Pillar "H49-9" CNC Bore and Dowel Machine  Ended

Ended

Pillar "H49-9" CNC Bore and Dowel Machine - Anaheim, CA

Anaheim, CA

- Winning Bid : $11,175.00 USD Sold

- 18 Bid(s)

- High Bidder: C****a

Pillar "H49-9" CNC Bore and Dowel Machine - Anaheim, CA ( Closed #64391199 )

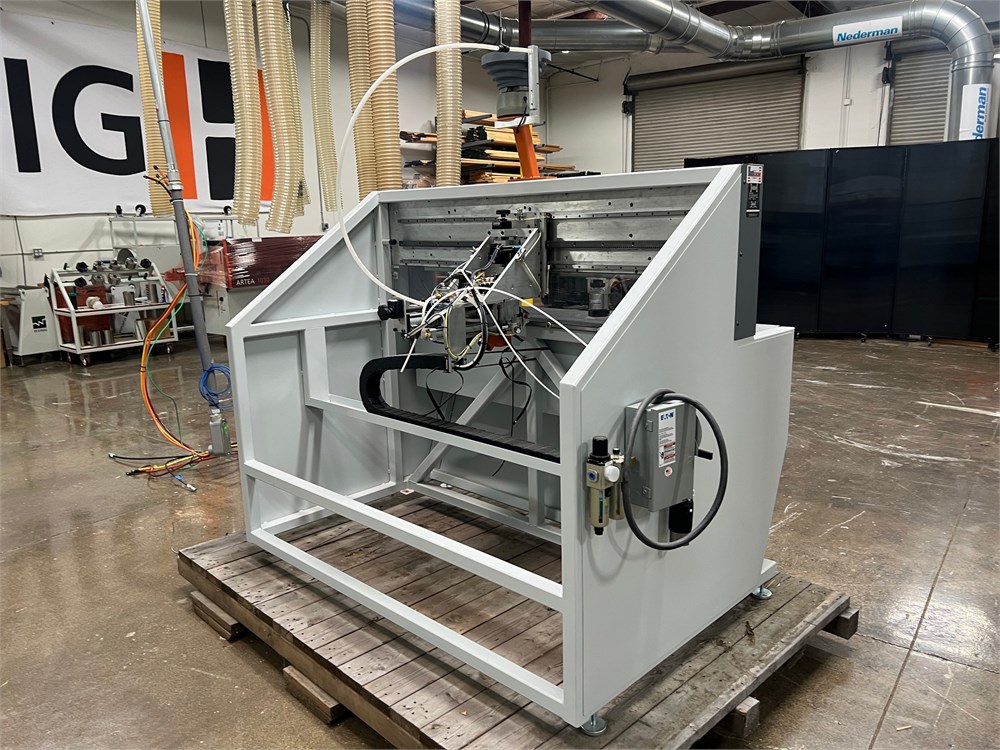

Machinery distributor in Southern California is auctioning a Pillar CNC bore and dowel machine no longer needed for their showroom. Machine has never been installed for production and is on a pallet ready for shipment.

-

Pick Up Location

4720 E. Hunter Ave. Anaheim, CA 92807

-

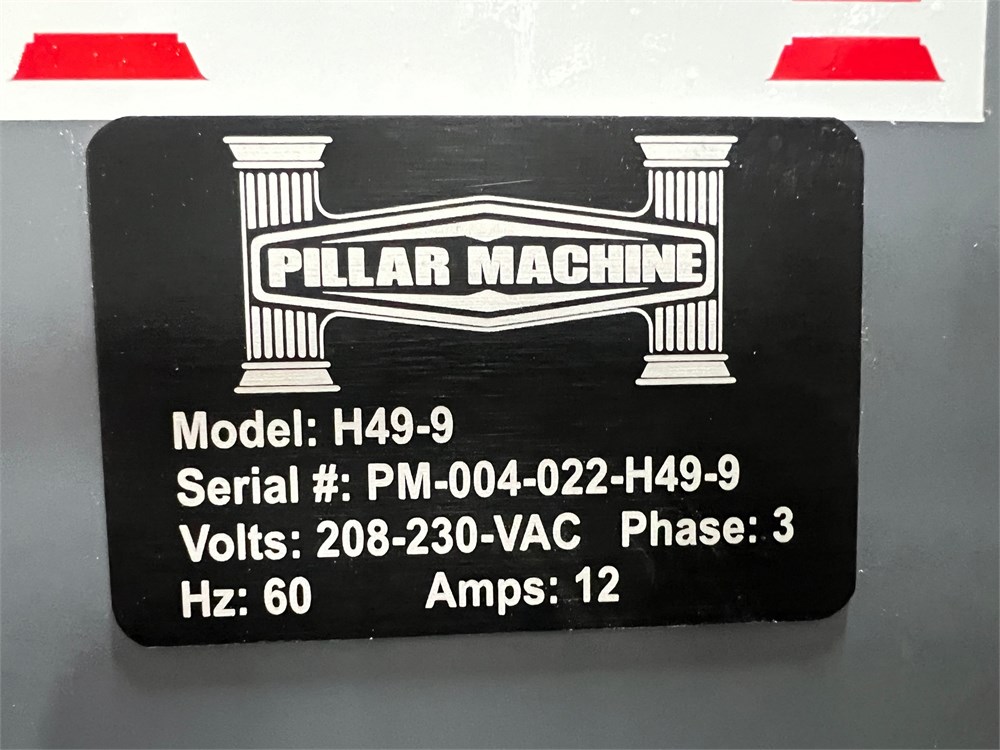

Make

Pillar

-

Model

H49-9

-

Serial Number

PM-004-022-H49-9

-

Year

2022

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

May 1 - May 10, 2024 (by appointment)

-

Estimated Dimensions

78" L x 52" W x 76" H

-

Estimated Weight

1,500 Pounds

-

Seller Comment

Seller will disconnect and load onto buyer's flatbed truck/trailer for non-negotiable $150 loading fee. Palletizing, crating or other services may be available at an additional cost.

-

Load Fee

150

-

Lot Notes

This machine was a showroom Demo!

-

page views

789

Pillar "H49-9" CNC Bore and Dowel Machine

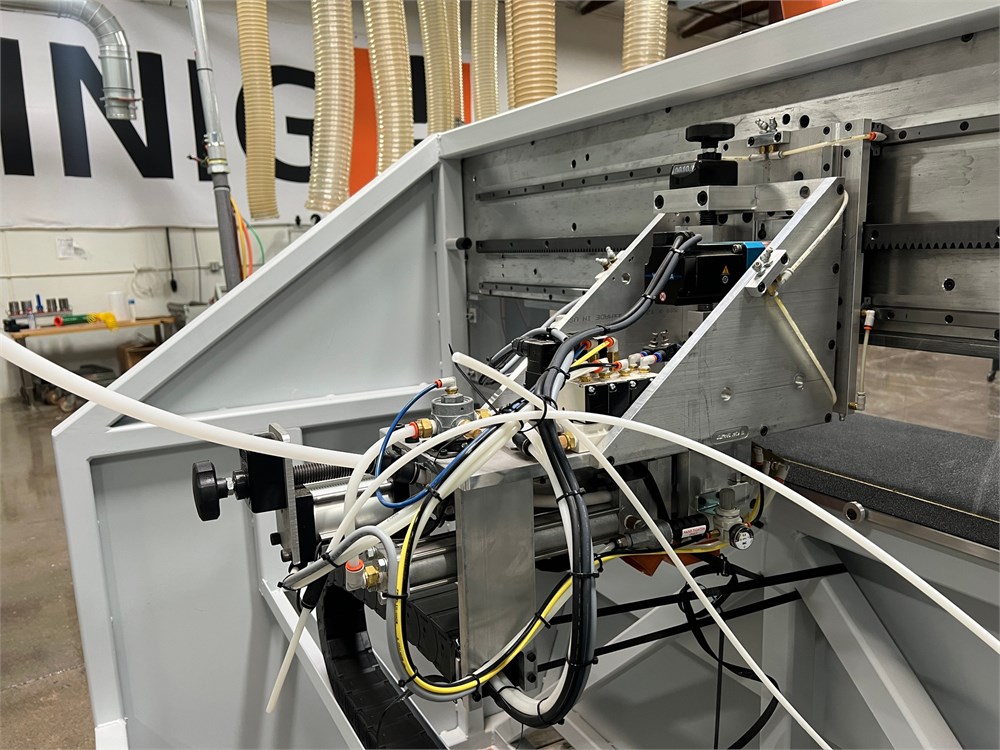

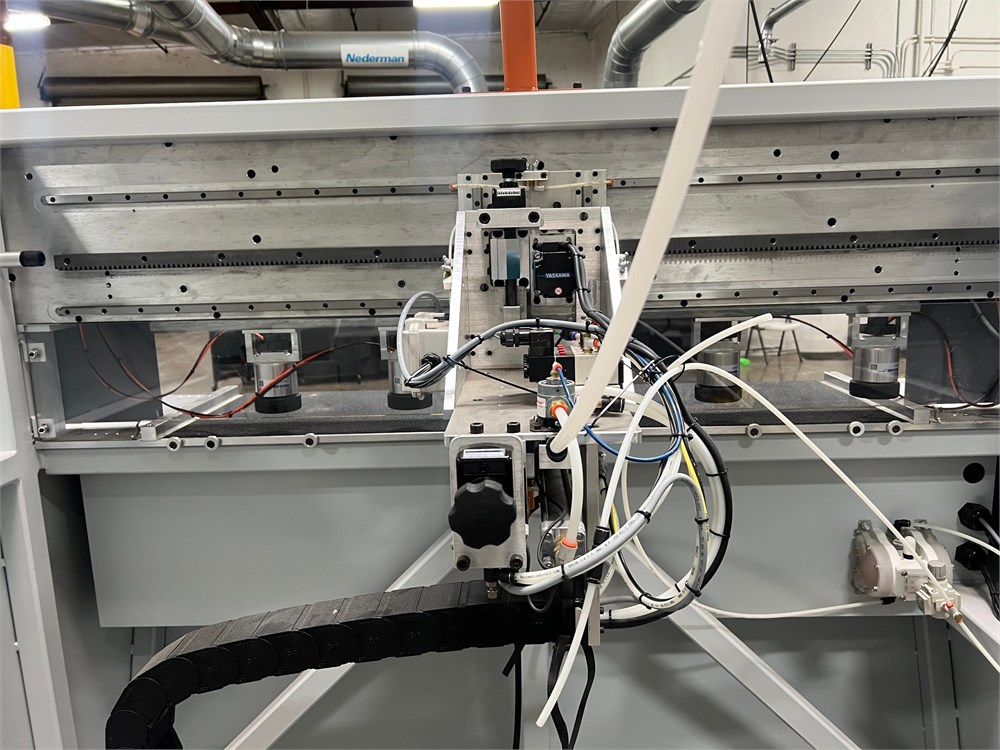

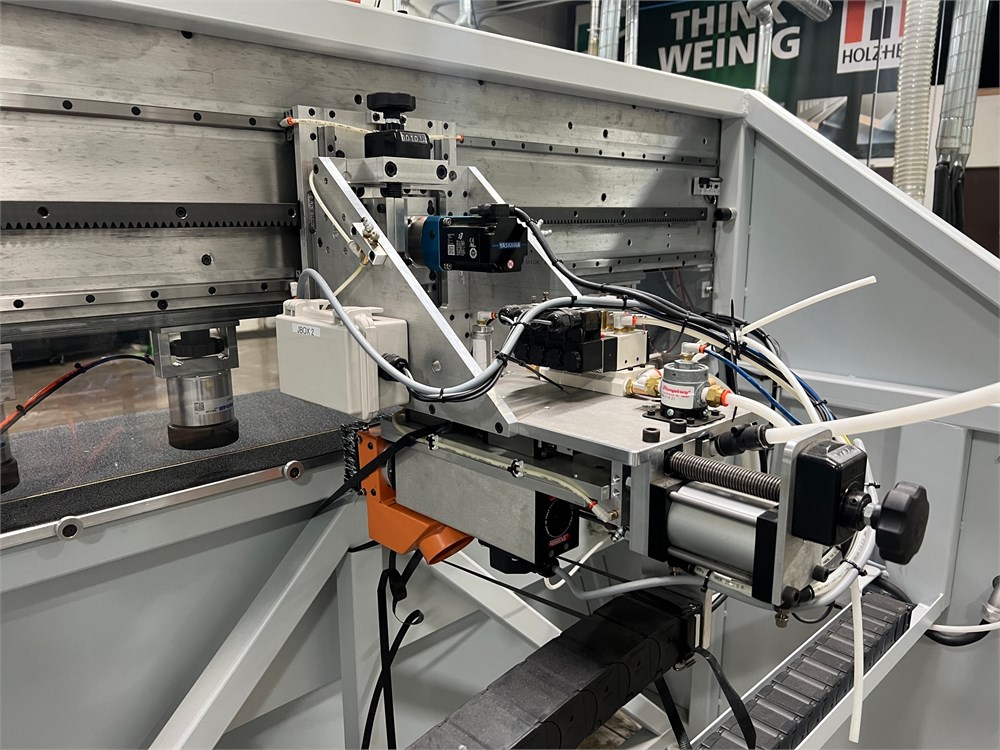

The H49 is a horizontal bore and dowel CNC machining center used for case construction in cabinet or furniture manufacturing. With the H49, you get quick and accurate assembly, gaining production times on CNC routers and point to points by shifting horizontal boring to this machine. It is designed to CNC position the spindle, bore a hole, then CNC position the inserter, inject glue or water, then insert a dowel. There are two (2) work zones on the H49 allowing for pendulum processing.

Made in USA

49" maximum part length

1" maximum part thickness

Unlimited part width

X axis - CNC positioning via motor and rack/pinion

Y axis - manual positioning with digital read out

Z axis - manual positioning with digital read out

Two (2) work zones with LH and RH fences

Controller with 15" color touch screen

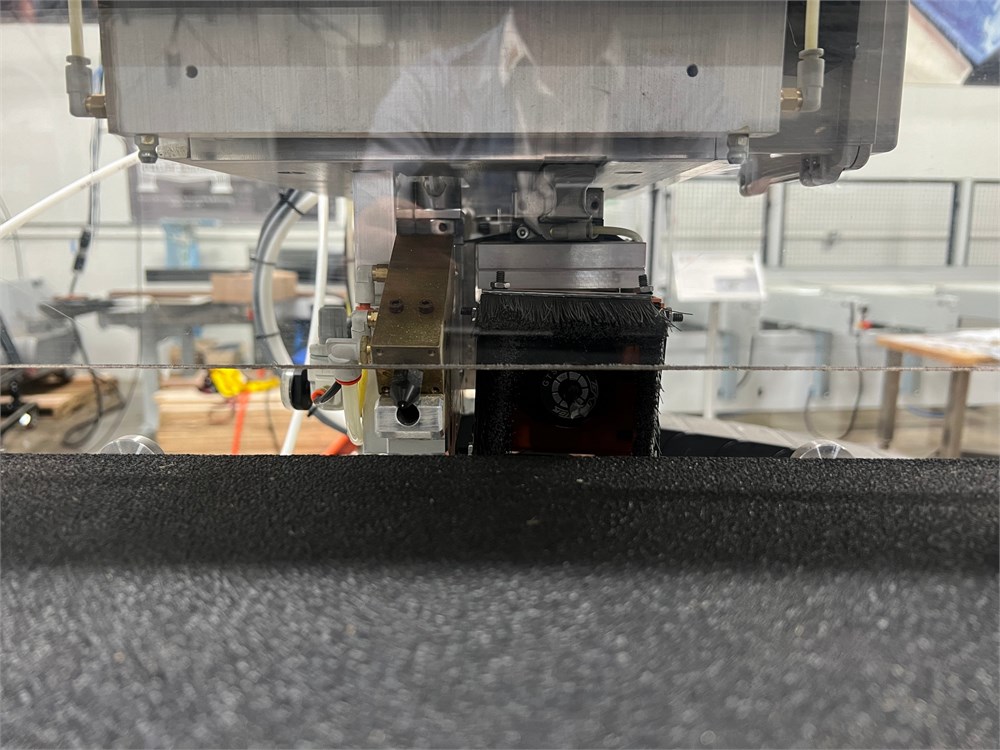

Drill unit

1 HP, 18000 RPM motor

Dowel inserter

"Direct Reject" patented system notifies operator of incorrect dowel size. Dowel reject slide is opened, dowel is removed and then normal operation continues.

Depth is set via mechanical read out on back of machine

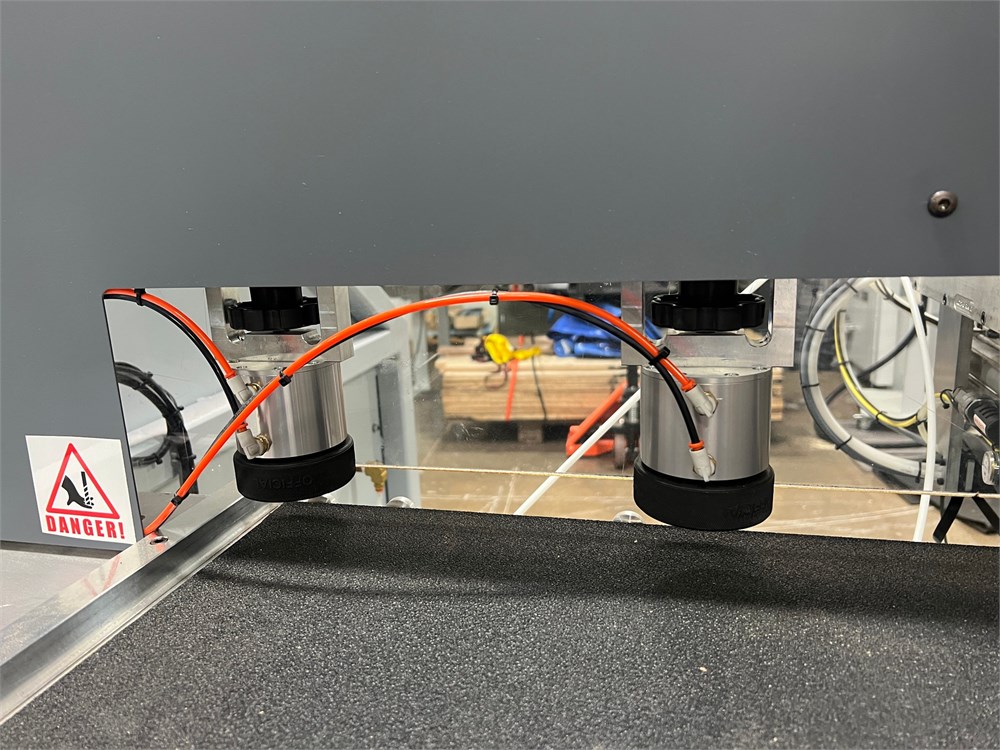

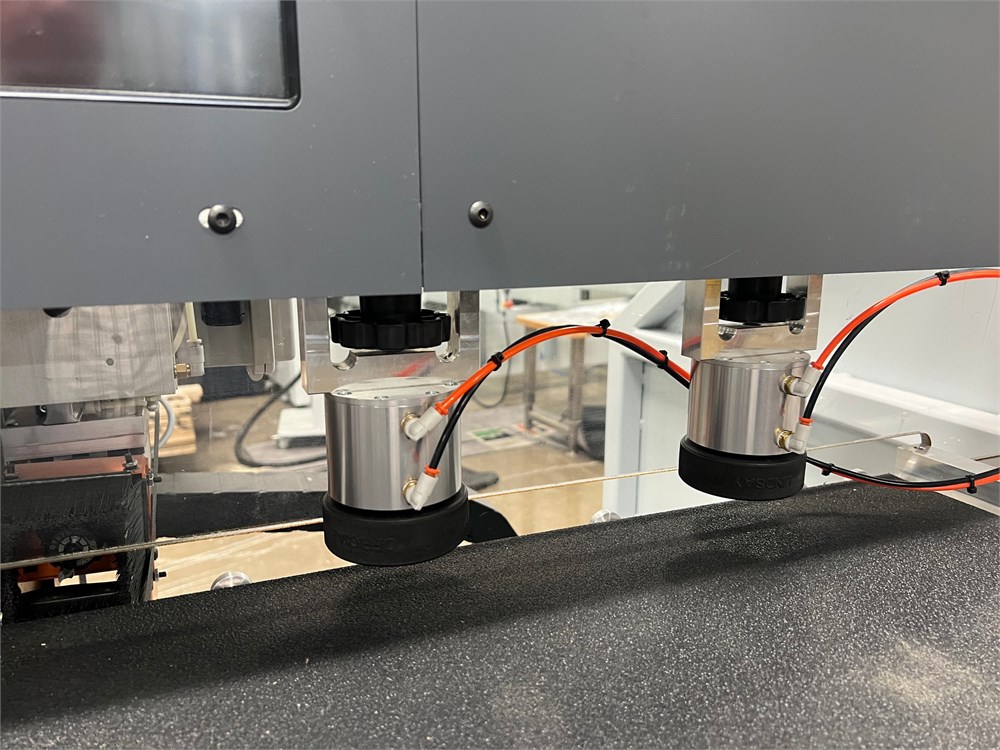

Glue inserter

Dowel hopper

Four (4) pneumatic clamps

Manual

Machine on pallet for ease of loading and shipping

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available