MB "Roba Profi Edge" Profile Edge Sander  Ended

Ended

Haas Cabinets - Complete liquidation Sale - Building #1

Sellersburg, IN

- Winning Bid : $5,450.00 USD Sold

- 4 Bid(s)

- High Bidder: n****e

Haas Cabinet liquidation of assets from all buildings- Building #1 Day 2 of 2 ( Closed #71085712 )

Founded in 1939 and after 3 generations, HAAS cabinet is closing their doors and offering up all assets in this online only sale. This sale includes the assets from Building # 1. This is Day-2 of a 2-Day sale. Some of the highlights included in this 700+ lot sale are: Biesse "Rover B 1638" CNC Router (2017), Biesse "Rover A 1332 ATS" CNC Router, Biesse "Sektor 450" Beam Saw - Front Load, MB "Roba Profi Edge" Profile Edge Sander, Accu-Systems "MMTJ" Miter Door Machine (2016), Unique "311" Double Cope Machine, Circle T "LM 214" Miter Shaper & much much more.

-

Pick Up Location

625 W Utica St, Sellersburg, IN 47172

-

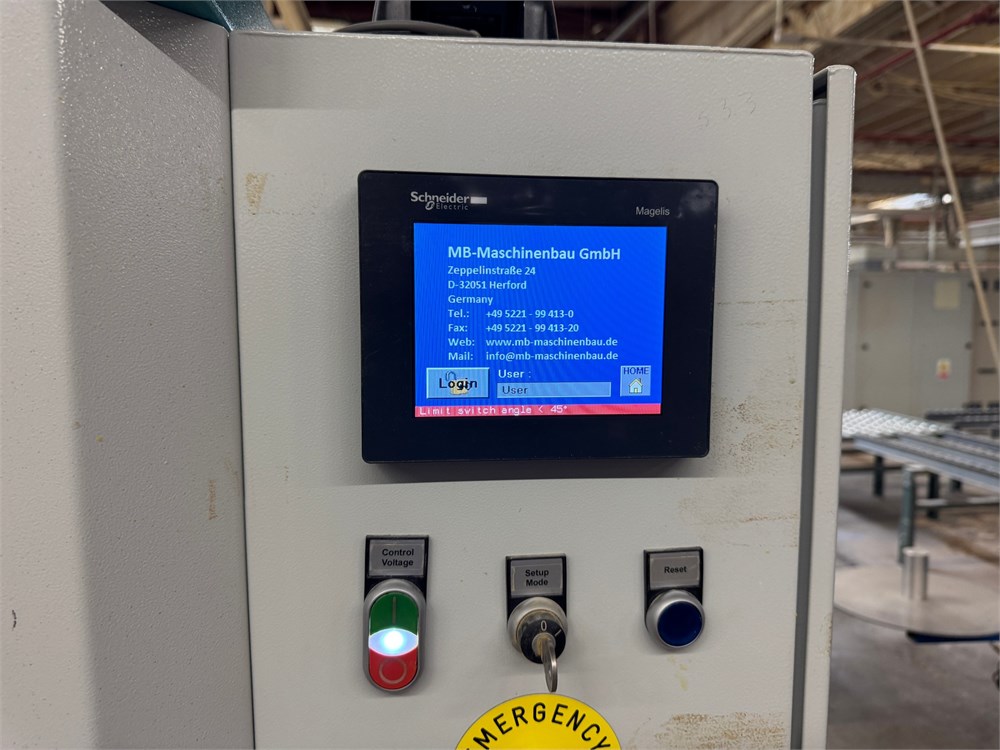

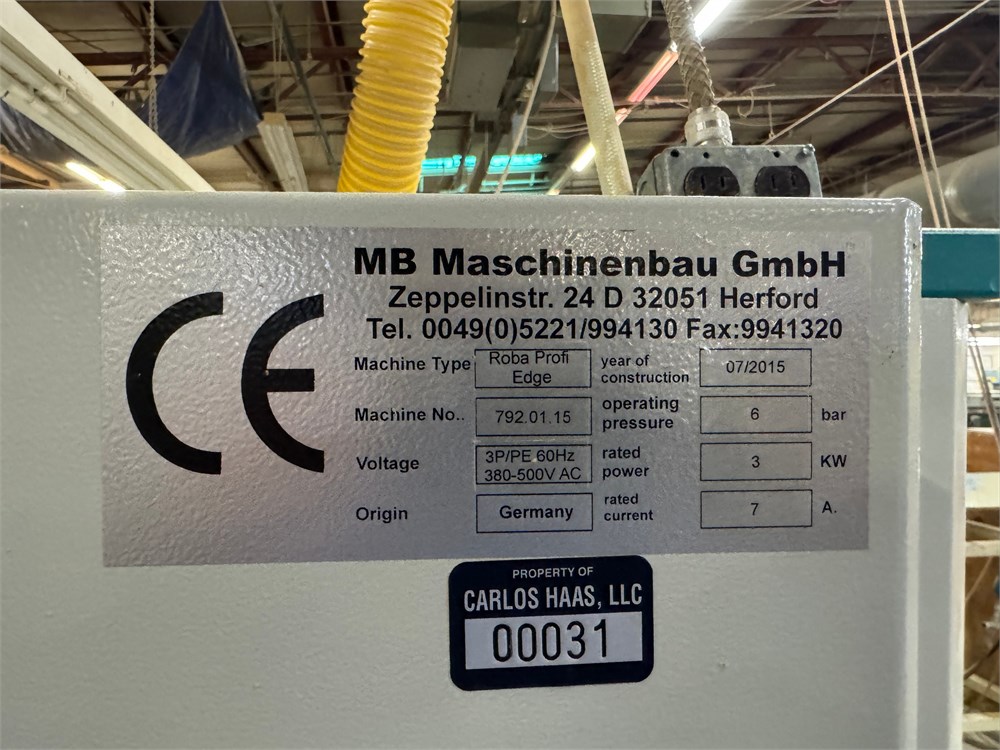

Make

MB

-

Model

"Roba Profi Edge"

-

Serial Number

792.01.15

-

Year

2015

-

Phase

3 PHASE

-

Voltage

460 VOLT

-

Buyer Inspection Period

April 23, 2025 8AM to 1PM & April 24, 2025 12PM to 4PM

-

Load Out Period

May 5 - 15th By appointment ONLY

-

Estimated Dimensions

128"L x 60" x 72"H

-

Estimated Weight

5,000 Lbs

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal. By appointment ONLY!

-

Load Fee

0.00

-

Lot Notes

-

page views

825

MB "Roba Profi Edge" Profile Edge Sander

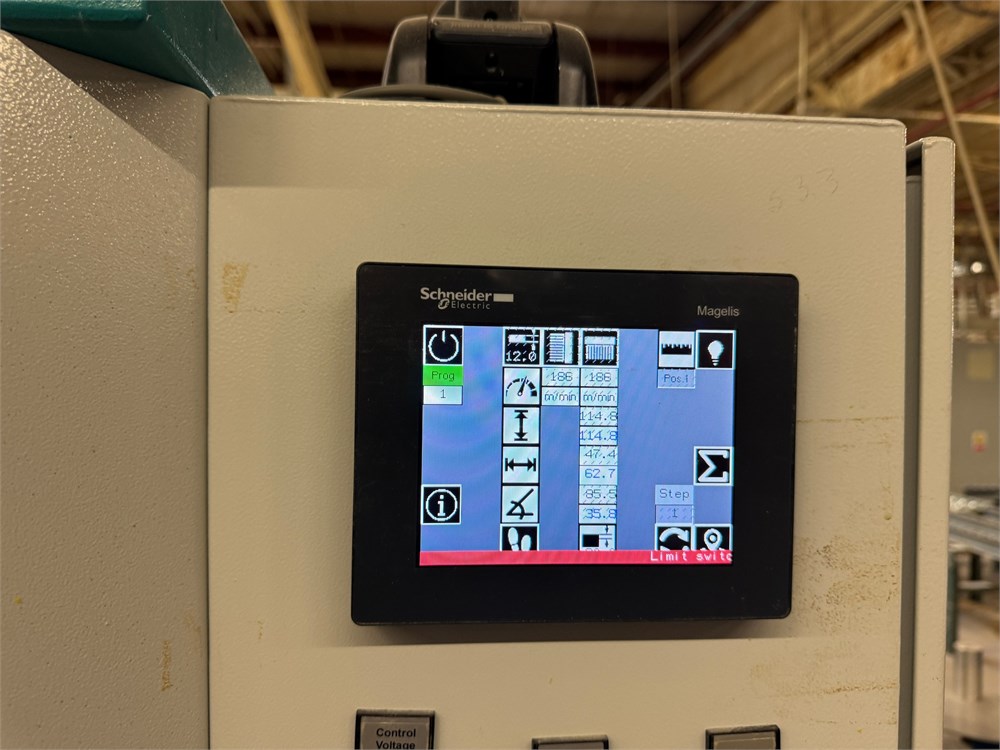

The machine uses the typical MB double brush unit, which is attached to a mobile support that moves in the background along the stationary workpiece. Extra-large sanding tools, which rotate frequency-controlled clockwise and counterclockwise, ensure an excellent sanding of the workpieces. A jump control avoids over rounding the corners and the unit oscillation ensures that the abrasives are fully utilized. A pneumatic pressure bar clamps the workpiece, which is particularly advantageous for large workpieces, as the parts do not have to be moved.

Rather, the workpiece rests and the sanding unit moves in the encapsulated machine, creating a save and dust free environment. The tools, which rotate in two directions, ensure that the end-grain areas of solid workpieces are perfectly sanded. When sanding MDF, protruding fibers are removed and the surface is smoothed. In both cases the further processing in the painting department is made considerably easier. Different tools can be flexibly mounted on the 200mm long spindles: A 200mm high cylindrical brush or two 100mm stacked tools, which can be equipped with different grits. Also tools with a chamfered sanding area are used for complicated edge contours. The combination of these options makes the machine very flexible. Which tool is used for a specific process is stored in the sanding program and will be pneumatically positioned.

The working cycle is typically executed in a way that e.g. a cabinet door, starting with the short side, is rotated by 90° after finishing a given edge till the four-sided sanding is complete. The actual sanding position is approached in high-speed mode, while the sanding area itself is passed at a programmed processing speed.

Sanding can be done in different ways:

– Sanding starting from the right parking position to the left, then back to the parking position in high-speed mode.

– Sanding starting from the right parking position to the left, waiting in this position until the workpiece has been rotated, to sand on the way from left to right.

– Sanding starting from the right parking position to the left, to sand again on the way from left to right.

– Sanding starting from the right parking position to the left, waiting in this position until another tool on the spindle has been called up in order to sand now with the new tool on the way from left to right.

These functions can also be used if you place and clamp several workpieces next to each other. This makes sense if the sum of the long sides does not exceed the working area and increases productivity.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available