Weeke "Optimat BP 120" CNC Pt. to Pt. Machining Center  Ended

Ended

CabinetWorks Complete Plant Auction (Day 3 of 3)

Thompsontown, PA

- Winning Bid : $5,450.00 USD Sold

- 33 Bid(s)

- High Bidder: A****3

CabinetWorks Complete Plant Auction (Day 3 of 5) -Thompsontown, PA ( Closed #69211555 )

Day 3 Featuring: (3) Schelling "FH6 330/310 Rear Load Auto Beam Saws, HolzHer "Accura 1554" Automatic Edgebander, (2) MB Maschinenbau "ROBA" Bottom Sanding Machines, HolzHer "Arcus 1334 V2" Automatic Edgebander, Lift Tables, Weeke "Optimat BHX 500" CNC Machining Center, Plus Much More!

-

Pick Up Location

Thompsontown, PA

-

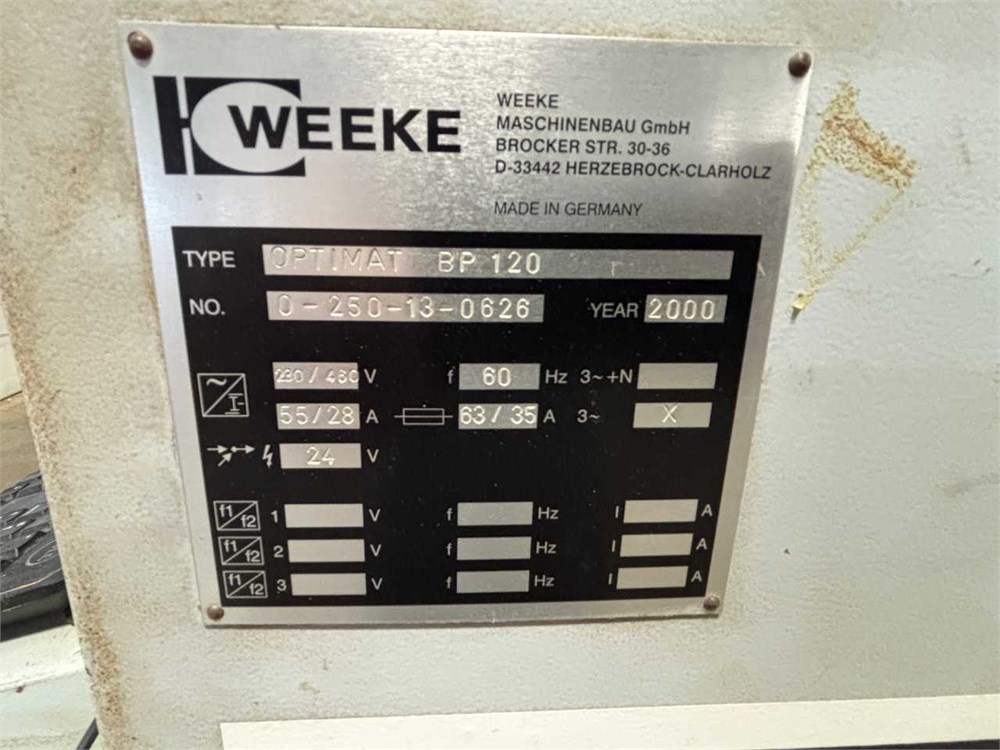

Make

Weeke

-

Model

Optimat BP 120

-

Serial Number

0-250-13-0626

-

Year

2000

-

Phase

3 PHASE

-

Voltage

230/460

-

Buyer Inspection Period

March 12 and March 13, 2025 (9 am - 3 pm) or by appointment

-

Load Out Period

March 24 - April 7, 2025 (8 am - 4 pm daily including weekends, by appointment) unless other arrangements made in advance

-

Estimated Dimensions

-

Estimated Weight

-

Seller Comment

Rigger Required for Removal

-

Load Fee

-

Lot Notes

-

page views

869

Weeke "BP 120" CNC Router - Pod & Rail

Work area cap. "X" axis110" (2,800 mm), "Y" axis 49.2" (1,250 mm), "Z" axis stroke 10.2" (260 mm), max. material thickness 6.7" (170 mm).

"X" axis 263 FPM (80 MPM), "Y" axis 196 FPM (60 MPM), "Z" axis 64 FPM (20 MPM). The head travels on THK linear motion guides on all axes.

(8) Moveable support rails w/side mounted raise & lower panel feeding rail, (2) square matrix vacuum pods each rail.

(8) Pneumatic backstops, (2) movable pneumatic side stops, (2) working zones for pendulum processing.

Boring Unit; 2 HP (1.5 kW) motor; (20) independent vertical spindles with (10) in "X" axis & (10) in "Y" axis with (1) shared spindle.

(1) Aux. separate spindle for up to 35 mm dia. drills.

(1) 4-Way Horizontal boring unit, (1) "X" axis grooving saw with 100 mm dia. blade.

(1) 10 HP (7.5 kW) Electro-spindle with HSK F63 adaptor. 1,000 -18,000 RPM.

(1) 8-Position ATC tool plate mounted to the back of the machine

There is NO vacuum pump included with this machine. Vacuum pumps available in other lots.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available