Omga "Optima 240" Optimizing Cut-off Saw (2020)  Ended

Ended

Haas Cabinets - Complete liquidation Sale - Building #1

Sellersburg, IN

- Winning Bid : $37,100.00 USD Sold

- 146 Bid(s)

- High Bidder: J****l

Haas Cabinet liquidation of assets from all buildings - Building #1 Day 1 of 2 ( Closed #70979205 )

-

Pick Up Location

625 W Utica St, Sellersburg, IN 47172

-

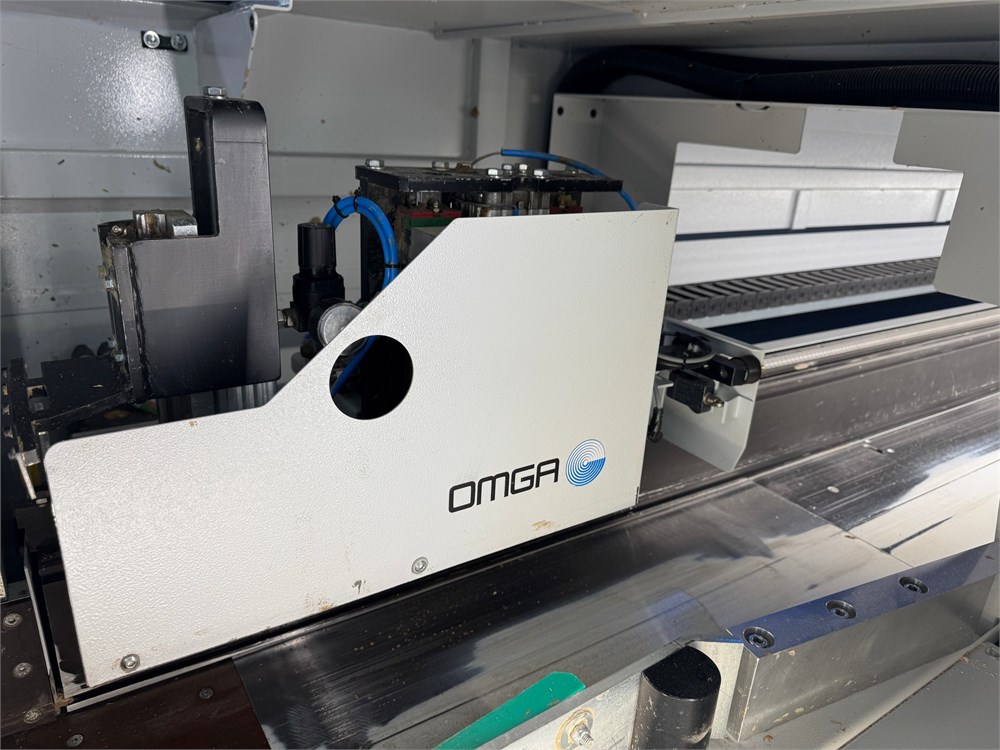

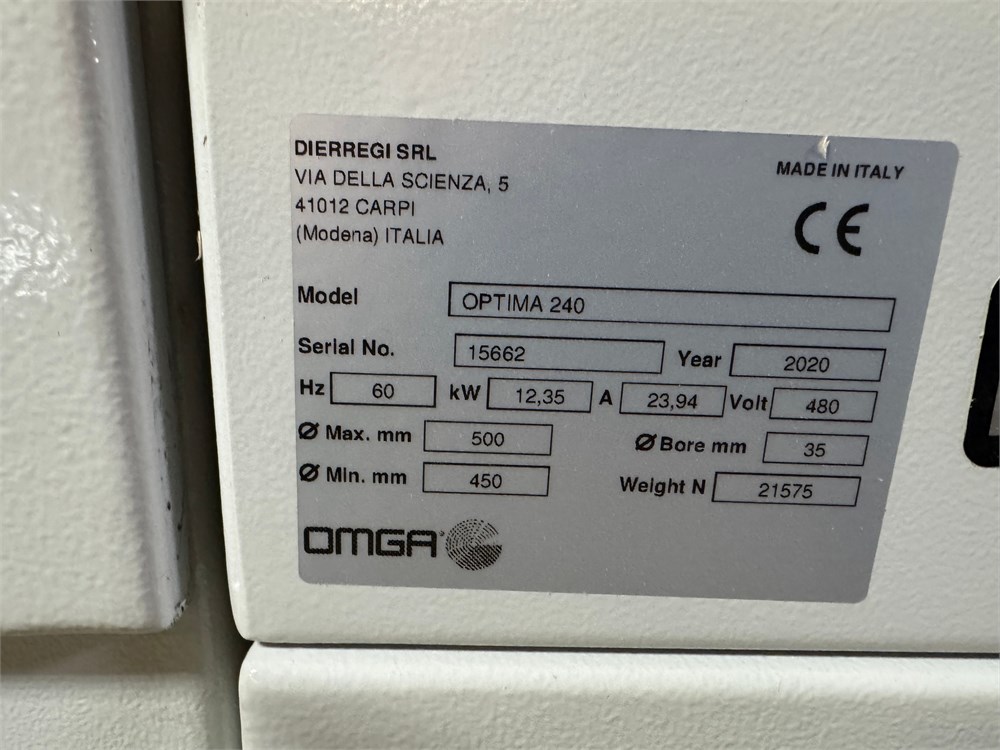

Make

Omga

-

Model

"Optima 240"

-

Serial Number

15662

-

Year

2020

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Buyer Inspection Period

April 23, 2025 8AM to 1PM & April 24, 2025 12PM to 4PM

-

Load Out Period

May 5 - 15th By appointment ONLY

-

Estimated Dimensions

See photos and description

-

Estimated Weight

6,000 Lbs

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal. By appointment ONLY!

-

Load Fee

-

Lot Notes

-

page views

1492

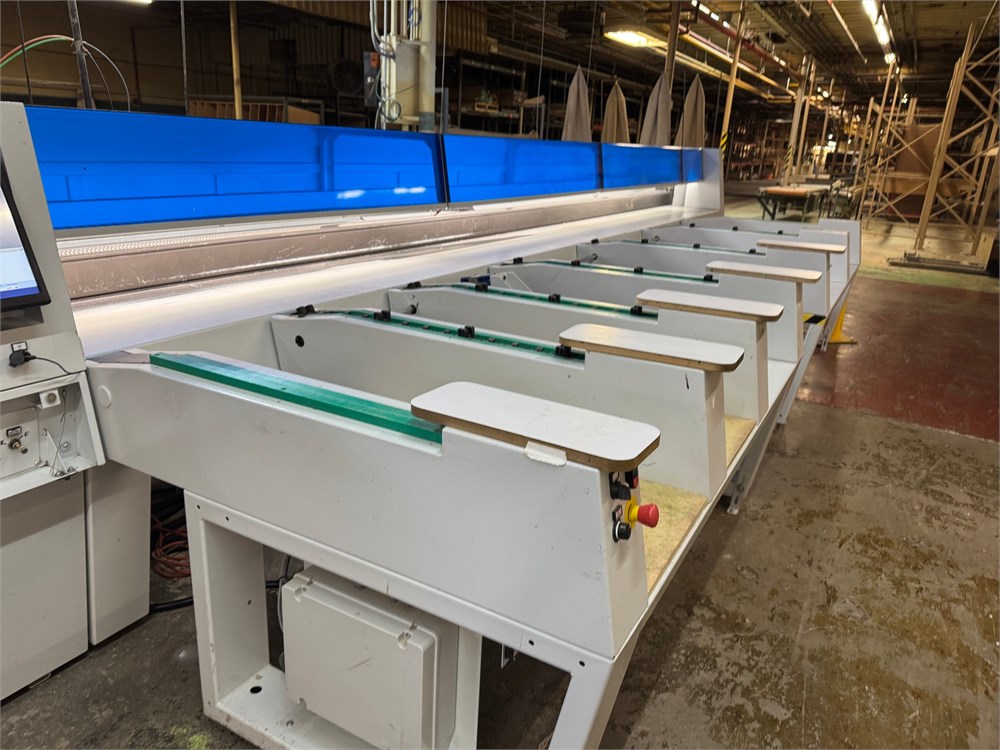

Omga "Optima 240" Optimizing Cut-off Saw (2020)

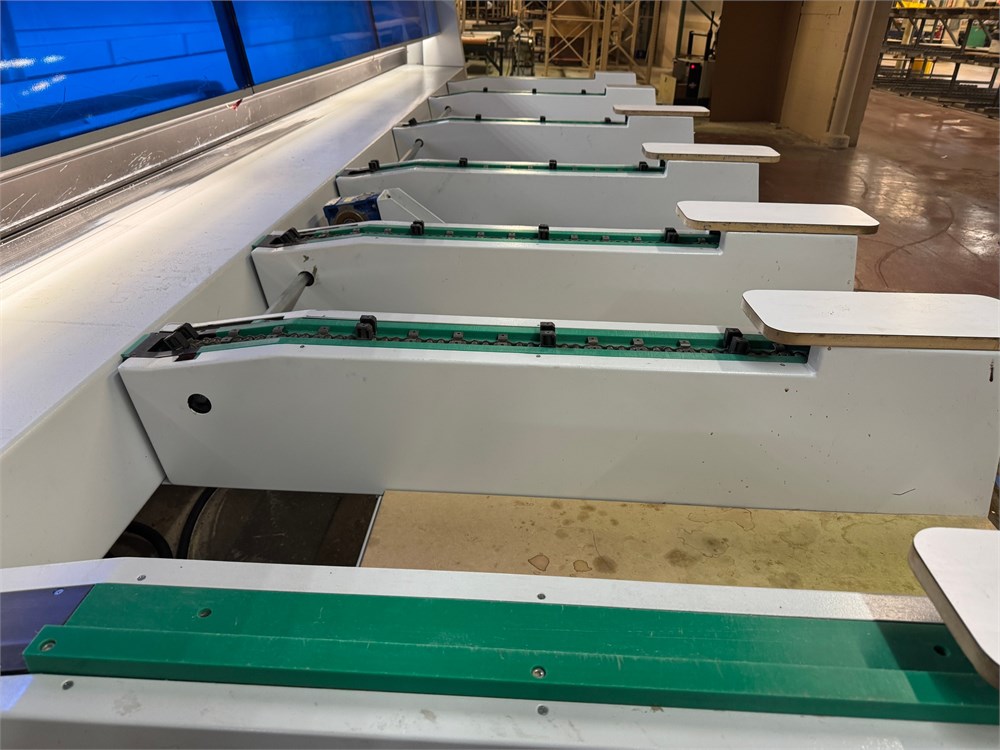

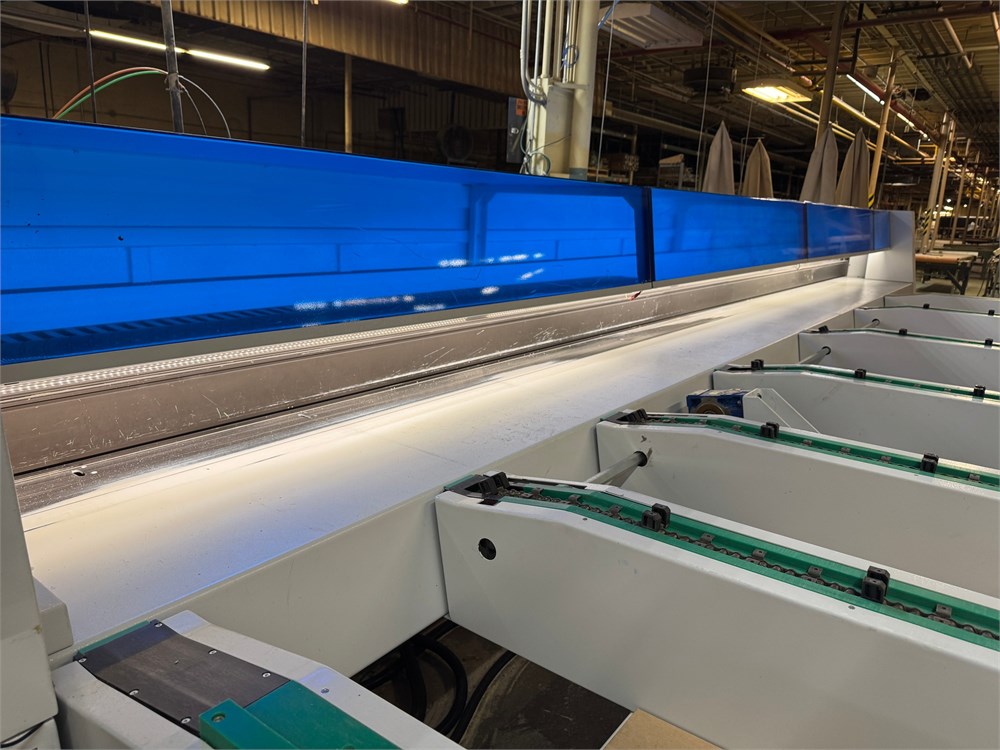

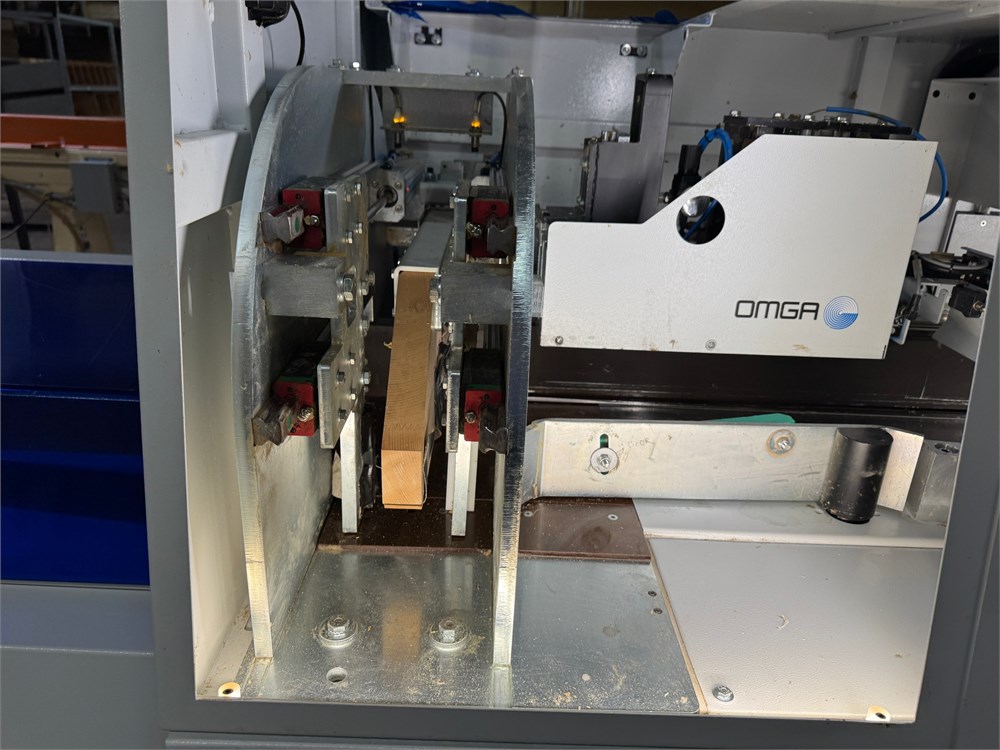

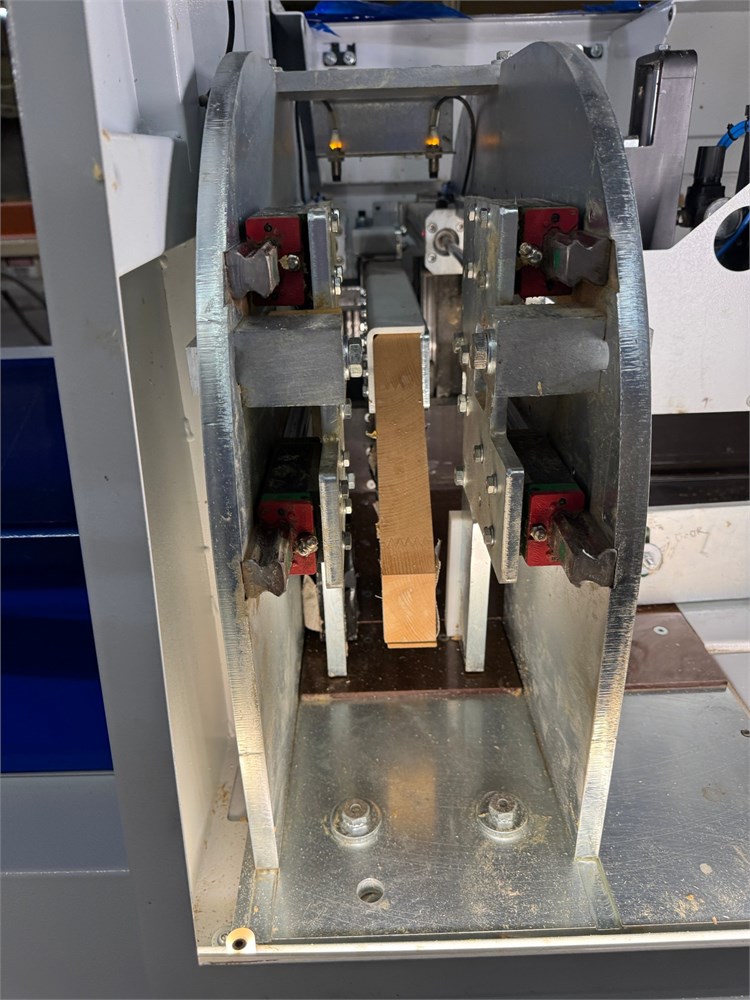

The OPTIMA 240 is a Push-Feed Optimizing and Defecting Cut- Off Saw, for high speed production. The last generation CNC, with Windows Embedded OS and connected to an adjustable 19" Touch Screen display, combines reliability, ease of use and always maintains the ergonomic position of the operator. The network connection is guaranteed by an available RJ45 Ethernet port and the software allows for reports on the ongoing production runs, to always be available on screen or through the network, without interrupting the process of the machine. The pusher system, rides on precision linear rails and bearings and, along with the pneumatic tail clamp and linear encoder, ensures very accurate positioning of the work piece (+/- 0.15 mm). The loading table, allows the operator to grade and prepare multiple boards which may be loaded in sequence, eliminating waste of time. The cutting area is fitted with a system of "intelligent" vertical and horizontal clamps, which automatically adapt to the dimension of the stock being processed, making the cutting cycle faster and ensuring the squareness of the cut pieces. The optimization software features a wide variety of available cutting programs and combinations, which make this system very versatile and ready to respond to the different needs of the industry.

(5) 42" Infeed chains, dogs spaced every 20", adj. to every 3".

6,200MM (20.15') Infeed pusher

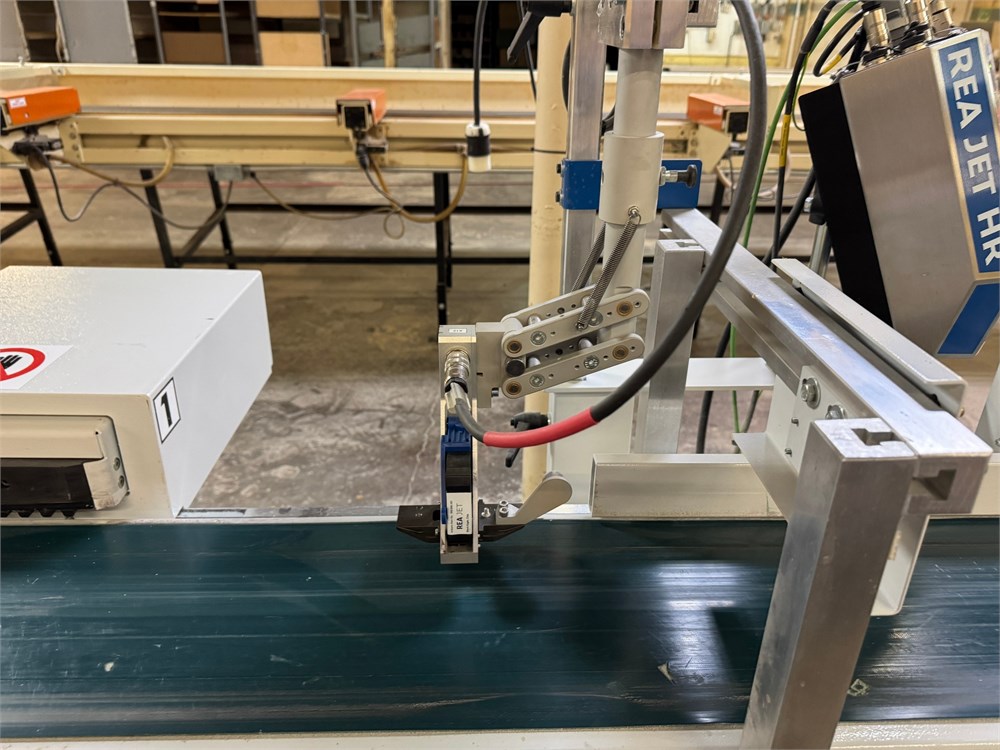

Powered belt 9" Wide out-feed belt, 502"L, (7) Kicking stations

26'L x 48" Tilted receiving deck

REA Jet High speed printer

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available