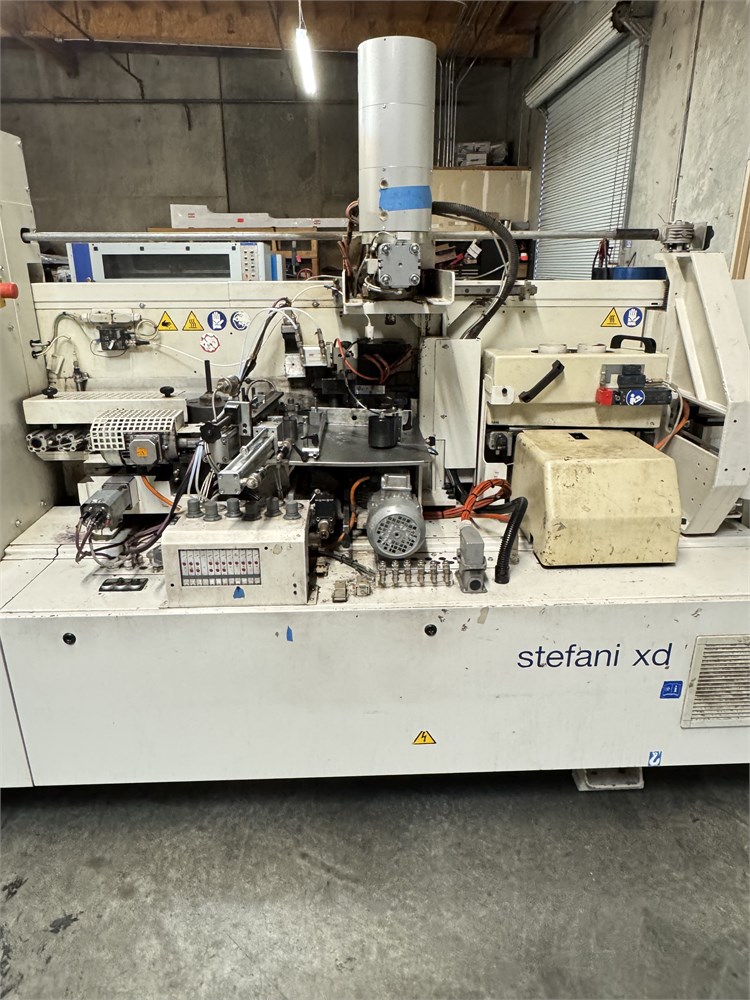

SCM Group "Stefani Solution XD Series" Automatic Edgebander (2018)  Ended

Ended

Woodworking Machinery Warehouse Auction - Tracy, CA

Tracy, CA

- Winning Bid : $11,050.00 USD Sold

- 32 Bid(s)

- High Bidder: T****y

Woodworking Machinery Warehouse Auction - Tracy, CA ( Closed #69083211 )

All assets moved to Tracy California warehouse for the convenience of buyers. Items include 2018 SCM Group Stefani XD High Production Edgebander, SCM SI400 Nova Sliding Table Saw, 2023 Kaeser Air Compressor System, Quincy Air Compressor System, SCM K560TE Edgebander, SCM K300E Edgebander, Maksiwa 2023 Edgebander, and much more.

-

Pick Up Location

2203 N. MacArthur Drive, Tracy CA 95376

-

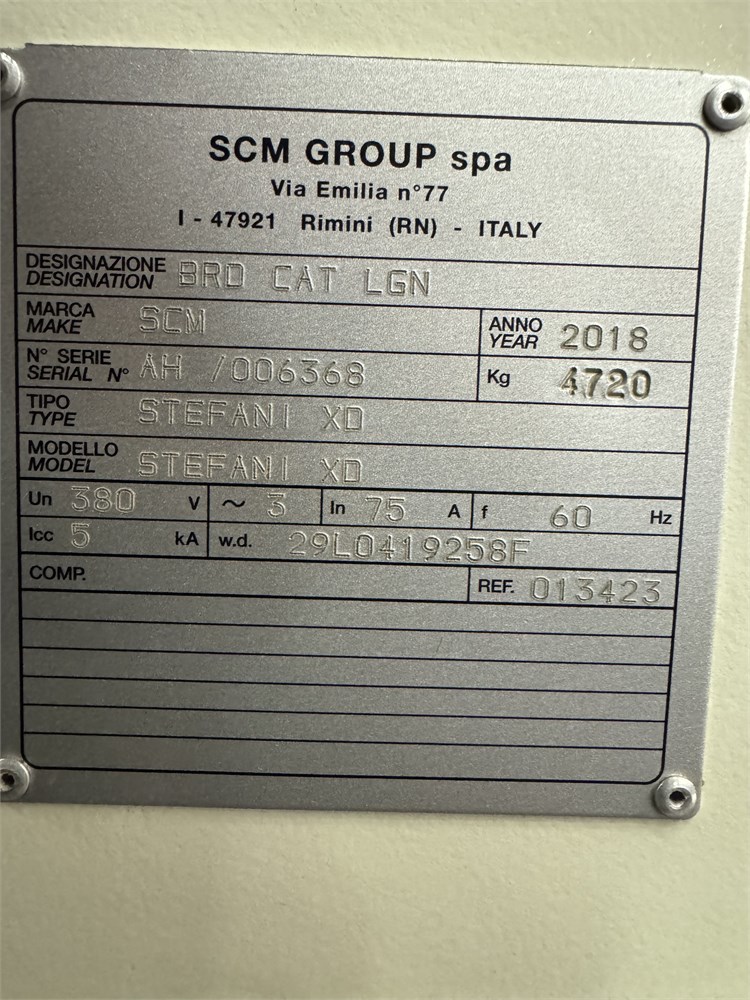

Make

SCM Group

-

Model

Stefani Solution XD

-

Serial Number

AH006368

-

Year

2018

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Buyer Inspection Period

By appointment. Please contact: Kirk Gass - [email protected] - 925-250-8248

-

Load Out Period

February 14th & February 17th , By Appt. Only

-

Estimated Dimensions

Approximately 30' Long

-

Estimated Weight

Approximately 11,000 lbs.

-

Seller Comment

-

Load Fee

1995.00

-

Lot Notes

-

page views

1241

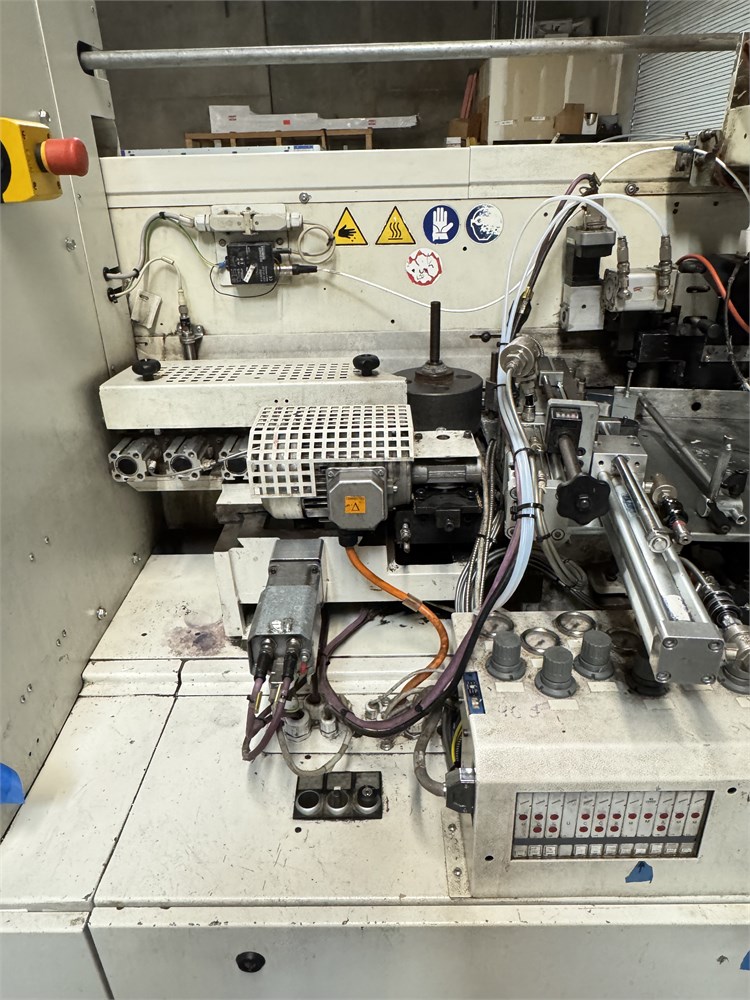

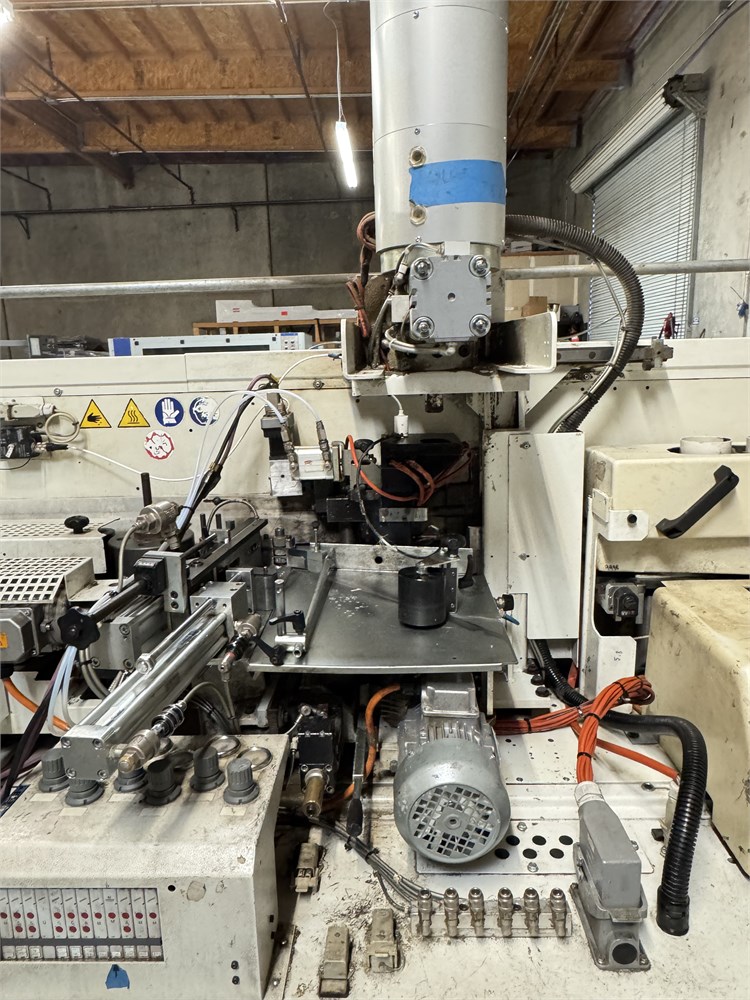

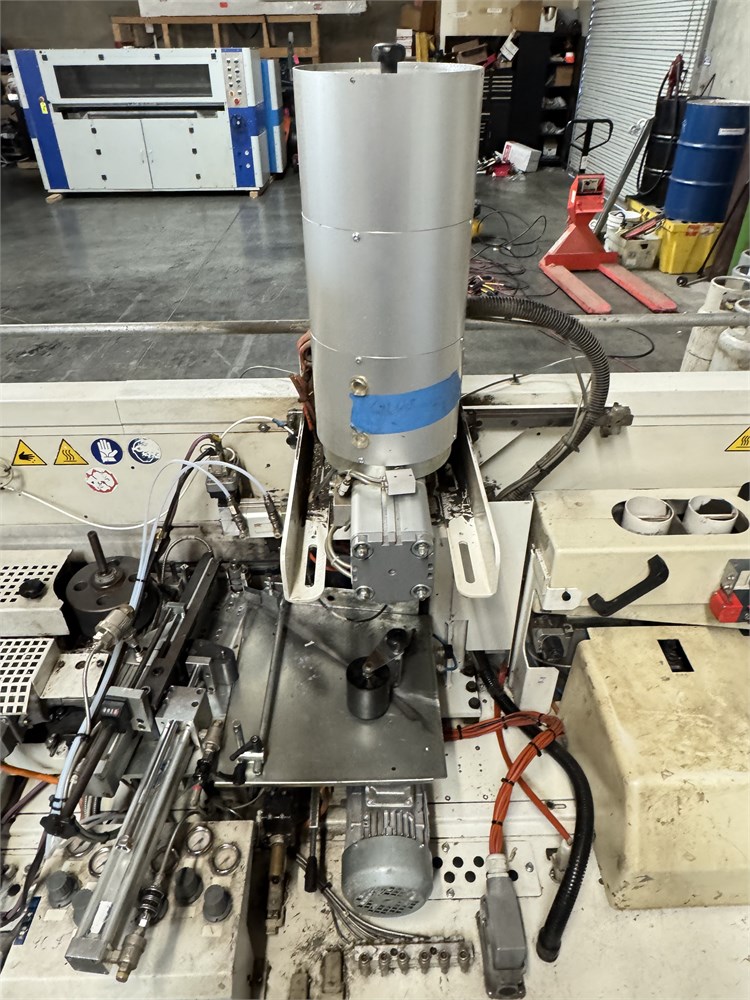

Solution XD 78 – Automatic Edgebander

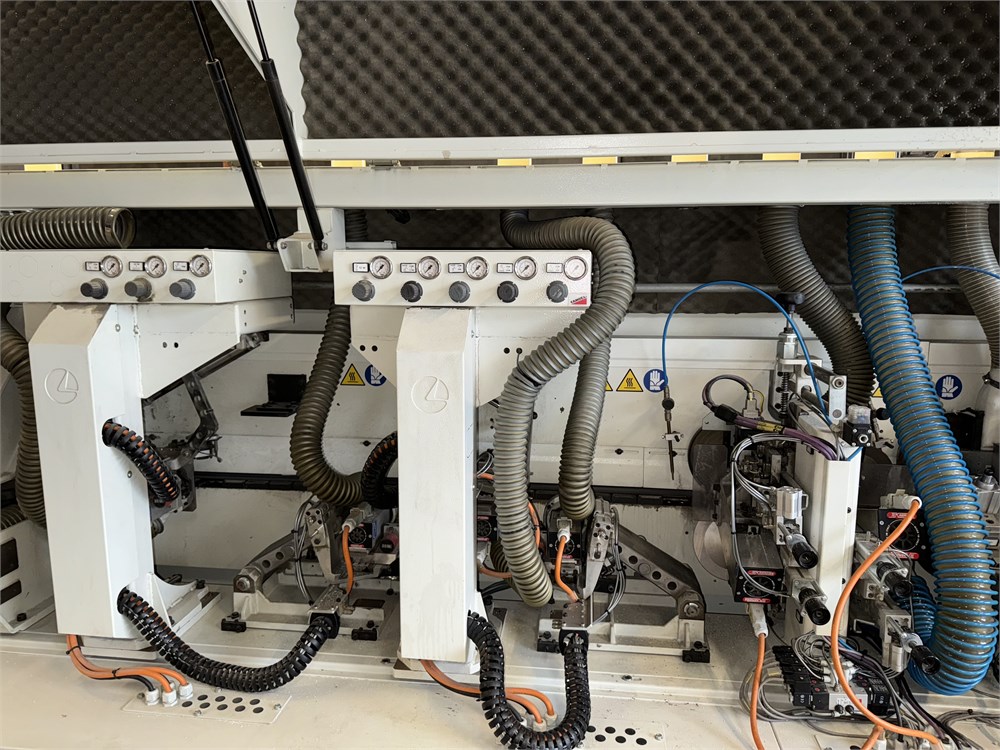

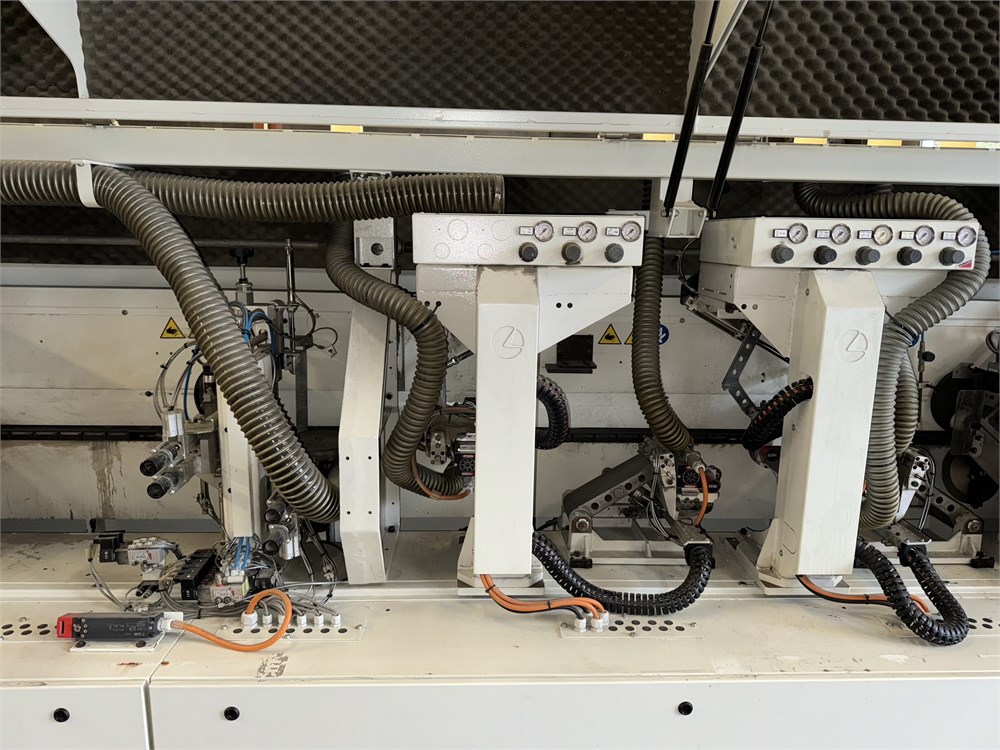

The machine base is fabricated using a heavy duty, mono-block design. This provides a solid surface for mounting all of the working units. This structure, pressure beam and working support units are all poured at SCM’s own Foundry & controlled throughout the fabrication inside the SCM Group, ensuring the most stringent specifications.

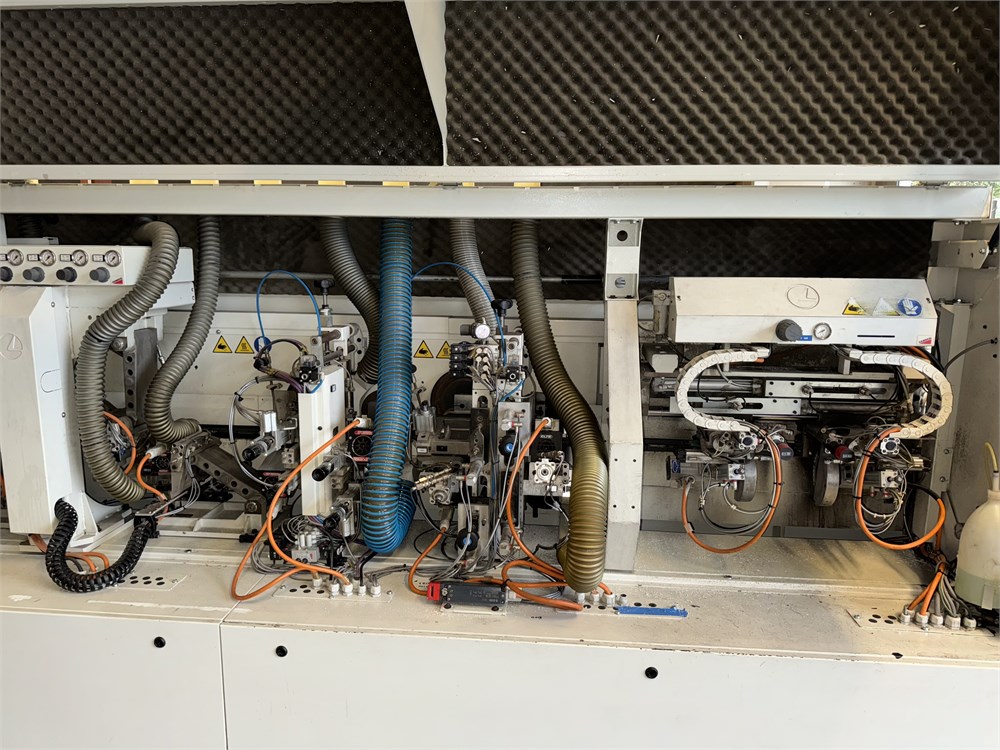

All working units are attached using the Heavy Duty “H” style supports that ensure a vibration free work environment which reduces the amount of “adjustments” that need to be made on motorized units under the hood.

The top pressure beam is made of thick steel to eliminate “flex” when maximum pressure is applied.

Top pressure beam is fitted with a twin-profile V-belt for even pressure & precise holding of even small work pieces.

The feed track consists of 70 mm wide, self-lubricating nylon sliders. The replaceable track pads are coated with wear resistant vulcanized rubber to prevent work piece movement.

The track guiding system consists of one flat guide and one round guide. The flat portion is located closest to the machine working units for maximum pressure while holding the work piece perpendicular to the working units. The round guide is located on the opposite side of working units to ensure perfect linear alignment by eliminating the possibility of “twist”. Both guides are made of hardened ground steel and are equipped with an automatic lubrication system.

The cabinet is coated with noise-reducing material and is illuminated with non-glare fixtures. The cabinet is custom configured to allow appropriate dust extraction for each working unit.

Technical Specifications

|

Working Height |

10-60 mm (3/8" – 2 3/8") |

|

Edge Thickness |

0.4-22 mm (7/8") |

|

Max. track speed (depending on edge thickness) |

12-25 m/min (40-82 FPM) |

|

Feed Motor Horsepower |

4 kW |

|

Minimum Panel Length: |

140mm (5 1/2”) 220mm ( 8 5/8”) with Corner rounding |

|

Minimum Panel Spacing |

630mm (24.5/8”) |

|

Min. coil length |

230mm |

|

Min. strips length (Solid wood and HPL) |

250mm |

|

|

|

|

Pre-Mill Unit |

|

|

Motor Power |

4 kW |

|

Rotation |

12,000 RPM |

|

|

|

|

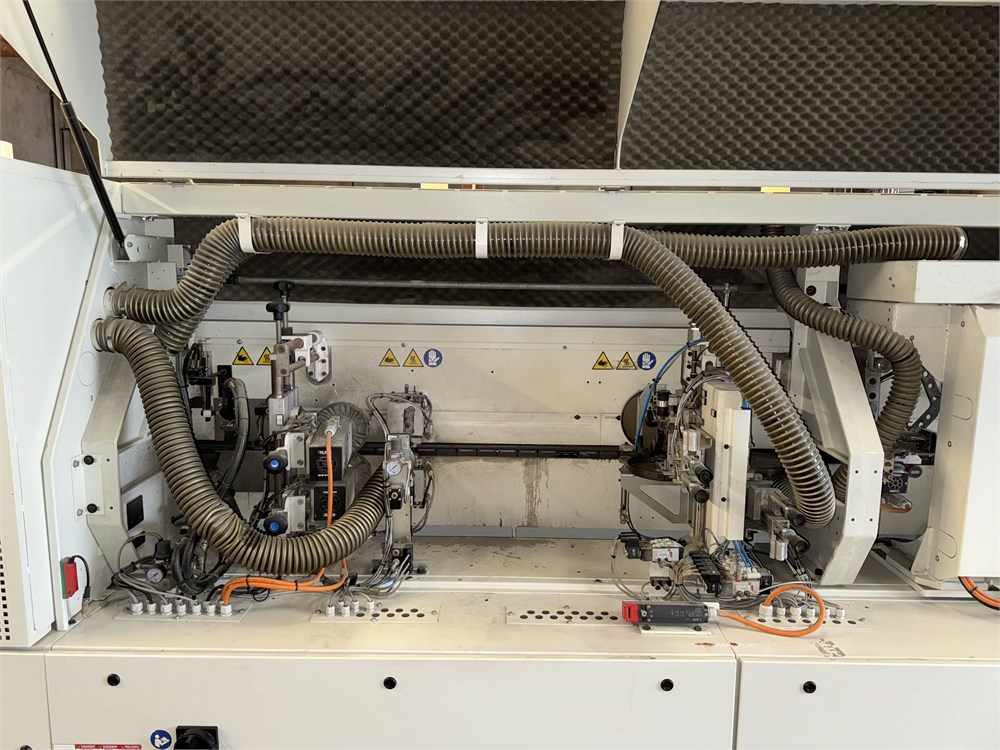

End Trimming Station: |

|

|

Motor Power |

0.8 kW ea. |

|

RPM |

12,000 RPM |

|

Automatic blade tilt |

0-22 degrees |

|

|

|

|

Edge Trimming Unit (1): |

|

|

Motor Power |

1.84 kW |

|

RPM |

12,000 RPM |

|

Tilting |

0-30 |

|

|

|

|

Edge Trimming Unit (2nd): |

|

|

Motor Power |

1.1 kW |

|

Tilt |

20 degrees fixed |

|

|

|

|

Cutting Tools, straight knife inserts (4) |

70mm x 12mm |

|

|

1 and 3 mm radius |

|

|

|

|

Corner Rounding Unit: |

|

|

Motor Power |

.35 kW ea. (4 motors) |

|

RPM |

12,000 RPM |

|

|

1 and 3mm radius |

|

Profile Scraping Unit: |

|

|

Knife Radius |

1 and 3mm radius |

|

|

|

|

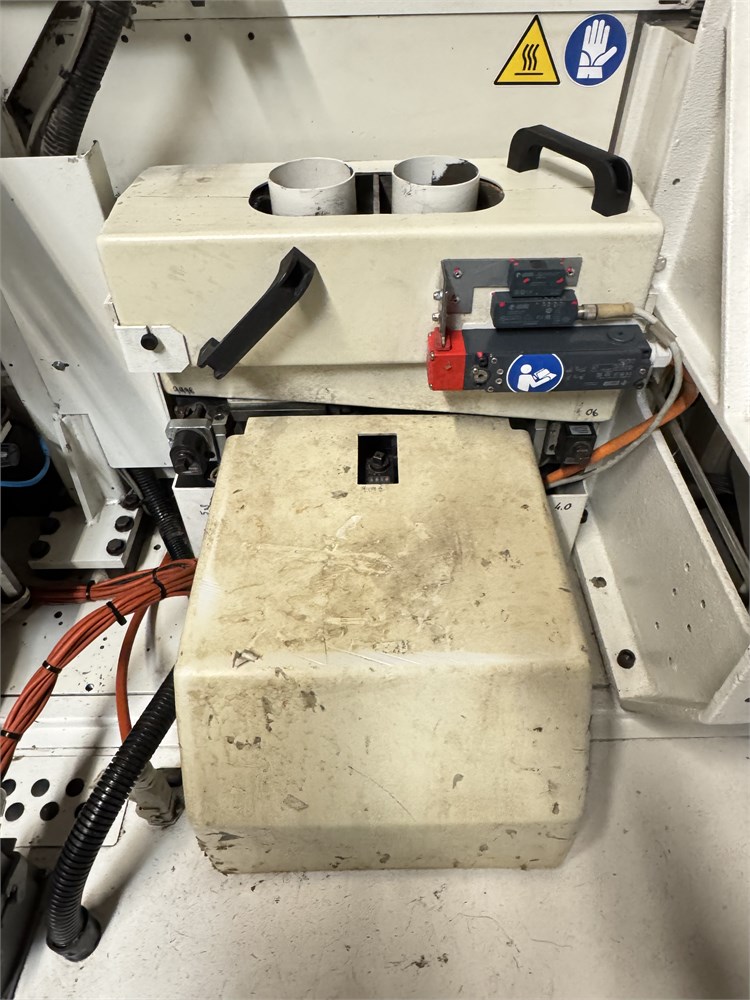

Glue Scraping Unit: |

|

|

Knife Radius |

Straight |

|

|

|

|

Buffing Unit: |

|

|

Motor Power |

0.29 kW |

|

RPM |

1,500 RPM |

|

Brush Dimensions |

150mm x 50mm x 33mm |

|

|

|

|

Pneumatic Operating Pressure |

90 PSI |

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available