Barberan "HOK-C-2-1400" UV Finishing Tunnel (2021)  Ended

Ended

CabinetWorks Complete Plant Auction Finishing Dept and Vehicles

Thompsontown, PA

- Winning Bid : $5,000.00 USD Sold

- 25 Bid(s)

- High Bidder: C****o

CabinetWorks Finishing and Vehicle Auction (Day 4 of 5) - Thompsontown, PA ( Closed #69666595 )

Finishing equipment including MB sanders, Superfici, Dubois, Prime Heat, Barberan, custom hang line and vehicles including semis and pickups.

-

Pick Up Location

Katy, TX

-

Make

Barberan

-

Model

HOK-C-2-1400

-

Serial Number

22040

-

Year

2021

-

Phase

3 PHASE

-

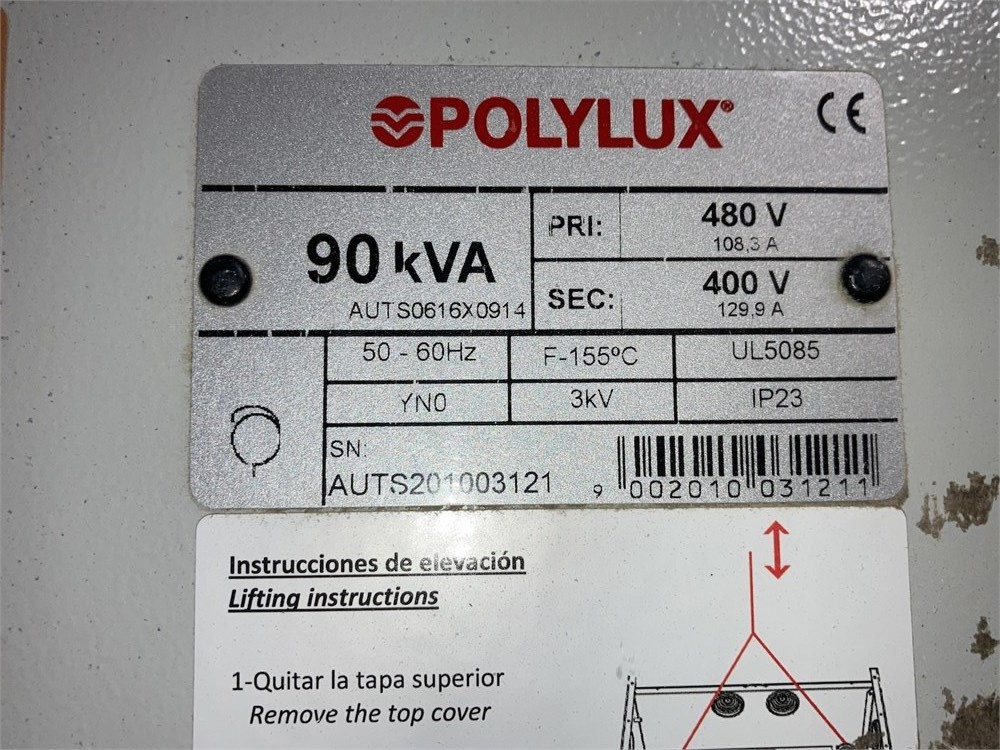

Voltage

480 VOLT

-

Buyer Inspection Period

March 12 and March 13, 2025 (9 am - 3 pm) or by appointment

-

Load Out Period

March 24 - April 7, 2025 (8 am - 4 pm daily including weekends, by appointment) unless other arrangements made in advance

-

Estimated Dimensions

96"L x 84"W x 60"H (Tunnel) - 72"L x 36"W x 84"H (electric cab.)

-

Estimated Weight

-

Seller Comment

A non-negotionable loading fee has been established. This includes loading onto a flat bed trailer. Requests for additional labor, crating or pallatization will be extra.

-

Load Fee

495.00

-

Lot Notes

-

page views

724

This unit has been moved to Katy, TX Warehouse

54" Width cap.

HOK Lamps 120 W.cm

480V to 400V Transformer

24KW Power

The tunnel holds two cross 80 W/m mercury UV curing lamps, each one in a high gloss elliptical aluminum reflection screen with turbine air flow cooling that has to be connected to the main exhaustion net of the factory (tubes longer than 4 m, need an extractor fan).

A continuous Electronic Power Supply switches to stand by power when no panels are passing through the drying tunnel. A photocell detects entering of pieces and switches the lamps to the set power. The lamp cooling system keeps in whatever condition the optimum working temperature enabling anytime the instantaneous switching to working mode.

A pneumatic lamp rotary shutter emergency system, with simultaneous stand by power

switch, hides the lamps automatically in case of conveyor stop.

An endless bar conveyor with a lower bed protection is used for the transport of the work pieces under the tunnel. Tilt protection covers at the tunnel in and out feed prevent the dazzling produced by the lamps. Built in the conveyor bottom there is the pressurized electric cabinet, that is fully wired with lamp control devices, non resetable hour counter, switch, the electronic speed inverter for the conveyor, and the PLC that manages the

lamps' rotary system and the maneuver probes.

A raised control board with the main emergency stop, commanding push buttons, and the touch screen for speed control and continuous lamp power regulation are also included.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available