Extrema "Magnum XP MXP-233HD" Surface Planer - Top & Bottom  Ended

Ended

Complete Woodworking Factory Auction - Damascus, OR

Damascus, OR

- Winning Bid : $7,050.00 USD Sold

- 44 Bid(s)

- High Bidder: J****l

Complete Woodworking Factory Auction - Damascus, OR ( Closed #68738156 )

After more than 40 years in business, the owner of Design Craft Door is retiring and auctioning all factory assets. This Portland, OR metro area auction features: Bacci CNC router, SCM moulder, Omga optimizing saw system, TigerStop, JLT clamps and clamp carrier, Carothers centralized dust collector, shapers, table saws, spray booths, forklift, racking, materials, shop supplies and more! No sales tax on Oregon auctions!

-

Pick Up Location

19767 SE Sunnyside Rd. Damascus, OR 97089.

-

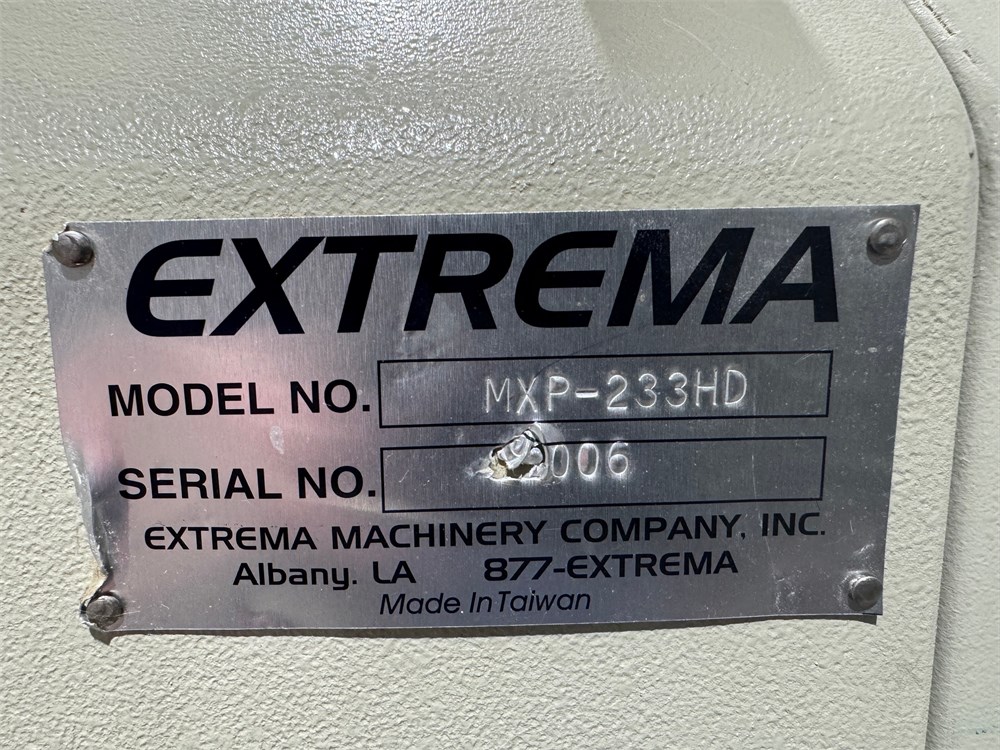

Make

Extrema

-

Model

"Magnum XP MXP-233HD"

-

Serial Number

2006

-

Year

2006

-

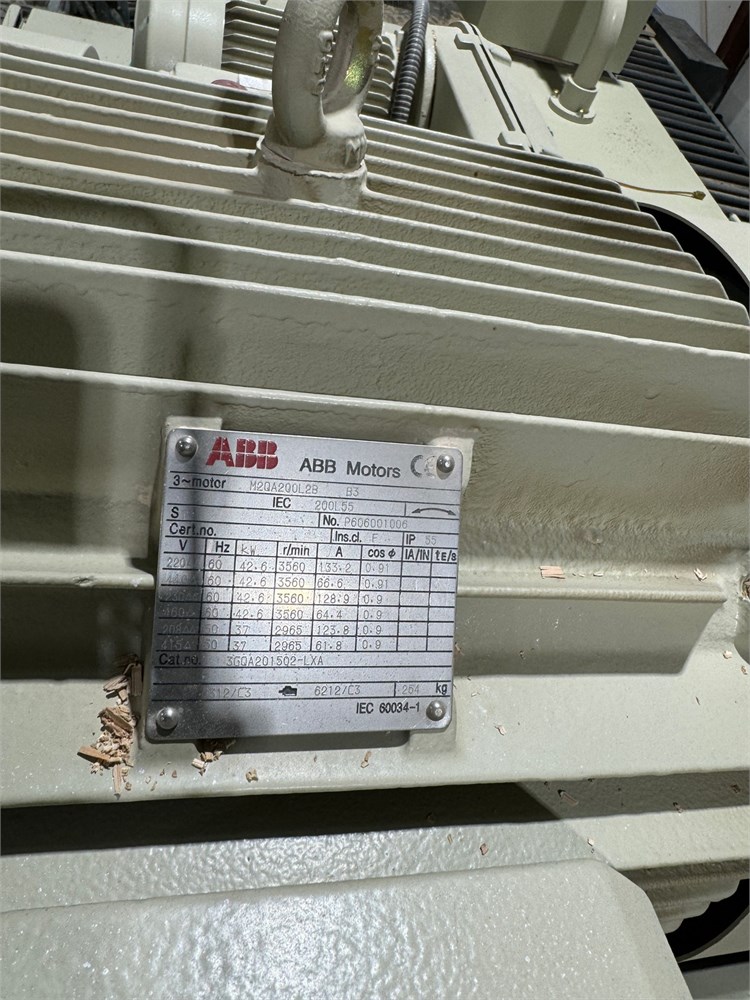

Phase

3 PHASE

-

Voltage

230/460

-

Buyer Inspection Period

January 28, 2025 (9 AM - 3 PM) or by appointment

-

Load Out Period

February 4 - February 6, 2025 - Text Mike for appointment 913-333-8396

-

Estimated Dimensions

10' x 6' x 7'

-

Estimated Weight

7,700 Lbs

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal.

-

Load Fee

-

Lot Notes

Please Note...Coupler on bottom head needs replaced

-

page views

1054

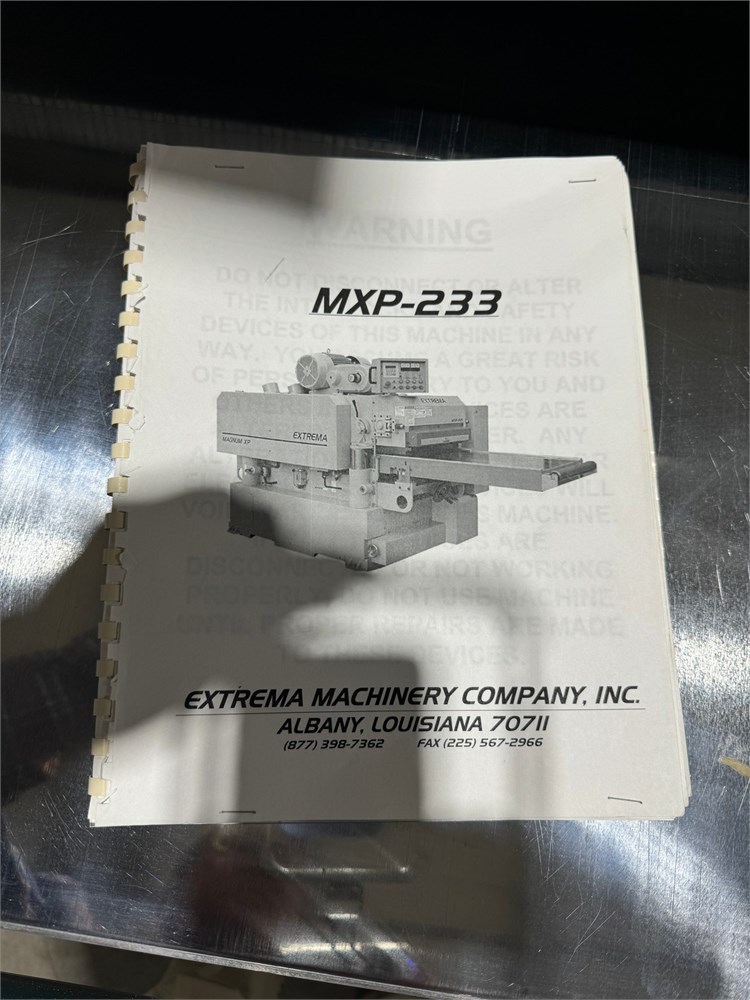

Extrema "Magnum XP MXP-233HD" Surface Planer - Top & Bottom

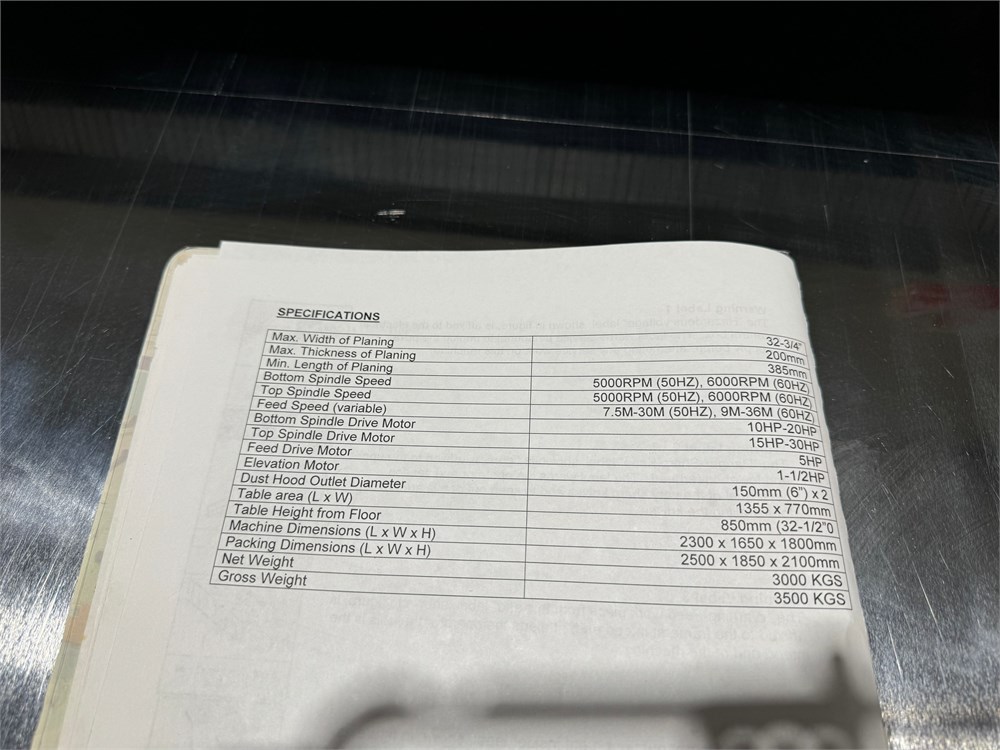

32-3/4" x 8" cap., 3/8" min thickness cap.; 1/2" max. top & bottom stock removal; microprocessor controlled thickness opening with LED readout and key pad entry for thickness, 50 HP top and 40 HP bottom head motor (bottom head first), both heads belt driven @ 6,000 RPM and feature "patented" SuperSlide with a 5 Sec. head removal.

Spiral carbide insert heads with (8) rows of (4) sided carbide inserts, cutterheads slide out in seconds for easy insert rotation or replacement; 37" spacing between top and bottom heads, 12" infeed lower bed, min. material length 16" (un-butted).

Releaving upper feed mat with multiple spring loaded fingers to allow positive feeding of cupped and bowed boards to the bottom head (feed system is excellent for straightening rough lumber), feed mat with lever adjustment up and down independent of thickness opening.

(1) Set top and bottom feed rolls before the top head with the upper roll serrated & segmented and air loaded, (1) set of top and bottom smooth feed rolls at the outfeed, upper rolls 6" dia. air loaded and lower feed rolls 4" dia., all feed rolls and upper feed mat are shaft driven; sectional chip-breaker with 1-1/2" wide spring loaded sections.

Variable feed speed 20 - 110 FPM, powered by 5 HP motor, feed system with a torque limiting clutch in case of a jamb-up, 2 HP motorized thickness adjustment 1/4" - 8", automatic part thickness adjustment, opening of machine on (4) 5" dia. heavy duty chromed columns via 2 HP motor, automatic upper feed mat lubrication, central grease lubrication system for the lifting jacks, hand pump central lube for the lifting posts.

Air caliper disc brakes on main cutter heads, separate electrical control panel with PLC keypad, push buttons and motor load meters mounted on front of machine.

Emergency stops at infeed and outfeed, over thickness safety interlocks on top rollers, (2) 5" dia. dust outlets for top head and (1) 6" dia. outlet for the bottom, anti-kickback fingers on infeed and manuals.

Please Note...Coupler on bottom head needs replaced

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available