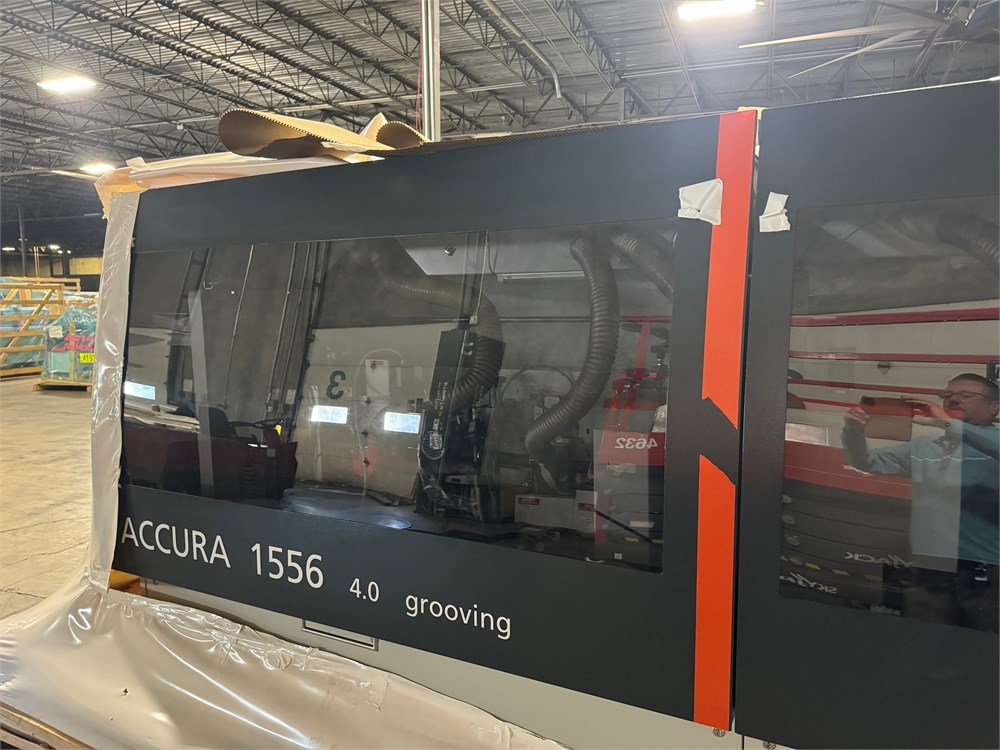

Holz-her "Accura 1556 4.0 Grooving" Edgebander (2023)  Ended

Ended

Machinery Warehouse Sale - Charlotte, NC

Charlotte, NC

- Winning Bid : $112,750.00 USD Sold

- 160 Bid(s)

- High Bidder: B****h

Charlotte, NC Warehouse sale - New & Used ( Closed #67623146 )

Charlotte, NC Warehouse sale - New & Used Machinery. Machinery Dealer has decided to liquidate machinery to make room for 2025 Machines!

-

Pick Up Location

2600 Hutchison McDonald Rd, Charlotte, NC 28269

-

Make

Holz-her

-

Model

"Accura 1556 4.0 Grooving"

-

Serial Number

260/2-301

-

Year

2023

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

See Homepage page for removal datess

-

Estimated Dimensions

29' x 5' x 7'

-

Estimated Weight

12,000 Lbs

-

Seller Comment

A non-negotionable loading fee has been established. This includes loading onto a flat bed trailer.

-

Load Fee

495.00

-

Lot Notes

On pallet & ready to load

-

page views

1751

Holz-her "Accura 1556 4.0 Grooving" Edgebander (2023)

See documents above for original quote and specifications.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense). MachineryMax does not ship- All buyers responsible for their own freight - For freight quotes please contact your preferred broker, or contact Aaron, at Always Trucking 541-608-6532

Payment is due within 24 hours of auction close. Payments must be made via bank wire transfer for any amount above $1,500. Credit cards may be used up to $1,500 (3% processing fee). Please Contact Sabrina Burns with payment questions at 209-839-7707 Any sales tax exemption documents are to be emailed to [email protected] at time of purchase/invoice for tax exemption consideration.