Diamond America "TF400" 4" Twin Feed Extruder  Ended

Ended

Munns Woodwork, Menomonie, WI

Mt Vernon, NY

- Final Bid Price : $10,000.00 USD Reserve Price Not Met

- 3 Bid(s)

- High Bidder: n****e

Munn Works Complete Woodworking Plant Auction - Mt Vernon, NY ( Closed #71438495 )

After more than 50 years in business, MunnWorks has ceased its Woodworking operations and is auctioning all assets. Featuring: Thermwood CNC Router, Weeke CNC Router, Brandt Ambition Edgebander, Ka Ma yr 2023 Auto Spray System, Air Compressors, plus much more!

-

Pick Up Location

Menomonie, Wi

-

Make

Diamond America

-

Model

TF400

-

Serial Number

22-024

-

Year

2022

-

Phase

3 PHASE

-

Voltage

230/460

-

Buyer Inspection Period

May 07 2025

-

Load Out Period

May 12 - May 15, 2025 (by appointment)

-

Estimated Dimensions

26.25 x 74.84 x 35.5

-

Estimated Weight

1650lbs

-

Seller Comment

-

Load Fee

475.00

-

Lot Notes

-

page views

727

THIS MACHINE IS LOCATED IN MENOMONIE, WI FACILITY

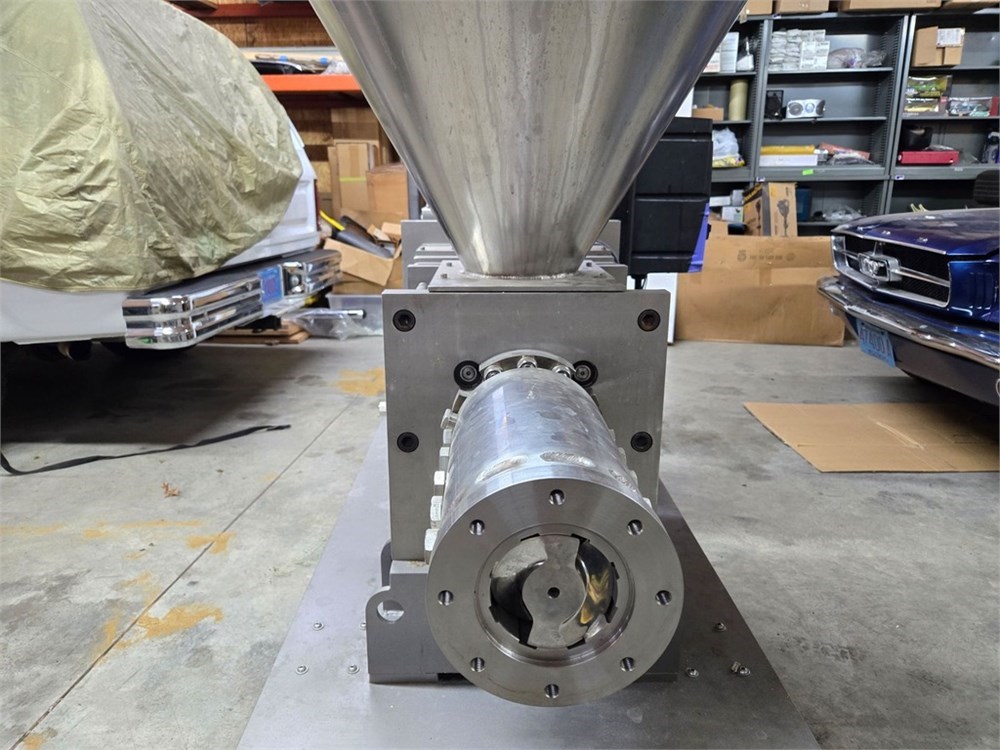

4" Screw Diameter

2 Packing Screws

6x10 Hopper Size

33,000 Max Volume in/Hr

25 HP Motor

55 Max RPM

28,500 Torque Lbs/inch

(1) Mobile Scissor Lift Table

The Diamond America TF400 Cold Feed Extruders provide high performance that can deliver up to 33,000 in3/hr. The TF400 features a four-inch diameter barrel screw, simple controls, improved serviceability and twin counter-rotating packing screws to keep material moving into the system. Its optional mobile cart allows the TF400 to be positioned wherever needed for use and an open, maintenance-friendly design ensures maximum uptime.

-

High quality materials of construction and exceptional engineering with tight tolerances reduces wear, maintenance, and downtime.

-

» Modular, open, hygienic design for easy cleaning.

-

» High capacity bearings with increased pressure capability meet aggressive demands.

-

» Gear motors eliminate belt slippage for continuous performance

-

» All material contact components made from Food Grade Stainless Steel.

Extrusion Screw

4" diameter extrusion screw made from 17‐4PH H1150 stainless steel, hard-faced flight O.D. for increased life. Screws are available slotted or continuous based on the type of material to be processed. Screw can also be bored for cooling or heating.

Extrusion Barrel

Available with serpentine flow channels or open jacket for liquid heating or cooling, and without jacket for electric band heating. Barrels are available with smooth or grooved, hardened Stainless Steel liners, with or without mixing pins. Barrels can also be manufactured to accept pressure/temperature probes.

Packing Screws

Counter-Rotating Packing Screws provide a positive feed with a consistent flow of packed material, minimizing starvation and non-uniform extrudate. Packers allow one extruder to process a wider range of materials, eliminating added capital equipment cost.

Hopper

17‐4 Stainless Steel with a 6" X 10" opening. Hopper is also machined to accept liquid cooling or heating.

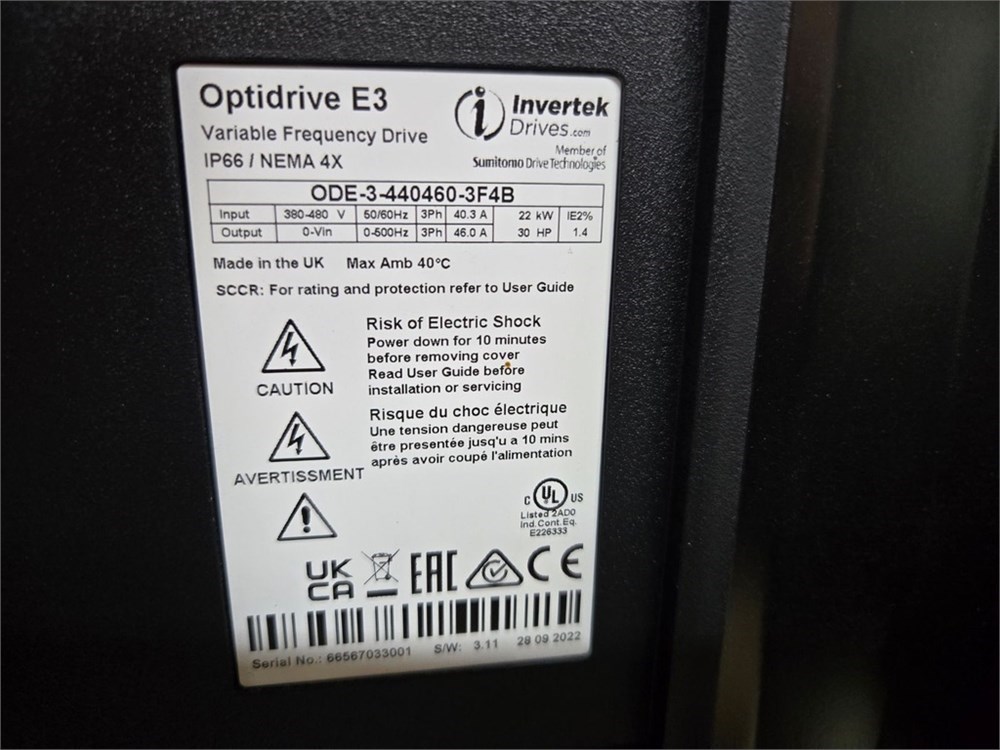

Drive Motor

Nidec uni-drive AC drive motor with bright, easy to read LED keypad and speed reference potentiometer.

Gear Motor

SEW‐Eurodrive 25HP AC gear motor with 55 RPM top speed and 28,500 pounds of torque per inch.

Controller

Custom built controllers with bright, easy to read LED keypad and a speed reference potentiometer.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available