Griggio "GB4/8" Automatic Edgebander  Ended

Ended

Woodworking Machinery Auction - Chatsworth, CA

Chatsworth, CA

- Winning Bid : $1,400.00 USD Sold

- 15 Bid(s)

- High Bidder: s****e

Woodworking Machinery Auction - Chatsworth, CA ( Closed #62448571 )

A commercial cabinet manufacturer in the greater Los Angeles, CA area is auctioning several woodworking machines that include an SCMI "M3" Gang Rip Saw, Weinig "Profimat 22N" Moulder, Powermatic Upcut saw with TigerStop positioner and tables, Unique "250MC" Raised Panel Door Machine, Timesaver "137-2HP" Wide Belt Sander, Two (2) JLT Door Clamp Machines, NorthTech "NT-DSM-1SA Dovetail Machine, and much more!

-

Pick Up Location

10215 Canoga Ave. Chatsworth, CA 91311

-

Make

Griggio

-

Model

GB4/8

-

Serial Number

-

Year

2012

-

Phase

1 PHASE

-

Voltage

230 VOLT

-

Load Out Period

February 27th, - March 5th , 2024 By appointment only

-

Estimated Dimensions

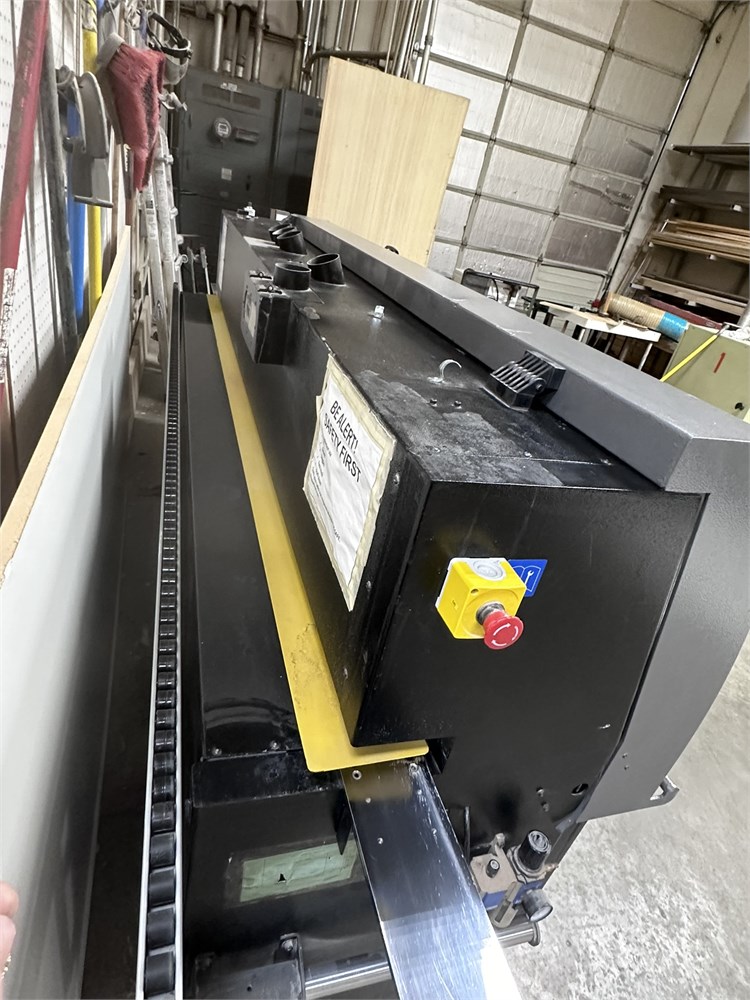

168" L x 72" W x 72" H

-

Estimated Weight

3,000 Pounds

-

Seller Comment

Buyer responsible for disassembly, packing and load out or hiring a rigger to do so

-

Load Fee

N/A

-

Lot Notes

-

page views

610

Griggio "GB4/8" Automatic Edgebander

Minimum width of the panel 3-1/2"

Minimum length of the panel 2-3/8"

Distance between panel 26"

Minimum thickness of panel 3/8"

Maximum Thickness of panel 2-3/8"

Strip edge thickness: 0.4 to 8 mm

Automatic loading coil thickness: 0.4 to 3 mm

Single Feed Speed: 39 ft/min.

Glue tank capacity: 4 Liter

Standard Equipment: Control panel is straightforward and easy to use

Manual adjustment of the upper pressure beam with digital readout

Heated infeed fence

Manual height adjustment of working units with digital readout

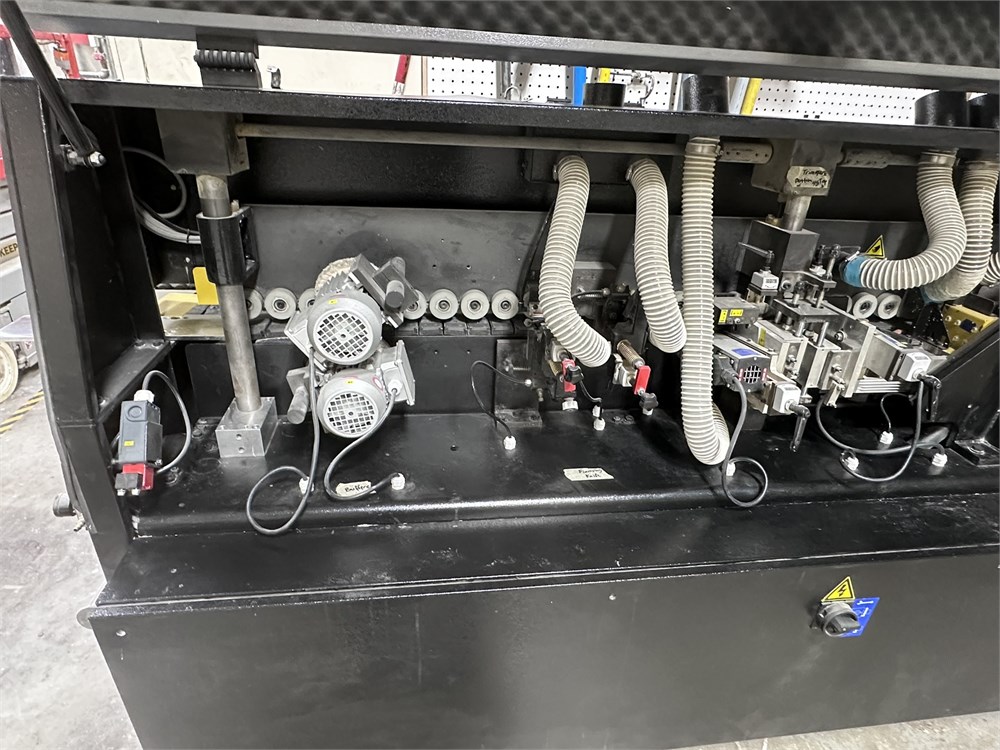

(4) Heavy duty working stations

Non-stick glue tank with quick heating

Auto-Temp control of temperature from 200 to 130 degrees Celsius

Quick Heat up

System and Auto Temp drop if machine not in use for certain amount of time

Shear unit is pneumatic and cuts edgebanding material from .04 to 3mm thick with automatic pull back of edgebanding after cut 3mm tape can be maximum height of 24mm

Side pressure station has three rollers 1 driven and 2 idle with digital adjustment to the edge strip width.

Separate adjustments for pneumatic roller pressure sections.

End Trim Unit has 2 tilting motors (0 to 15 degrees) of 0.5 HP each includes saw blades

Top and Bottom Trim Unit has 2 motors 0.75 HP each with fine adjustment and digital readout includes combination radius and flush trim knives with cutterhead

Scraping Unit with digital readout

Buffing Unit with (2) 0.25 HP motors and two 6” diameter cloth wheels

Separate box to collect PVC scrapings

Support extension with rollers for wide panels

Listed specifications were taken from manufacturer's published information and is assumed to be correct but not guaranteed. Bidder is encouraged to inspect the machine, call with questions or contact the manufacturer for more information.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense).

Payment is due within 24 hours of auction close. Payments must be made via bank wire transfer for any amount above $1,500. Credit cards may be used up to $1,500 (3% processing fee). Please Contact Sabrina Burns with payment questions at 209-839-7707 Any sales tax exemption documents are to be emailed to [email protected] at time of purchase/invoice for tax exemption consideration.