SCM "SuperSet NT" Moulder  Ended

Ended

SCM "SuperSet NT" Moulder - Harbor City, CA

Harbor City, CA

- Winning Bid : $26,501.00 USD Sold

- 89 Bid(s)

- High Bidder: R****3

SCM "SuperSet NT" Moulder - Harbor City, CA ( Closed #64511656 )

Custom woodworking business in Southern California is auctioning their SCM moulder no longer required for continuing operations.

-

Pick Up Location

1429 W. 259th. St. Harbor City, CA 90710

-

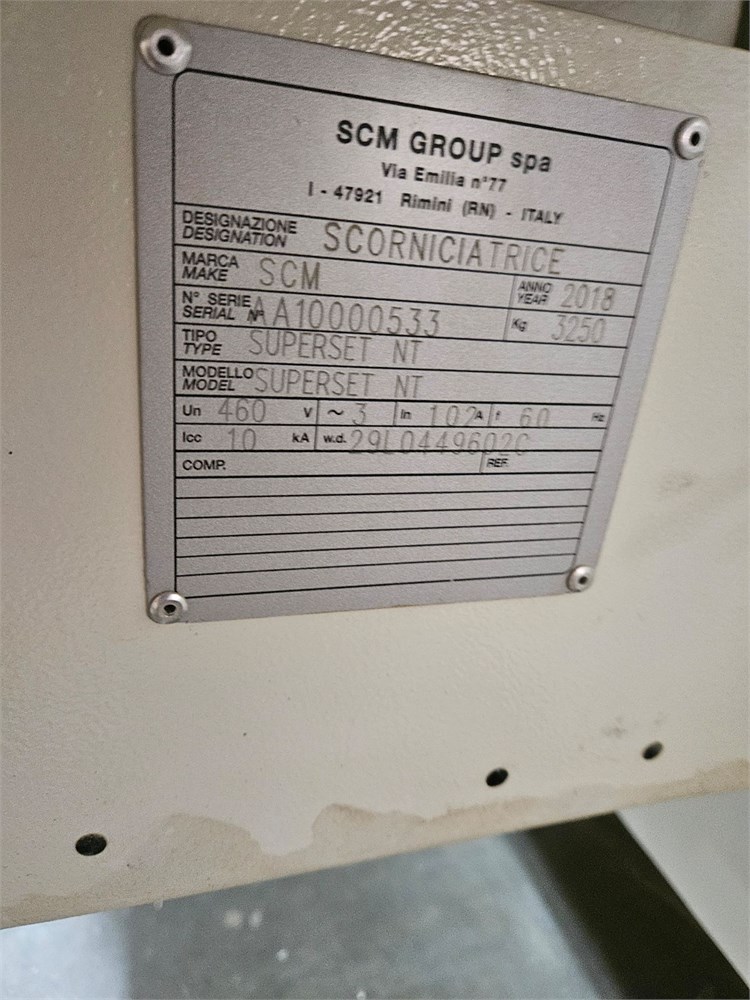

Make

SCM

-

Model

SuperSet NT

-

Serial Number

AA10000533

-

Year

2018

-

Phase

3 PHASE

-

Voltage

460 VOLT

-

Load Out Period

May 9 - May 17, 2024 (by appointment)

-

Estimated Dimensions

165" L x 65" W x 69" H

-

Estimated Weight

7,150 Pounds

-

Seller Comment

This lot requires a rigger, see home page for details.

-

Load Fee

-

Lot Notes

-

page views

1573

SCM "SuperSet NT" Moulder

6 mm (0.24") x 15 mm (0.6") minimum finished part cross-section

120 mm (4.7") x 240 mm (9.4") maximum finished part cross-section

620 mm (24.4") minimum part length

Variable feed speed, 19 - 118 FPM

Infeed fence, 2500 mm (98.4")

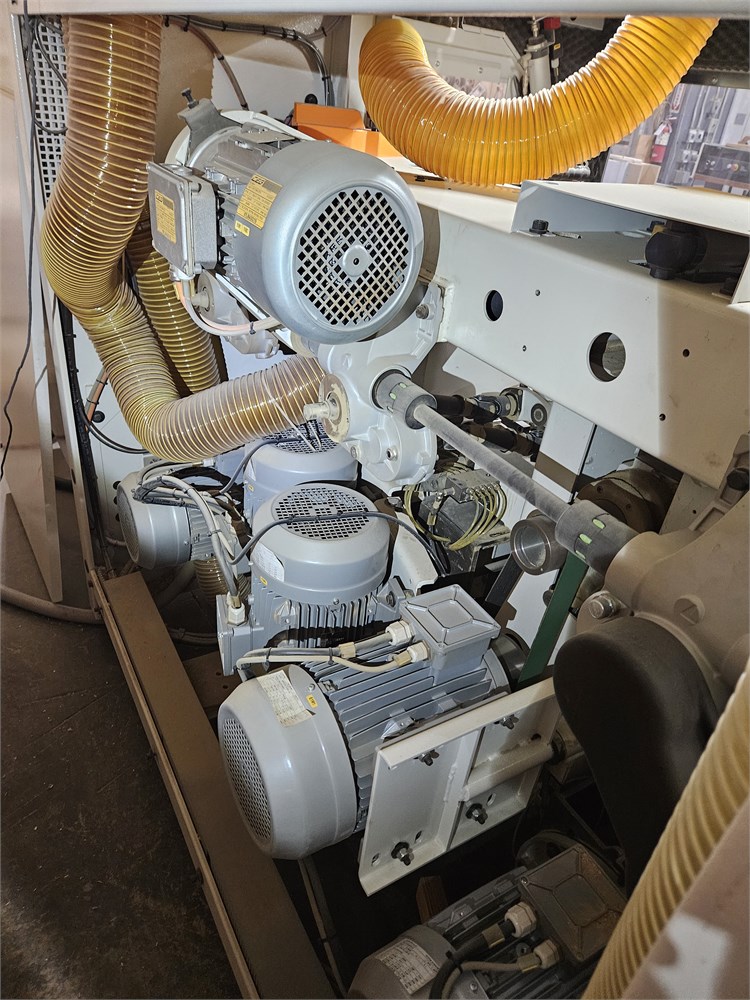

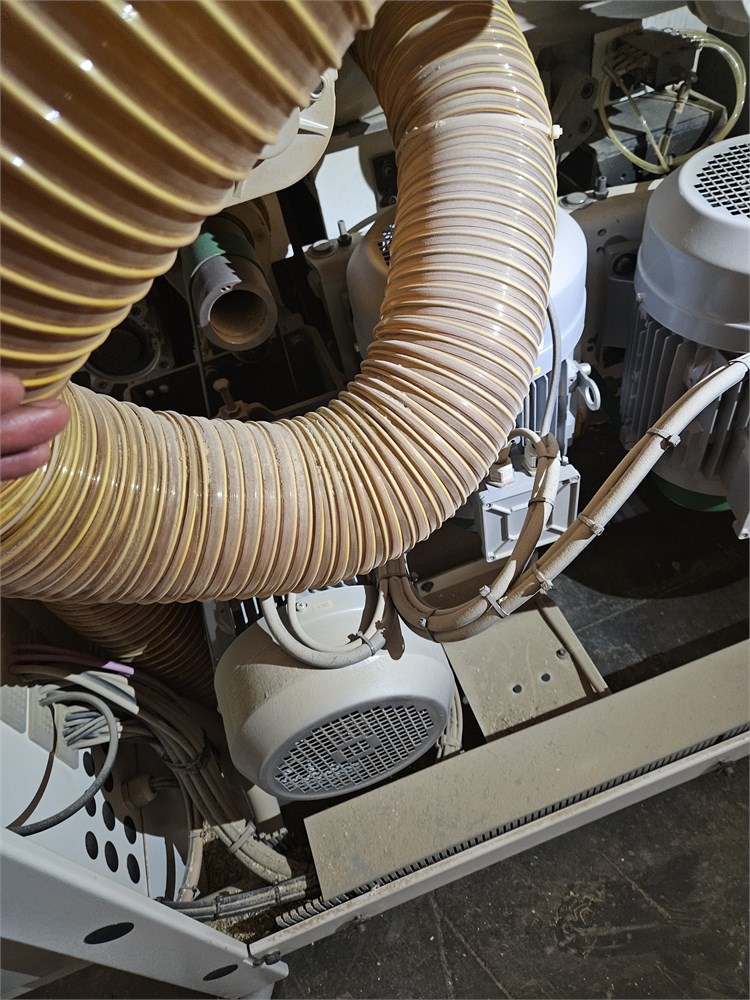

Five (5) stations:

Bottom - 12 HP

Right - 12 HP

Left - 12 HP

Top - 17 HP

Bottom - 12 HP

Auto-braking motors

1-13/16" spindle diameter

140 mm (5.5") vertical spindle length

250 mm (9.8") horizontal spindle length

6,000 spindle RPM

80 mm (3.1") axial adjustment of vertical spindles (reference to table)

45 mm (1.8") axial adjustment of horizontal spindles (reference to RH fence)

120 mm (4.7") - 140 mm (5.5") surface planer tool diameter

100 mm (3.9") - 200 mm (7.9") profiling tool diameter. 40 mm (1.6") profiling capacity under table on LH spindle.

15 mm (0.6") profiling capacity on second bottom/horizontal spindle with 200 mm (7.9") tool diameter.

7.5 HP feed motor

Powered feed rollers

One (1) idle pressure roller in front of RH spindle

Tandem feed unit in front of RH spindle with rapid exclusion. Placed before the first right vertical spindle, the tandem unit applies additional feed pressure to the work piece reducing tool chatter.

Feed vertical adjustment device in front of top spindle. For vertical positioning of the steel feed rollers (before top horizontal spindle/s). It is possible to quickly lower the feed rollers to a position lower than their normal orientation to the top horizontal spindle/s, using a pneumatic switch located on the control panel.

Two (2) sector pressure shoe after top spindle. Applies pressure uniformly on two points of the profile of the work piece, avoiding vibration that may be caused by the tool.

One (1) motorized roller on outfeed

"SET UP" quick setup system

All spindles are fitted with this quick setting-up system which enables the machine to be set in only one movement: just set the minimum diameter of tool (e.g. when dealing with a top horizontal spindle). At this point tool, working thickness, chip-breaker, rear pressure shoe and feed rollers are simultaneously adjusted.

"T-SET" rapid tool locking system. Locking/unlocking of tools via compressed air.

Adjustment of spindles is controlled from the front of the machine with mechanical decimal readouts.

Pneumatic exclusion of first feed roller

Motorized top beam positioning

Automatic centralized lubrication system

Lighted sound enclosure

PC control on mobile stand

Windows operating system

SCM's "Maestro 4-Side" software package for machine management

Management of tool library (import of tool image)

Management of work programs storage (import of profile image)

MDI function (it allows manual axes positioning through interactive messages guiding the operator)

Control of feed rate speed

Control of motor start-up

Control and management of different operators working with the machine (2 access levels, operator and administrator)

Color screen

Standard keyboard and mouse

Cutterheads NOT included

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available