Brandt "Optimat KD 77 C" Edgebander - Corner Rounding  Ended

Ended

JMC Wood Manufacturing - Bridgeton, MO

Bridgeton, MO

- Starting Bid : $250.00 USD

- 0 Bid(s)

JMC Wood Manufacturing ( Closed #66402119 )

Excess machinery no longer required in continuing operations of JMC Wood Manufacturing in Bridgeton, MO

-

Pick Up Location

13519 Northwest Industrial Drive, Bridgeton, MO 63044

-

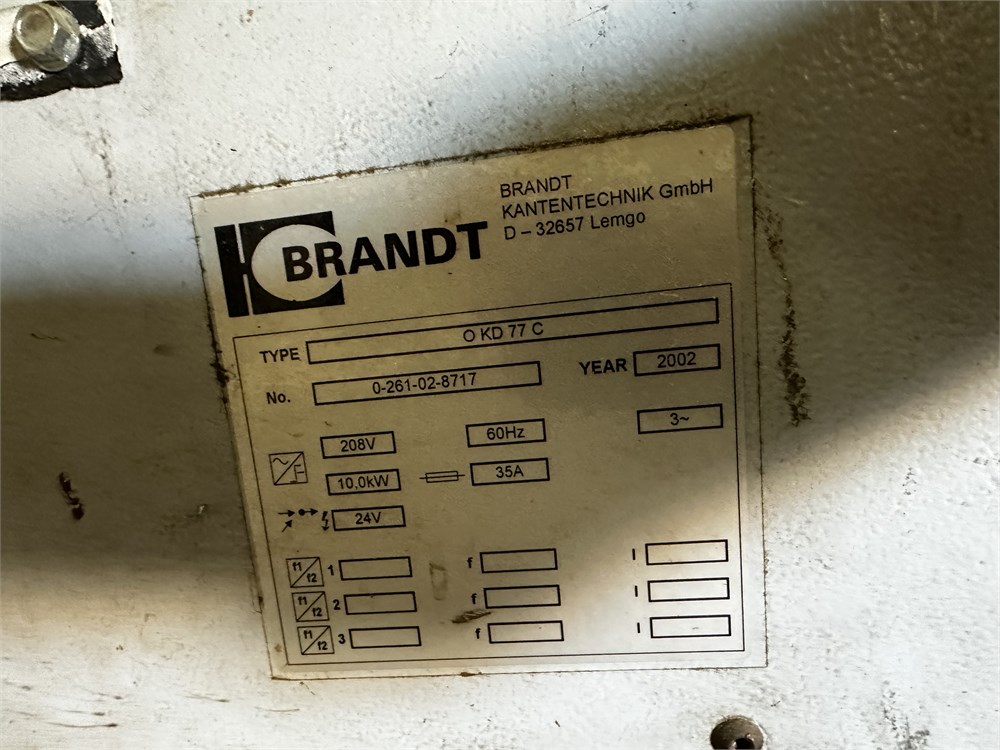

Make

Brandt

-

Model

"Optimat KD 77 C"

-

Serial Number

0-261-02-8717

-

Year

2002

-

Phase

3 PHASE

-

Voltage

208

-

Load Out Period

See home page for details

-

Estimated Dimensions

-

Estimated Weight

-

Seller Comment

-

Load Fee

195.00

-

Lot Notes

-

page views

625

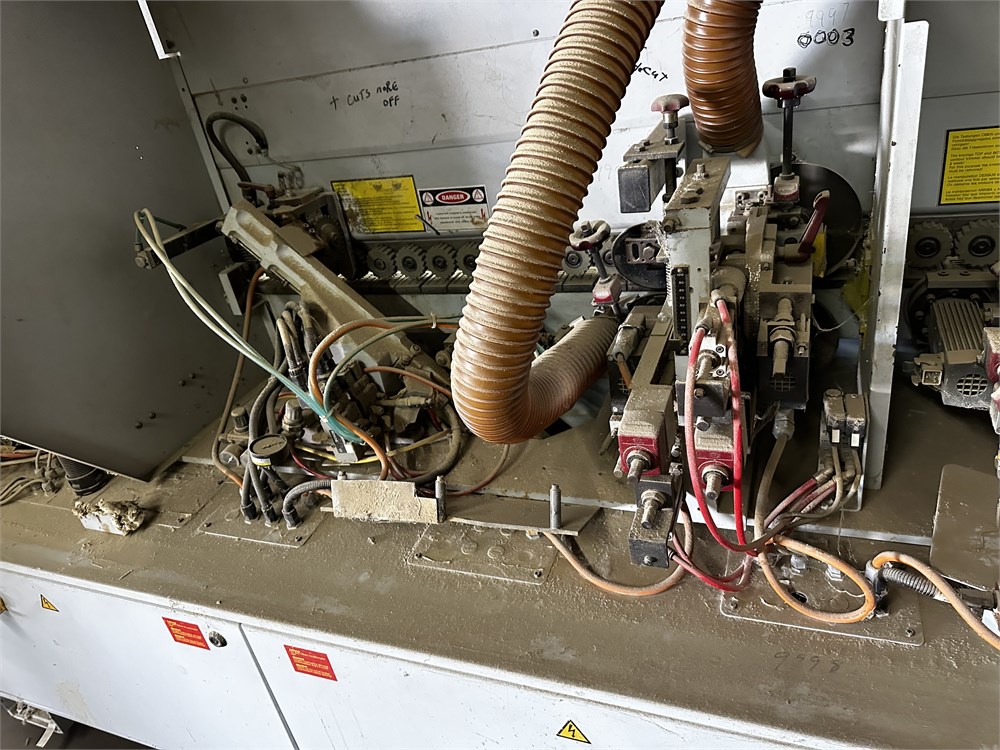

Brandt "O KD 77 C" Edgebander - Corner Rounding

Screen not working

1/2" (12.7 mm)Edge cap., panel thickness 3/8" (9.5 mm) - 2-3/8" (60 mm); with line control (no limit switches) for workstation function. ~ Quick heat-up glue system w/overhead hopper feed, quick change glue tank for maintenance & glue color change.

Automatic magazine for strip & coil stock, 3 mm PVC guillotine, reversible rotation glue roller w/infrared heat zone to follow, (1) drive plus 2-idle roller "pneumatically controlled" pressure section w/digital readout setting.

End Trimming: (2) motor (0.5 HP - 12,000 RPM motors), chamfers 0° - 15°.

Fine/Bevel/Radius Trimming: Top & bottom with insert knives for 3 mm PVC radius, chamfers 0° - 25° (0.35 KW - 12,000 RPM motors).

Corner Rounding Unit: 2-Motor for top & bottom corners, (0.55 KW - 12,000 RPM motors).

Profile Scraping Unit: Top & bottom for 2 - 6 mm radius, pneumatically controlled blow-off nozzles.

Buffing Unit: Top & bottom (0.25 HP - 1,400 RPM motors).

All trimming stations have HF motors w/electronic brakes and are equipped with mechanical digital readouts for quick setup & adjustment; Feed speed 46 FPM, 3 HP feed drive.

Swiveling PC-16 Program Control w/12" LCD screen, 8 MB IDE flash disk, 8 MB RAM, internal modem for remote diagnostic link; Signal in-feed light to ensure proper spacing between panels.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense).

Payment is due within 24 hours of auction close. Payments must be made via bank wire transfer for any amount above $1,500. Credit cards may be used up to $1,500 (3% processing fee). Please Contact Sabrina Burns with payment questions at 209-839-7707 Any sales tax exemption documents are to be emailed to [email protected] at time of purchase/invoice for tax exemption consideration.