Omga "T.2005 OPT 6000" Optimizing Cut-off Saw with Kicking Station & Printer  Ended

Ended

Complete Woodworking Factory Auction - Damascus, OR

Damascus, OR

- Winning Bid : $12,750.00 USD Sold

- 40 Bid(s)

- High Bidder: t****p

Complete Woodworking Factory Auction - Damascus, OR ( Closed #68738156 )

After more than 40 years in business, the owner of Design Craft Door is retiring and auctioning all factory assets. This Portland, OR metro area auction features: Bacci CNC router, SCM moulder, Omga optimizing saw system, TigerStop, JLT clamps and clamp carrier, Carothers centralized dust collector, shapers, table saws, spray booths, forklift, racking, materials, shop supplies and more! No sales tax on Oregon auctions!

-

Pick Up Location

19767 SE Sunnyside Rd. Damascus, OR 97089.

-

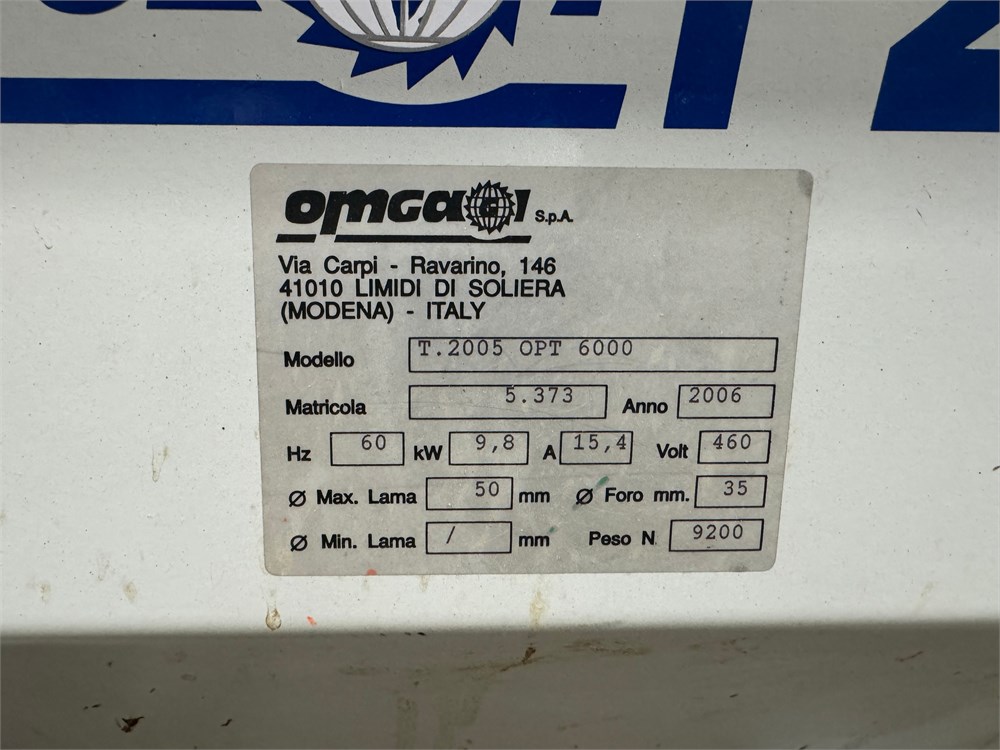

Make

Omga

-

Model

"T.2005 OPT 6000"

-

Serial Number

5.373

-

Year

2006

-

Phase

3 PHASE

-

Voltage

460 VOLT

-

Buyer Inspection Period

January 28, 2025 (9 AM - 3 PM) or by appointment

-

Load Out Period

February 4 - February 6, 2025 - Text Mike for appointment 913-333-8396

-

Estimated Dimensions

See Description

-

Estimated Weight

4,000 Lbs

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal.

-

Load Fee

-

Lot Notes

See Video!

-

page views

4259

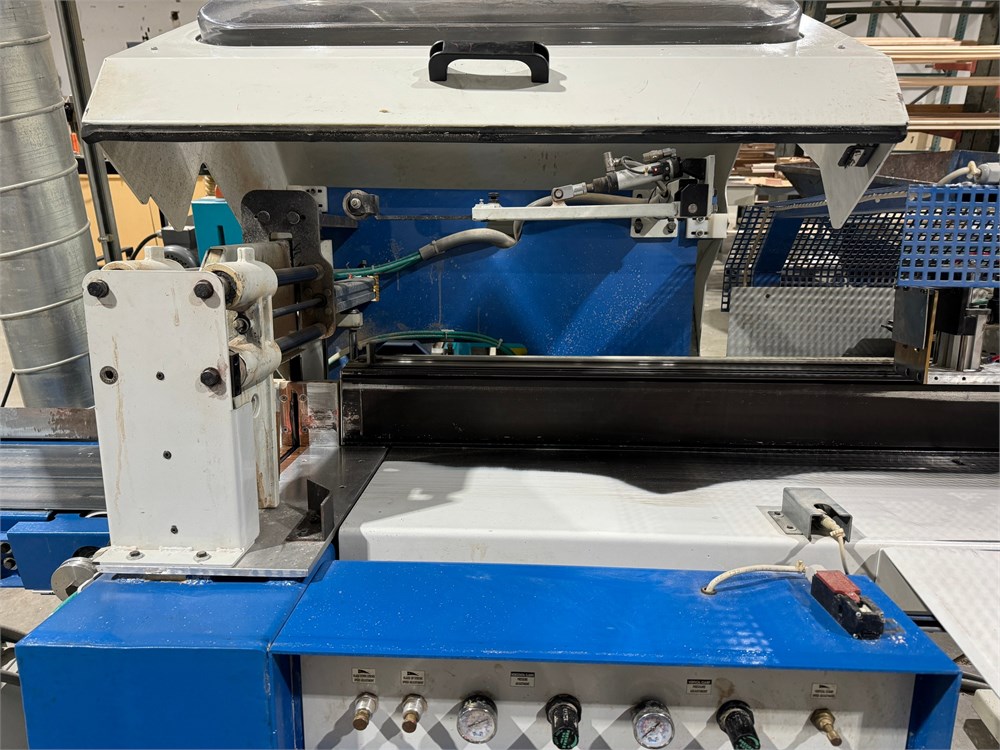

Omga "T.2005 OPT 6000" Optimizing Cut-off Saw with Kicking Station & Printer

10" width x 5" thickness capacity (or 12-3/16" x 2"). Automatic Crosscutting Saw System and Stop/Pusher suitable for cutting up to 19.5' long lumber. Cuts single or multiple stacked pieces (a vertical pneumatic gripper on the pusher insures holding on stack cuts with great accuracy).

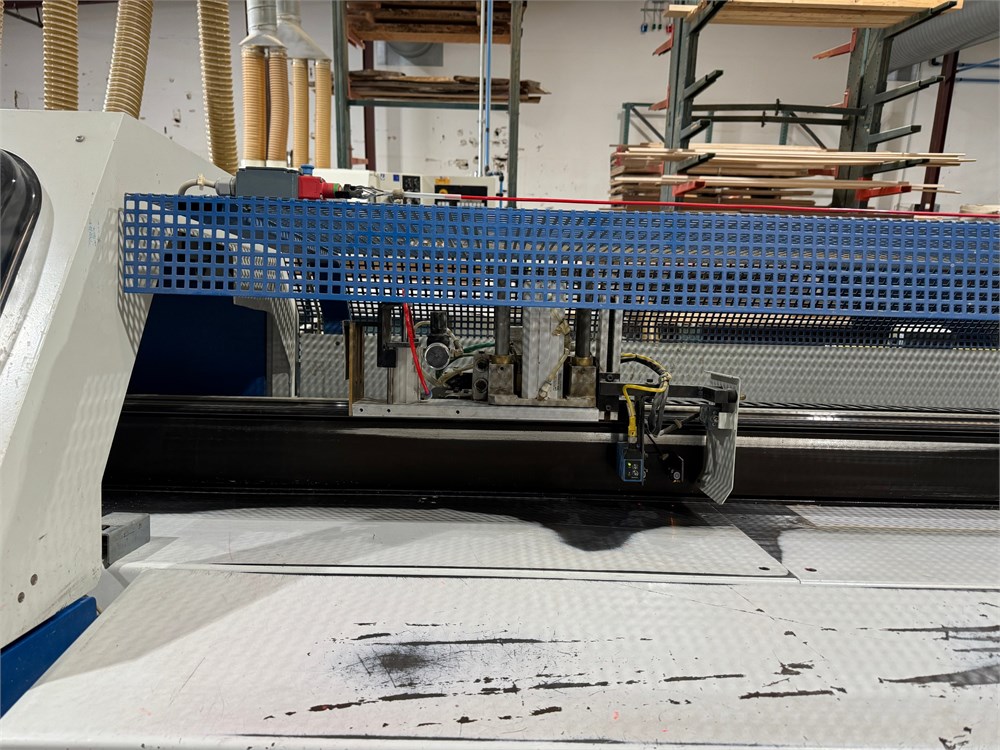

Upcutting Push-Feed Cutoff Saw with cutting cycle speeds from (0.5 - 1) Sec, 18" dia. saw blade included.

Cutting cap.: 10" Wide x 5" Thick; 13' max. infeed lumber length; 7.5 HP saw motor drives arbor at 3,400 RPM. 5 HP feed motor powers the pusher up to a maximum feed speed of 400 FPM.

A vertical adjustable pneumatic guard clamp with replaceable chipbreaker cycles with the upstroke of the blade completely covering the saw blade while ensuring the smoothest possible cut. A safety hood with Plexiglass window offers total protection of the cutting area. A pneumatic cylinder with adjustable flow controls located at the front of the machine controls the up-stroke speed.

The loading station consists of a galvanized flat metal surface where the operator is able to mark several boards to be loaded. A 10° incline flat steel table ensures the boards are flat against the fence while making the loading operation very ergonomic.

(2) Pressure rollers, one to to the left and one to right of the blade automatically controlled in the cycle gurantee that the board is against the fence.

A camera placed on the feeding carriage reads the crayon marks assigned by the operator enabling the machine to perform the optimized cut on the remaining material after defect removing. OMGA Programmable stop or pusher accurately positions lumber to selected lengths (+/- 0.5 mm).

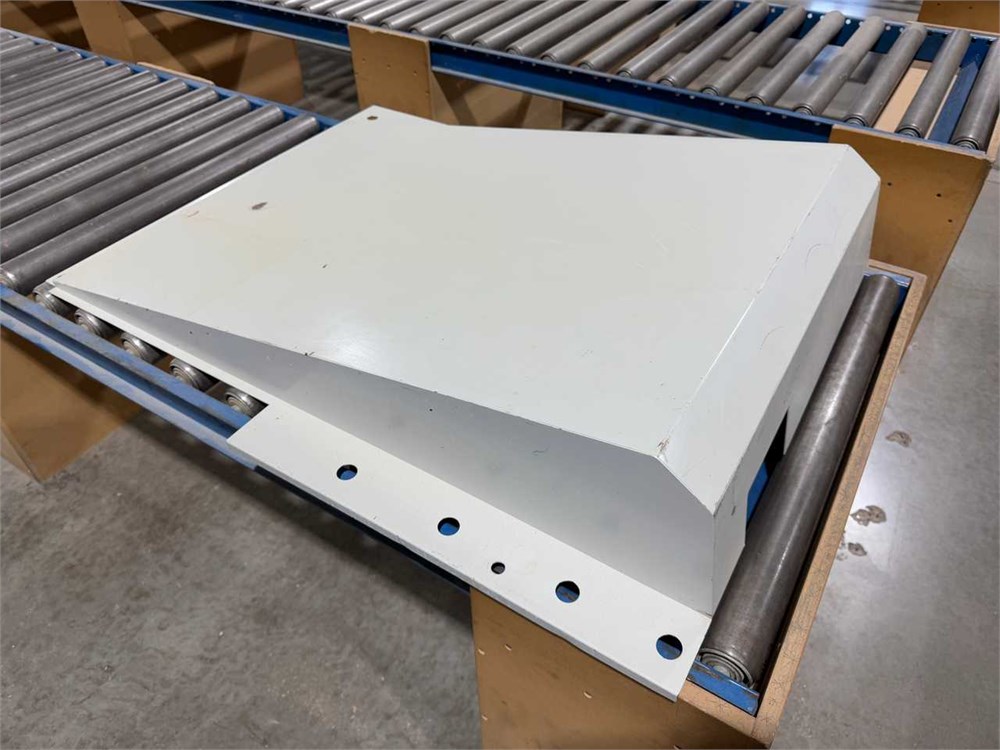

The outfeed section consists of 32' outfeed belt, (6) sorting kickers and and incline sorting table.

Ink-Jet labeling station

4' x 20' Outfeed table

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available