2020 Viet (Biesse) "Opera 5-3.3 XLL" Finishing Sander  Ended

Ended

Woodworking Machinery Auction - Austin, TX

Del Valle, TX

- Winning Bid : $30,250.00 USD Sold Reserve Price Met

- 49 Bid(s)

- High Bidder: n****e

Woodworking Machinery Auction - Austin, TX ( Closed #68387342 )

Custom woodworking business in the Austin, TX metro area is auctioning several late model machines no longer required for continuing operations. Two (2) Anderson CNC routers, Becker vacuum pumps, 2020 Holz-Her Vertical panel saw, 2020 Viet (Biesse) widebelt sander, and Atlas Copco air compressor. Contact me with any questions or to arrange an inspection.

-

Pick Up Location

5235 Hwy. 71 E., Building A Del Valle, TX 78617

-

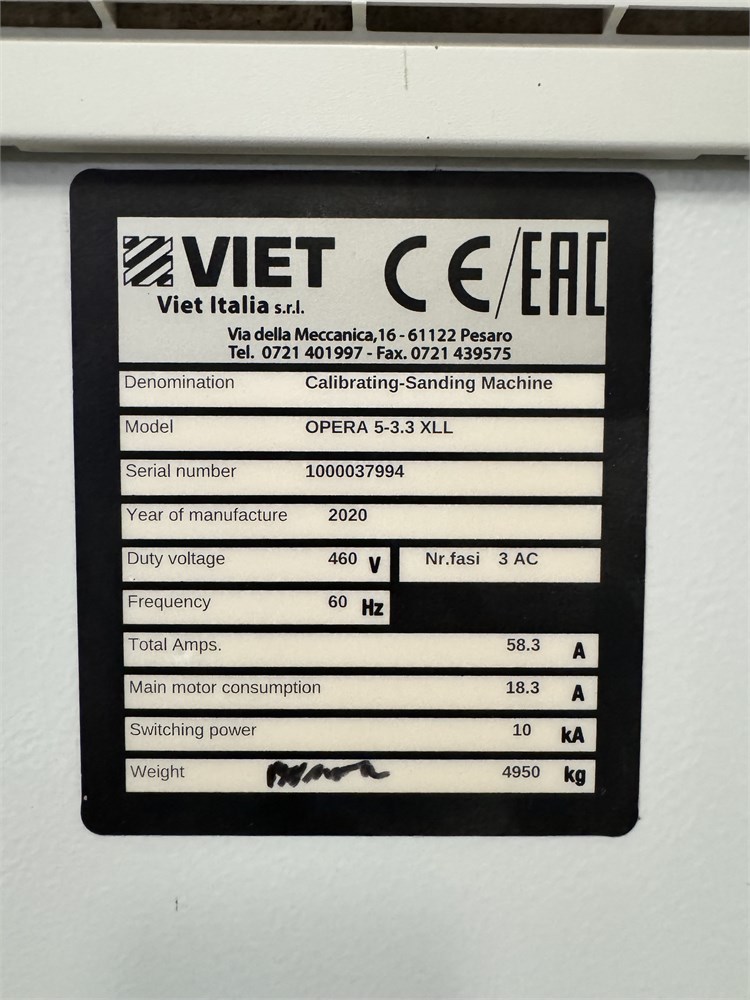

Make

Viet (Biesse)

-

Model

Opera 5-3.3 XLL

-

Serial Number

1000037994

-

Year

2020

-

Phase

3 PHASE

-

Voltage

460 VOLT

-

Load Out Period

December 20, 2024 - January 10, 2025 (by appointment)

-

Estimated Dimensions

102" L x 86" W x 104" H

-

Estimated Weight

11,000 Pounds

-

Seller Comment

This lot requires a rigger, see home page for details.

-

Load Fee

-

Lot Notes

-

page views

1960

2020 Viet (Biesse) "Opera 5-3.3 XLL" Finishing Sander

Only 489 run hours!

This machine sells now for $180,000

This Biesse OPERA 5 - 3.3 Finishing Center is a valuable asset for cabinetry, furniture manufacturing, and door production, ensuring high productivity and reliability for all finishing tasks. With only 489 hours of runtime, this machine is practically like-new. Its advanced control system, specialized working heads, and energy-efficient design make it perfect for medium and large-scale operations, offering unmatched precision and productivity.

Key Features:

• Advanced Control System: 15-inch IPC Touch-Screen Panel managing up to 1,000 custom operations, automatic thickness adjustments, real-time diagnostics, and LAN connectivity for remote troubleshooting.

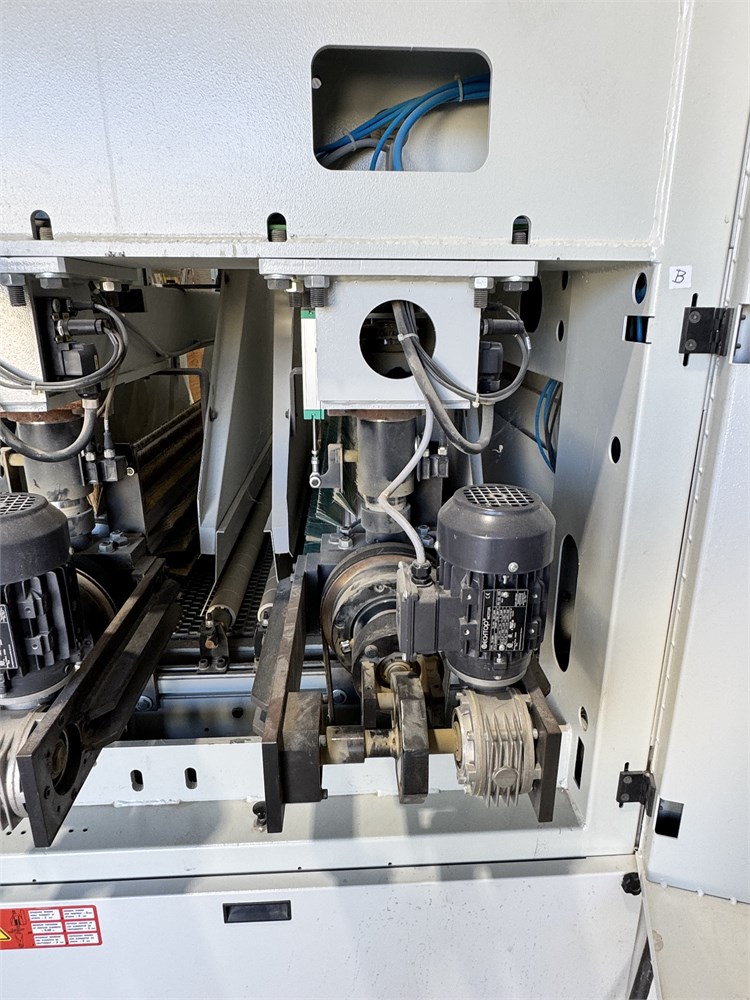

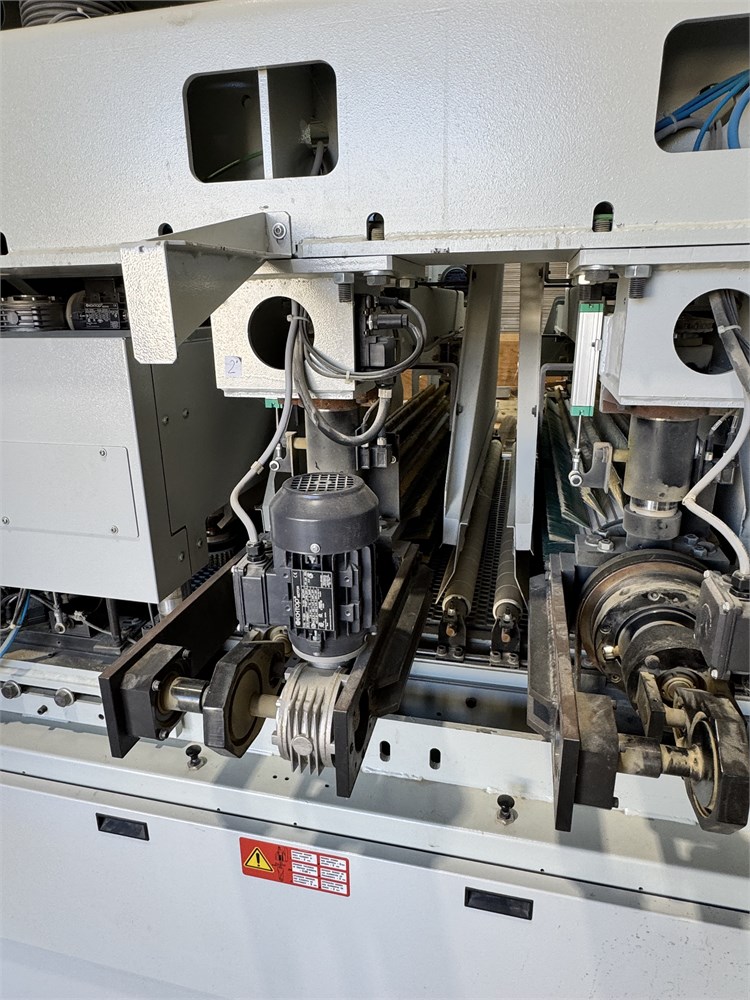

• Three Specialized Working Heads:

- X-Spin Brush Head: 15 discs with abrasive inserts for fine, even finishes, ideal for denibbing and intermediate sanding.

- First Roller Brush: 11.8” diameter with 36 abrasive inserts, motorized adjustment, oscillation, and reverse rotation for precision in complex profiles.

- Second Roller Brush: Identical to the first for maximum versatility in demanding projects.

• Vacuum Hold-Down Table: Secures small parts like cabinet doors and contoured surfaces, minimizing misalignment risks.

• Specialized for Contours & Cabinet Doors: Perfect for cabinetry, furniture manufacturing, and door production. Handles fine sanding, intermediate sanding, and detailed finishes.

• Grained Finishes with Wire Brushes: Creates textured finishes on wood, enhancing grain definition for specialized woodwork.

• Energy-Efficient Design: Inverter-driven motors for precise power control and reduced operational costs.

• Automatic Thickness Measurement: Real-time adjustments ensure consistent results across all parts.

• Efficient Cleaning System: Rotative air blower keeps the workspace dust-free, extending the life of abrasive components.

• Safety Standards: Built to CE norms with emergency stop bars and pressure sensors for over-thickness detection.

Specifications:

• Compressed Air Consumption: 410 NL/min (15 cfm)

• Dust Collector Requirement: 6,370 m³/h (3,750 cfm)

• Total Amps: 58.3 A

• Power Requirement: 38 kW

• Compressed Air Intake: 3/8”

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available