Biesse "Akron 1445 A" Edgebander - Servo & Pre-mill (2017)  Ended

Ended

Complete Shop Closure - Torrington, CT

Torrington, CT

- Winning Bid : $39,250.00 USD Sold

- 69 Bid(s)

- High Bidder: D****z

High End Custom Cabinet Shop Closure - Torrington, CT ( Closed #67113113 )

High End custom cabinet shop featuring: 2017 Biesse Rover B FT 1536 5 Axis CNC Router, Winstore 3d Material Handling System, Biesse Akron 1445 A Edgebander, Viet Opera 5 3 Head Wide Belt Sander, Bream Vertical CNC Machining Center, Gannomat concept Case Clamp, plus much more! Over 500 Lots

-

Pick Up Location

Torrington, CT

-

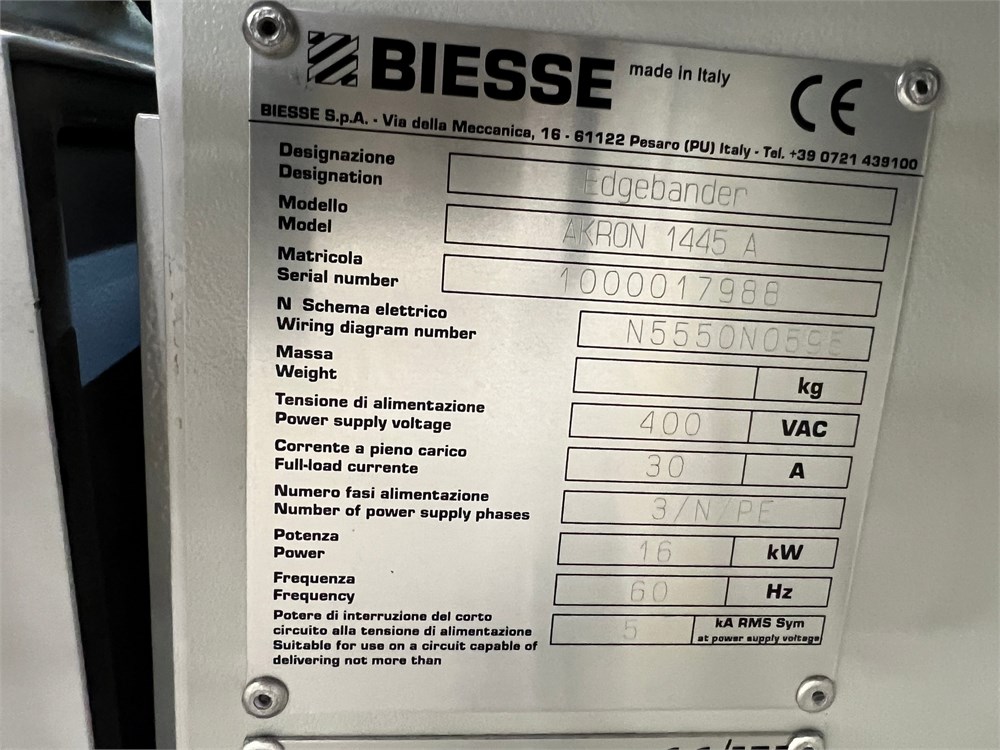

Make

Biesse

-

Model

"Akron 1445 A"

-

Serial Number

1000017988

-

Year

2017

-

Phase

3 PHASE

-

Voltage

230/460

-

Load Out Period

See Homepage page for removal dates

-

Estimated Dimensions

20'L x 4'W x 6'H

-

Estimated Weight

5,000 Lbs

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal. Tom Preston @ Preston Machinery, [email protected], (269) 685-7591

-

Load Fee

-

Lot Notes

Please see video! See Lot 004A for spare parts!

-

page views

1860

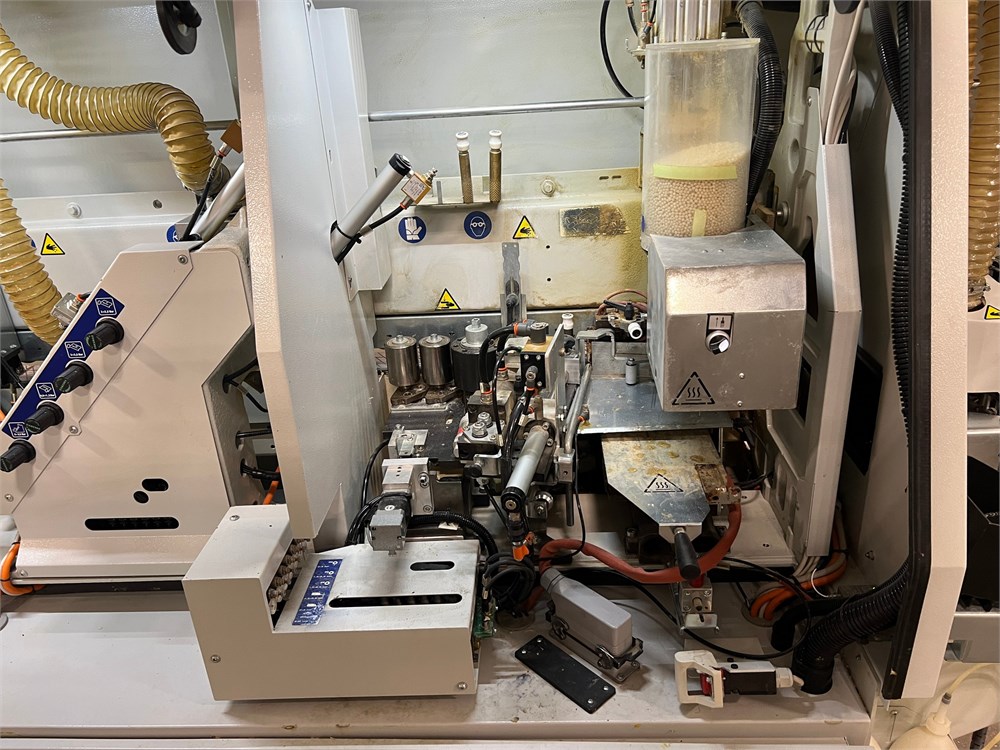

Biesse "Akron 1445 A" Edgebander - Pre-mill (2017)

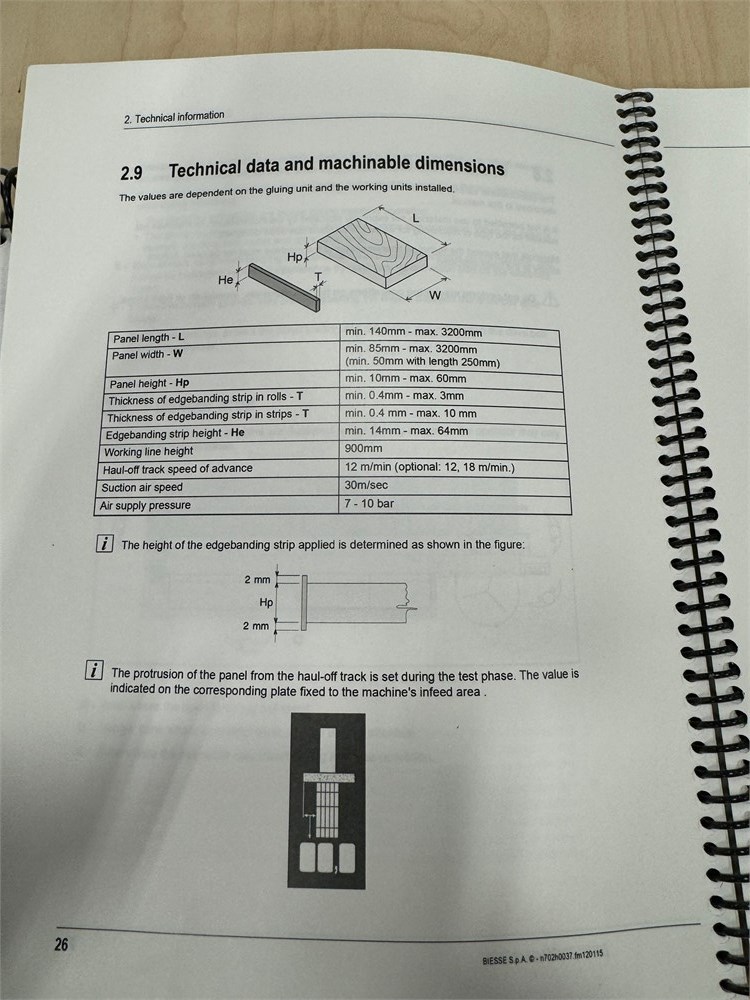

Min. panel height: 10 mm, Max. panel height: 60 mm, Height of edgebanding material: 14-64 mm, Thickness of edgebanding material in rolls: 0.4-3 mm, Thickness of edgebanding in strips: 0.4-12 mm, Min. panel protrusion from the track: 25 mm, Panel length: 140 - 3200 mm, Min. panel width (with length 140 mm): 85 mm, Min. panel width (with length 250 mm): 50 mm.

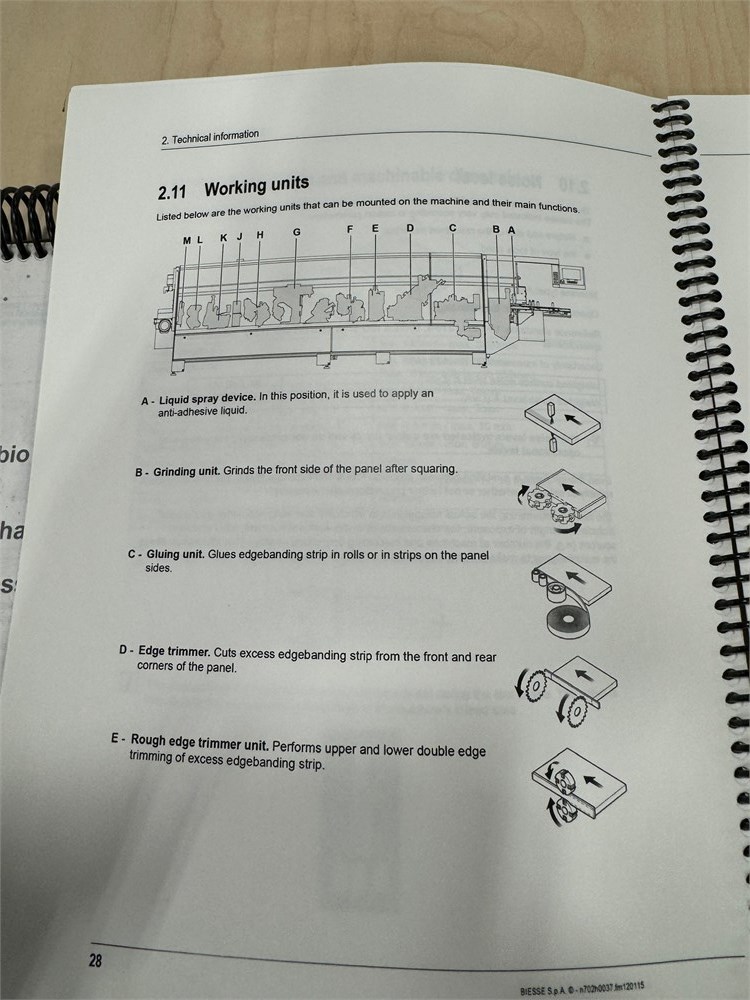

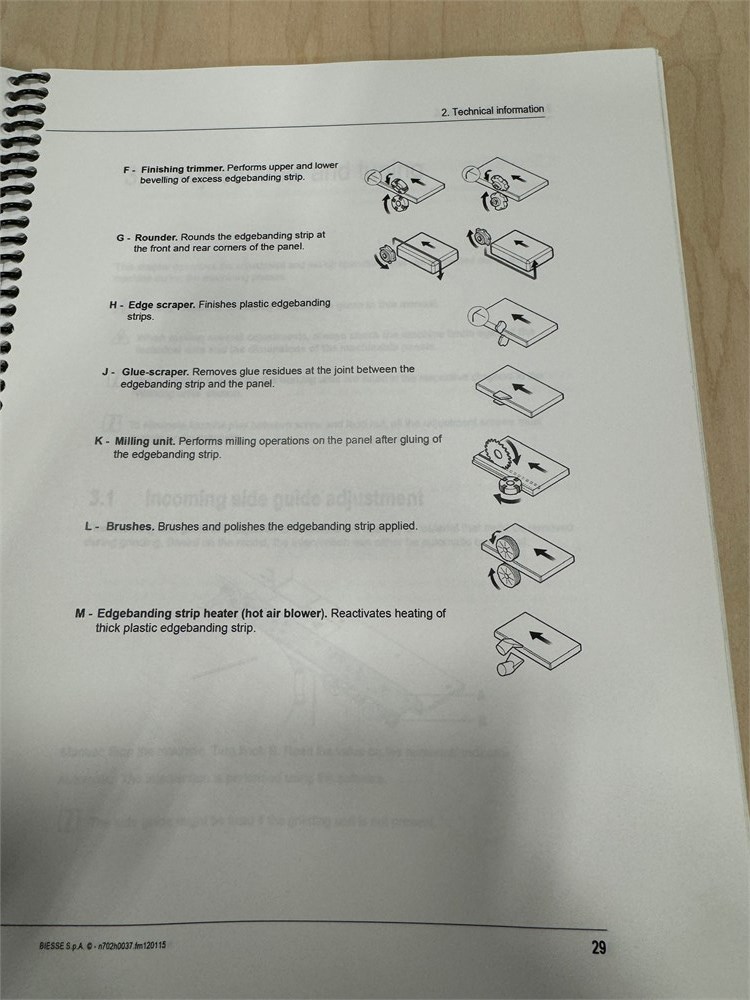

Pre-milling unit

Hot Melt Gluing

Single coil edge feeding

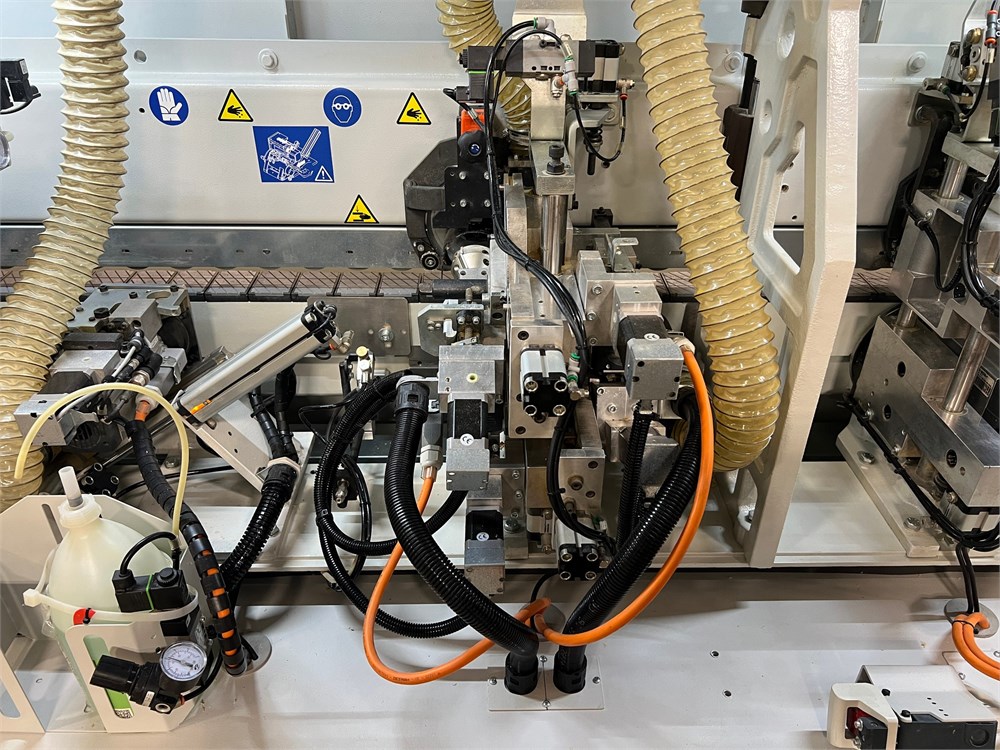

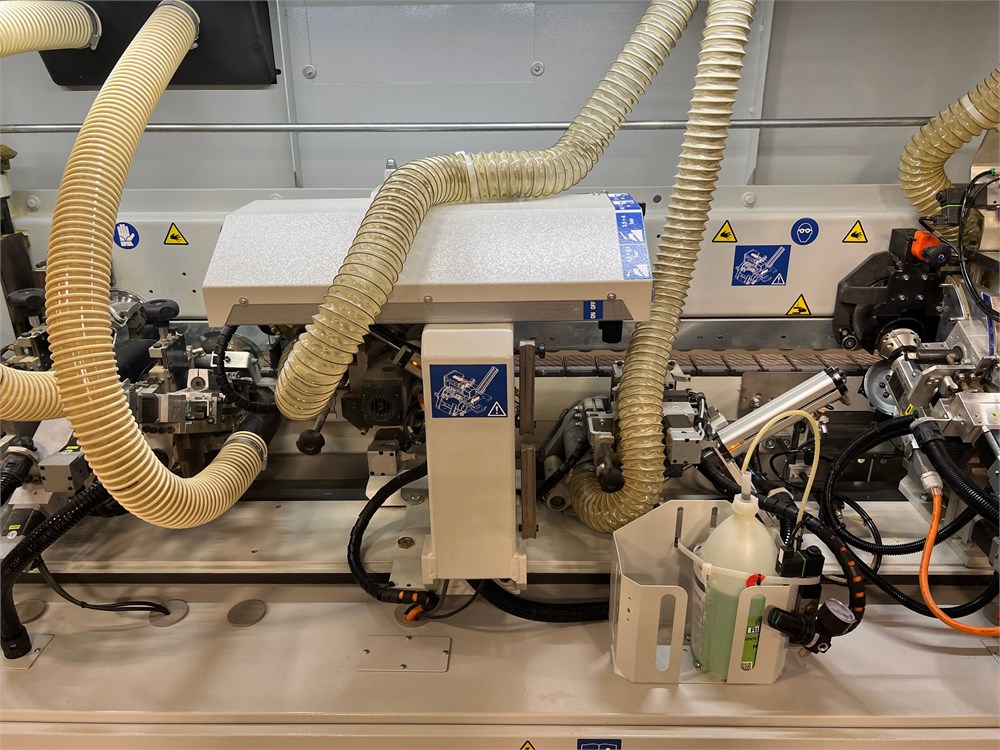

Pressure application section, servo controlled

Front & Back End trimming unit

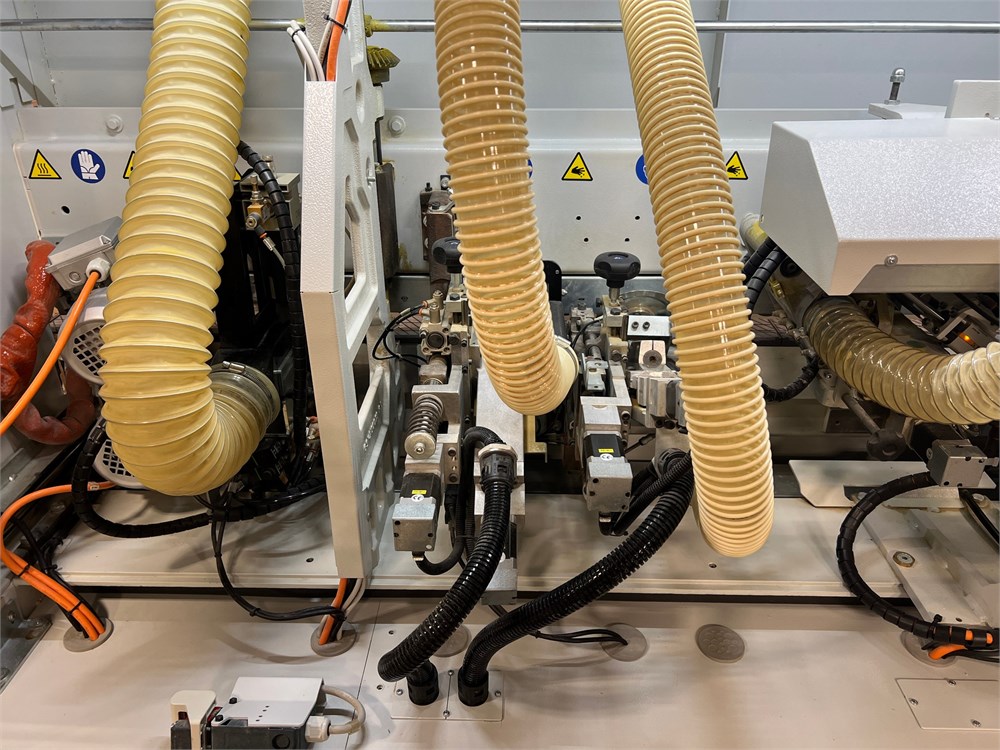

Top & Bottom trimming unit, servo controlled

Multifunction 2-motor corner rounding unit, servo controlled

Top & Bottom Edge Scraping unit, servo controlled

Top & Bottom glue scraper unit

Top & Bottom Buffing station

Hot air blower unit

Belt pressure beam. The top presser comprises a rubber belt with a stain-proof coating. The thrust exercised on the panel is provided by springs housed on techno polymer connecting rods.

Automatic track lubrication system with dynamic track absorption.

Multiple speed kit, 12 - 18 m/Min

Anti-adhesive unit ADZ02, applies the anti-adhesive liquid on the top and bottom of the surface of the panel to ease a good cleaning of the piece being processed.

One coil automatic edge feeding

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense).

Payment is due within 24 hours of auction close. Payments must be made via bank wire transfer for any amount above $1,500. Credit cards may be used up to $1,500 (3% processing fee). Please Contact Sabrina Burns with payment questions at 209-839-7707 Any sales tax exemption documents are to be emailed to [email protected] at time of purchase/invoice for tax exemption consideration.