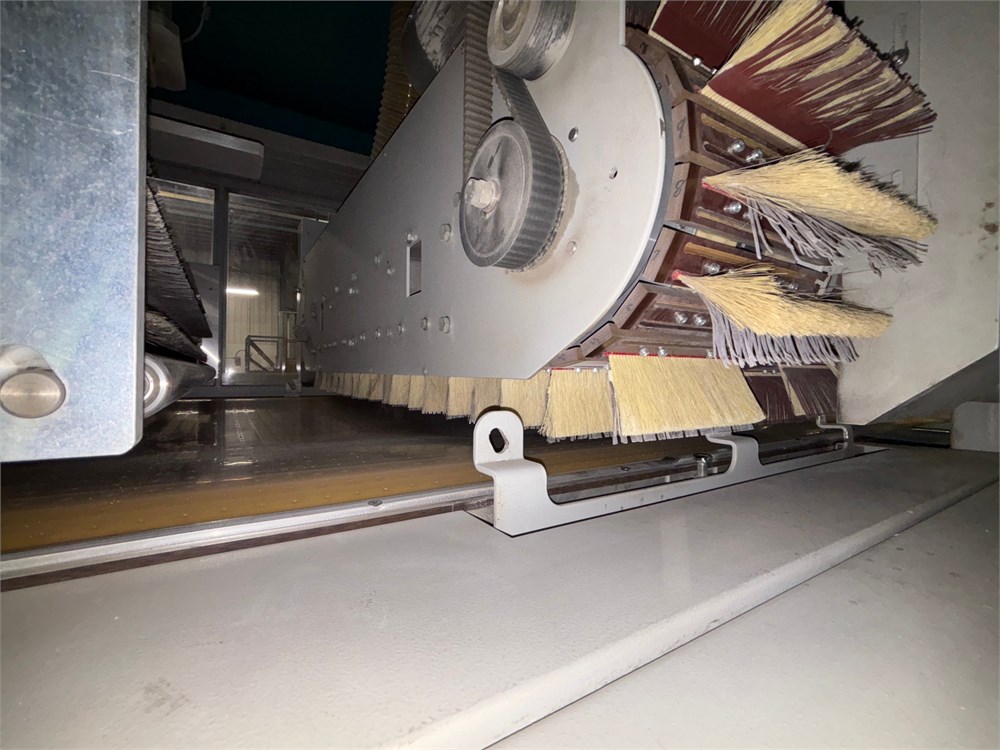

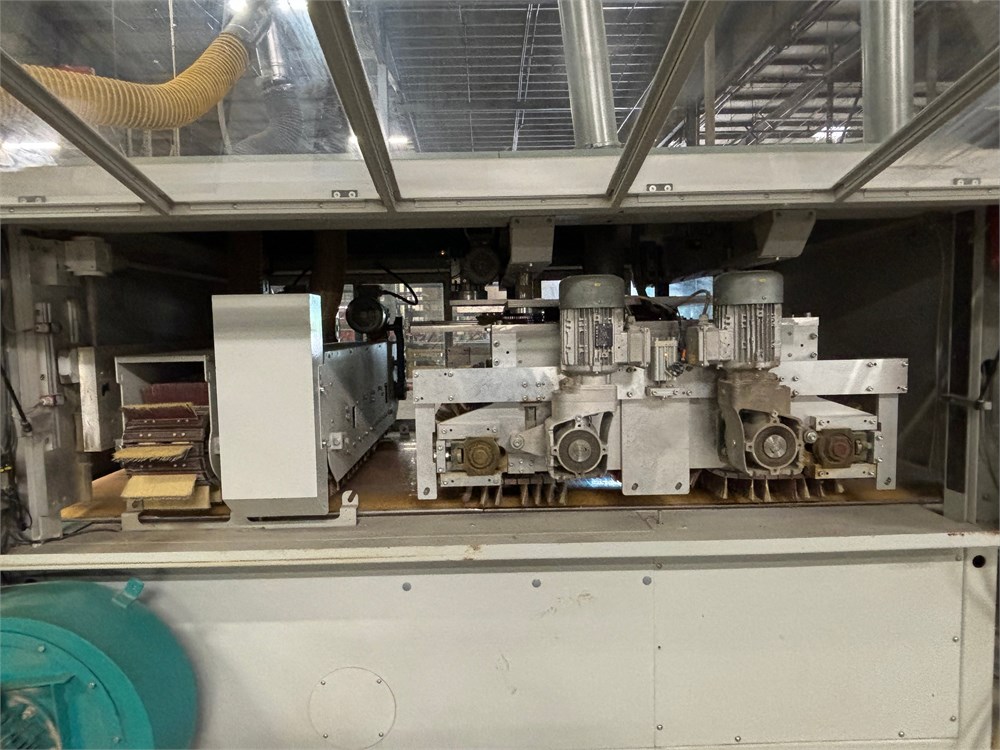

The patented Roba Tech principle is used for the sanding of flat and profiled surfaced. The rotational brush belt sanding system for optimal processing in the areas of:

• Intermediate lacquer sanding

• White wood sanding

• MDF sanding

Due to its innovative sanding method the ROBA Tech offers for all these areas optimal prerequisites for best surface quality.

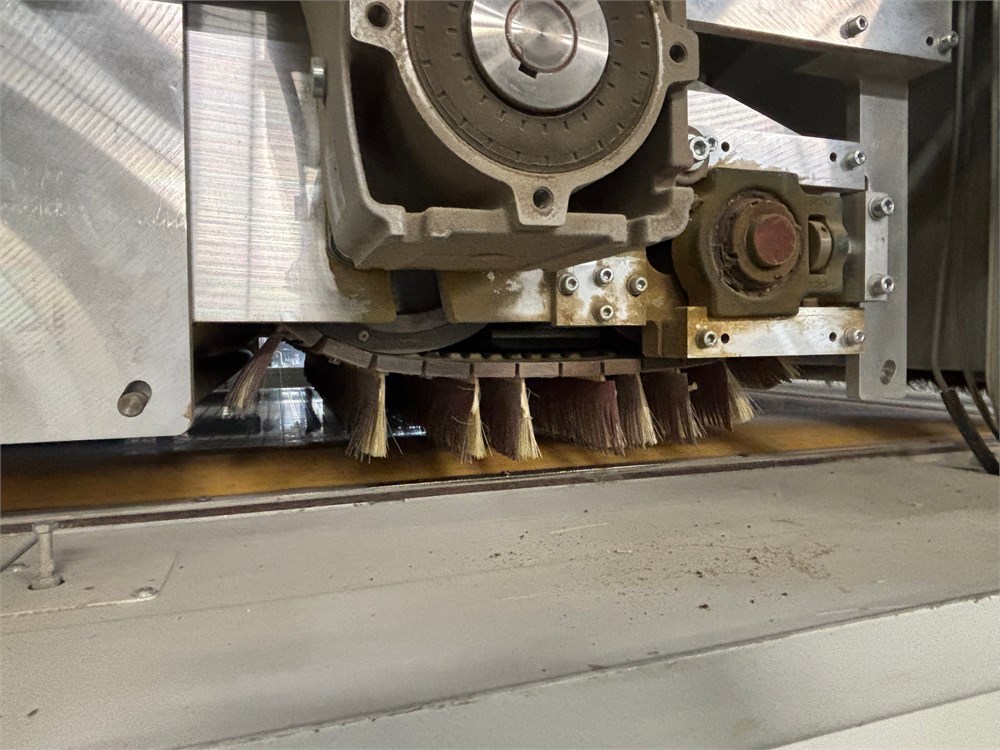

SANDING METHOD

The main idea of the Roba Tech principle is to avoid the main disadvantage of all today known drum based brush sanding machines: Those who work normally with sanding drum with a diameter of about 310 mm are only in a very small area in touch with the work piece, about 30 mm. O nly in the vertex of the circle circumference of the tool a sanding process is possible. To compensate the very small sanding area normal sanding systems must increase their rotation speed to a high level. Only this way they have a chance to get nearly the same effectiveness. But this results a “hard touch” of the sanding paper which leads to an aggressive behavior on the edges, high temperatures and wavy optic of the material. Hurt edges and totally denibbed surfaces are often the result. The innovative and patented Roba Tech is equipped with a totally new developed sanding belt containing 174 sanding strips and provides a sanding area of approx. 1300 x 1500 mm in touch with the work piece and more than 250 meters of sanding material on all aggregates. This is unique in the market of brush sanding machines. A 360 ° rotation of the sanding aggregate over the work piece makes it possible to reach all edges and corners of a work piece. Due to the by this means enlarged sanding effectiveness the machine can get the best cutting results at lowest rotation speeds. As a result of this, low movement speeds allow the sanding strips slide gently into the milled grooves and sand them every effective. Many by PLC adjustable sanding options help the operator to set the machine to his special sanding requirements.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available