Homag "KL 78/A20/S2" Edgebander - High Speed  Ended

Ended

Stockton, Ca Machinery Auction

Stockton, CA

- Winning Bid : $1,600.00 USD Sold

- 7 Bid(s)

- High Bidder: u****y

Warehouse Machinery Auction - Stockton, CA ( Closed #65355189 )

Assets no longer required for continuing operations. Featuring Weinig Powermat 1000 Moulder, Homag KL78 High speed Edgebander, Optisand Rotary Brush Sander, Baretto 37SG Stump Grinder plus much more!

-

Pick Up Location

Stockton, Ca

-

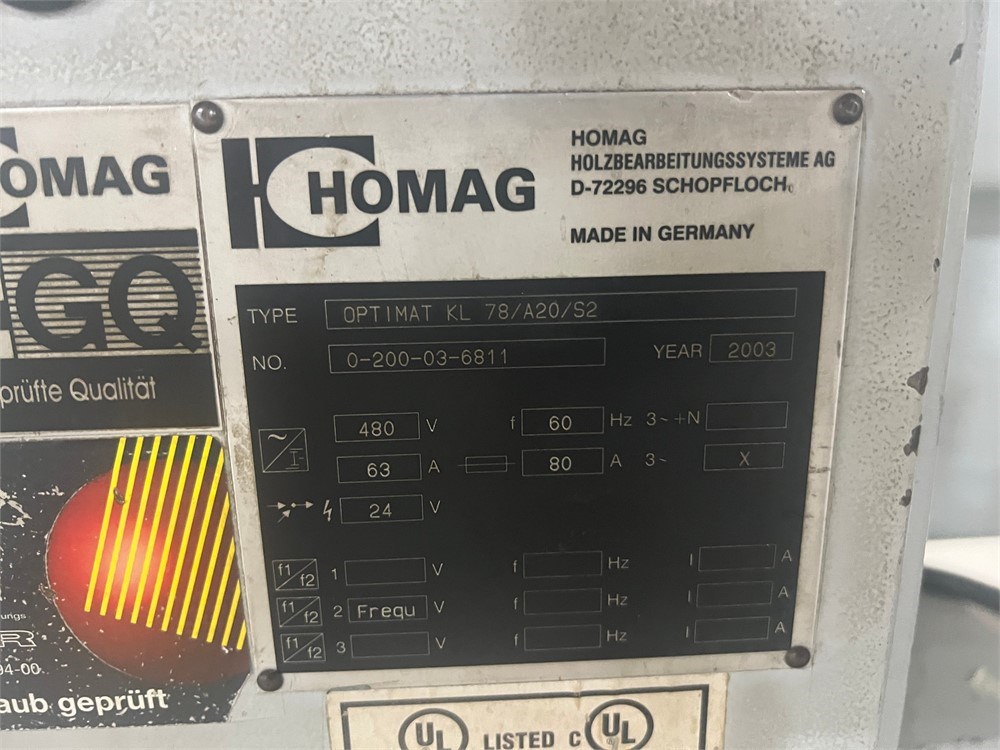

Make

Homag

-

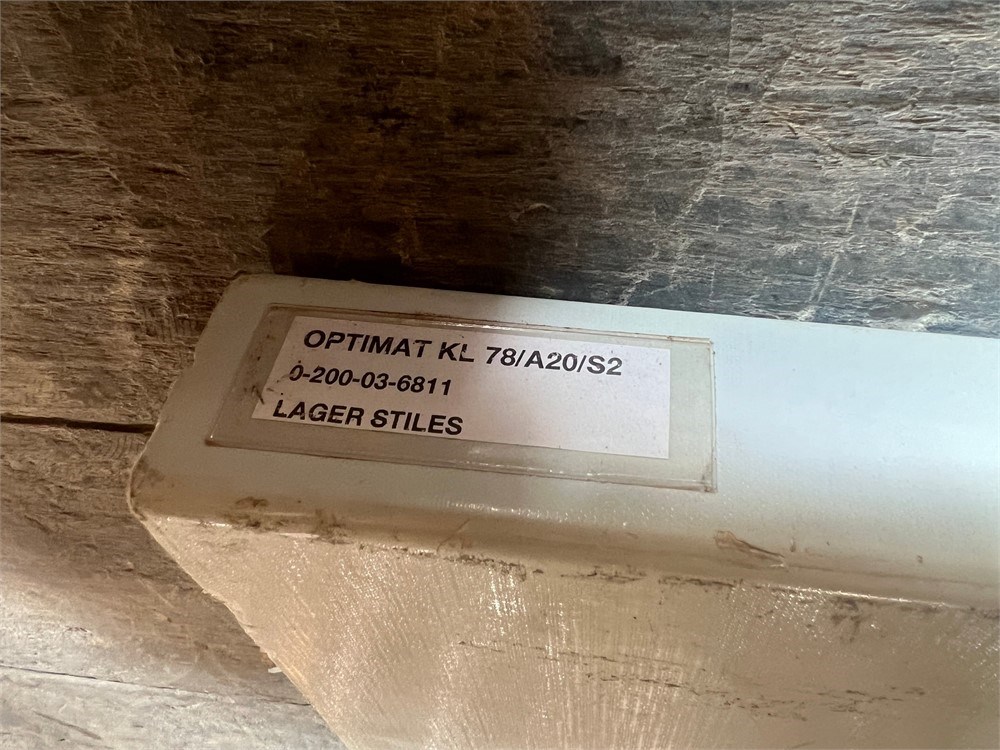

Model

"KL 78/A20/S2"

-

Serial Number

0-200-03-6811

-

Year

2003

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Load Out Period

See Homepage

-

Estimated Dimensions

32' x 4' x 6.5'

-

Estimated Weight

-

Seller Comment

-

Load Fee

A Rigger is required for this lot. Buyer is responsible for break down & loading.

-

Lot Notes

-

page views

892

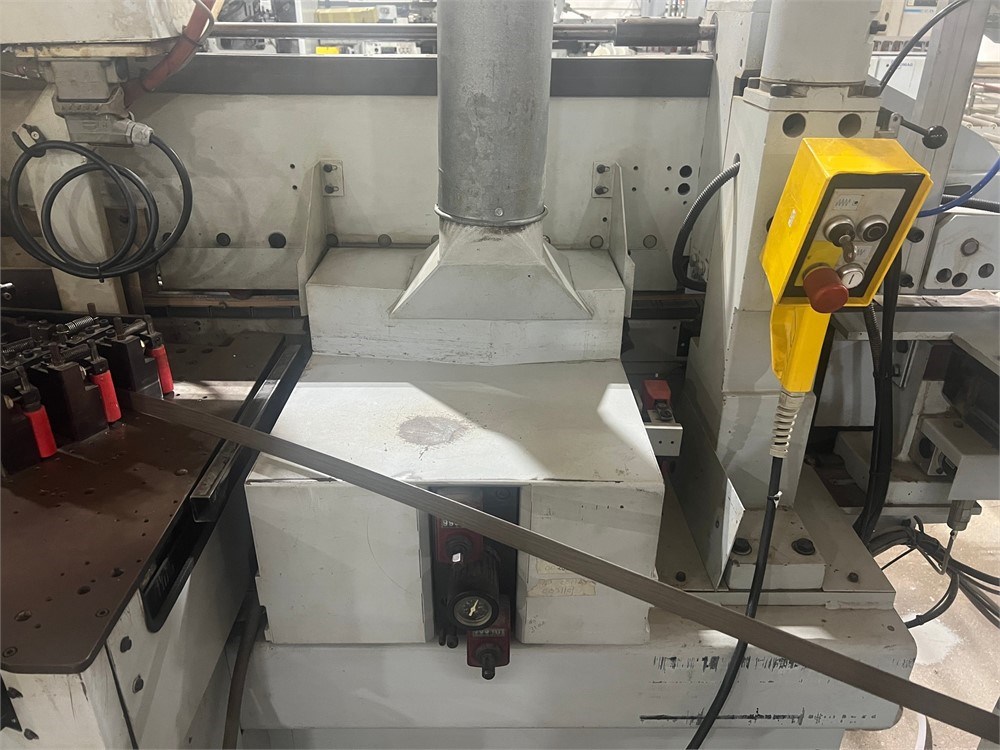

Homag "KL 78/A20/S2" Edgebander - High Speed

0.4 - 20 mm Edge thickness cap., min. panel width 55 mm (2-1/4"), panel thickness 12 - 60 mm, min. edge length 7.8"

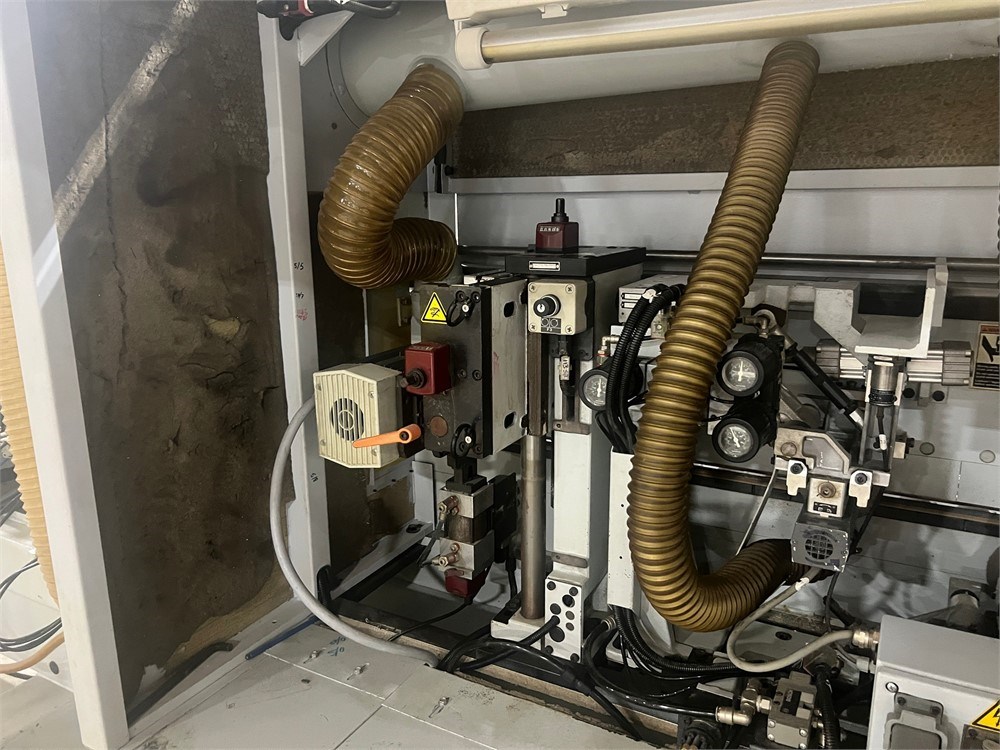

Stations Include: Premill w/ Servo Fence, Pneumatic 7 Pressure Rollers, End Trims, Top/Bottom Trim Hog, Top/Bottom Trim Profile w/ Servos, 4 Motor Corner Rounder, Radius scrapers, Hot air blowers, Buffers.

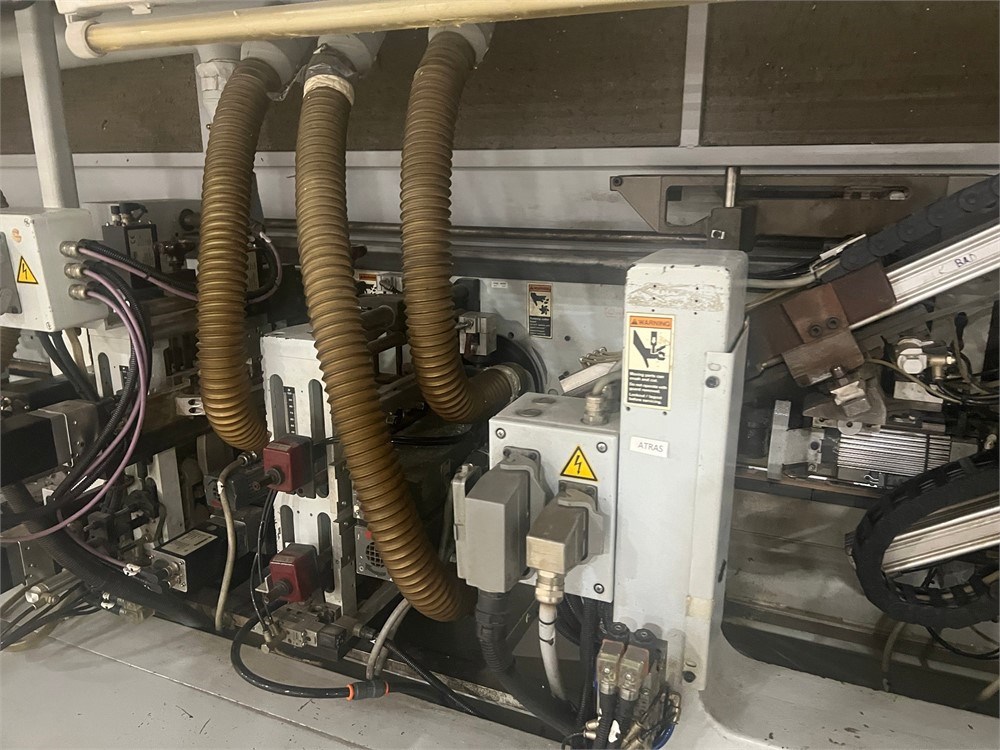

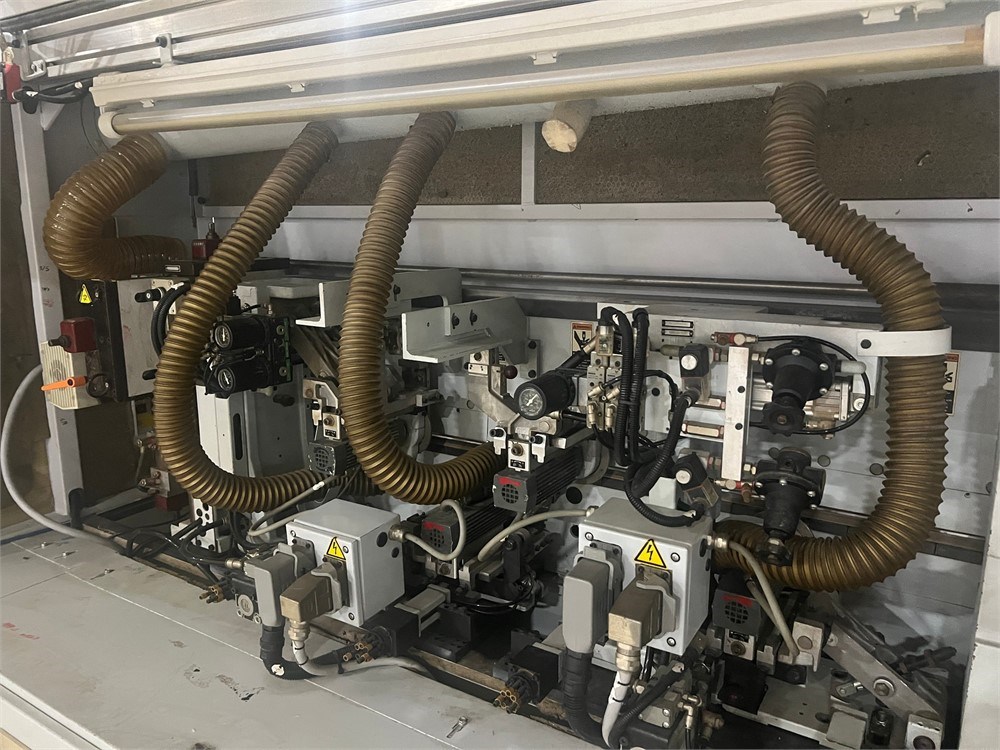

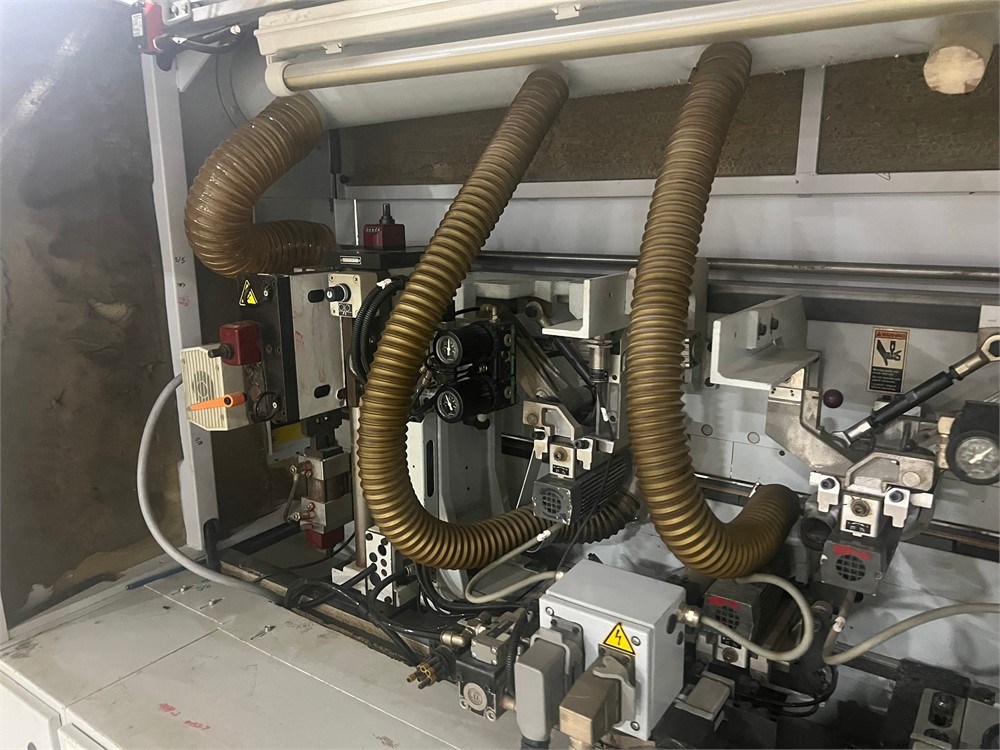

(2) Pre-milling heads (each with 3 kW - 6,000 RPM motor, one with jump control); chip blowoff unit after last head; SIKO digitals for horizontal & turret for vertical adjustments; pre-heating infeed fence (for panel edge).

Automatic multiple coil feed magazines for coil material up to 3 mm thickness, strip feed magazine for up to 20 mm (3/4") solid wood banding.

"Quick Melt" glue system "QA 34" with per melt hopper feeder & roller applicator (reversible); pneumatic pressure roll section with (1) large dia. driven & (6) idle rollers.

Double motor front & rear end trim (0.7 HP - 12,000 RPM motor ea.), pneumatic chamfer setting.

Top & bottom rough trims (2 HP - 12,000 RPM motor ea.).

Top & bottom bevel & radius trims (0.6 HP - 12,000 RPM motor ea.), tiltable 0° - 30°; pneumatic exclusion from operator panel.

Top & bottom profile trim units for leading & trailing edge (four 0.6 HP - 12,000 RPM motors), up to 4 mm edge thickness (all trim station motors are 200 Cy HF and equipped w/electronic brakes).

Profile tracing from top, bottom and side for chamfering or rounding of pre-trimmed PVC edges; pneumatically controlled blowing nozzles; max. edge thickness 3 mm (1/8"), panel thickness 12 mm to 60 mm (15/32" to 2-3/8"); unit laterally adjustable by max. 50 mm (1-31/32"); collection box for PVC shavings; height adjustment with top pressure beam without tools; manually adjustable with digital mechanical counters.

Top & bottom buffing unit w/oscillation control (0.3 HP - 1,650 RPM motors).

Motorized top pressure beam with powered V-belt holddown, 80 mm wide Heavy Duty feed chain w/rubber pads, automatic chain track lubrication system, 5 HP feed drive for variable feed speed of 23 - 98 FPM.

Line control with HOMATIC "NC 21" controller features: Real-time "OS9" operating system, functions in Windows environment; PLC w/storage for (40) working programs, each with (160) functions for remote control of processing units; keypad w/LCD display, fault diagnostic, etc.

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available