Biesse "Rover B FT 1536" Flat Table Machining Center - Load/Unload (2016)  Ended

Ended

Complete Woodworking Factory Auction - Oakland, CA

Oakland, CA

- Winning Bid : $55,000.00 USD Sold

- 100 Bid(s)

- High Bidder: F****T

Complete Woodworking Factory Auction - Oakland, CA ( Closed #65817919 )

After more than 35 years in business, Creative Wood is retiring their business and auctioning all assets. This 70,000 square foot factory auction near San Francisco, CA offers over 400 lots of woodworking machinery, tools and supplies. Featuring a late model Biesse Winstore panel system with Biesse Rover CNC router with loading/unloading and rear-load Selco beam saw. Please join me for an open house July 12, 2024 (9 AM - 3 PM).

-

Pick Up Location

900 77th. Ave. Oakland, CA 94621

-

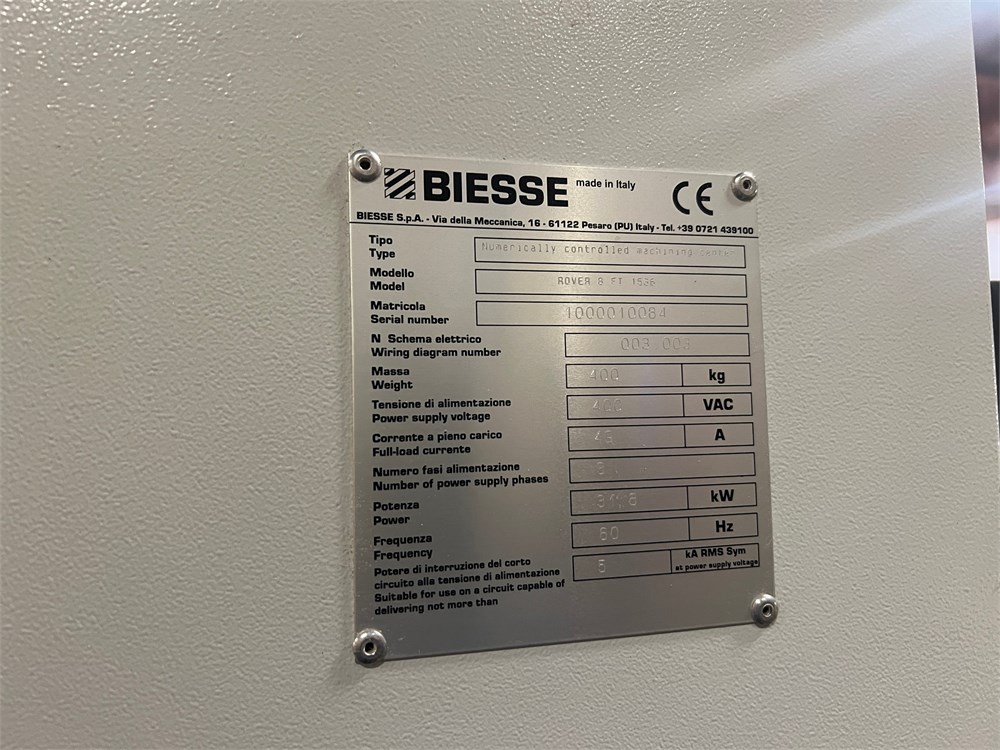

Make

Biesse

-

Model

"Rover B FT 1536"

-

Serial Number

1000010084

-

Year

2016

-

Phase

3 PHASE

-

Voltage

208-230/460

-

Load Out Period

See home page for details

-

Estimated Dimensions

Infeed: 8'W x 18'L x 7'H, CNC: 268"L x 160/102"W x 96"H, Outfeed: 180" x 80" x 48"

-

Estimated Weight

8,140 Lbs CNC + Infeed & Outfeed

-

Seller Comment

This lot requires a rigger, see home page for details.

-

Load Fee

-

Lot Notes

See Video & Documents

-

page views

3856

Biesse "Rover B FT 1536" Flat Table Machining Center - Load/Unload (2016)

Please see the pdf documentation for original info we received from manufacturer.

5' x 12' "Matrix" grid phenolic surface for "Nested Base Manufacturing"

"X" Axis 148.2" (3,765 mm), "Y" axis 61.4" (1,560 mm), "Z" axis stroke is 20.2" (515 mm), max. material thickness 10" (250 mm).

"X"& "Y" Axis 279 FPM (85 MPM),"Z" axis 115 FPM (35 MPM);

"X" & "Y" Axes use a precision rack & pinion system, "Z" axis uses precision ball screws.

All axes movement is on precision linear guides & ways and controlled by digital, brushless AC Servo motors.

All motion components are maintained by an automatic lubrication system.

Flat table design with "Matrix" grid phenolic surface for "Nested Base Manufacturing",

The machine has (2) working areas with 2-left origins, 2-right origins, 1 front origin& 1 rear origin.

(14) External pneumatic pop-up stops with (2 LH + 2 RH) rear stops, (3 LH + 3 RH) front stops & (2 LH +2 RH) side stops for material positioning;

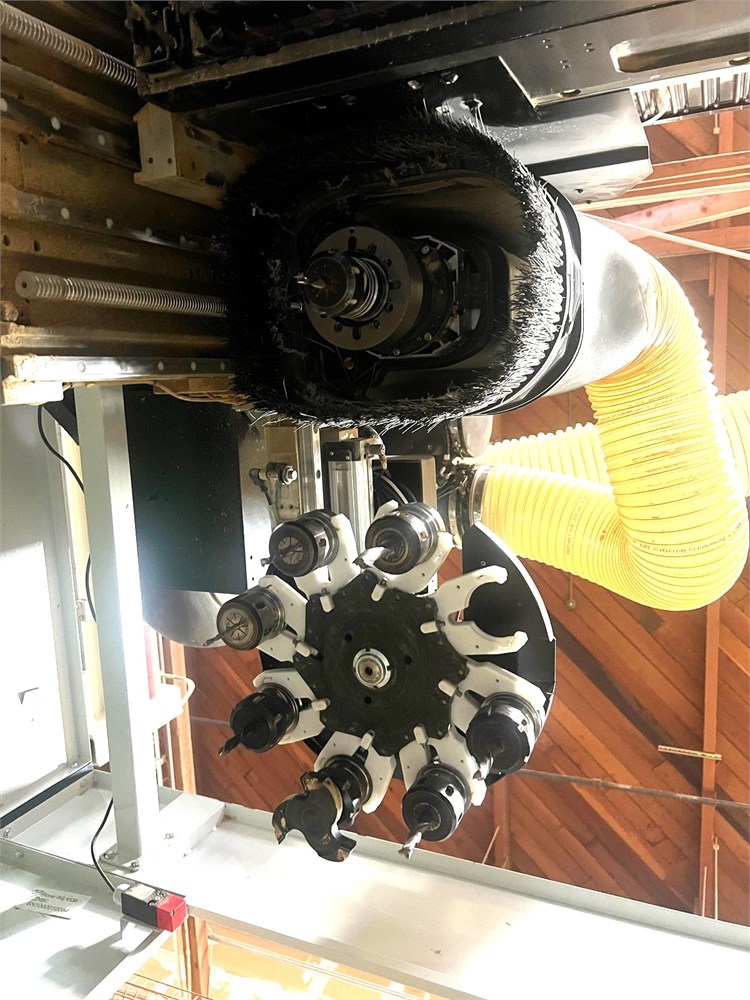

(1) 4 HP (3 kW) motor with variable speed up to 6,000 RPM: BH-10 Boring unit with(43) independent vertical spindles, (22) in "X" axis & (21) in "Y" axis.

(1) 22.5 HP (approx) "HSDElectro-Spindle" with HSK F63adaptor, RH & LH rotation; variable speed from 1,000 - 18,000 RPM.

(1) 8-Position ATC tool carousel

NC controlled Tool Touch-off prob for the measurement of the tool length, max 5.1" (130 mm) tool dia.

PC Front End with: Biesse "BH 660" + "Biesse WORKS " + WINDOWS "WRT" (Windows Real-Time) operating system;

Air Conditioned control cabinet, 21.5"LCD Flat screen monitor; server, full keyboard & mouse all mounted on a mobile cart;

"Biesse WORKS"Graphic interface makes full use of the operating methods typical of the Windows operating system: assisted graphic editor used to program machining operations; programming and guided creation of parametric macros.

Import of CAD and other external software files in DXF and CID3 format; 3D simulation of the tool path, calculation of machining time & the ability to create rotate virtual faces.

(2) 300 / 360 m³/Hr (50Hz / 60Hz) "BUSH" vacuum pumps; system for linear guides, pads and re-circulating ball screw;

Universal Auto-Transformer for voltages between 200 - 600 V, 50/60 Hz; Tele-Service capabilities; Perimeter Safety System & fencing;

62" x 149" Phenolic load table, Feeding arm with (2) vacuum cups & ride along printer, side alignment device.

112" Infeed roller connecting the infeed table to the main table.

(1) Rake system to sweep cut parts onto out-feed belt conveyor;

(1) 62" x 173" NC controlled & powered belt out-feed table with vacuum sweeping system

Outfeed labeling system

Remote hand-held control pendant/keyboard.

|

|

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available