Giben "KG368J" Automatic Edgebander  Ended

Ended

CabinetWorks Complete Plant Auction (Day 3 of 3)

Thompsontown, PA

- Winning Bid : $2,100.00 USD Sold

- 13 Bid(s)

- High Bidder: Q****r

CabinetWorks Complete Plant Auction (Day 3 of 5) -Thompsontown, PA ( Closed #69211555 )

Day 3 Featuring: (3) Schelling "FH6 330/310 Rear Load Auto Beam Saws, HolzHer "Accura 1554" Automatic Edgebander, (2) MB Maschinenbau "ROBA" Bottom Sanding Machines, HolzHer "Arcus 1334 V2" Automatic Edgebander, Lift Tables, Weeke "Optimat BHX 500" CNC Machining Center, Plus Much More!

-

Pick Up Location

Thompsontown, PA

-

Make

Giben

-

Model

KG368J

-

Serial Number

-

Year

2014

-

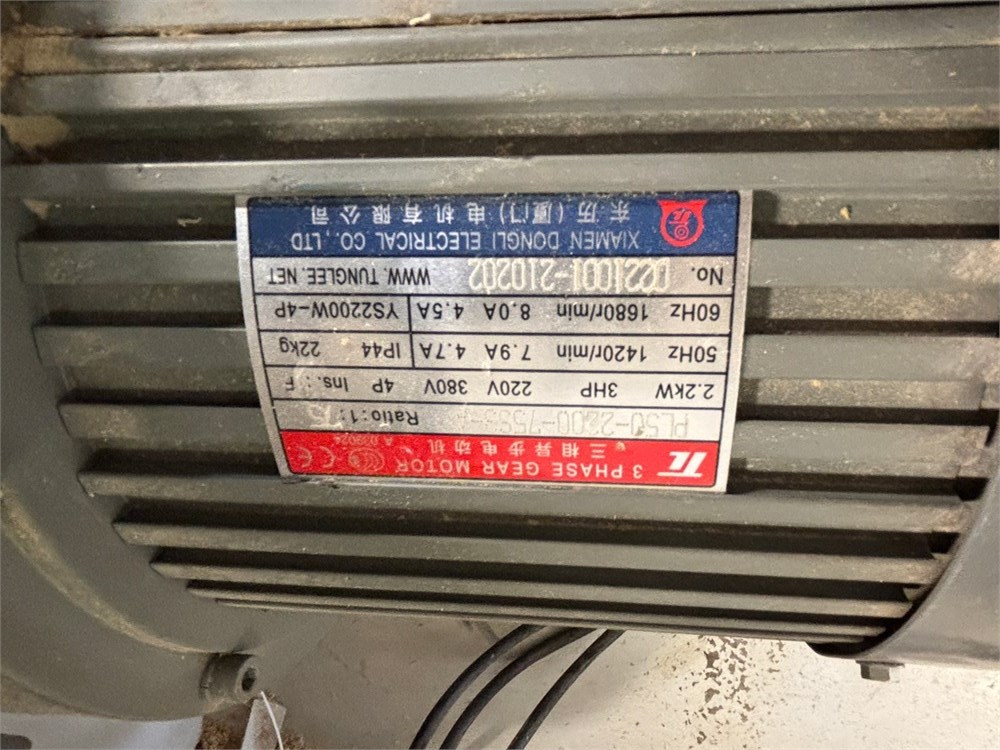

Phase

3 PHASE

-

Voltage

230 VOLT

-

Buyer Inspection Period

March 12 and March 13, 2025 (9 am - 3 pm) or by appointment

-

Load Out Period

March 24 - April 7, 2025 (8 am - 4 pm daily including weekends, by appointment) unless other arrangements made in advance

-

Estimated Dimensions

18' x 4' x 6'

-

Estimated Weight

4000 pounds

-

Seller Comment

A non-negotionable loading fee has been established. This includes loading onto a flat bed trailer. Requests for additional labor, crating or pallatization will be extra.

-

Load Fee

250.00

-

Lot Notes

-

page views

939

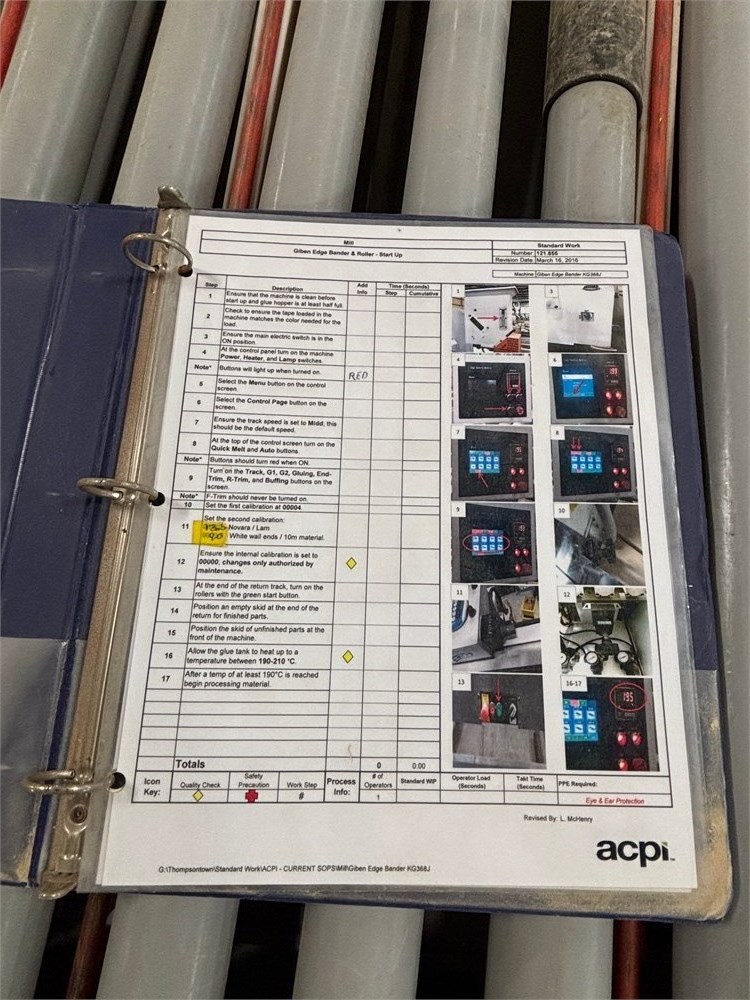

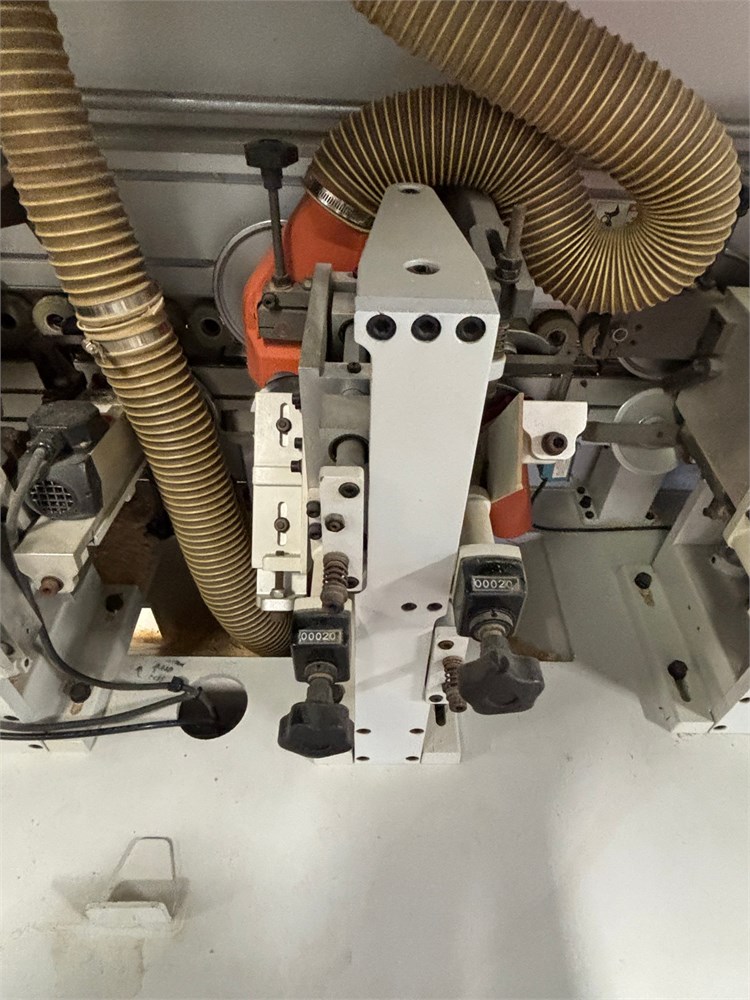

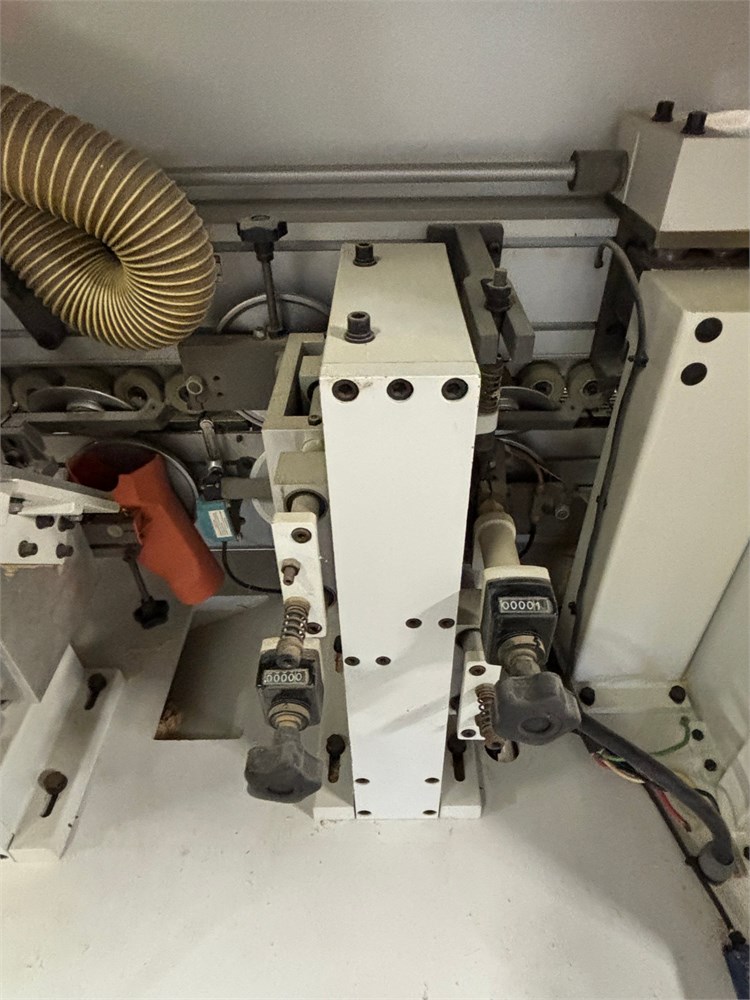

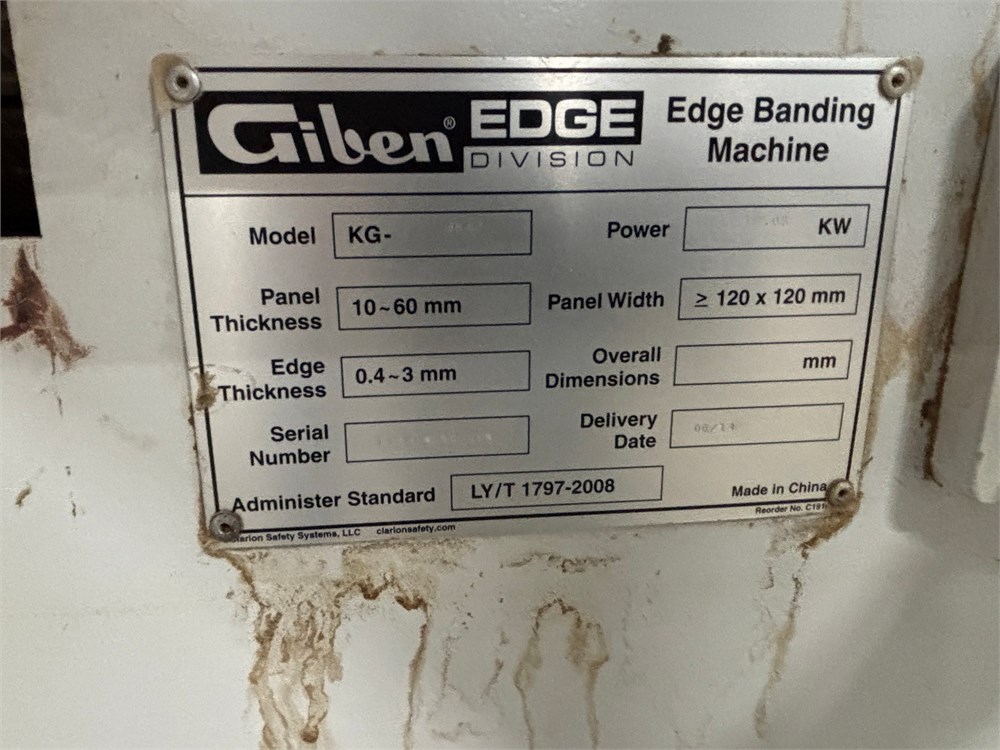

Giben "KG-368J" Edgebander

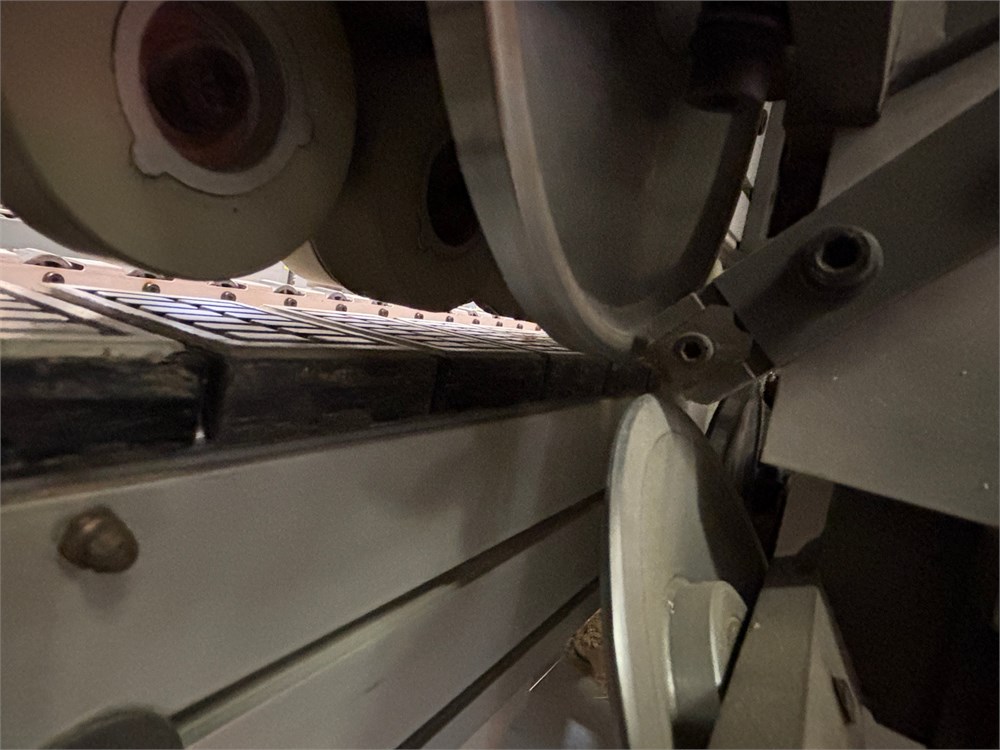

10 - 60 mm (0.4 - 2.4") panel thickness

0.4 - 3 mm (0.02 - 0.12") )edgebanding thickness (coils)

120 mm (4.7") minimum panel width

Motorized raising/lowering of top beam

Variable feed speed

Touchscreen PLC

Edgebanding infeed table

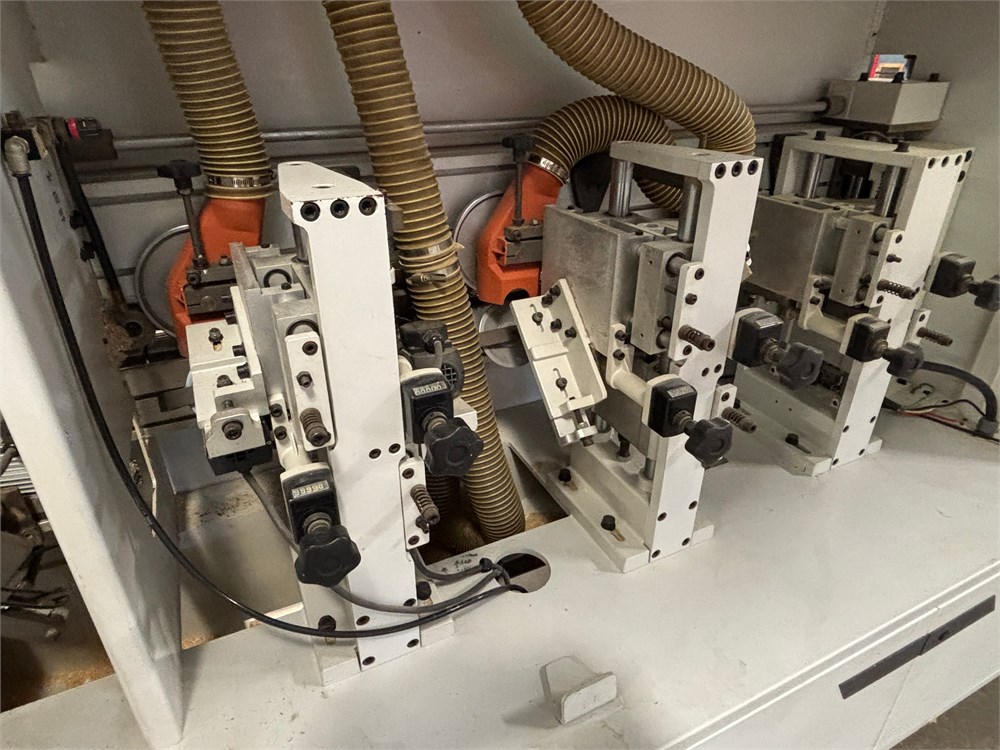

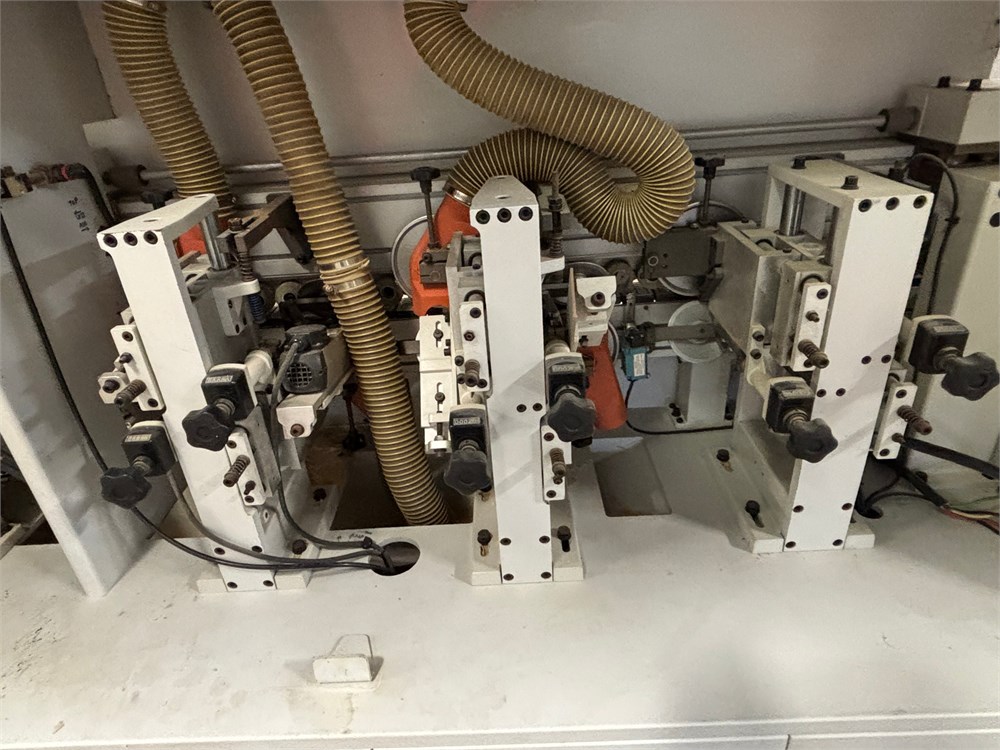

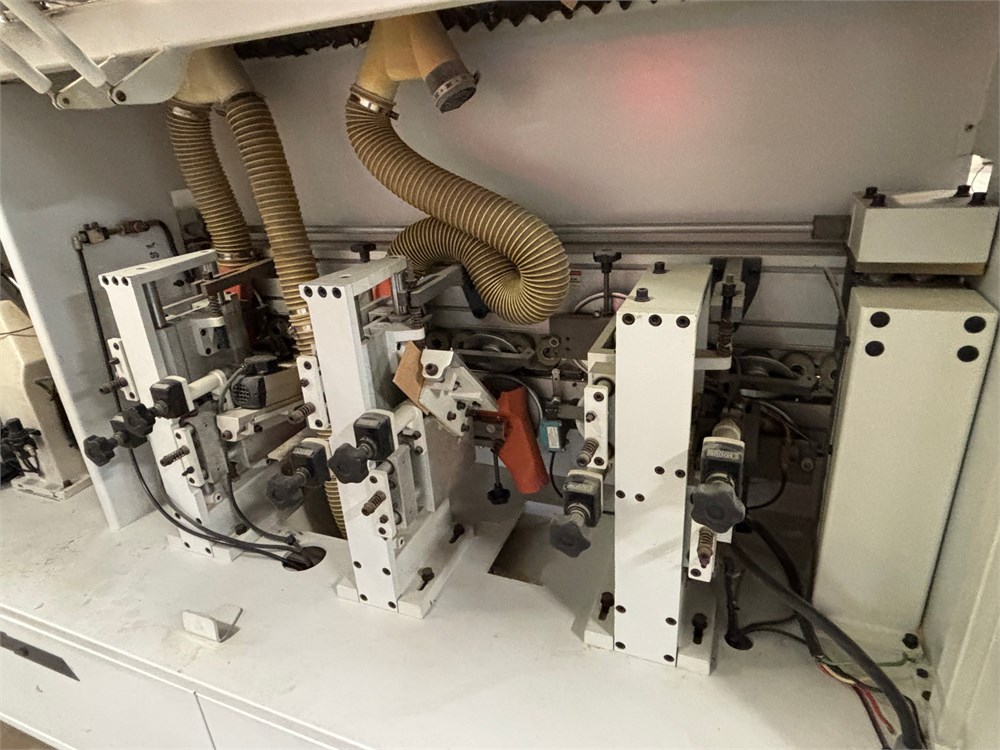

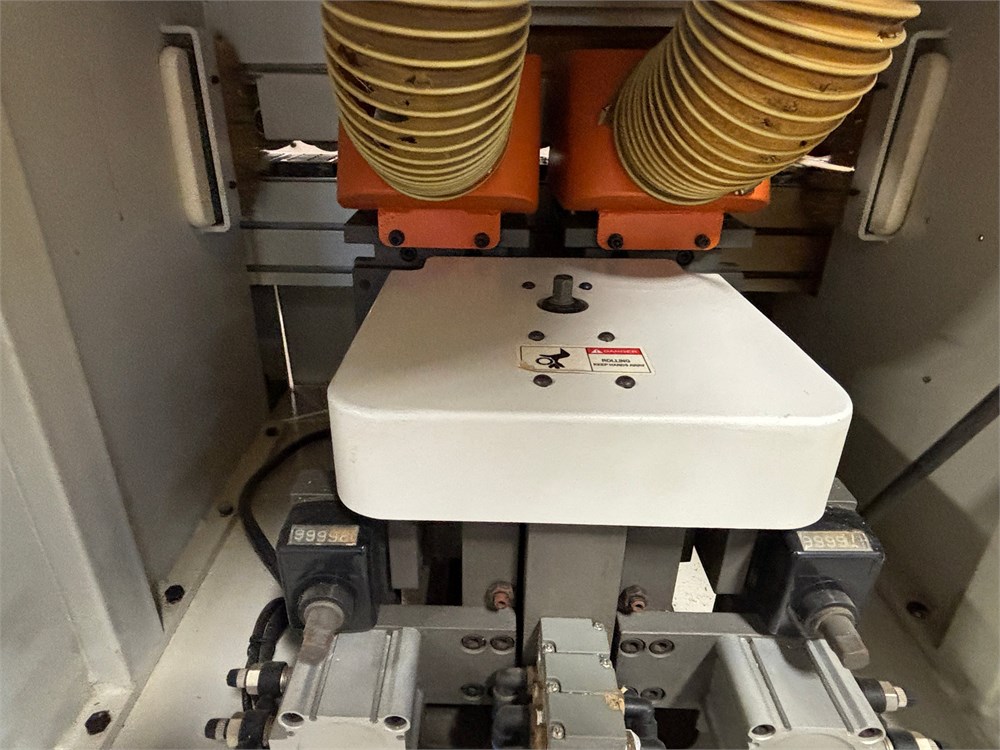

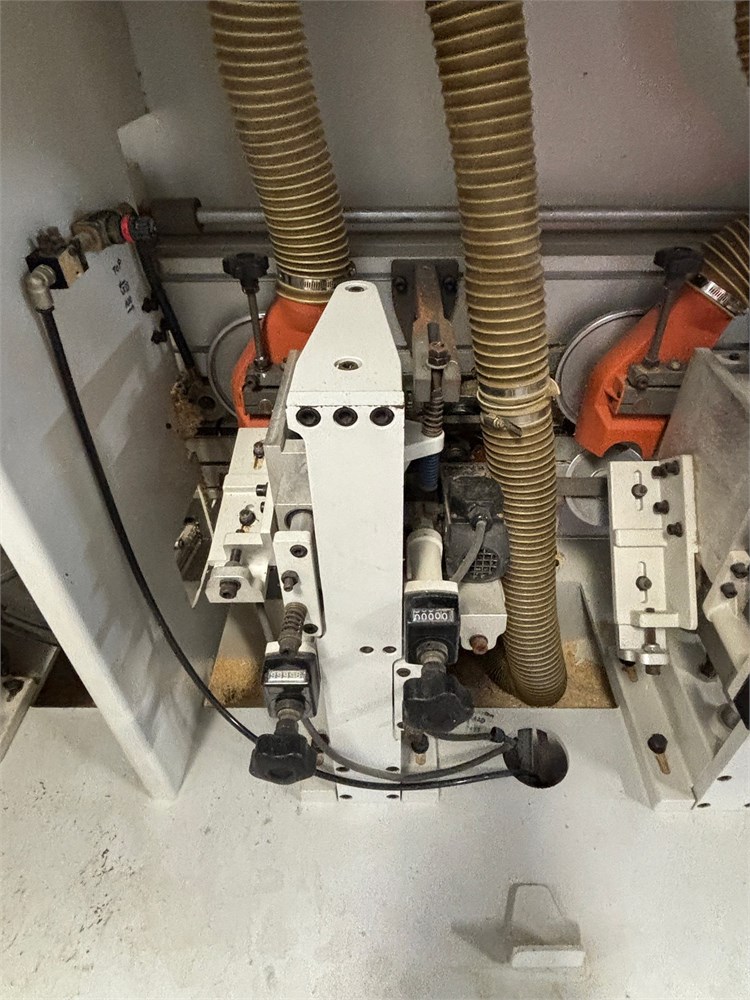

Two (2) motor premill station

Guillotine

Glue station with roller and premelt hopper

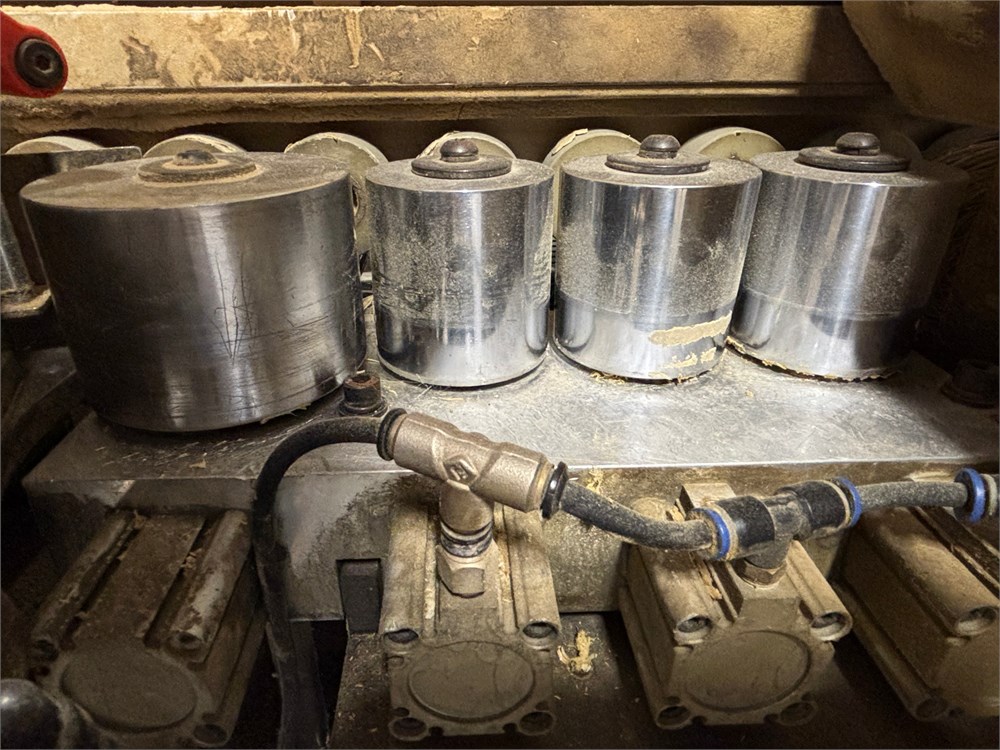

Pressure station

One (1) driven roller

Three (3) idle rollers

End trim station

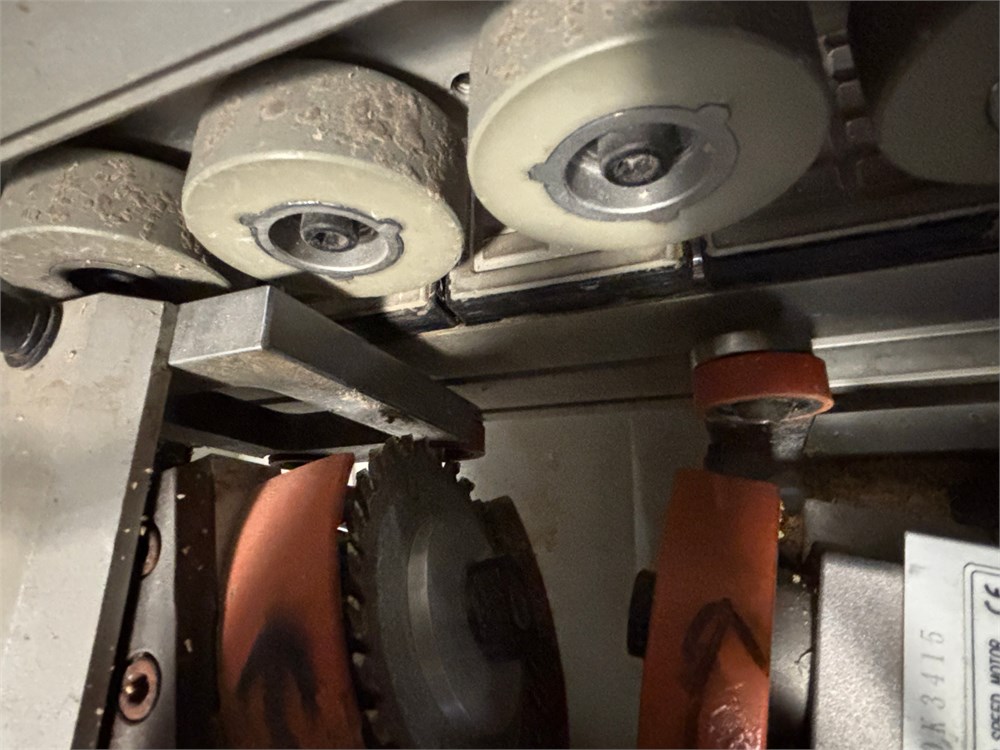

Top/bottom trim station (rough)

Top/bottom trim station (fine)

Top/bottom scrape station

Sound enclosure

Outboard roller support

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available