Biesse "Akron 1440" Edgebander with Air Force, Premilling & Corner Rounding  Ended

Ended

Complete shop closure- Phoenix, AZ

Phoenix, AZ

- Winning Bid : $15,050.00 USD Sold

- 75 Bid(s)

- High Bidder: C****b

Complete Shop Closure - Phoenix, AZ ( Closed #64187875 )

Finn Retail in Phoenix is retiring and offering all machinery, tools, material, and shop supplies for auction. Two (2) Biesse flat table CNCs. Biesse edgebander, SawStop table saw, Martin sliding table saw, solid surface, material racks, laminate & much more.

-

Pick Up Location

1945 E. Watkins Phoenix, AZ 85034

-

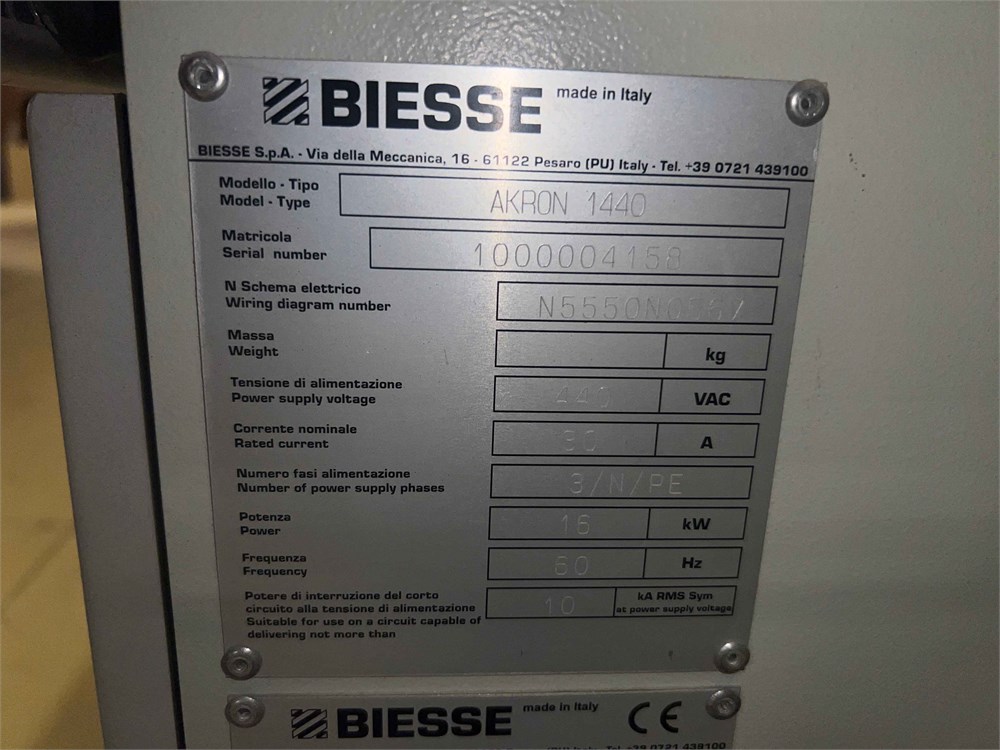

Make

Biesse

-

Model

Akron 1440

-

Serial Number

1000004158

-

Year

2015

-

Phase

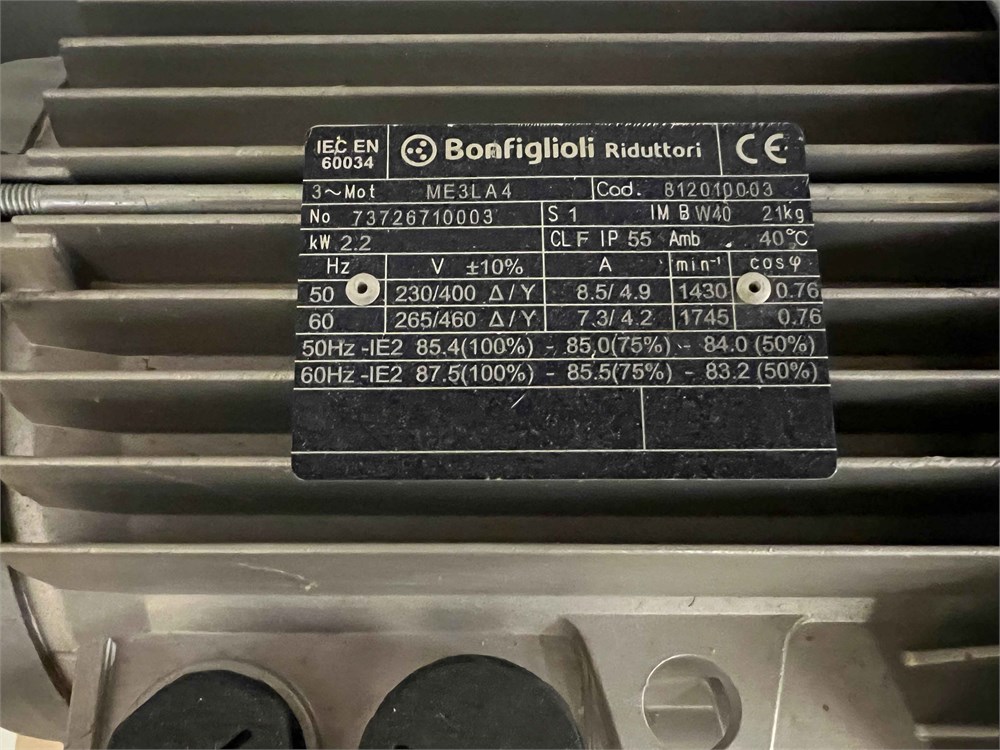

3 PHASE

-

Voltage

230/460

-

Load Out Period

See main page for loading dates

-

Estimated Dimensions

18' x 4' x 6'

-

Estimated Weight

4,200 Pounds

-

Seller Comment

A non-negotionable loading fee has been established. This includes loading onto a flat bed trailer. Requests for additional labor, crating or pallatization will be extra.

-

Load Fee

400

-

Lot Notes

-

page views

1462

Biesse "Akron 1440" Edgebander with Air Force, Premilling & Corner Rounding

Min. panel height: 10 mm, Max. panel height: 60 mm, Height of edgebanding material: 14-64 mm, Thickness of edgebanding material in rolls: 0.4-3 mm, Thickness of edgebanding in strips: 0.4-12 mm, Min. panel protrusion from the track: 25 mm, Panel length: 140 - 3200 mm, Min. panel width (with length 140 mm): 85 mm, Min. panel width (with length 250 mm): 50 mm.

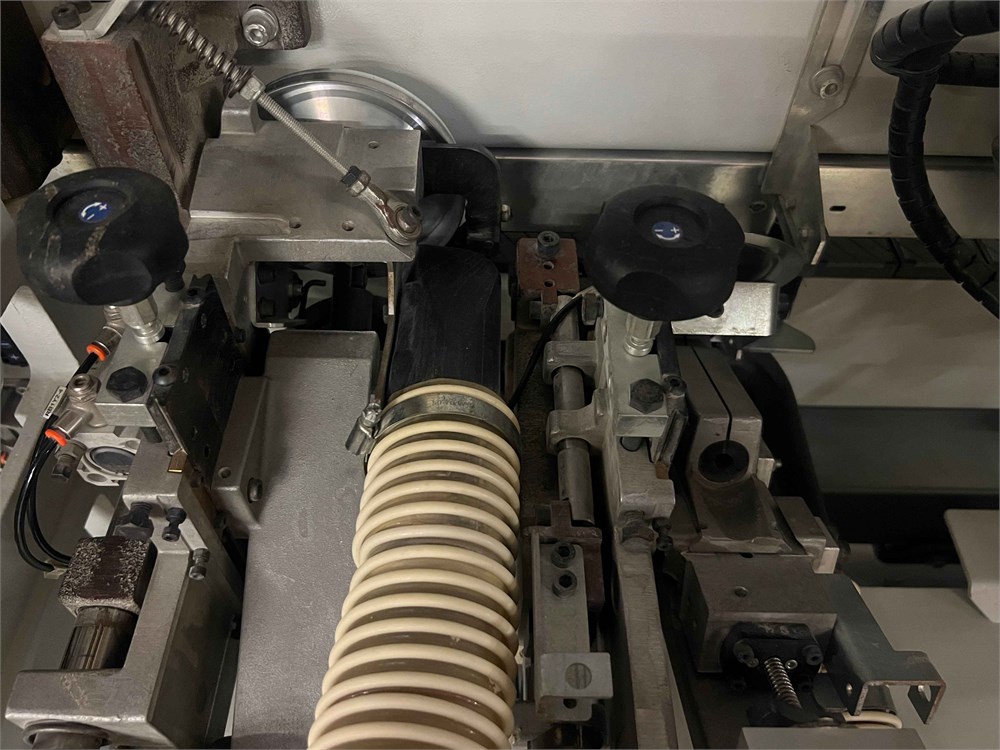

Pre-milling unit

Gluing, edge feeding, and pressing unit

Air Force Edge Unit

End trimming unit

Fine trimming unit

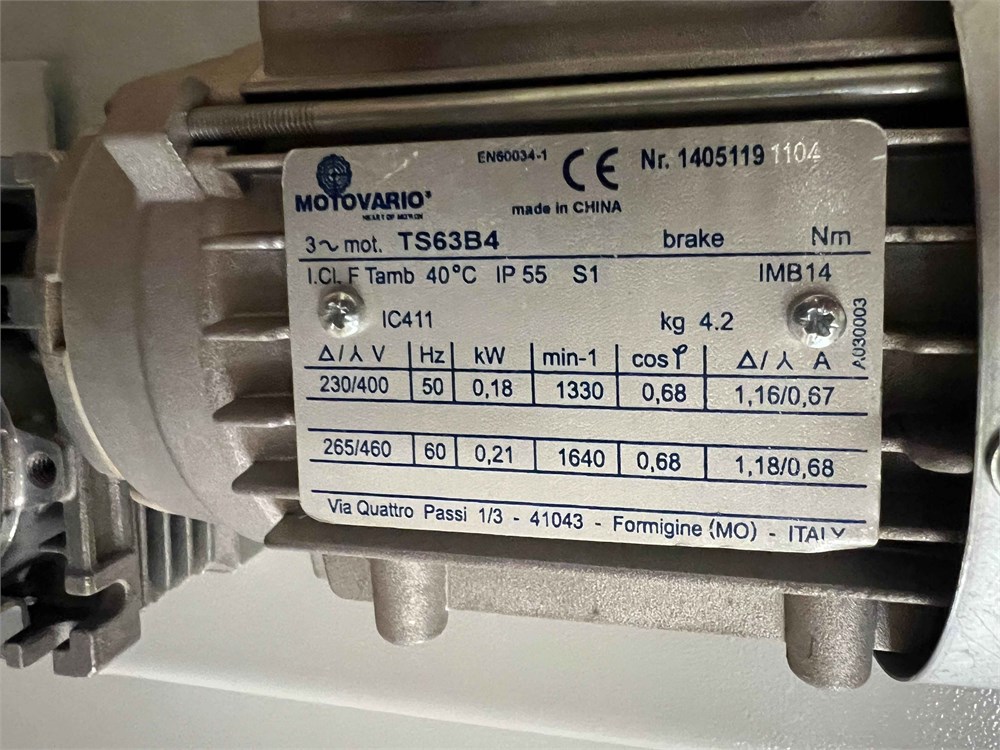

Multifunction 2 motor corner rounding unit

Edge scraper unit

Glue scraper unit

Brushing unit

Hot air blower unit PH-501

Belt pressure beam. The top presser comprises a rubber belt with a stain-proof coating. The thrust exercised on the panel is provided by springs housed on techno polymer connecting rods.

Automatic track lubrication system with dynamic track absorption.

Multiple speed kit, 12 - 18 m/Min

Manual infeed system for narrow pieces

Anti-adhesive unit ADZ02, applies the anti-adhesive liquid on the top and bottom of the surface of the panel to ease a good cleaning of the piece being processed.

One coil automatic edge feeding

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available