Biesse "Rover B 7.40 FT-K" CNC Router  Ended

Ended

Biesse CNC Auction - High Point, NC

High Point, NC

- Winning Bid : $3,300.00 USD Sold

- 28 Bid(s)

- High Bidder: a****m

Biesse "Rover B 7.40 FT" CNC Router - High Point, NC ( Closed #71462788 )

A Top Tier furniture manafacturer in the greater Charlotte, NC area is auctioning a Biesse "Rover B 7.40 FT" CNC Router no longer required for continuing operations. Please call me directly with any questions.

-

Pick Up Location

2401 Collage Dr. High Point, NC 27260

-

Make

Biesse

-

Model

Rover B 7.40 FT-K

-

Serial Number

76443

-

Year

2006

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Buyer Inspection Period

April 16th - May 6th, 2025 (By Appointment Only)

-

Load Out Period

May 6th- May 13th, 2025 (By Appointment Only)

-

Estimated Dimensions

236" L x 86" W x 82" H

-

Estimated Weight

7900

-

Seller Comment

Riggers will warehouse the machine Contact Erik @ ChrisCo Machinery Inc. [email protected] 336-339-3133

-

Load Fee

-

Lot Notes

-

page views

1234

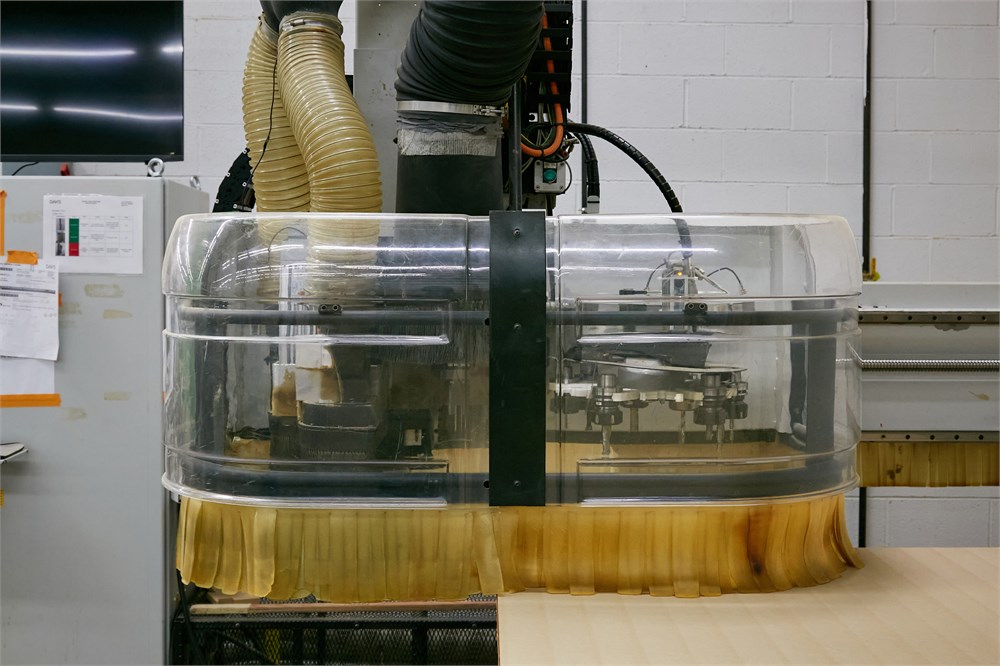

Biesse "Rover B 7.40 FT-K" CNC Router

SEE VIDEO OF MACHINE

SEE PDF

Working capacity. X-Axis is 145" (3,685 mm), Y-axis is 61" (1,550 mm), X-axis working field with all the tools is 145" (3,685 mm), X-axis working field with main spindle is 157" (3,996 mm), Y-axis field with all verticle spindles is 60.6" (1,539.5 mm), Y-axis working field with main spindle is 72.8" (1,850 mm), Z-axis clearance is 7" (180 mm ).

Programmable speed: X- & Y-Axis is 3,937 IPM and Z-axis is 1,181 IPM.

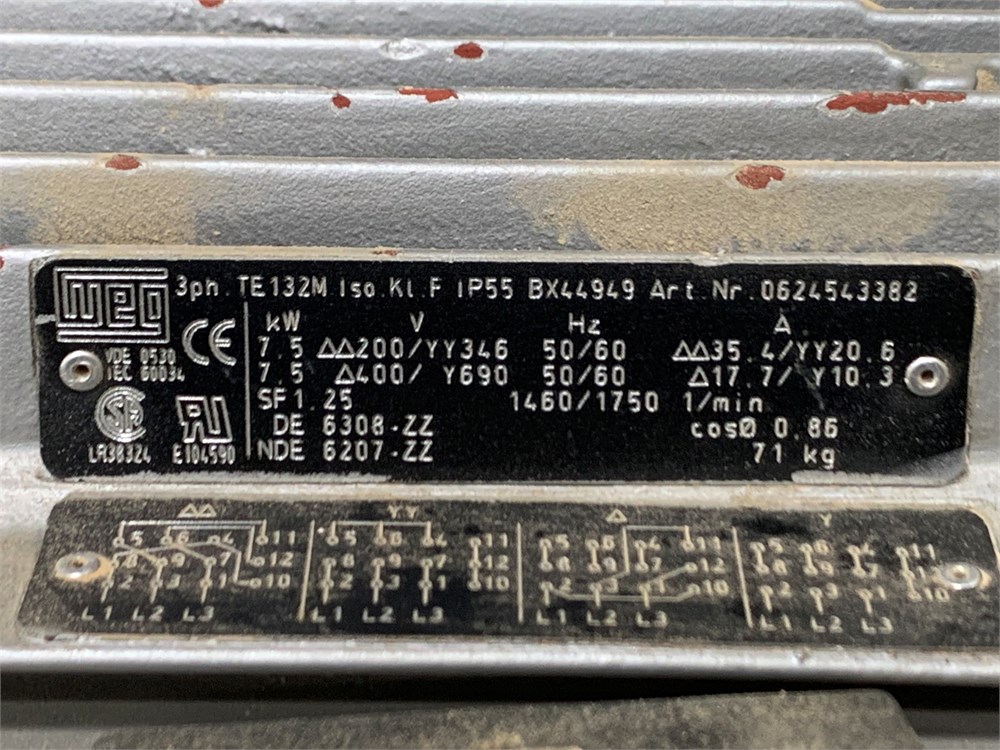

Equipped with: (12) Independent vertical boring spindles forming an L-configuration with (6) spindles on the Y-axis & (6) spindles on the X-axis; inverter controlled 2.3 HP spindle motor with 4,000 RPM.

A total of (6) horizontal spindles provide horizontal boring capabilities on all (4) edges of the panel, (4) on the X-axis (2 in ea. direction) and (2) are paralleled with the Y-axis (1 in ea. direction), X-axis grooving saw.

Options included: (1) 16.3 HP Vertically mounted HSD Electrospindle, liquid cooled and inverter driven at 1,000 - 24,000 RPM with max. torque from 12,000 - 20,000 RPM.

"Ride Along" 10-position Automatic tool changer for "on-the-fly" tool changes with HSK-63F tool holders.

Work area with: Flat table designed for "Nested Base Manufacturing" with (2) independent working areas, (12) external pop-up reference pins with (8) on the back of the table and (2) on the RH side and (2) on the LH side. The unit is prepared for (optional) "quick fit" vacuum outlets for optional clamping of small or irregularly shaped parts.

Separate control console Controller, MS-Windows based technology, Pentium- CPU, hard drive, CR-ROM reader, mouse, USB ports, parallel port, Serial port, and network card. Software for easy programming of boring, routing, and grooving functions.

Operating system for real-time multitask processing; programs can be transferred via diskette or downloaded by wire; built-in 1,500 W air conditioner for constant temperature & dust-free environment.

Emergency stop rope & pressure sensitive safety mats that will instantly place machine in "pause cycle" when stepped on and surrounding safety cage; sound absorbing protective head enclosure with debris curtain around bottom edge.

Busch vacuum pumps included

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense).

Payment is due within 24 hours of auction close. Payments must be made via bank wire transfer for any amount above $1,500. Credit cards may be used up to $1,500 (3% processing fee). Please Contact Sabrina Correa with payment questions at 209-839-7707 Any sales tax exemption documents are to be emailed to [email protected] at time of purchase/invoice for tax exemption consideration.