Homag "Drillteq V-200" CNC Machining Center - Vertical (2022)  Ended

Ended

Pladac Industries - Salinas, CA

Salinas, CA

- Winning Bid : $58,750.00 USD Sold

- 128 Bid(s)

- High Bidder: I****O

Late Model Homag Machinery - Salinas, CA ( Closed #64679706 )

Complete shop closure! Featuring 2022 Homag Sawteq B-200 Beam Saw, 2022 Homag Drillteq V-200 Vertical CNC Machining Center, 2022 Homag Cabteq S-250 Case Clamp, 2021 Biesse Jade 225 Edgebander, plus much more!

-

Pick Up Location

Salinas, CA

-

Make

Homag

-

Model

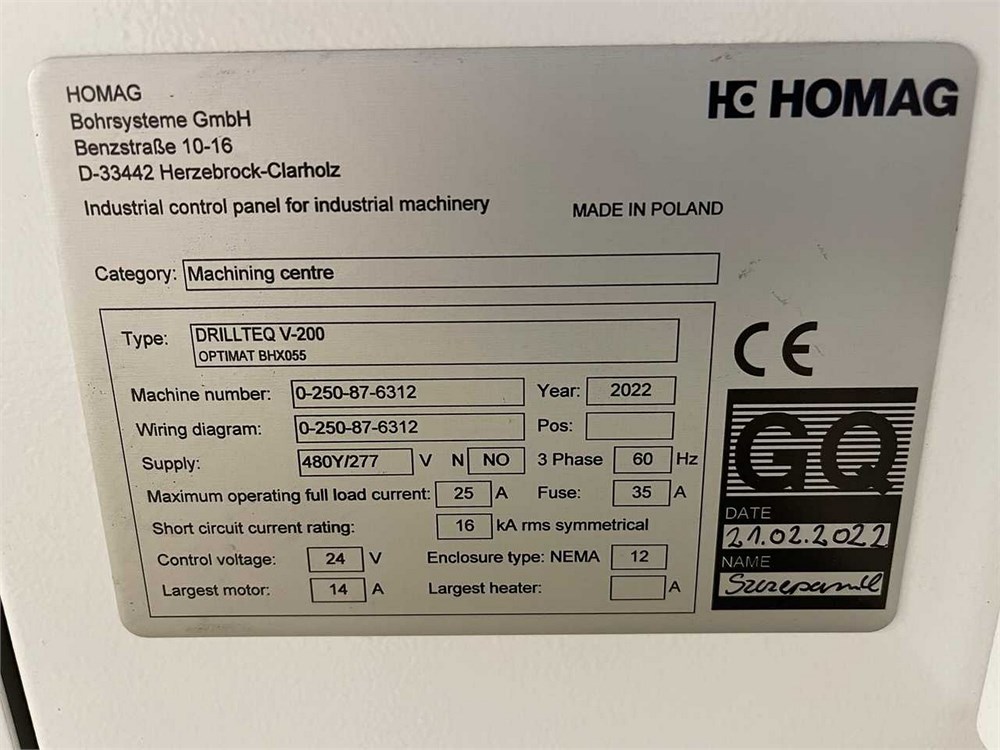

Drillteq V-200 Optimat BHX055

-

Serial Number

0-250-87-6312

-

Year

2022

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Load Out Period

See Homepage

-

Estimated Dimensions

140" x 80" x 75"

-

Estimated Weight

4,000 Pounds

-

Seller Comment

Small Footprint!

-

Load Fee

A rigger is required. Buyer's Responsibility for Break-down, loading and removal.

-

Lot Notes

Please see video!

-

page views

5894

Homag "Drillteq V-200" CNC Machining Center - Vertical (2022)

See video of machine in operation

Flexible "Vertical" Machining Center with boring, routing and sawing. Small footprint with big capabilities!

Maximum workable part size for "X" axis is 120" (3,050 mm); "Y" axis 33.4" (850 mm); max. part thickness 3.1" (80 mm).

Minimum worktable part size for "X" axis is 7.8" (200 mm); "Y" axis 2.75" (70 mm); min. part thickness of 0.31" (8 mm).

Automatic infeed and outfeed from the LH or RH side.

The "V-200" can reach movement speeds of 164 FPM (50 MPM) in "X" & "Y" axis & 50 FPM (15 MPM) in "Z" axis with total safety, providing an unmatched working capacity.

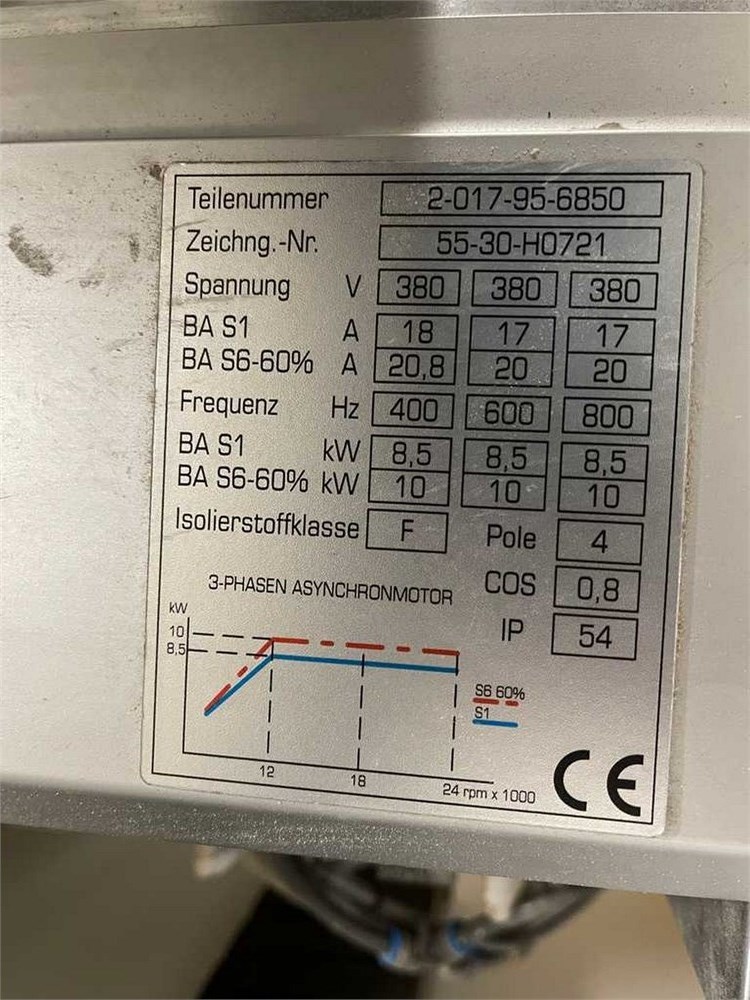

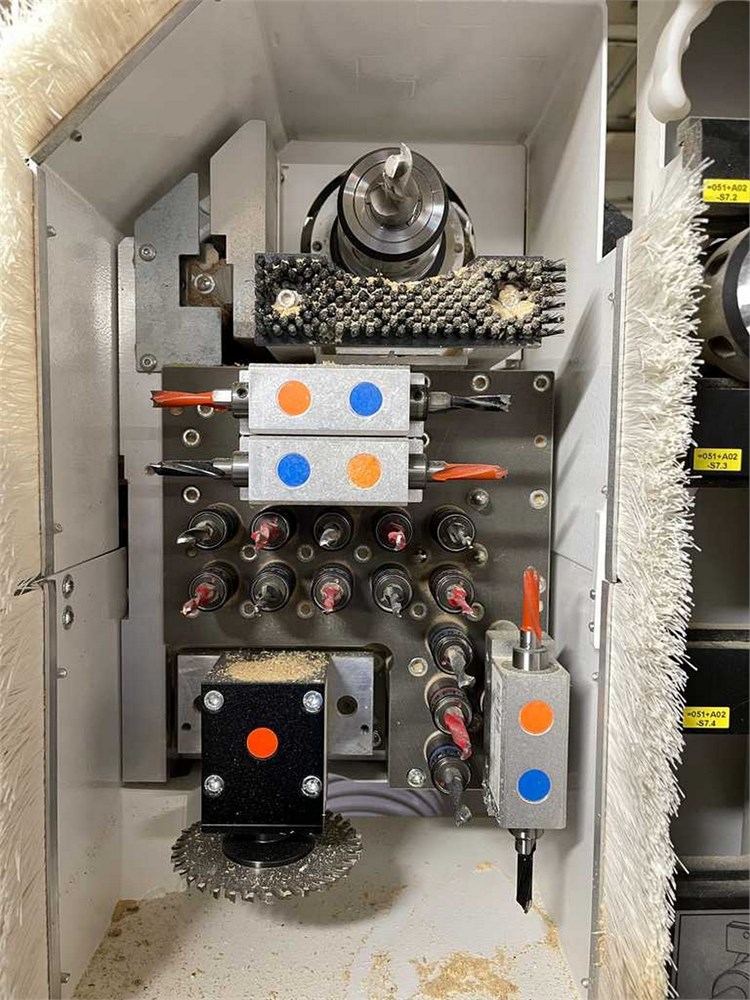

Boring unit with one (1) 3 HP motor; Variable speed from 1,500 - 7,500 RPM; Thirteen (13) independent vertical spindles; six (6) horizontal spindles; boring block has "QUICK CHANGE" spindle system

One (1) "X" Grooving Saw; 9,000 RPM, max. saw blade dia. 100 mm (3.9").

One (1) 12 HP Electro Spindle router with HSK F63 adaptor; variable speed from 6,000 - 24,000 RPM

Four (4) position tool changer for router

Pneumatic part clamping devices; sound enclosure

Foot pedal operation

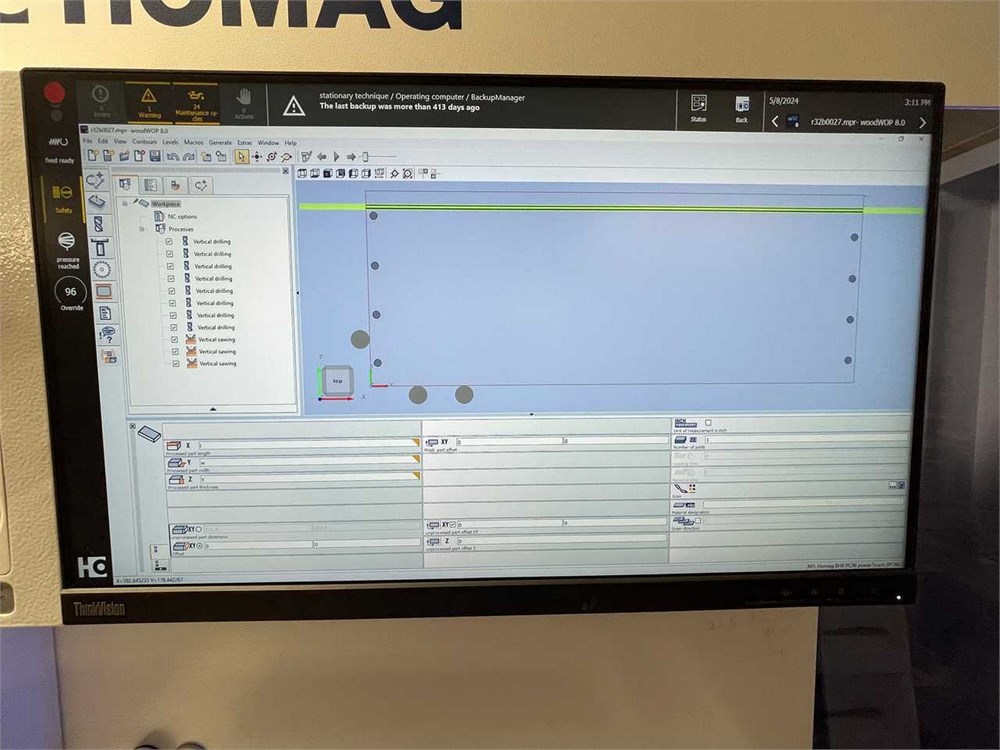

HOMAG "POWERTOUCH" + Windows + WoodWOP Operating System; "IntelCore 2 DUO" Processor.

21" TFT Monitor; international keyboard, soft touch keypad & industrial mouse; RS-232 Serial ports, USB ports; (1) 1.44 MB floppy disk drive, (1) CD RW drive, modem, Ethernet connection.

Real-time multitask processing; programs can be downloaded by network

Installed barcode scanner (wired)

Uninstalled barcode scanner (wireless), new in box

Installed and extra tooling

Manuals

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense). MachineryMax does not ship- All buyers responsible for their own freight - For freight quotes please contact your preferred broker, or contact Aaron, at Always Trucking 541-608-6532

Payment is due within 24 hours of auction close. Payments must be made via bank wire transfer for any amount above $1,500. Credit cards may be used up to $1,500 (3% processing fee). Please Contact Sabrina Burns with payment questions at 209-839-7707 Any sales tax exemption documents are to be emailed to [email protected] at time of purchase/invoice for tax exemption consideration