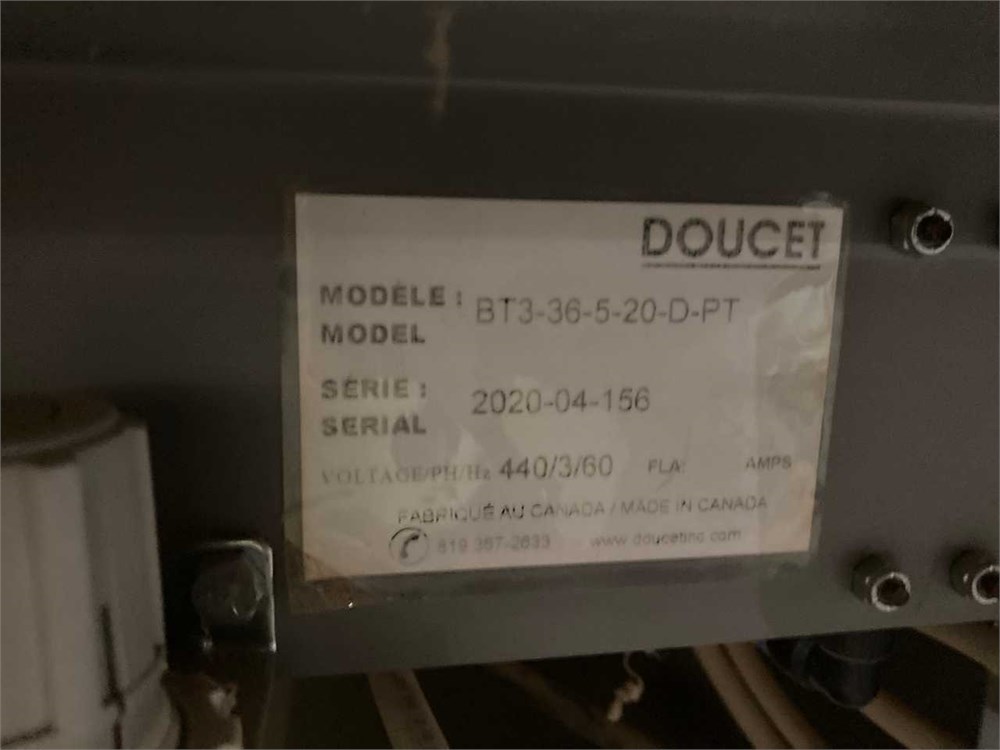

Doucet "BT3-36-5-20-D-PT" Return Conveyor (2020 model year)  Ended

Ended

Holz-Her Edgebander, Doucet Conveyor and Cefla Spray Machine - Del Valle, TX

Del Valle, TX

- Winning Bid : $13,500.00 USD Sold

- 48 Bid(s)

- High Bidder: G****k

Holz-Her Edgebander, Doucet Conveyor and Cefla Spray Machine - Del Valle, TX ( Closed #64377157 )

Custom woodworking company in the Austin, TX area is auctioning three (3) late model machines no longer required for continuing operations. All three machines are 2020 models!

-

Pick Up Location

5235 Hwy. 71 E., Building A Del Valle, TX 78617

-

Make

Doucet

-

Model

BT3-36-5-20-D-PT

-

Serial Number

2020

-

Year

220-04-156

-

Phase

3 PHASE

-

Voltage

440 Volts

-

Load Out Period

May 1 - May 10, 2024 (by appointment)

-

Estimated Dimensions

See photos and description

-

Estimated Weight

4,000 Pounds

-

Seller Comment

Seller will disconnect and load onto buyer's flatbed truck/trailer for non-negotiable $250 loading fee. Palletizing, crating or other services may be available at an additional cost.

-

Load Fee

250

-

Lot Notes

-

page views

910

Doucet "BT3-36-5-20-D-PT" Return Conveyor (2020 model year)

Seller purchased this machine new in June of 2020. Seller maintained it regularly with in-house maintenance techs. Cleaned daily.

New machine is price approximately $40,000.

See video of machine in operation narrated by seller

See attached Doucet sales brochure (for reference only, not all options apply)

BT3 Return Conveyors are equipped with a variable speed drive to match the processing speed of the equipment, receiving table speed is adjustable from 30 to 90 ft/min, belt transfer speed is fixed at 180 ft/min and return conveyor speed is adjustable from 60 to 180 ft/min.

A PT-90 Panel Turner to return long rectangular panels lengthwise after finishing of their narrow sides. Available on all models, this device simplifies processing short sides on long and narrow panels. The panels are turned 90° as part of the transfer process between the receiving and return rollers, thus eliminating panel overhang.

Its receiving rollers are equipped with a down stroke mechanism that is activated by detection of the trailing end of the panels exiting the equipment.

Transfer belts nested in between the rollers are used to side shift product to a set of motorized rollers parallel to your equipment.

Those return rollers are 2" lower than the pass line on the equipment in order to avoid interference when overlapping panels are traveling in opposite directions.

Once the panel has cleared the reception area, the receiving rollers return to their upper position ready to receive the next panel.

36" wide x 5' long receiving conveyor with 2" Ø pvc rollers on 3" centers

36" wide x 15' long return conveyor with 2" Ø pvc rollers on 3" centers

Belt transfer device 6' wide featuring 9 transfer belts

Transfer by-pass switch

Variable speed switch located on operator console

Motorized infeed rollers

Panel deviator to redeploy narrow parts over several rollers

Right-hand return

4" x 12" minimum panel size with panel deviator

52" x 52" maximum panel size (four sides)

52" x 96" maximum panel size (long side and 5' receiving)

36" x 96" maximum panel size (four sides with PT-90 and extension)

Edgebander NOT included, offered in lot 001

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available