Heesemann "MFA 10 OSR" Wide Belt Sander - 3-Head (2022)  Ended

Ended

Late Model Sander & Door Machine in Shelby, NC

Shelby, NC

- Winning Bid : $257,250.00 USD Sold

- 179 Bid(s)

- High Bidder: M****2

Heesemann "MFA 10" Wide Belt Sander - Shelby, NC ( Closed #68430513 )

A Well known Top Tier Millwork and Cabinet maker in the greater Charlotte, NC area is auctioning a 2022 Heesemann "MFA 10" Wide Belt Sander no longer required for continuing operations. This is a rare find on the auction platform! Please call me directly with any questions.

-

Pick Up Location

Shelby, NC

-

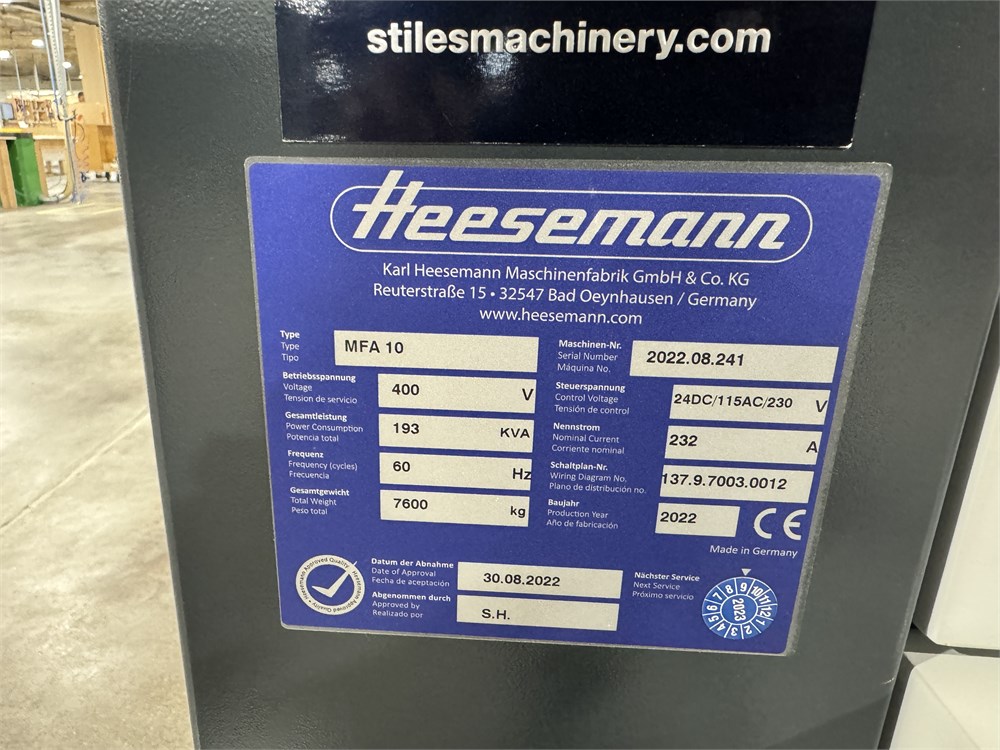

Make

Heesemann

-

Model

"MFA 10 OSR"

-

Serial Number

2022.08.241

-

Year

2022

-

Phase

3 PHASE

-

Voltage

400

-

Load Out Period

See Homepage page for removal datess

-

Estimated Dimensions

-

Estimated Weight

16,720 Lbs

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal. By appointment ONLY!

-

Load Fee

-

Lot Notes

See video $425,0000 NEW!

-

page views

1534

Heesemann "MFA 10 OSR" Wide Belt Sander - 3-Head (2022)

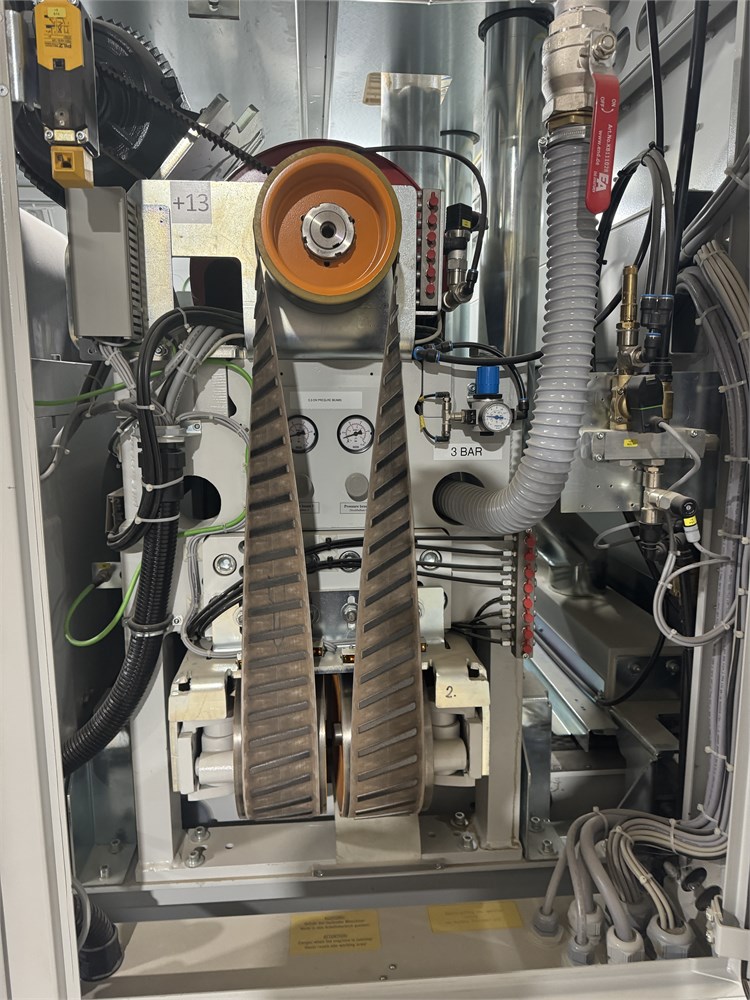

51"W Vacuum belt

1st Station DB-S Head

2nd Station, Orbital sanding unit

3rd Station, Orbital sanding unit

4th Station, Air jet part cleaning

Working height: 880 mm (36.2"), Workpiece thickness: 3 mm to 150 mm (0.118" to 5.9"), Working width: 1300 mm (51"), Transport belt speed: 3 mpm to 15 mpm (10 fpm to 49 fpm)

Abrasive belt size: 2620mm x 1320mm* 103” x 52”*, Sanding belt access: Left hand Operators side: Left hand,

Equipped with a high-pressure vacuum blower for safe movement of workpieces shorter than

700 mm (27.5") in feed direction including integrated ventilator. Can be turned on or off via

controller or in individual programs. The high-pressure blower allows for high vacuum pressure

while keeping the power consumption low.

This machine is equipped with interlocking of emergency stop and feed, which is necessary

when linked in a line of machines.

Emergency stop buttons are located at the machine outfeed, with one located on the right side

and one located on the left side of the machine.

Doors have glass inserts for visual inspection while machine is operating

LED lighting in on the inside of the machine – belt change side.

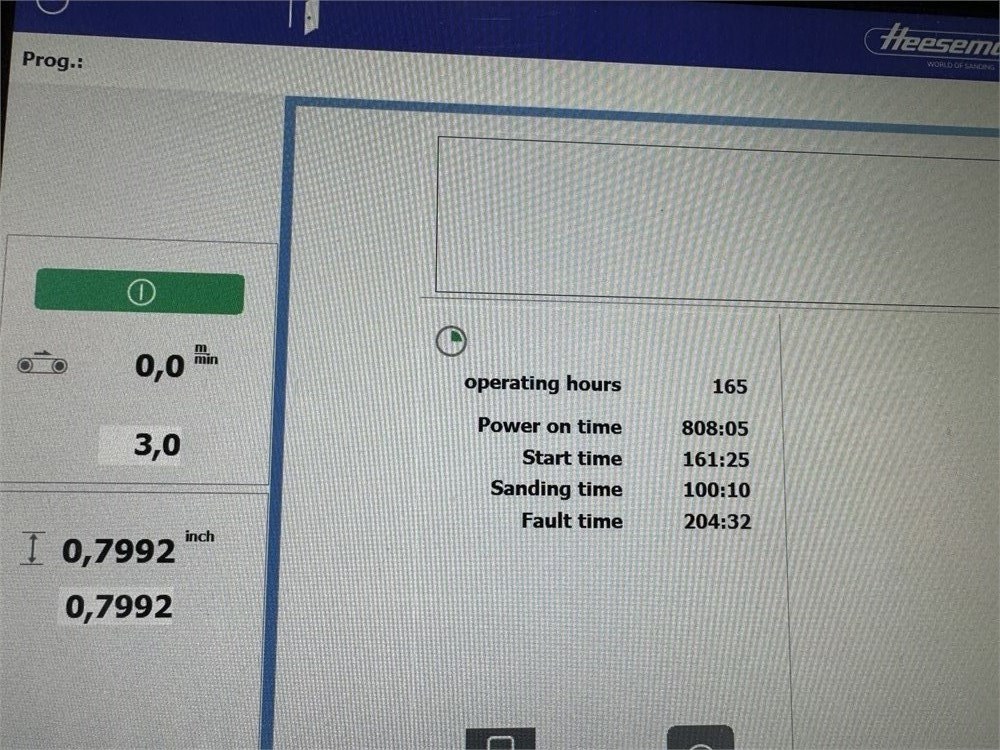

This sander is equipped with a 21.5" high resolution touch screen / industrial PC and features:

High resolution display, CF card 1 GB, Windows® embedded operating system, Pendent mounted with adjustable viewing position, Ethernet connection, Configured as web address for easy network access, Automatic on-screen diagnostics, Metric or English input, 1000 memory addresses, Alpha/numeric format, Password protected, Digital keypad input, Workpiece thickness, Conveyor belt feed speed, Sanding pressures, One button start

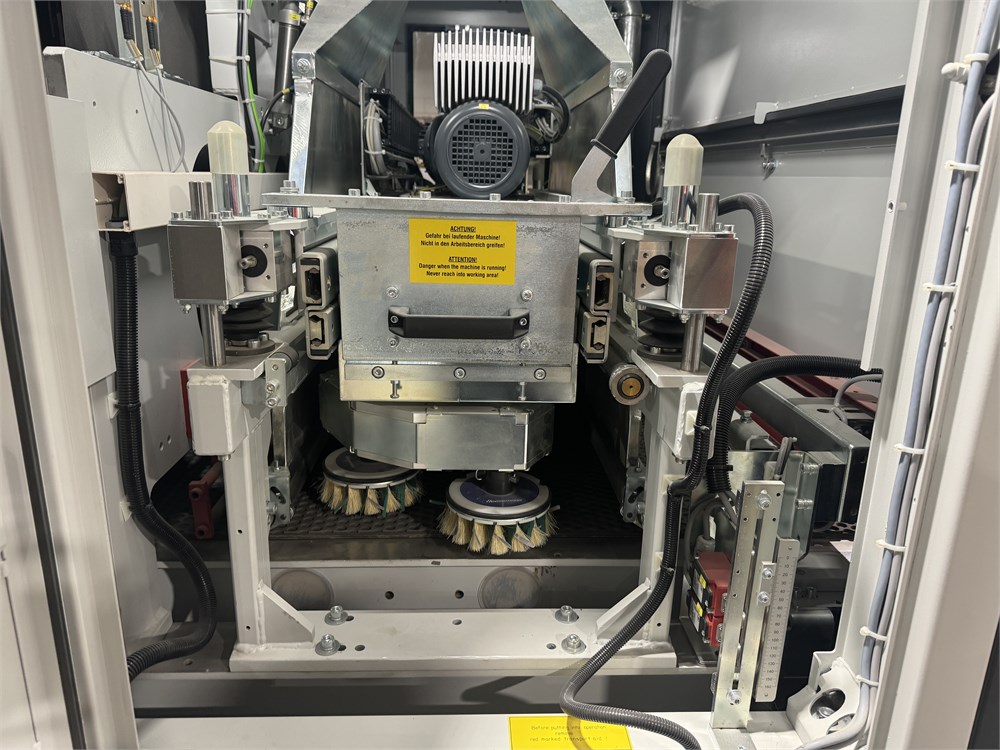

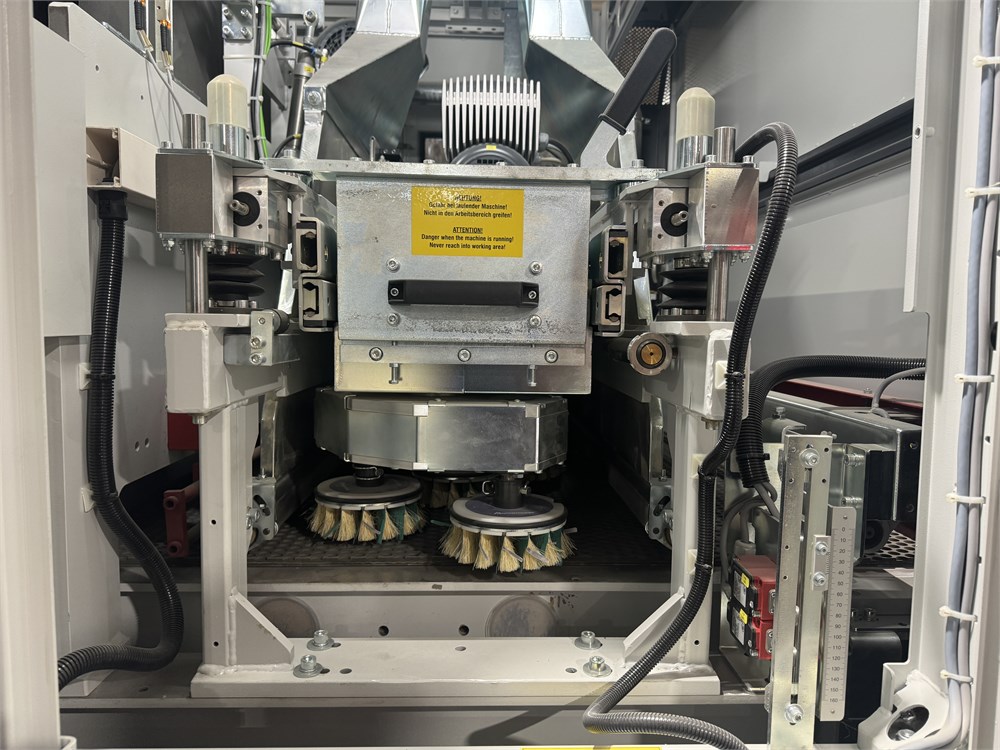

Head 1: DB-S Head – Rotating Planetary Sanding Unit

Heesemann's DB-S rotating sanding head incorporates sanding discs for the purpose of

smoothing the work surface and breaking edges. This sanding head offers incredible flexibility

and can be easily controlled via the controller to make the result more or less aggressive. With

the quick-change head inserts and pull out head, it is easy and quick to change abrasives and put

additional types of tools on the sanding head (wire brushes, Anderlon brushes, discs / pads, etc.),

offering flexibility for additional functionality and flexibility.

10 driven brush discs with quick changing device

Rotation in both directions

Central height adjustment

5.5 kW (7.5 Hp) motor to power the discs

1.5 kW (2 Hp) motor gear box

Trimming / Tool: Flex Trim / Discs / Wire Brushes / Anderlon Brushes

Diameter: 150 mm (6”)

Other brush discs available on demand

One set of disc brush heads is included with sanding head.

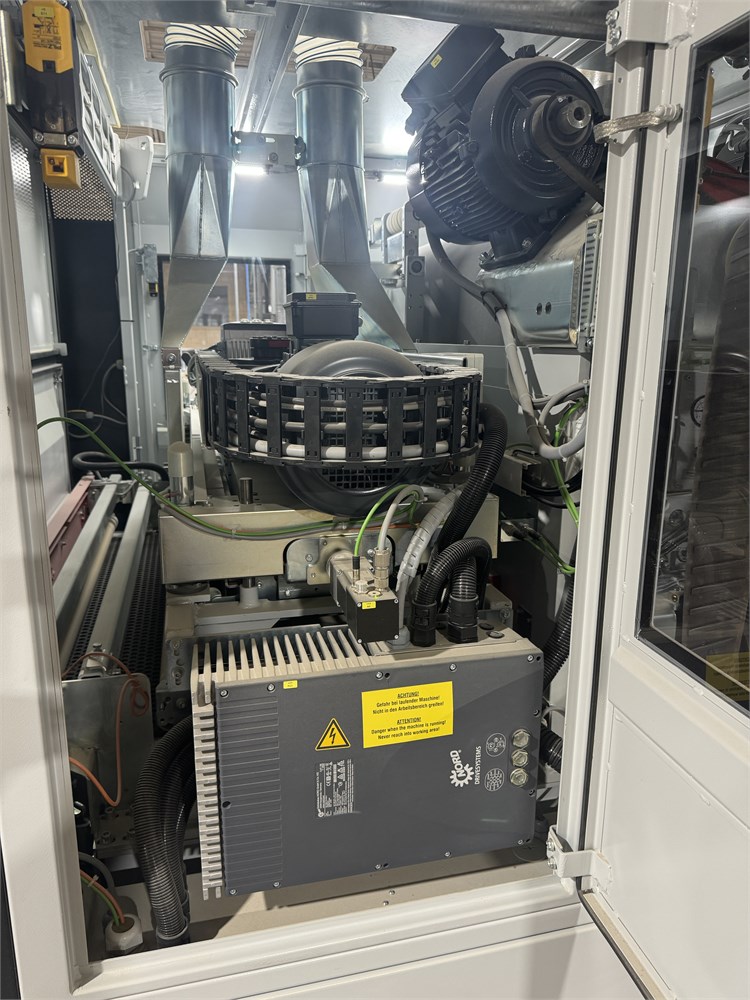

Head 2: OSR Head – Orbital Sanding Unit

The patented orbital sanding unit combines a variable speed single orbit rotation with a variable

speed lamella belt that has a serpentine movement and runs inside the abrasive belt to break up

the orbit scratch, providing a truly random scratch. The wide belt floats on an air cushion to

allow for an easy movement of the abrasive in the orbit rotation without providing significant

vibration. The orbital sanding unit uses traditional wide belts which advance automatically with

an automatic belt advancing function for low abrasive belt cost and long service life prior to a

belt change.

Roller hold down prior to sanding unit

Kevlar reinforced pressure segment belt system (7,400mm x 100mm)

Automatic belt advancing to move to fresh abrasive material

User friendly abrasive changing device for quick abrasive changes

Abrasive belt dimensions: 2620 mm x 1400 mm (103" x 55")

Drive power (pressure belt): 7.5 kW (10 hp) with 15kw (20 hp) Freq. Drive

Drive power (orbit rotation): 3 kW (4 hp) with 5.5kw (7.5 hp) Freq. Drive

Head 3: OSR Head – Orbital Sanding Unit

The patented orbital sanding unit combines a variable speed single orbit rotation with a variable

speed lamella belt that has a serpentine movement and runs inside the abrasive belt to break up

the orbit scratch, providing a truly random scratch. The wide belt floats on an air cushion to

allow for an easy movement of the abrasive in the orbit rotation without providing significant

vibration. The orbital sanding unit uses traditional wide belts which advance automatically with

an automatic belt advancing function for low abrasive belt cost and long service life prior to a

belt change.

Roller hold down prior to sanding unit

Kevlar reinforced pressure segment belt system (7,400mm x 100mm)

Automatic belt advancing to move to fresh abrasive material

User friendly abrasive changing device for quick abrasive changes

Abrasive belt dimensions: 2620 mm x 1400 mm (103" x 55")

Drive power (pressure belt): 7.5 kW (10 hp) with 15kw (20 hp) Freq. Drive

Drive power (orbit rotation): 3 kW (4 hp) with 5.5kw (7.5 hp) Freq. Drive

Workpiece Blasting Device

Rotating compressed air nozzles for blasting workpiece surface. Only operate if a workpiece is

present.

Conveyor Belt Cleaning Program

Software function to use workpiece blasting to clean conveyor belt

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense).

Payment is due within 24 hours of auction close. Payments must be made via bank wire transfer for any amount above $1,500. Credit cards may be used up to $1,500 (3% processing fee). Please Contact Sabrina Burns with payment questions at 209-839-7707 Any sales tax exemption documents are to be emailed to [email protected] at time of purchase/invoice for tax exemption consideration.