SCM Group/MiniMax "ME25" Automatic Edgebander  Ended

Ended

Woodworking Machinery Warehouse Auction - Tracy, CA

Tracy, CA

- Winning Bid : $5,650.00 USD Sold

- 25 Bid(s)

- High Bidder: P****s

Woodworking Machinery Warehouse Auction - Tracy, CA ( Closed #68722169 )

All assets moved to Tracy California for convenience of buyers. Items include brand new in box machines, trade ins, and excess equipment moved to central warehouse.

-

Pick Up Location

2203 N. MacArthur Drive, Tracy CA 95376

-

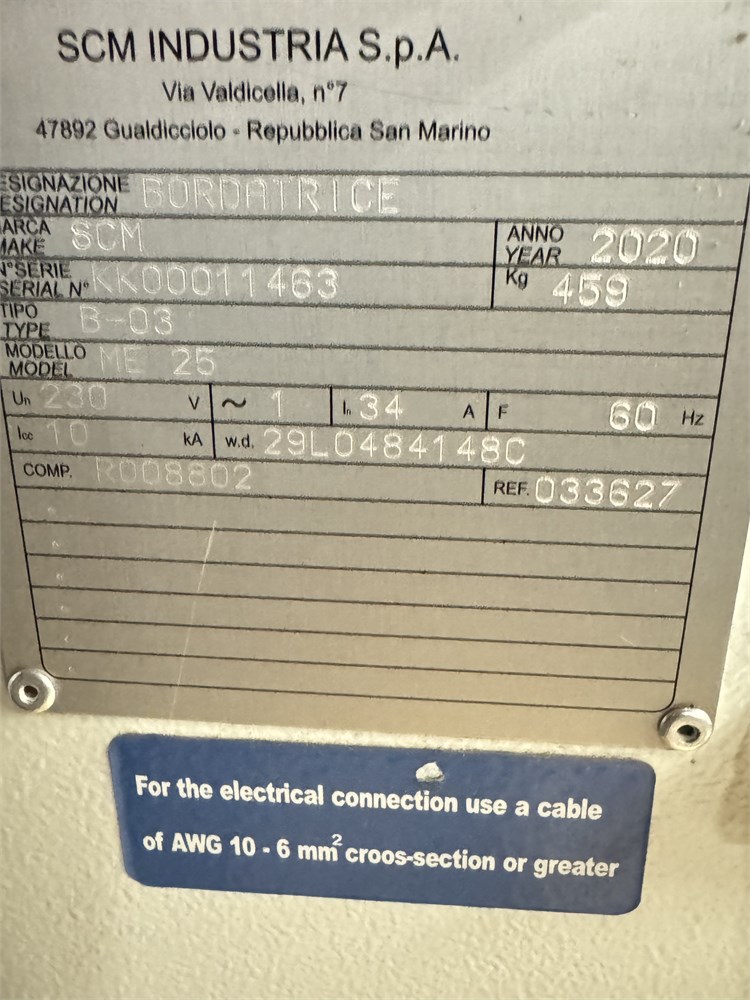

Make

SCM Group/Minimax

-

Model

ME-25

-

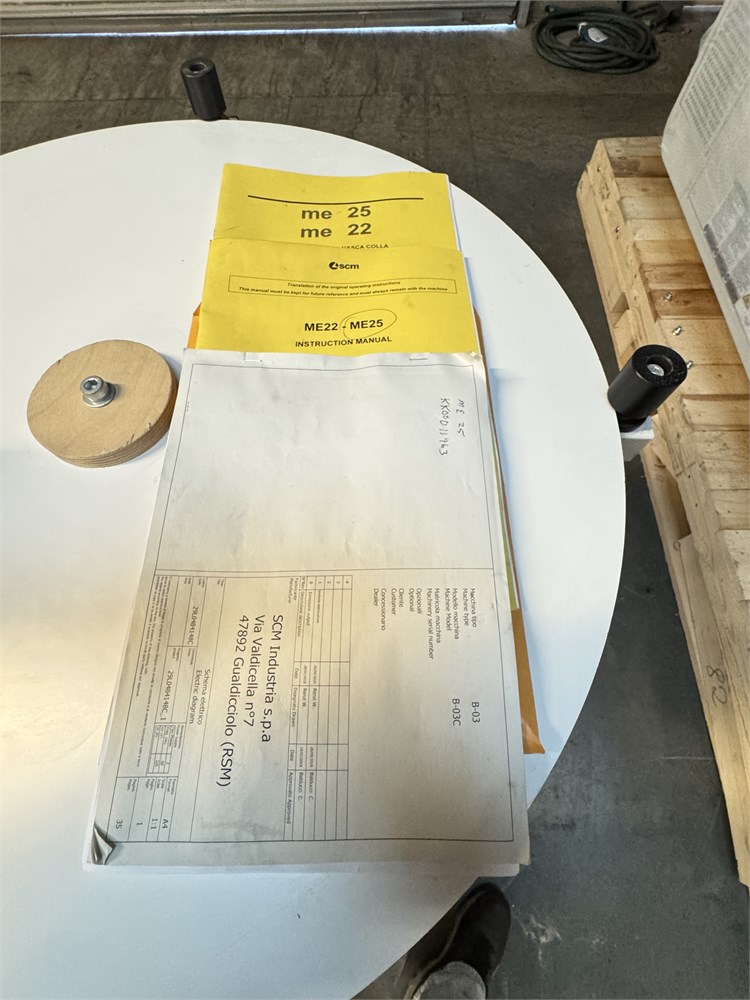

Serial Number

KK00011463

-

Year

2020

-

Phase

1 PHASE

-

Voltage

230 VOLT

-

Buyer Inspection Period

By Appointment Only, [email protected], 925-250-8248.

-

Load Out Period

January 23rd thru January 24th, 2025 , By Appt. Only

-

Estimated Dimensions

10' L x 3'W x 5'H

-

Estimated Weight

Approximately 1100 lbs.

-

Seller Comment

-

Load Fee

100

-

Lot Notes

-

page views

1206

SCM Minimax me 25

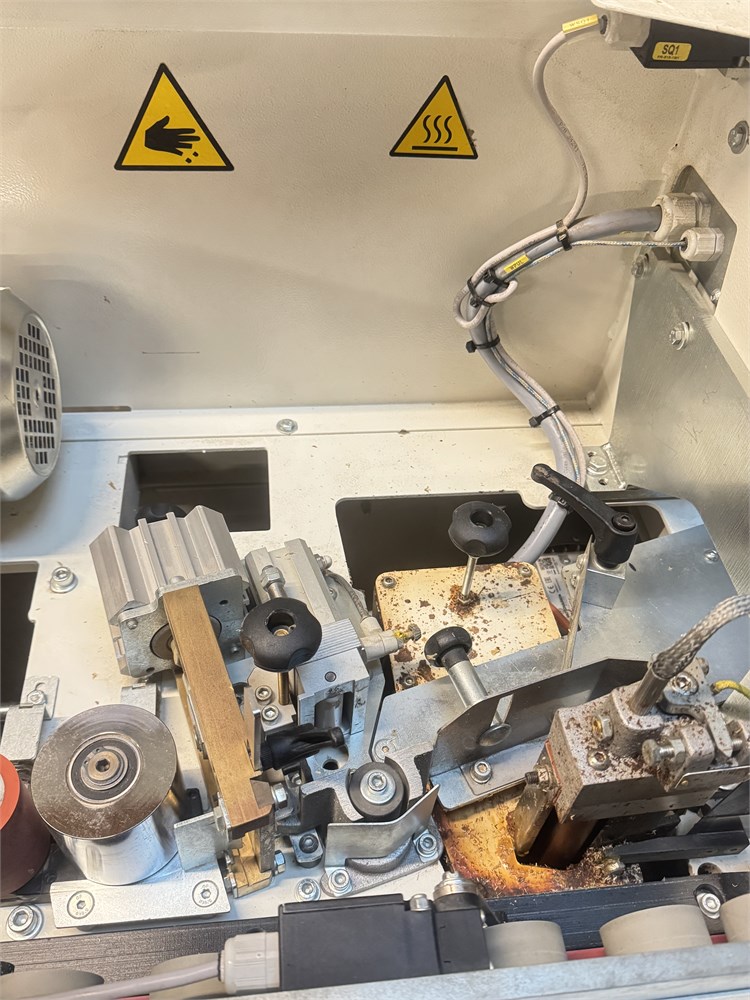

The Minimax ME 25 is a compact machine boasting capacities usually only found on much larger units. Buffing, Scraping, and 3mm edge processing (5mm strips) is standard. This machine is perfect for the small to medium sized panel processing shop, this small machine packs a lot of features...

Absolute precision offered by the end-cutting unit, with a cutter and an independent asynchronous motor

The edge scraping unit grants high finishing quality of plastic material edges thanks to the radius knives that ensure the complete elimination of any marks left from the trimming unit tools. The brushing unit with tilted, vertically adjustable motors optimizes the cleaning/polishing action on the panel edge

Error-free machining is ensured by the simple and intuitive control panel positioned on the front of the machine, that allows an easy selection of all the main functions, among them, the operating units switching on and off. The PLC guides the operator during maintenance, cleaning, diagnostic operations, etc.

The very best finishing of the panel edge is also guaranteed by the panel conveying track (exclusive solution), which prevents the panel having the feed affected by the typical pulses generated by the pinion of a traditional feed track and ensures a smooth and linear panel movement

| workable dimensions | [mm] | 2600 x 530 (102.37” x 20.87” |

| workable height | [mm] | 904 (35.56”) |

| thickness of rolled edges | [mm] | 0.4 ÷ 3 (up to 0.12”) |

| thickness of edges in strips | [mm] | up to 5 (up to 0.19”) |

| min. ÷ max. panel height | [mm] | 12 ÷ 50 (0.5” ÷ 1.94”) |

| min. ÷ max. panel height using edge scraping unit | [mm] | 16 ÷ 50 (0.62” ÷ 1.94”) |

| min. panel length/width with rolled edges | [mm] | 190/65 ( 7.5” / 2.56”) |

| min. panel length cut only on the front | [mm] | 120 (4.75”) |

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available