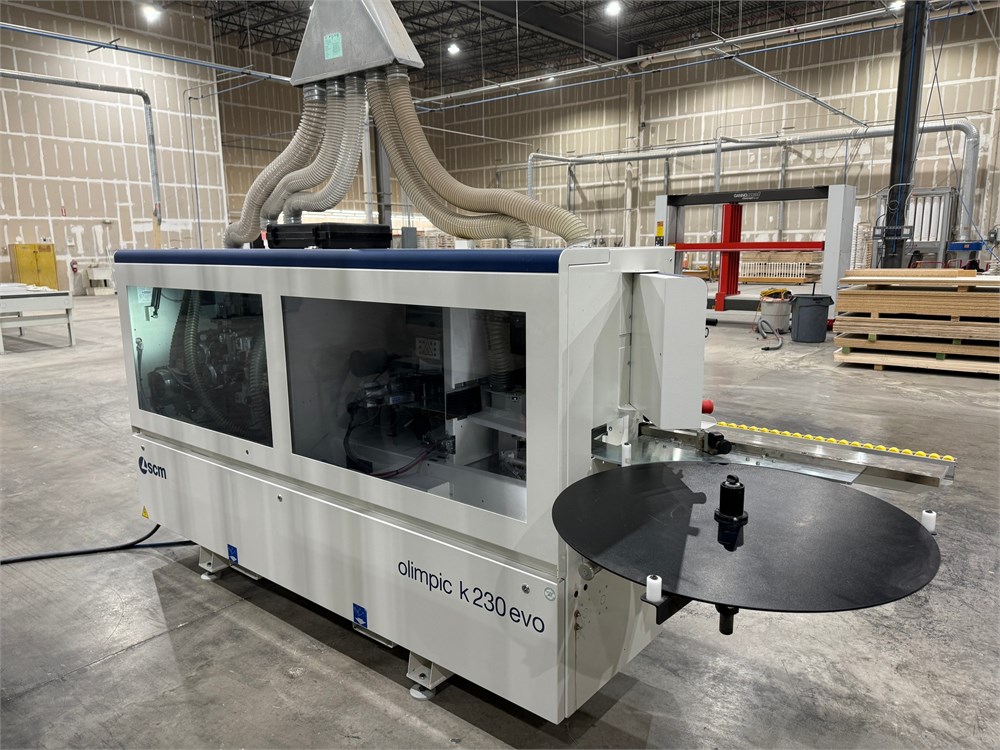

SCMI "Olimpic K 230-TE EVO" Edgebander with PreMill (2022)  Ended

Ended

Coastline Cabinetry & Custom Millwork - Fort Meyers, FL

Fort Myers, FL

- Winning Bid : $13,250.00 USD Sold

- 54 Bid(s)

- High Bidder: e****m

Coastline Cabinetry & Custom Millwork ( Closed #68994638 )

Over a 140 Lots of Late model machinery & more...including: SCMI "Morbidelli X200 Cell" CNC Machining Center (2022), (2) Coima "SHK5" Dust Collectors (2021), SCMI "Olimpic K 230 EVO" Edgebander (2022), Kaeser "Aircenter SK 20" Air Compressor Center (2022), Gannomat "Concept 70 ECO" Case Clamp,SCMI "Olimpic K 560" Edgebander (2017), Edgetech "CTS740" Countertop Saw, Edge Automation "ERC" Return Conveyor System, Evans/Midwest Laminating Line, VAC-U-CLAMP "FT 900" Thermoforming Vacuum Press, Toyota "7FGCU25" Forklift, Coima "SHK3" Dust Collector.

-

Pick Up Location

Fort Meyers, FL

-

Make

SCMI

-

Model

"Olimpic K 230 EVO"

-

Serial Number

AB00026294

-

Year

2022

-

Phase

3 PHASE

-

Voltage

220 VOLT

-

Buyer Inspection Period

Open House will be February 5, 2025 9Am - 3PM. No appt. Needed. Kirk Gass 925-250-8248 (text ok)

-

Load Out Period

February 11-13, 2025 (by appointment)

-

Estimated Dimensions

156" x 48" x 68"

-

Estimated Weight

2,400 Lbs

-

Seller Comment

A non-negotionable loading fee has been established. This includes loading onto a flat bed trailer. Paletization or other Services available for an extra fee.

-

Load Fee

750.00

-

Lot Notes

-

page views

1586

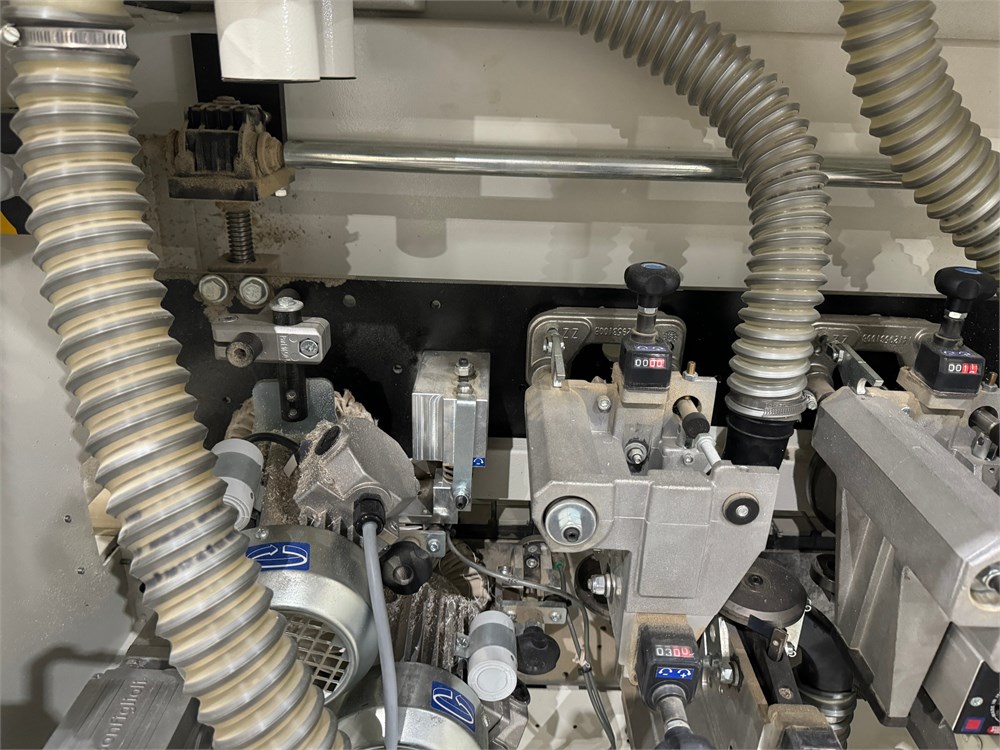

SCMI "Olimpic K 230TE EVO" Edgebander (2022)

0.4mm to 3mm Edge thickness, Panel thickness 8mm to 60mm (0.3" to 2.36"), minimum part width 60mm (2.36"), minimum part length 140 mm (5.5").

Fixed feed speed, 1.0 HP (0.75 kW) feed drive.

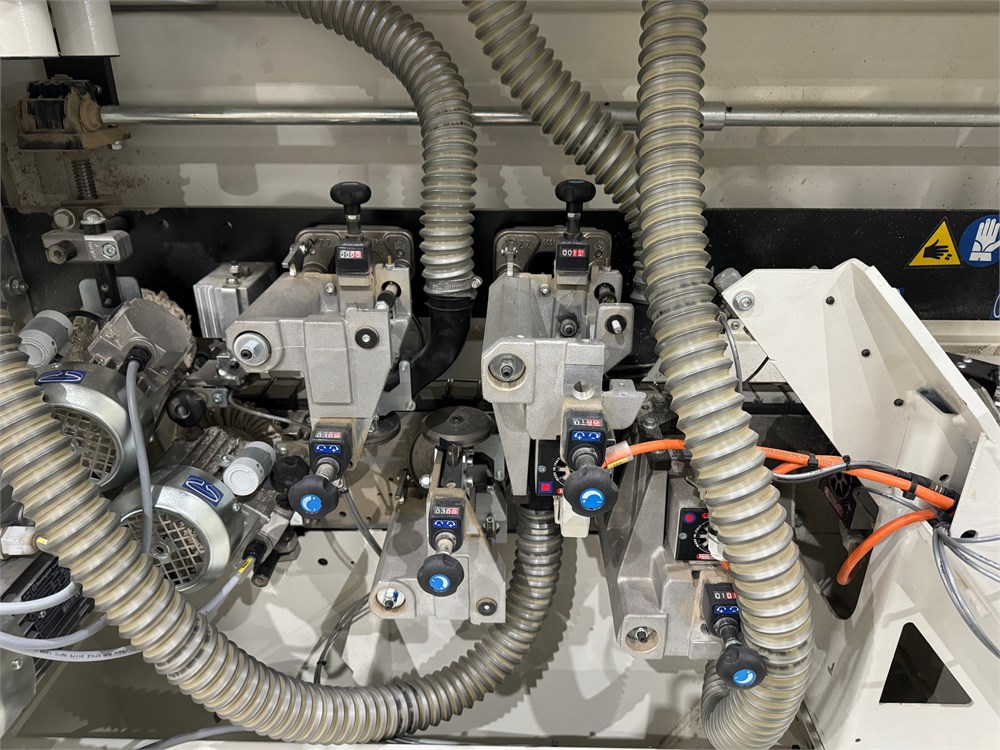

Pre-milling station, (2) 2.0 HP (1.5 kW) - 9,000 RPM motors, to rectify/clean panels already sized.

Adjustable In-feed Fence:Manually pre-set with digital indicator, pneumatic in/out positioning.

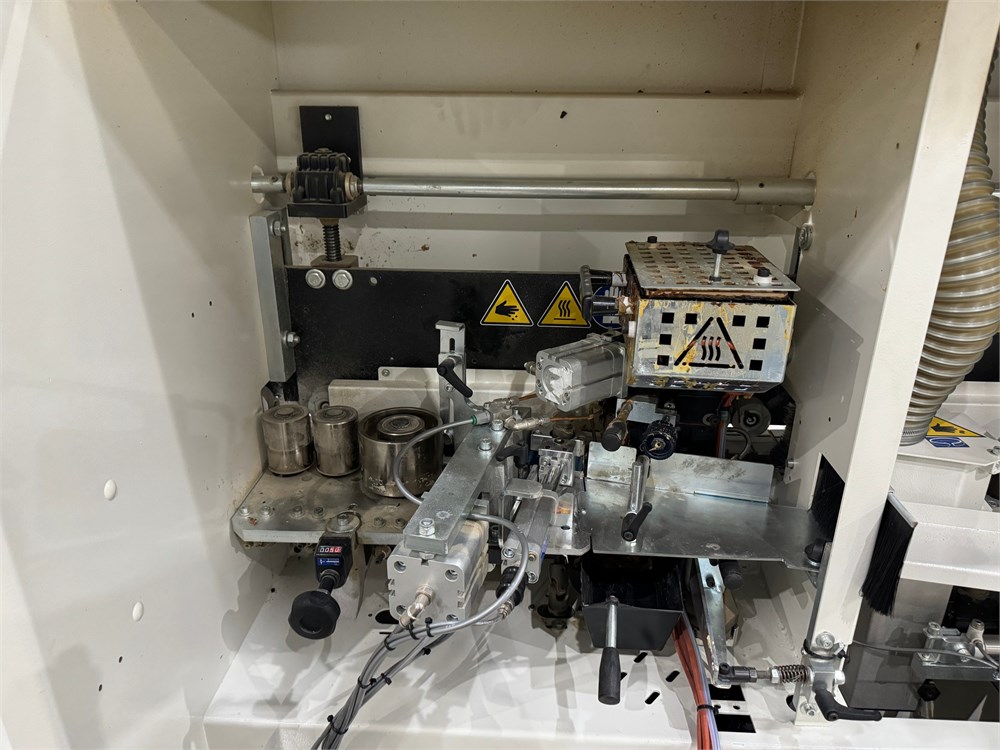

1.5 Kg Teflon-coated glue pot, glue roller application system complete w/automatic recycling device for unused glue.

Digital thermostat adjustment for temperature control. pneumatic guillotine, heating time approx. 8-10 min.

3-Roll pressure unit w/pneumatic controls for all pressure rollers.

Automatic strip & coil feed magazine

2-Motor End Trimming (0.25 HP - 12,000 RPM ea. motor), tilts 0° - 15°, end trimmers mounted on THK guides.

Top & bottom flush & bevel trims with quick release mount and plug-in motors for quick tooling changes.

(0.5 HP - 12.000 RPM motor ea.), bevels 0° - 15° with precision digital indicators for quick manual setup.

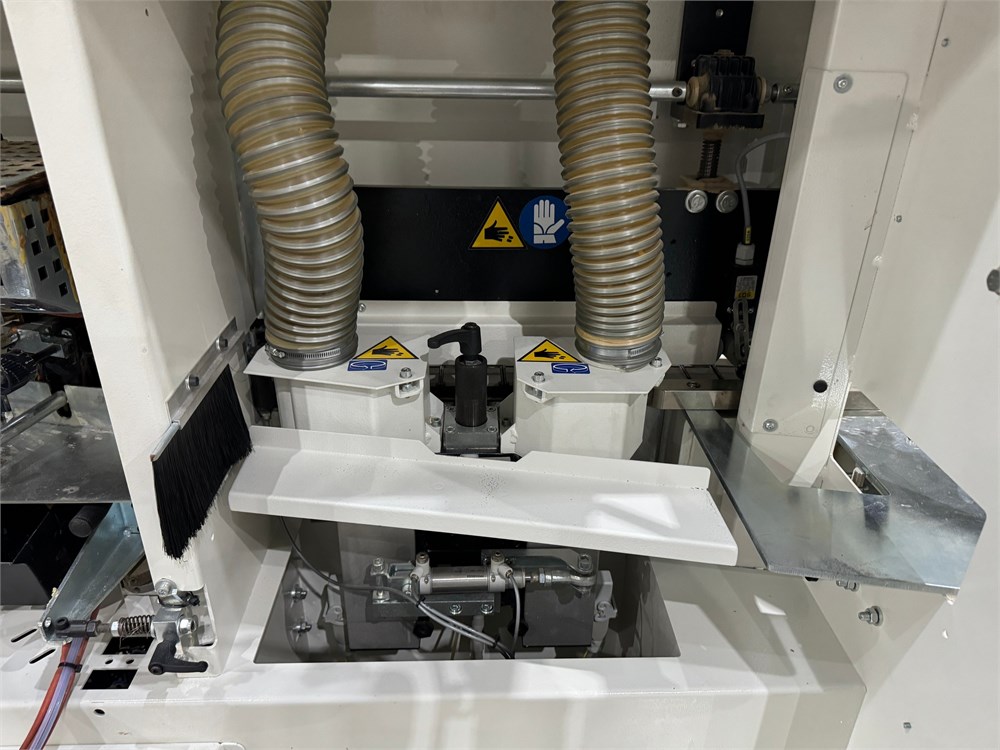

Top & bottom Profile Scraping unit w/manual positioning via digital read-outs. Top & bottom flat/glue Scraping unit w/manual positioning via digital read-outs.

Top & bottom buffing unit with up to 12° tilt; (0.25 HP - 3,000 RPM motors).

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available